-

Posts

20 -

Joined

-

Last visited

-

Days Won

2

Posts posted by Sage-AndersenHitches

-

-

While this is a well thought out and very useful product for many SOB owners, I fail to see a need for these as they relate to Oliver Owners. The rear jacks are for lifting, leveling and stabilizing our trailers and they fulfill all three functions admirably without the need to carry additional equipment. Your needs may differ from mine.

You are correct about that and have no obligation to use any of our products. Oliver is selling these bags at the factory so I decided to do a shameless sales pitch to help them get the word out. They may not be necessary but they are very handy.

-

Thanks for the offer and shipping arrangements. Is there a “special” price for your loyal fans?

Hi Bill, We would love to give a discount to all our loyal customers. Our business model is dealer direct so you would need to talk to Oliver about ordering products where everything will be billed through them. We just launched a new website and do a drawing each month for anyone who registers their Andersen products, that could help quite a bit with the purchase of a Trail Gear Bag. http://www.andersenhitches.com/register/

-

-

Hi Carole,

I have responded to your email but wanted to put this on here in case anyone else has this issue. I also have two posts up in the towing section of this forum that will help, one is an Overview of the Andersen WD (Read first), the other is FAQ.

Here is the response to your question via email.

I am sorry for the problems you have been having with your hitch. It sounds like there may be two things happening that is causing an undesirable experience.

The noise is most likely coming from what we call a friction cone. That is the material between the ball and the ball housing. We have had some of those cones that don't do well when they get some moisture in there. We can send you a replacement friction cone to change or if you would rather send us your ball housing and ball we can refurbish it and ship it back to you. That will fix the grinding noise you are hearing.

The loose chains could be the frame brackets, they should have the bottom side angled forward and the top towards the back of the trailer and be an equal distance from the ball. Once you have verified those are properly installed a couple tricks when you hook up will be helpful. First lock the trailer coupler on the ball, then with the tongue jack lift everything a couple inches. Now swing the triangle plate up and pin it to the bottom of the ball. Hand tighten the nuts on the back of the chains then put a few turns on them with a wrench to get an equal number of threads on each side. Retract the tongue jack and it is ready to pull. The red bushings on the back of the chins should have a little bulge when the chains are properly tensioned.

When unhooking have the trailer and tow vehicle as straight as possible, loosen both chains so the pin on the triangle plate comes out easily and the plate swings away from the tow vehicle then unhook like normal.

-

1

1

-

-

Preparing to travel and noticed that one of the brackets under trailer is angled forward about an 1/2 inch. The bracket is bolted to the frame with an set screw on the top side. There is no set screw on the lower side and there is enough play to allow movement. I would appreciate any suggestions.

This is usually an installation error that we have been seeing. When installing the bracket rotate it so the bottom is angled toward the tow vehicle and the top of the bracket toward the rear of the trailer. The two bracket bolts should be touching the top and bottom of the frame. This not only creates a bind on the frame that will prevent movement but also aligns the square tube with the tensioned chains. Tighten the main bracket bolts with the bracket in this position and then tighten the set screw. Drilling a small hole in the frame for the set screw to rest in is also an option if the bracket continues to slide when properly installed.

-

1

1

-

-

One of the Andersen WD Hitch frame mounts has moved forward. It appears that there is enough space for this. There is a gap at the bottom of the bracket that is wide enough to allow this movement. The set screw is at the top of the bracket.

This is an installation error that we have been seeing lately. When installing the bracket rotate it so the bottom is angled toward the tow vehicle and the top of the bracket toward the rear of the trailer. The two bracket bolts should be touching the top and bottom of the frame. This not only creates a bind on the frame that will prevent movement but also aligns the square tube with the tensioned chains. Tighten the main bracket bolts with the bracket in this position and then tighten the set screw.

-

Does one need to loosen the tensioning nuts each time one unhitches and Oliver Trailer from the TV?

I would encourage you to loosen the nuts a few turns and re-tighten them each time you hook up, it will make it much easier to get the pin in and out especially if you are not quite strait. I know several people that do it the way this video shows and are happy with the results, I prefer a tighter chain for more weight distribution.

-

Is there a point at which I could do damage? How do I know where that point is? I am using a torque wrench and I could set it to whatever you recommend.

Our red bushings should fail before something else does, however I just got a little nervous about the 4432 lbs of chain tension from a previous comment, that is enough force to cause serious damage to not only our hitch but the aluminum trailer frame and pickup receiver. My recommendation is 2-3 threads past hand tight before loading the weight on the vehicle. The more threads you go past hand tight the more weight will be distributed. A torque wrench may not be the most accurate method if you are slightly crooked when hooking up. Try a few different thread counts to get a good feel for your application and what you like when you are driving.

