Tony and Rhonda

Members-

Posts

73 -

Joined

-

Last visited

Everything posted by Tony and Rhonda

-

Hopefully I'm posting in the appropriate thread and it has not already been posted here. Just saw this on Bloomberg via MSN: https://www.msn.com/en-us/money/companies/ford-recalls-4-4-million-vehicles-on-trailer-controller-flaw/ar-AA1X88AR?ocid=hpmsn&cvid=69a1a8ea953d4482be96a7f27cdc157f&ei=145 Bloomberg (subscription required): https://www.bloomberg.com/news/articles/2026-02-26/ford-recalls-4-4-million-pickups-suvs-on-lighting-system-flaw

-

- 2

-

-

-

Moving Stabilizer Jack Switches

Tony and Rhonda replied to Tony and Rhonda's topic in Ollie Modifications

We've installed a LevelMate Pro and it seems to work well. I ran into an issue when zeroing it out. Front to back wasn't a problem but our Ollie has a slight crown right to left. I tried to split the difference when calibrating the LevelMate Pro. @Ronbrink's post above about leveling his Norcold has me rethinking this. We had issues with a non-working furnace in another RV when the rig wasn't level. Don't want this to happen with the Ollie. We also have the 3-way Norcold. As @Ronbrink mentions, the top of the frig door should work for front to back. What about right to left? Are the internal shelves 'level' or do they slope in or out? Is there another place that would be better to use for level? Thanks, Tony -

Browsers may or may natively not open a text file. Sorry, it looks like I left out the step where you download the file to your device then change the suffix from .txt to .htm. When re-labeled as an .htm file, it will open in your browser. I'll add the .htm version as an attachment to the post. John E Davies -HOW TO threads and Tech articles LINKS.htm This should open directly in a browser. If it doesn't, please let me know. Tony

-

John Davies has a wealth of modification knowledge in his list. I can download the list but can't open it due to using an older version of MS Word (2010). As I think I posted in another thread, I found all the links went to the same article. I also found it difficult to find what I was looking for since each subject is only shown in the URL. So, I downloaded the page and modified the links so the subjects are easier for me to read and opened to the correct thread. I've attached my edited version of John's list as a text file. If anyone wants to use it, just change the file suffix to .htm and it should work just like a web page. John E Davies -HOW TO threads and Tech articles LINKS - Copy.txt And I thank John for all the help he's posted! Tony

-

Disabling the speaker on an Apple Air Tag

Tony and Rhonda replied to Patriot's topic in General Discussion

We use Tile Pro trackers (by Life360). Works with Android and iOS. Don't know if they are as feature rich as AirTags (don't have an iPhone) but they have several models with different features. https://www.amazon.com/Tile-Life360-Pro-Bluetooth-Compatible/dp/B0D637HWC5/ref=sr_1_19?crid=2XJAY04P3UCDH&dib=eyJ2IjoiMSJ9.bO9LSRG-Q2eHGVfY3qcVHIf7ZNIXZ0jEakdV-K7k_LsylnUuOmqcGy1y1rYMhs1V3ByTDGfVetzFThllP0vFn9iWM7HTzU4hz2ioekXd_UnjhNATNzHYQ46Y4UjAwPyAUbcFXq7FqepiYY9ZLAxqHqMm2ZKB_vP-lR5USAiQVijIddJulZNzaBQD76w6inYTfd4IfG-jbosNxodqQaPOUZoa2ehnzJbLDOfEBFpUPoU.fYN5jHbnmqMjz2TA9I1VgJJJJNhHkT9dpjResmsEYIM&dib_tag=se&keywords=tile%2Bfor%2Bandroid&qid=1765854073&sprefix=tile%2Bfor%2Bandroid%2Caps%2C127&sr=8-19&th=1 -

Changing tires in the wild - lessons learned

Tony and Rhonda replied to John and Jodi's topic in General Discussion

@Jamie Peghiny I've been following this thread and I just read you added your Ollie's year and hull number to your signature and wonder it you have a typo? Your sig. shows and 2012 LE2 hull #802. We're a 2017 LE2 with hull #251. Something doesn't add up. Lots of knowledge here so I only bring this up so you get accurate help. Tony -

