sailorashore

-

Posts

50 -

Joined

-

Last visited

-

Days Won

1

Posts posted by sailorashore

-

-

John Davies:

Take a look at the port visors offered by Seaworthygoods.com. Used as rain deflectors mounted over vessel portholes. Come with 3-M tape ready for mounting. It may be that something may be adaptable for what you want. I have a port visor over the bathroom window and it has stayed in place for the last 2,000 miles.

John Shkor

SailorsAshore-

2

2

-

-

Am I missing something? Isn’t the ideal solution disc brakes coupled with the Dexter EZ-lube spindle? Then you can keep the bearings lubricated without the risk of blowing a seal and getting grease on the brake pads & drums. Whether it should be 3500 lb or 5000 lb axles I don’t know. Doesn’t cure John Davies desire for more throw in the suspension, but for those of us who explore more on the interstate than off-road it would seem to be just right. If Dexter offered a disc-brake-and-EZ-lube replacement axle package, that might be a useful way forward.

John Shkor

SailorsAshore-

3

3

-

-

Bill: I have used the socket handle and can see no evidence of damage. The new model Anderson shaft ball turns much more easily than the old. If I happen to have the triangle plate installed and the chains unshackled I can turn the shaft with just my hands on the triangle plate, That of course is with no trailer weight on the ball. Best regards,

John Shkor

SailorsAshore-

2

2

-

-

More on a Larger Dinette Table

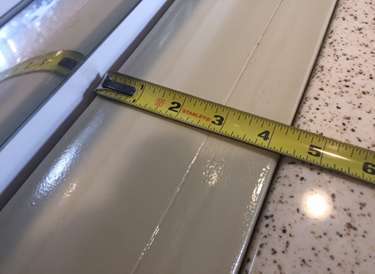

A number of interesting ideas came up in the responses to my proposal that Oliver should offer a larger dinette table as an option, and for after-market sale to current owners. I wanted to provide some additional information for some of them.1. As can be seen in the picture of my "new" table below, even after adding almost five inches to the table length there is actually still more than 26" of space in the walkway between the table and the refrigerator. Plenty of room for two people to maneuver. If I were to do it again, I would add a full 5" to the table, making the new table dimensions 27 3/4"W and 29" long. Then the walkway would be exactly 26"

2. I like the idea of a drop leaf and other expanding table designs when space permits, but in exploring design options for myself I was concerned that unless raised the drop leaf would block one from sitting down at the dinette. Also, I was concerned about sharp square corners being a safety hazard when the leaf was down, and wanted to preserve the rounded corners for safety.

3. For those who might to want to use their third bunk, if Oliver were to follow the same pattern used for its current table, the larger table could still be used as the filler for establishing the bunk. Probably with a couple of barrel bolts underneath and near the sidewall to lock the table in place when it was in the "down" position.

4. Finally, and just to gild the lily, I led the charging cables for our computers & smartphones up through the table edge under the window. When not in use they drop back down into the holes and are out of the way. Much neater than having them flop all over the place. Oliver ought to do a similar thing with its table(s).Thanks to all who chose to comment.

John Shkor

SailorAshore

-

3

3

-

-

Larger Dinette Table

Having a properly sized dinette table contributes significantly to the pleasures of life in an Ollie. That’s how Sheila and I feel after I modified our dinette table to add 4 1/4 inches to the table’s length. What a difference a small amount of additional space makes. We find it more comfortable, now have room for morning computers and coffee, and indoor dinners are more gracious. Also, I can now put both elbows on the table if I want to.

We have had a desire for a larger dinette table ever since we picked up our Ollie (hull 217) and got some experience under our belts. We camp as a couple, never set up the third bunk, and don’t like having a table that is too small because of the bunk design issue.

Oliver wasn’t interested in making a larger table when I broached the subject. Why mess with a successful product? But hunkering down to avoid corona virus gave me some extra time, and I used it to modify my existing table to see if I was on the right track. I worked up a design that used material from my leftovers bin, and which would allow me to undo the mod if it didn’t pan out.

