Search the Community

Showing results for tags 'how to: stone stomper gravel guar'.

-

@Topgun2 Bill: I see you have the 2017 F-150 set-up very simular to my 2019 F-150 lariat FX4. Did you have to modify the Rock Tamers mounting collar? Any issues with the back-up camera? Thanks, GJ

-

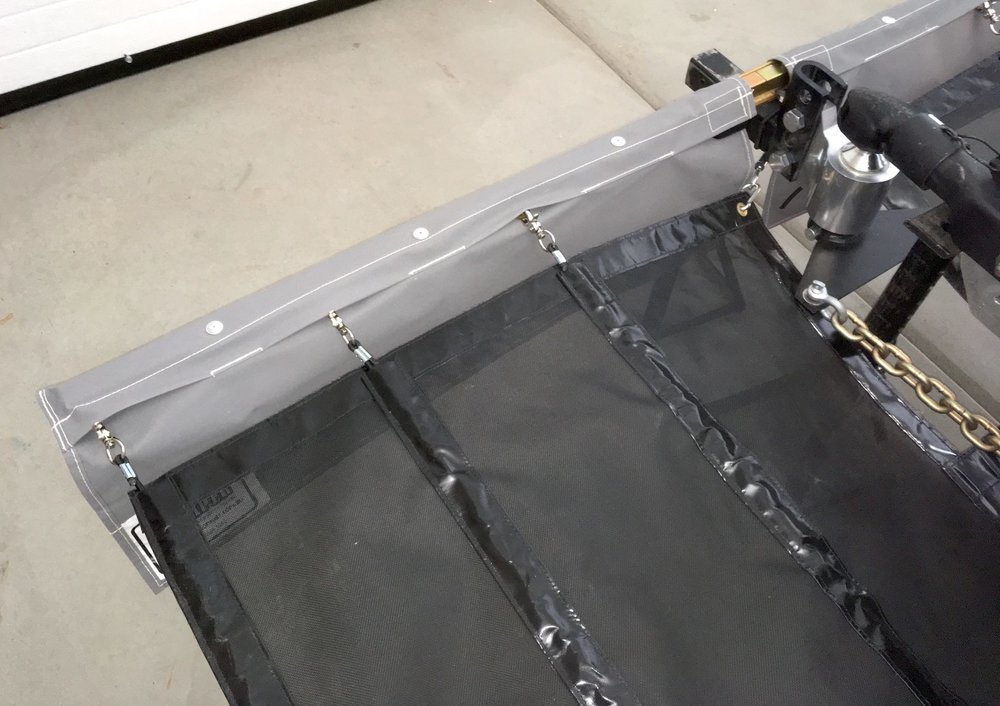

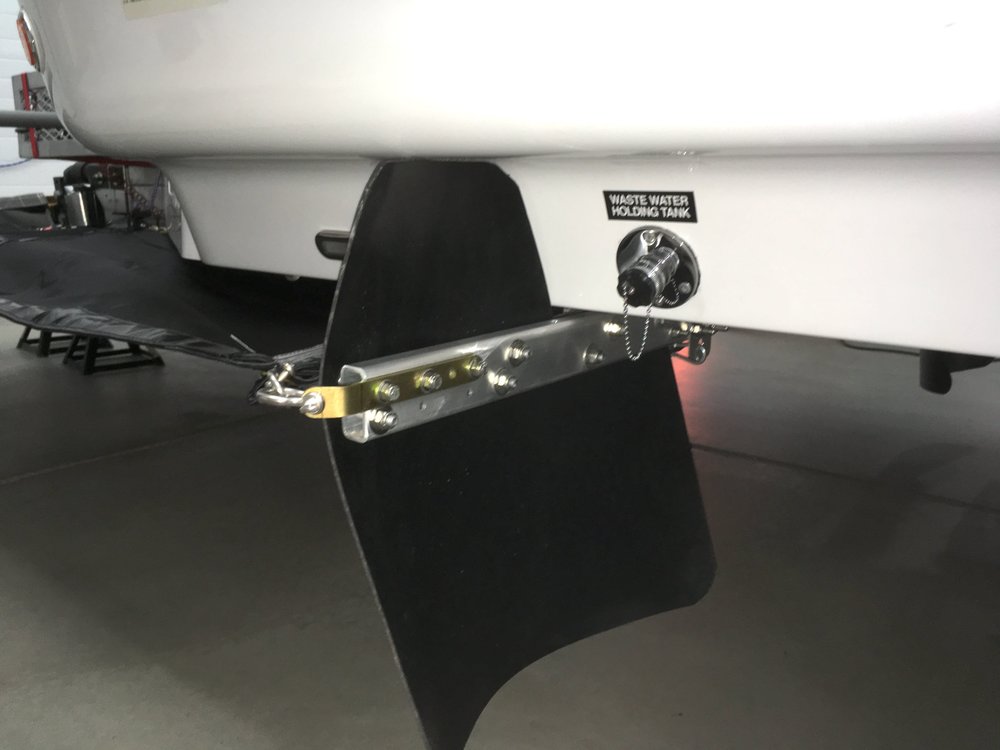

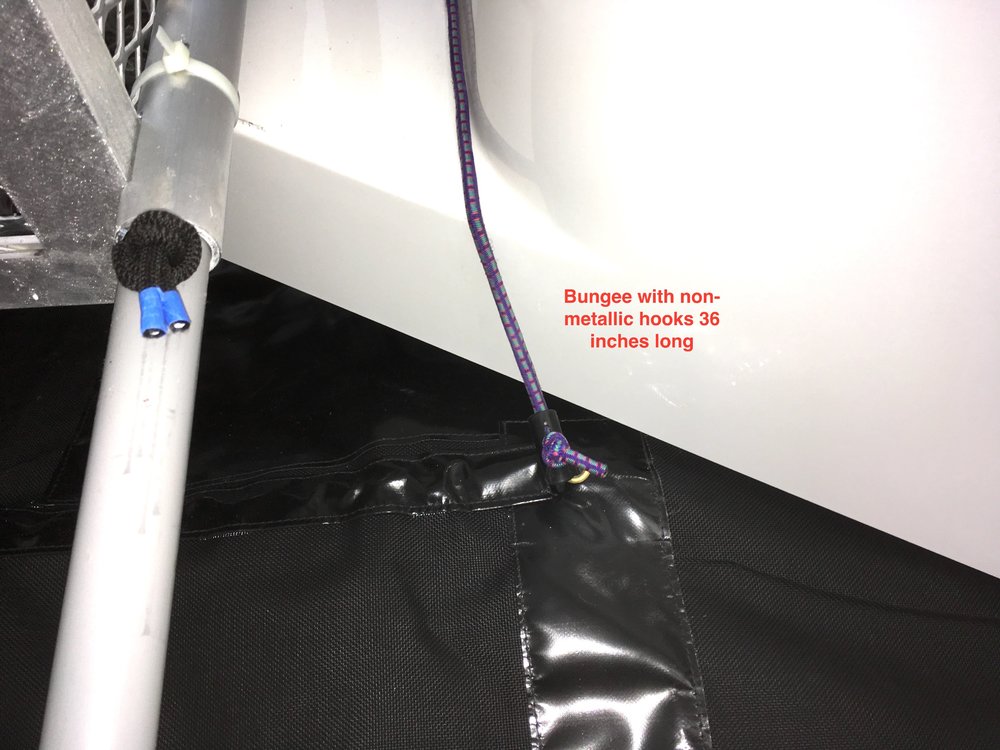

EDIT 03/27/18. Added text to first four parts. JD EDIT 03/29/18: Added road test with pics, see the below post with this date. This is going to be a super long thread, I have a lot of pics and text to work on. For now I am going to get my order document (with measurements) and the install pics loaded. I am going to be away from home for a week, but maybe I can work on getting the "How To" text entered also. While I am doing that I will insert the pics into the text as needed. The job is finished but I have not yet towed with it. A road report will follow somewhere, somewhen. Please look at this doc for ordering and measuring info: DAVIES-Stone-Stomper-NOTES-MEASUREMENTS-013118-EDITED-FOR-POSTING.docx PART 1 EDIT 03/27/18 SUMMARY AND BASIC DESCRIPTION This is frustrating, a very long, 20 minute edit vanished. Completely. I should know better than to write online and not back stuff up. I hate the forum software. It is a measure of how much I like you guys that I will rebuild that post. Stone Stomper is an Australian manufacturer that has been making these guards for many years, they are extensively engineered and tested over tens of thousands of miles of rough tracks to perform well under harsh conditions. The owners who use them really like the product. There are plenty of reviews and videos, so I will just send you to their site for now: …. http://stonestomper.com.au At this time they have virtually zero market exposure in the USA, though they have shipped them here. I really hope that they will consider opening a small USA distributor/ manufacturer so that the issues with exchange rate, high International; shipping and possible warranty claims would be more palatable. I don’t think that will happen unless we as foreign buyers ask hard. At the end of this thread are “unboxing” and “initial layout” pics. I will add some comments there. The basic premise is that an underslung heavy mesh fabric that rides underneath the entire A Frame structure stops rocks from getting past, stopping paint erosion, gravel rash and damage to the trailer body and the