Moving Stabilizer Jack Switches

Tony and Rhonda replied to Tony and Rhonda's topic in Ollie Modifications

I got the idea of moving the switches while watching @shhQuiet's videos. It does seem there are positives and negatives of the two (or three) locations. I have lots of chores I need to do on the camper so I can put this on the back burner and think about it some more. Thanks everyone for your imput, Tony -

I've tried searching the forum but haven't had any luck finding what I'm after so.... My 2017 hull has the stabilizer jack rocker switches located at the front of the trailer. This is not so convenient since I can't see the jacks during operation. I've noticed the newer trailers have the switches behind the basement door so the are jacks visible. Has anyone moved their switches? This seems like a fairly straight forward mod but I've been surprised before. Thoughts, comments? Thanks, Tony

-

Andersen WD Hitch Friction Cone Noise

Tony and Rhonda replied to Tony and Rhonda's topic in Towing an Oliver

Our upgrade was supposed to be delivered today but it's now shown as delivery on Monday. Even though we're about 20 miles from UPS WorldPort, UPS decided to route our shipment through New Jersey and Pennsylvania (so far). Tony -

Just an FYI for anyone still with the old style Andersen WHD ball mounts with the exposed friction cone. I can't find the post (circa 2022?) that started me down this road (about horrible noise from a wet Andersen ball cone) but we encountered this after a night of rain during our last trip. It was still making noise after a week of dry weather. I did find a Service Bulletin from 2018. I called Andersen and was told I could replace the friction cone under warranty or I could upgrade to the newer style ball housing and triangle plate (whale tail). The price has increased but is still pretty reasonable compared to full price replacement purchasing the parts. The upgrade now costs $150 and includes the 2" Ball, Ball Housing, Triangle Plate, Friction Cone, Snap Ring, Pin and Clip. The 2 5/16" ball may be available also. Tony

-

Towing with a Chevy Colorado Tow package 7500 pound

Tony and Rhonda replied to jgilliam1955's topic in Towing an Oliver

I'm hesitant to reply to this since we're new Oliver members/owners but the rule of thumb I've been told is trailer should be no more than 80% of your TV's rated tow capacity. For your Colorado that's 6000#. I think towing right at your rated capacity is also going to cause more wear and tear on the TV. Another consideration is your towing experience. If you're crawling up hills at 45mph in a 70-80mph speed zone it's not going to be pleasant. Lot's of questions on this forum on towing so try the search function, or better yet search with Google. Tony -

Thanks, the sight tube is a good idea. Tony

-

@Ronbrink Once I had a brand name for the coupler, I searched the forums and found some of the old threads. I'm considering adding the clear length of hose that you did. I assume you bought another cap for the coupler and added the brass fitting. Do you remember what parts you used; fitting, hose, valve at the end? The "another identical buckle/latch on the other side" is just the other cam latch on the coupler. Only one was visible in my photo. Thanks, Tony

-

I can see how a porch light to the rear of the trailer could be useful but I was actually asking about the utility of a light _in_ the rear bumper space so I could see the connections better.

-

@jd1923 I think there's just one hole in the Ollie hull. It's sealed with a rubber grommet around the wire. It looks like a second hole due to photo perspective. I think, I'll check again in the daylight tomorrow. I'm thinking about pulling the wires but I'm also considering adding a light to the bumper area. Do any of you more experienced owners see a need for a light in that area? Thanks to @Steve Morris for identifying the plumbing connector. Unfortunately I don't think I have the whole Waste Master system, at least not as pictured in Steve's post. My hoses are orange and I don't have the 90 degree with handle and valve on the end. I do have a couple sections of the orange hose and a clear 90 on one end. This is our first travel trailer (with indoor plumbing) so I could be wrong about the hoses. They accordion in and out very well and seem durable. I don't have any experience with other waste hoses to compare these to. I'll have to look more closely but I don't think I can remove the DrainMaster piece with the latches. I'll check tomorrow (if it's not raining) but I think it's all glued up as one piece now. I wanted to attach the drain hose as @jd1923 suggested but, as configured, the pipe extends out to just short of the hinged bumper. Thanks for your help and advice, Tony