Unless you are really looking for it, the additional table length is not readily apparent. Aesthetically everything still looks proportional. The added length doesn’t interfere with the refrigerator door, and there is plenty of room to move about.

While the pictures below show what I did, this isn’t really a how-to-do-it report. My goal is to stimulate Oliver. My hope is that the powers-that-be at Oliver will order a mock-up of a table like mine to be made, sit at it, and confirm for themselves how much nicer it is. It is my hope Oliver will then authorize a supplemental mold for laying up the larger table, offer it as an option to new buyers, and make it available for purchase by existing owners. I would be one.

If you think you might like a larger dinette table too, please tell me in a comment to this string. I would like to ascertain if there is actually any demand for this, and if so, report same to Oliver. And if you are so inclined, please contact Oliver directly as well.

Best regards,

John Shkor

SailorAshore-

3

3

-

6

6

-

-

I have been reluctant to take my Ollie to a shop for wheel bearing and brake service. Don’t lift under the axles, don’t lift under the aluminum frame, the guidance says. How does one ensure a shop tech doesn’t do one of these bad things when you aren’t there to observe? Any practical experience with this? Am I being overly concerned? Advice appreciated.

Thanks,

John Shkor

SailorsAshore -

Overland:

Fully understand. The Blue Seas 360 is a nicely engineered panel. And if you have spent enough time inside the boat cabin during foul weather, electrical panels begins to look good anyway.

Carnivore:

Look forward to reading about your 12V lithium ion battery experience. We have lithium batteries in two electric bikes, and they pack a lot of power in a small package.

Best regards,

John Shkor

SailorsAshore-

2

2

-

-

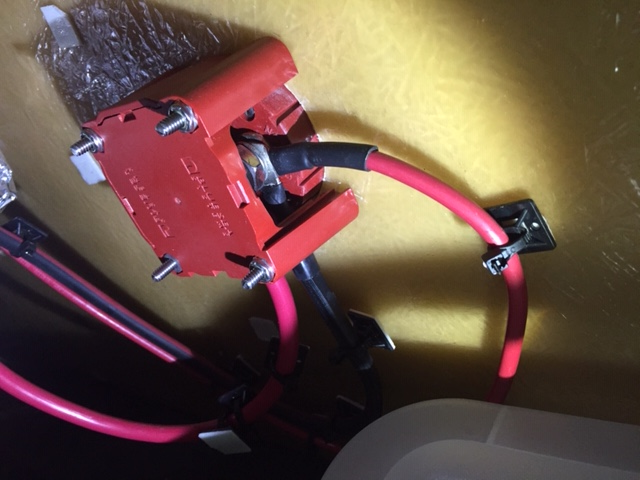

How I Installed a Battery Cut-Off Switch:

After much delay becuse I couldn't figure it out, I finally installed a battery cut-off switch on our Ollie hull 217, and it turned out easy to do. We store the trailer at a remote covered location. I didn't like to keeping the batteries on charge for long periods, and I didn't like the seemingly unavoidable small drains take the batteries down over time. My new switch installation cures both these problems.

I know other owners have installed similar switches, but still wanted to share my method. The installation will be familiar to anyone with boating experience.

I wanted the switch inside for convenience, and because I had installed safety bolts on the slides on each side of the battery rack. The rack is really secure, but removing these bolts takes a bit of time. Fortunately on my Ollie both of the two hot (+) wires installed by the factory and and coming off the batteries both go through the aft compartment wall and into the space underneath the streetside bunk. That greatly simplified my switch installation.

The steps were:

1. Disconnect & remove batteries from rack. With four batteries there are a lot of short connecting wires. Take a picture or make a sketch before you disconnect anything so you know battery orientation and what wires go back where.

2. Install a Blue Seas or similar marine battery switch underneath the streetside bunk. With a properly sized hole saw and a bit of sanding the body of the switch can be placed into the under-bunk compartment with only the switch face projecting into the living space.