The way you shortend your chains looks great!

-

Hey guys let's not overthink this thing. If you want to see if the WD is making a difference on the scales weigh the vehicle and trailer connected with the WD chains loose, then tension the chains properly and weigh it again. If the weight on the rear axle is less than the first weight you win, if not it needs more tension on the chains. Comparing a truck with no trailer to one that is hooked up??? The amount of force it would take to actually make the front axle heavier in this situation could easily damage things; trailer, hitch, and vehicle. A F-150 would safely tow an Oliver with just a regular ball. If it tows well and the truck feels stable when driving that is the goal. Buzzy is using this hitch correctly based on his photos and comments I have seen.

-

As I look at the attachment of the brackets to the frame, moving them aft might not be possible. Would shortening the chains be an alternative option you might recommend?

Yes shortening the chains would work as well.

-

I will add, the resulting change in how my tow vehicle feels is dramatic. Not knowing the metrics or how the steering would feel with an engaged WDH, I was quite frankly stunned my how much better the F150 behaves. Originally, my focus on collecting metrics was to determine if I really needed to use a WDH. Now my focus has changed to whether or not I am realizing the maximum benefit. I have attached a few pictures below which might be helpful. Buzzy Bulge in Red Bushing.

That is great news, I am glad that you noticed an improvement in the towing. I might suggest moving your frame brackets aft another inch or so to give you a few more threads to work with and for your socket to reach a little easier. The bulge you have in your photo is about perfect for a smaller trailer, a good rule of thumb is the larger the bulge of the red bushing the more weight will be distributed.

-

Do you care to answer my questions about the greaseless hitch ball?

We do build several hitches with the greaseless balls, however we do not make that ball available for our WD hitch. That cap has come off a few times or been damaged by something but it has a lifetime warranty so we will send a replacement cap if ever needed.

-

John, you are correct there will always be some movement between the ball and coupler, it may even wear the chrome plating on the ball, it may develop rust. Grease is just fine to use so you are welcome to do what works best for your situation. The WD Hitch only comes with our plated steel ball but due to the minimal movement between it and the coupler grease is not necessary. Will grease extend the lifespan? Yes, but even without a lubricant the ball and coupler will outlast the tow vehicle, the trailer and most likely the owner's desire to pull a trailer. So let's leave this up to the end user to decide if the messy hands and greasy shin wounds be more of a benefit than an oxidized ball.

-

2

2

-

-

Sage: Is there any issues with the Anderson WDH if grease is used on the trailer ball?

John is exactly right. Greasing the ball is not necessary but it will not adversely effect anything if you do.

-

How does the hitch do in continual heavy dust? Does the friction insert get damaged or become sticky in its movement? I drive on north Idaho National Forest dirt roads and in the summer they can be extremely dusty.

This hitch does great in dusty conditions. The only issue we have ever had is the friction cone material took a couple tries to get it right for all conditions and we are covering that through warranty. It was a combination of the high pressure and moisture that would cause the problems with the previous cones but dust and dirt have never been a problem. They are always sticky in their movement, the heavier the tongue load the harder it pushes on the friction material creating more resistance. It will be almost impossible to rotate the ball by hand especially after you have pulled a trailer. The fiction cone is a wear item $12.99 but should last for many years and thousands of miles.

-

Hi I am the factory rep at Andersen Hitches for Oliver Travel Trailers. First off congratulations on your purchase of the best built RV I have ever seen. I had the opportunity to go tour the Oliver factory and get to know some of the staff, you are in great hands. We sincerely appreciate the endorsement of our weight distribution hitches and the opportunity to help give you the best towing experience possible. As a factory rep for Andersen Hitches I have joined the forum to help inform, educate, and assist in any way possible with our products.

-

Hi Buzzy, Thanks for the warm welcome,

Based on your comment from my other thread: "I am a new owner (June 9, 2016). I really like using the Andersen Hitch, but I do not really know how much weight is being redistributed to the front axle on my tow vehicle. The “bulge” in the red bushings is new knowledge for me. I do maintain an equal number of threads on each side. However, I clearly have not attempted to seek tension on the chains prior to retracting the tongue jack. As a result, I bet I am not gaining the kind of weight distribution I seek." It sounds like your chains may not be tight enough to activate the weight distributing or sway control of the hitch so it is not fighting your trucks computer system. I would guess that as you tension the chains before putting the weight down and get a slight bulge in the red bushing it will start to conflict with the truck anti-sway feature. Basically if you are using our hitch for weight distribution you will probably want to turn off the trucks sway control, if you are just wanting sway control your F-150 will do great by its self and you could remove the chains and use the ball as a regular hitch.