tow vehicle rear hatch and glass. The design offers way, way more coverage than your typical RV gravel flaps. The mesh is suspended in front with 6 long shock cords connected to a custom crossbar, and is anchored to the ball mount with a seventh short one. During maneuvering, the inside part folds in on itself and the cords stretch on the outside part. Normally the mesh just “floats” on the six main cords. On longer installations like the Ollie, there is a central support bar that helps to hold up the fabric in turns and also has other functions. Short coupled camp/ utility trailers don’t have or need the support bar. The gray fabric up front is light and fairly flexible, and it is intended to sail up to seal the gap between the TV and the front of the fabric when moving. When not being used you can roll it up and slide on optional sleeves made in a matching material. The challenge on the Oliver is that there is no easy way to attach the supplied rear anchors to the hull. One could drill into the fiberglass but that would be ugly and it would not get the rear of the fabric positioned in the best place. I elected to build aluminum mount bars that extend out to provide complete coverage of the fiberglass, and also to give me a place to mount additional sheet neoprene guards to protect the steps, underneath puddle lights and the black tank rinse fitting. The center support bar was a challenge. The instructions call for a simple one piece section of 1 inch ID plastic conduit, lying on top of the frame and slid into the two sleeves. That seemed primitive and again, I did not want to deal with a really long pipe, so I designed a system where two small pipes slide into a fixed center alloy tube. Shock cord comes down from the tubes and allows me some adjustment of the support tension. The reason for plastic supports is two fold: they are strong, cheap, UV resistant, flexible and the material can be found at any hardware store for $0.40 per foot. And if they take a hit, or I somehow jackknife into them, they will hopefully bend or break before damaging the TV. Being short allows me to carry pre-cut spare sections easily, since they are less than three feet long. At Stone Stomper’s suggestion, I added a short length of chock cord just in front of the doghouse, with plastic hooks slid under the rear or the innermost SS shock cords. This helps support the fabric and keep it from drooping down under the center of the frame. MORE TO FOLLOW. John Davies Spokane WA