3. Pull the two factory installed hot (+) supply wires through the aft compartment wall and into the space under the streetside bunk. Do not disconnect the wires from their connections inside the under-bunk compartment.

4. Prepare and run a new hot (+) supply wire to run from the batteries to the new switch. There needs to be enough slack so that the battery rack can be pulled out once the installation is complete. In my case I used 48" of #6 gauge wire, with a 5/16" and a 3/8" terminal at each end. Only #6 gauge wire, because most everything in our Ollie is low amp load LED or solid state. If I had a larger amp draw, perhaps from an inverter, I would have used #2 gauge wire for the new supply run, and used automotive lugs which can handle a higher amp load. Run the new supply wire through the battery compartment wall and hook up to the input side of the Blue Seas switch.

5. Continue to leave the old hot (+) wires connected to the factory installed terminals inside the under-bunk compartment. Prepare new runs for these two wires backwards so they can be hooked up to the load side of the new switch. Cut the wires to the right length so they can be connected to the new switch without too much excess length. Install new wire terminals and connect these two wires to the load side of the new switch. Secure these wires from vibration along their runs with self-stick mounts and cable ties.

6. Carefully reinstall the batteries and rewire.

7. When desired, turn off the new switch to completely disconnect batteries from the trailer load. If plugged in, I disconnect shore power before doing so.Best regards to all,

John Shkor

SailorsAshore

-

1

1

-

2

2

-

-

Go to Defender Industries or West Marine. Both marine suppliers. Get the 12 volt fans with suction cups. I have two. They work great and run forever. I think they are Carafamos, but I am not in the the trailer. Should be about $25. Biggest benefits are circulating ambient air when not too hot, and circulating cold air from AC when running. Good luck.

John Shkor, SailorsAshore

-

John Davies:

Got it. Makes sense. Will use side bolts.

John Shkor SailorsAshore

-

1

1

-

-

John Davies

Thank you for the report and pictures. For some time I have been thinking about adding an extra bolt to the coupler-tongue assembly. Drill a 1/2” hole vertically through the top of the coupler and install bolt about where the letters “FT” show up in your first photograph. Can you think of a reason why this would be a bad idea/wouldn’t work? Please advise.

John Shkor

SailorsAshore

-

What Da:

Great idea. Thanks.

John Shkor, SailorsAshore

-

Mary & Bill:

Funny, we just had your problem for the first time. We are camping in Maine, yesterday was an unusually hot hot day, and we chose to start the AC. Had the same intermittent cutouts you describe, with everything losing power and coming back on a minute or two later. At first I thought it was electrical overload, with the fridge, hot water heater and AC all calling for electricity. Couldn't find any circuit breakers that had tripped. I changed the fridge and the hot water heater to gas, but that didn't cure the problem.

Turned out the issue was our Progressive Industries EMS30 surge protector (external, plugged in at the electrical supply post) which was apparently working properly and doing what it is supposed to do. It was cutting off the flow of electricity and then coming back on after a time delay. It showed an E4 low voltage code. Not surprising in that a lot of other air conditioners got turned on in this camp site. However, according to the manual, the device cuts out if the line voltage goes less than 104V for six seconds. The device when I looked at it was showing a line voltage reading of 116V. It being a hot day I balanced marital harmony with risk to the AC from low voltage, and decided to take the EMS30 surge protector out of the line. So far all is well. AC continues to function well and we had a cool night inside the Ollie.

Best regards,

John Shkor, SailorsAshore

-

1

1

-

-

Mike:

I will definitely contact Anderson about this issue, once we get home. On the road now and comms sometimes difficult. I have always gotten great customer support from Andersen and expect a satisfactory outcome.

Best regards,

John Shkor, SailorsAshore

-

2

2

-

-

To my fellow Andersen users:

I am a fan of the Andersen WD hitch, and believes it provides both safety and ease of towing to a number of us. But I also believe there is a design defect in the new model, one with a simple fix, and can't understand why Andersen hasn't yet taken care of it. I too like to raise the hitch assembly with the trailer tongue jack to put slack in the tension chains and enable easy installation or removal of the whale tail. And occasionally the ball shaft will "pop up" in its cone, pinching the pin if the whale tale is installed, or preventing the pin from going in if not. Then I have a real problem. I regard Andersen's semi-obvious advice to "don't lift the tow vehicle too much" as a bit silly, as none of us can tell beforehand when the ball shaft is going to lift up. We are engaging in what has become an operationally accepted practice, and the design should be such that the pop up/pinching problem should not occur.