-

These are a few of the common issues and questions we get about our WD Hitch. Most of the issues experienced are due to improper installation or hook up. See the Andersen WD Hitch thread for general information about our WD.

Q. How do I get my triangle plate straight?

A. Often times when someone discovers their plate is crooked is when they are trying to hook the trailer up again and can’t get a chain to reach. Why this happens is the trailer is unhooked when it is turned and then they back straight into the trailer to hook up. It will be practically impossible to move the tringle plate by hand at this point (Don't hammer or try to pry it straight), hook the coupler on the ball and release the short chain from the triangle plate. Once the short chain is released, pin the triangle plate in place, retract the tongue jack and drive forward perhaps even turning the other direction to get the attached chain to straighten the triangle plate. Once it is straight raise the tongue, reattach the chain and hook up as normal. To prevent this issue, try to unhook and hookup as straight as possible.

Q. Why is my WD making an awful noise?

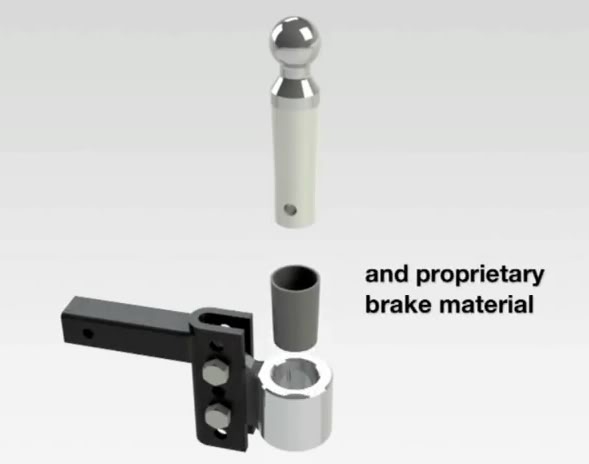

A. This is the unfortunate side effect of doing all of our R&D testing out West where it is very dry. What is happening is the quietest WD on the market is getting moisture in the friction material and it sounds like the spawn of the underworld has manifest in your RV. For this we sincerely apologize, it does not affect safety but it can be uncomfortable and embarrassing. The good news is there is an easy cure; Send me and email: Sage@Anderseninc.com with “ Noisy WD Warranty” in the subject line, include your name and shipping information and we will send you a new friction cone with an updated material that handles moisture much better. If you are changing this the easiest way to get the ball out is to remove the retainer clip from the bottom of the ball assembly, then reinstall the rack in your receiver hitch and use a jack to lift the ball out of the housing. After inserting the new friction material you can turn the drop rack upside down in your receiver hitch and jack the ball in so the retainer clip will go on.

Q. Can I back up without unhooking?

A. Yes you can. Because of the ball turning in the housing there is no need to unhook anything when you back up, it will not damage the hitch or trailer. With any hitch it is possible to jackknife a trailer so please don’t turn so sharp in reverse that the trailer contacts the bumper of the tow vehicle.

Q. When I get to about 40 MPH my trailer starts swaying bad. What should I do?

A. This is a conflict of two great systems and is not exclusive to Andersen WD. Many of the newer vehicles are coming with a trailer sway protection on them. This is a system that applies slight braking inputs to the opposite sides of the vehicle to minimize and correct trailer sway. The newer F-150 is the most common vehicle with this feature. This system fights against anti-sway hitches of any manufacturer. If this is something you are experiencing just turn that feature off in your vehicle each time you start it.

Q. Can I turn my drop rack over and use it in the rise position?

A. Yes you can. The rack is safe to use in the drop or rise position, the important thing is to get your trailer riding level.

Q. I have a class 5 receiver will this hitch work?

A. Yes, we have two options; there is a reduction sleeve 2.5” to 2” but this can create extra movement in the receiver. We also build the drop rack in in the 4” and 8” drop that has a 2.5” receiver for the class 5 tow package. Have your dealer order the appropriate receiver when buying the hitch to avoid shipping and restock charges.

Q. I have the rack in the rise position and can’t open the back of my SUV.

A. We build the racks with a custom 3” extension on the shank to get you a little better clearance, this also works well for spare tire interference.

Q. My truck is lifted will this hitch still work?

A. Most likely, we can do a 4” and an 8” adjustment on the rack. The 4” works on most vehicles and the 8” gets you a little more reach. See our fit guide at AndersenHitches.com. Have your dealer order the appropriate receiver when buying the hitch to avoid shipping and restock charges.