-

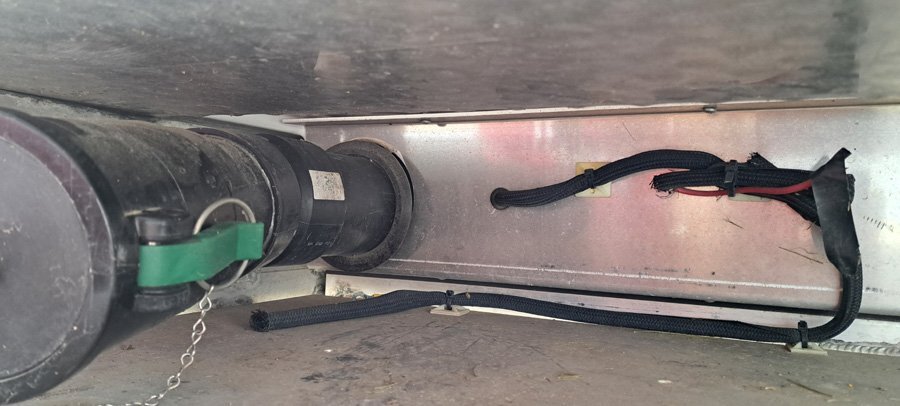

Yes @jd1923 the flex hose attaches there. There's another identical buckle/latch on the other side. I had hoped to be able to leave the flex hose attached to the waste pipe but it extends too close to the bumper. That does seem like an odd location for the propane. That's why I asked the question. The "other" wire hidden by the Techflex sheath has a ring terminal attached. As you can see in the photo, the red wire (+?) is just cut off and wrapped in electrical tape.

-

Since we have a new to us older Oliver, I've been wading through the threads here. I found the thread about the gasket on the waste pipe in the rear bumper. I checked and it was loose. I've re-seated it but I found another issue. I have an electric line laying sort of loose in the rear bumper cavity. The wires need to be terminated better but does anyone know what they were for? I also found a propane connection in the rear bumper. Is this a standard feature? Thanks, Tony

-

HOW TO: Rear mud flaps for the Ollie

Tony and Rhonda replied to John E Davies's topic in Towing an Oliver

The URL shown in John's first post results in a 404 error. The new URL is: https://olivertraveltrailers.com/forums/topic/2504-how-to-stone-stomper-gravel-guard/ -

TPMS sensors are user installable if you purchase the sensors that screw onto the valve stem. Internal (to the tire) sensors require professional installation. You will also need professional installation if you need to replace rubber valve stems with metal. While some have good results without switching the stems, my TST flow-thru sensors require metal stems (per the TST instructions). After a shop replaced my rubber valve stems with metal stems, I installed and calibrated the sensors following the instructions.

-

Lowering Television For Viewing

Tony and Rhonda replied to Tony and Rhonda's topic in Mechanical & Technical Tips

Thanks @Rivernerd, I'm overthinking again. Tony -

Lowering Television For Viewing

Tony and Rhonda replied to Tony and Rhonda's topic in Mechanical & Technical Tips

Thanks @Dennis and Melissa, that worked. Guess I was overthinking it. The screen doesn't hang vertical due to pull from the cables. Is there a way to lock it vertical or do I need to pull slack in the cables? Thanks, Tony -

I've been searching the forum and the Oliver videos but I can't find instructions for lowering the television. Would someone point me to the instructions or video. Or just explain it to me. Thanks, Tony

-

Changing tires in the wild - lessons learned

Tony and Rhonda replied to John and Jodi's topic in General Discussion

sorry for the double post. How did that happen? Can someone delete it?