-

Posts

3,122 -

Joined

-

Last visited

-

Days Won

160

Posts posted by ScubaRx

-

-

I bought one of these many years ago when I was installing an inverter and updating the Outlaw Oliver to 4/0 battery cables. It will make a hexagon shaped crimp that really looks good. Out of curiosity, I once cut thru a connector and examined the crosscut strands inside under high magnification. Each strand had been compressed into a hexagon shape and fused together.

Here is a really good video showing exactly how it should be done although he calls it a "flaring" tool!

-

Usually, this is the result of water in the umbilical connector. I causes a short and the tail lights (or other body lights) will come on while not hooked to the truck. It is back feeding from the trailer batteries.

-

2 hours ago, JRK said:

...I have only had an issue with the door step binding when I try to slide it into the chassis. I took a few extra minutes today to figure out how it works, and think that I see the issue. The rod binds in the slot, and does not allow the step to properly seat, then binds in the slots when trying to return. There must be a trick to shoving in the step...

Spray the slot with WD-40, work the step in and out a few times and you will be amazed how smoothly it works. Aluminum has a tendency to "stick" to itself when it is dry.

-

1

1

-

2

2

-

-

A "relatively" simple solution would be to drain the bathroom sink water into the black tank. You could achieve this with gravity only. Pull the black tank valve to dump at any time. I would save 15 gallons of space in the gray tank.

-

2

2

-

-

5 hours ago, Moonlight Mile said:

Same thing happened to me with my now-gone Andersen (well before this gentleman’s post). Service ticket done. Mine was not just disconnected. It was deformed, stretched, sometime during a two day drive. I just happened to notice it. To me this is extremely dangerous, whatever the cause(s). I was also told no adjusting and it was constant adjusting and very difficult, to put it mildly.

Sheri, so, did you ditch the Andersen WD hitch? What hitch are you now using?

As we discussed on the phone, your Threaded Quick Link deformed and stretched because it was not properly screwed together. That link is easily replaced if you want to begin using the Andersen again. Checking these links to make sure they're tight before travel is necessary (but, since your truck likely needs no weight distribution, as Overland stated, it was not a dangerous situation). There is no reason to ever loosen them as this would not serve for any adjustment. As some have suggested, if I had an Andersen set-up (I don't) I would put a drop of Loctite on the threads and tighten them down well.

-

1

1

-

-

14 hours ago, Geronimo John said:

Funny, I was looking on line at the very same chains! Thanks for posting.

I was thinking of using my curly safety strings to connect up to the real safety chain attachment points, and run them back to a second attachment point under the propane tanks. Sort of a safety cable to the safety chain approach. No point in tossing them.

I actually put them on a utility trailer that previously had none.

-

Apparently the OP (John M) has left the building or has lost interest in this thread.

-

1

1

-

-

The Bright Way Group batteries are manufactured by Trojan.

-

6 hours ago, Chukarhunter said:

...

My father used to raise Chukar's.

-

2

2

-

-

-

-

The production team does not need a wiring diagram. Early in the build of every new Oliver a custom wiring harness is installed. Said harness can handle any and all options the customer orders. Wiring sizes were predetermined when the harness was developed.

Earlier builds do not enjoy the neatness and benefits of the harness. I was told at delivery of our Hull #050 they used "5 miles of wire..." an exaggeration, I'm sure but there sure is a lot of it!

-

4

4

-

-

til it overflowed

-

11 minutes ago, Hokieman said:

My Salesperson, Josh, told me 2 weeks ago that 2022 models of LE2 come standard with Dexter 3500 lb axles, drum brakes and sealed bearings. 5000 lb axles are available as an upgrade. Disc brakes are not an option they are offering at this time.I’d suggest you confirm these details if you are looking to get a 2022.

Actually, the upgrade will be 5200 pound axles de-rated to 3500 pounds due to the four leaf spring packs. As you stated "...Disc brakes are not an option they are offering at this time..." But we are speaking about the 2022's.

-

Disc brakes with larger axles on the 2022’s might be a factor.

-

2

2

-

-

display of wild...

-

The picture of the rear of the (probably rental) trailer shows a heavily loaded Curt basket on the rear receiver. It is speculated that the combination of a lighter than normal tongue weight and the probably inexperienced driver just lost control. In his case the trailer most likely well outweighed the truck as opposed to us Oliver owners generally being the other way around.

I have a feeling in the same situation with our trucks and trailers, it would have torn the safety chains off the trailer.