As I understand the hitch instructions it is the "cir-clip" on the underside of the ball shaft that is supposed to keep the ball shaft from coming out. The cir-clip in its groove is strong enough to keep the hitch from coming out even when we use the tongue jack to lift up the hitch assembly to generate slack in the chains. However, when the ball shaft does pop up, the cir-clip is forced to the bottom of its groove, and then the top of the whale tail collar (or retaining lugs on one variant) is pinched against the cir-clip with real force. The groove on the shaft of my unit is about twice as wide as the thickness of the cir-clip, allowing it to be pushed down when the ball shaft pops up.

The problem as I see it is that Andersen is manufacturing the new model system with too little clearance between the top of the whale tail and the groove for the cir-clip. The fix as I see it would be to have an additional 1-2 mm clearance between the groove for the cir-clip and the top of the whale tail when mounted. Either relocate the hole for the mounting pin a bit lower on the shaft, or reduce the height of the whale tail collar slightly to provide more clearance. Then it wouldn't pinch even when the ball shaft has popped up in its cone. Andersen should recognize the problem for what it is, and fix it.

I have admired Andersen's efforts over time to perfect their design, and would like to see them fix this current problem some users are experiencing. Hopefully they will.

John Shkor, SailorsAshore

-

3

3

-

-

Jitters:

Like John Davies I am a believer in the center-line mounting for the Andersen chain brackets. There are a number or reasons. The center beam is extremely strong and the line of chain pull is parallel to the long axis of the beam. No sideways element of tension, and no tension force being carried through aluminum welds, as is the case with the factory mounting system. Finally, you get to “double up” the mounting brackets, ensuring they will not move over time, as has happened to some with the factory mounting system.

Is the center mount necessary? Probably not. I am not aware of any frame damage or failure from the factory mounting system. On the other hand you need a whole lot of tension, more than most people are comfortable with, if you want to shift 200-300 lbs of weight off the hitch and 1/2 of that onto the front wheels of your tow vehicle. I use the higher range of tension, and like the peace of mind knowing I am not going to break anything.

I worked out the original center-line mount, but John Davies instructions and pictures are better than mine.

While it is intuitive that the “wider stance” of the chains is better for controlling sway, it isn’t really true. Sway control in the Andersen system results from friction in the ball shaft cone bleeding energy out of the sway as the trailer tries to move side-to-side. The key thing is that the trailer, the whale tail, and the ball shaft all have to rotate together around the vertical axis of the ball shaft, against the friction resistance of the cone insert. As long as the chains are properly tensioned they will. The spread of the chains where they are attached to the trailer frame doesn’t make any difference.

Hope this helps as you sort out your preferences. Best regards.

John Shkor, SailorsAshore

-

1

1

-

-

Nrvale0:

I had to replace my bumper pins. Numerous vendors on line. Google “quick release pins.” Opt for stainless steel, 3/8” diameter, and minimum of 3” useable length. My replacements were/are 3.5” useable length and work fine. Good luck.

John Shkor. SailorsAshore

-

3

3

-

-

I think there is another reason that Oliver will ultimately have to come out with a new model. It is that as they build and sell a goodly number of Elite I & II’s, the resale of used Elites will begin to cannibalize the sale of new units. We saw this with Island Packet yachts when we were sailing. Island Packet was a very successful boat builder, and they kept the appetite up for new boats by replacing current models with new models after a 5 or 6 year run for a given model. The new model in a given length would have more bells and whistles, so that would be the one you would want. I think we are seeing more ads for used Ollies than we used to, so it may be starting now. Food for thought.