Q. How is this a greaseless system?

A. The way the ball turns in the housing eliminates any friction between the coupler and ball, they turn together so there is no friction and no need for grease.

-

5

5

-

-

As a factory rep for Andersen Hitches I have joined the forum to help inform, educate, and assist in any way possible with our products. As for the Weight Distribution hitch (WD) it is very unique in the industry and designed to not only distribute the tongue weight of the trailer but also reduce sway and bucking. Oliver does a great job of installing this hitch on their trailers utilizing our chain extensions. By understanding how the hitch works will help you use it properly and tow safer.

Weight Distribution

The weight distribution is accomplished by the force of the chains pulling the triangle plate backward and the coupler of the trailer pushing the ball forward. This works very similar to a cable suspension bridge. We have to build the bridge between the truck and trailer and then put the weight down so the hitch can do its job. If the hitch is installed properly, hooking up is a cinch.

Simply lock the coupler on the ball, then using the trailer tongue jack lift the tongue a couple inches. The triangle plate should be attached to both chains and easily swing up and attach to the bottom of the ball assembly with one pin, insert the pin on the triangle plate then tighten the nuts on the back of the chains. The number of threads showing is not as important as them being equal on each side, having both chains tensioned with an equal number of threads showing is desired. Once the chains have been tensioned retract the trailer tongue jack to transfer the weight to the vehicle.

With the full tongue weight on the tow vehicle the red urethane bushings should have a slight bulge to them and the chains should be very tight. (The bigger the bulge the more weight is displaced) When the trailer is straight the tringle plate should also be straight.

Anti-Sway

The design of this hitch allows for an active sway control which is accomplished through the ball assembly. Once the trailer is hooked up with a slight bulge in the red bushings the ainti-sway can function properly. When the trailer turns, the chains will pull and rotate the tringle plate with the ball it is pined to inside the ball housing. This housing and ball have a slight cone shape that prevents the ball from coming out of the bottom of the housing. There is a friction material sandwiched between the ball and the housing that provides a smooth quiet ride. (If yours is making noise when turning see the known issue thread for warranty info.) The best part is you don’t have to worry about doing anything once it is hooked up properly, the aint-sway will do its job.

Oh Yah, because of the ball turning in the housing instead of in the coupler there is no need to grease the ball or to unhook anything when you back up, it will not damage the hitch or trailer. With any hitch it is possible to jackknife a trailer so please don’t turn so sharp in reverse that the trailer contacts the bumper of the tow vehicle.

Anti-Bounce

Normally when pulling a trailer when the vehicle hits a bump in the road it bounces then the trailer hits the same bump and bounces causing more bouncing in the vehicle, this back and forth bouncing can continue for quite a distance after the bump. This is known as bucking and chucking which creates extra wear and tear on everything and often discomfort and fatigue to the passengers. With a traditional WD hitch they utilize tempered steel bars (AKA giant springs) to distribute weight. When driving over bumps these spring bars act like a diving board and exaggerate the bucking and chucking even longer than having just a ball. That is the Job of the red urethane bushings on your Andersen Hitch they work like shock absorbers dampening the bums and bounces between the trailer and vehicle.

Disconnecting

To unhook try to get the vehicle and trailer straight, then raise the tongue enough to release the weight from the tow vehicle, loosen the nuts on back of the chains, pull the pin on the triangle plate and let the plate swing down. Now you can raise the trailer off the ball and you are good to go.

-

5

5

-

Bulldog coupler destroys Anderson ball

in Towing an Oliver

Posted

Well it is great to see that John is hooking his Andersen WD up properly. Unfortunately the wear on the ball is normal when our hitch is used as designed. With the chains correctly tensioned the coupler does push on the back of the ball and will leave evidence of that. With our WD hitch and a regular coupler the locking claw leaves a (smiley face) in the chrome plating because the ball is designed to be softer than the claw so the trailer is not having excessive wear in inconspicuous safety related spots. It seams to wear rapidly at first then it stops once the initial wear has settled in. Anytime there is metal on metal friction there will be wear, even with grease. As we can see from John's original ball, the difference is where it happens. Is it on the top and front of the ball with a traditional hitch or is it on the backside with the Andersen? If the ball is harder than the coupler the ball will not show much sign of wear but the inside of the trailer coupler will, however; that often goes unnoticed until it is to late. With the design of the Bulldog coupler there is a different wear pattern on the ball and it should wear to a point similar to the photo John provided then neutralize. This should not affect the performance or the safety of the connection at all.