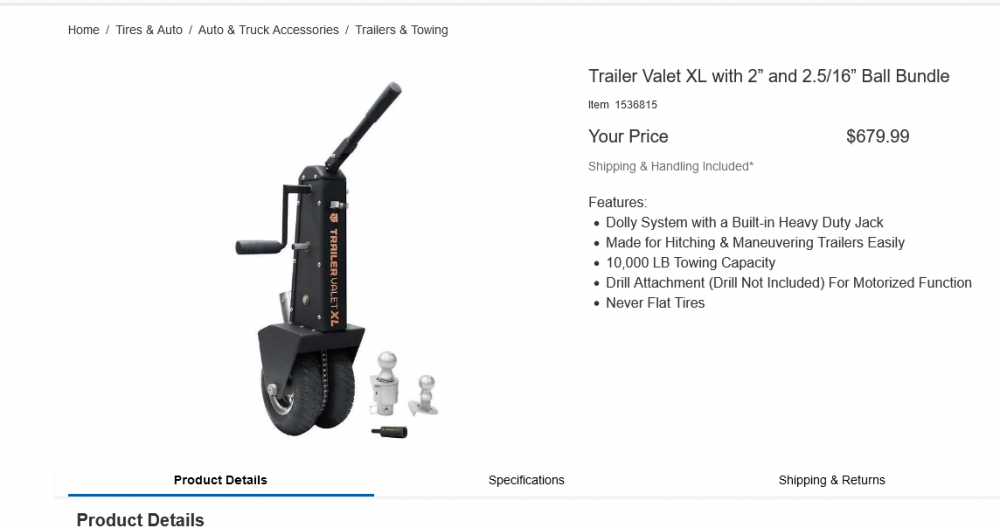

I replaced the springy cables with chain and oversized hooks. When I bought this I thought it was way more that I could possibly ever need, now I'm not so sure.

-

2

2

-

-

Relax guys, this is not a major issue. I've owned two different Oliver's over the past 13 years. Both an Elite and a Elite II. If you hit a big enough bump or drop into a deep enough hole, the suspension will probably bump the frame. I have noticed evidence of contact on both trailers thru the years. Other than cosmetic, there was no damage to the frame.

The Elite's are supplied with 5200 pound axles with larger brakes and bigger spring packs than the two 3500 pound axles on the Elite II's.

-

4

4

-

-

What are you planning to tow?

-

7 hours ago, hobo said:

Trying to find a source for a short power cord simply to run from my generator in my basket to the inlet on the front curbside of the trailer. Maybe something in the five to six foot range. I hate using the much longer cord for that purpose as it gets in the way. Any suggestions??

I looked for one 13 years ago for that very reason with Hull #026. No luck, I built one. It is about three feet long and perfectly goes from the generator to the front of Hull #050, our current Oliver.

Not being aware I was not supposed to, I have been known to run the generator while under tow, but with no apparent problems. I suppose I’ll just chalk that up as further justification of our Oliver’s name...The Outlaw Oliver.I’m still using the same generator I bought in 2008 for the first Oliver. It has ridden in the baskets of both trailers for over 150K miles and has been on every trip we’ve ever been on.

I would just purchase the parts to make my own cord. That way, it will be perfect for your application.

-

1

1

-

3

3

-

-

I would not let them cut the furnace return in Hull #050. Robert Partee (service manager, the only salesman, my friend, the MAN) argued with me about it every time I was at the factory during our build in 2013. I won. The furnace has run fine and heated very well for these past seven plus years. I had it on just the other night during the recent wave of ice and snow when it was in the low teens here in the Deep South.

I did have them install three of the lower access doors. At the time, it was just something I dreamed up during one of my build visits. I thought they would look cool and I suggested using the same hatch that was to be used in the bathroom (only reversed so it would open down instead of up.) In retrospect, they've come in handy for us to access the basement and the valves under the curbside bed (we have the raised beds) the one under the street side bed was really just for symmetry and looks, but it does allow me to easily reach the reset button on the inverter if I need to. Apparently the folks that saw ours started asking for them and now they are options?

If I need to introduce more air flow into the basement I just open one or more of those doors. They would serve nicely as the furnace return also, although we don't open them for that as it doesn't seem necessary. I've always been able to keep the basement areas within 10-15 degrees of cabin temperature with no great amount of effort.

I've never noticed the furnace to be noisy, except the time the fan got into the shroud and I had to pull the furnace and tighten up everything. Ours has to come out through the inside and it's sort of a PITA.

-

4

4

-

-

There is quite possibly a solution for this situation coming soon...

-

1

1

-

4

4

-

-

4 hours ago, John E Davies said:

I don't get it. ??

John Davies

Spokane WA

I believe he's suggesting that since you don't tow with a diesel (as many of us do) you don't technically have a dog in this race.

-

2

2

-

2

2

-

2

2

-

-

Empty the black tank first, then the gray. This will allow the gray water to somewhat clean the hose after the black water has gone through it.

-

2

2

-

Heating System

in Ollie Modifications

Posted

Will there be 27 of them...with a paragraph on the back of each one explaining...?