John Shkor, SailorsAshore

-

We like to keep our bathroom window open as much as possible for ventilation. I did two things to reduce the likelihood of rain getting in and let us have ventilation even when it is raining. They have worked out pretty well. The first was to mount a "port visor" over the bathroom window. These are made for boats to go over portholes and keep rainwater from running off the deck and into portholes on the cabin sides. This resulted in a substantial improvement, mostly in keeping rainwater coming off the roof from streaming in. But I still wanted more rain protection. So I trimmed an old automobile side window rain deflector to the width of the window and mounted it with two-sided tape onto the bottom of the upper fixed window. Now, unless it is blowing a whole gale we can leave the bathroom window open without having to worry about rain. Each piece has stayed on with no trouble over the last two years of travel. Pictures attached below. Port visors are available at "SeaworthyGoods.com", and side window deflectors from Weathertech or your local auto parts store. Just make sure you get a piece that has enough "straight" for the width of the bathroom window. Best regards to all.

John Shkor, SailorsAshore

-

5

5

-

-

Pete: The bilge heaters is see in the marine catalogs are both powerful (high wattage) and expensive. Is that what you used, or did you find something smaller? Would like to know how you did it. Best wishes for the holidays. John Shkor, SailorsAshore

-

We had a problem with our heater that we should have caught when taking delivery, but didn’t. Furnace would ignite a flame but it would go off after a few seconds. Manufacturer of furnace speculated it was a faulty thermocouple. Oliver diagnosed faulty mother board and replaced under warranty. No problems since. Good luck with yours.

John Shkor, SailorsAshore

-

1

1

-

-

We use the Andersen hitch on our Elite II and like it. We tow with a GMC Yukon, so the springs are soft and the ride comfortable. I tried and continue to use a center mount method for installing the chain anchors onto the center spar of the trailer, which I think is better than the factory install. Easier to adjust the chains, mounted to the strongest piece of aluminum in the frame, and with a fair lead angle. My install is buried somewhere in an old thread. John Davies has also used this mounting method, and done and posted a much better description and set of pictures.

We picked up our Ollie before installing the Andersen hitch. So, we had the experience of a comparison (albeit a statistically invalid sample of one). The trailer imparts less “bounce” and side-to-side tug to the back end of the Yukon with the hitch installed. We never experienced sway with or without the hitch, but take comfort that the friction cone is bleeding energy out of any developing sway situation. I fully load up the chains and believe that the extra weight on the front wheels of the Yukon ensures solid steering in bouncy situations where they might otherwise unweight.

Like anything that requires care and attention, there is a learning curve in hooking up with the Andersen hitch. But after a few times you get the hang of it and the hookup is easy.

I think the folks who tow with heavy full size pickups are right (for them) when they say the Anderson hitch isn’t really necessary. And the Ollie Elite II certainly has a reputation for being well mannered when being towed. But for we lesser mortals, with vehicles closer to the limit, it is a nice bit of comfort.

Best regards, John Shkor, SailorsAshore

-

2

2

-

-

Randy:

Maybe send the picture to Dexter and see what they have to say.

John Shkor SailorsAshore

-

The Lukens put out some good word on this a year or so ago. Their tip was to remove the rotating closure element in the bathroom vent. This doubles the area open for hot air to move through the vent. We have done it and it helps. In addition we leave the bathroom door open a half inch at night. There isn’t an air return in the bathroom, and having the door open compensates for that. Good luck with this.

John Shkor, SailorsAshore

-

2

2

-

Andersen WDH Mounting Point

in Towing an Oliver

Posted

Ralph:

The center beam installation has a lot to recommend it. I think I was the first and did a post on how to do it. John Davies did a follow up with much better pictures. The advantages: 1. Center beam is strongest structural member with better lead angle; 2. Center beam installation allows brackets to be doubled-up, ensuring that there is no slippage; and 3. easy to reach for adjusting the bolts. If I were handier with the forum would give you a link, but I’m not. You should be able to find our posts with a bit of research.

Best regards,

John Shkor, SailorsAshore