-

Posts

113 -

Joined

-

Last visited

-

Days Won

2

tallmandan last won the day on October 31 2021

tallmandan had the most liked content!

My Info

-

Gender or Couple

Couple

My RV or Travel Trailer

-

Do you own an Oliver Travel Trailer, other travel trailer or none?

I own an Oliver Travel Trailer

-

Hull #

627

-

Year

2020

-

Make

Oliver

-

Model

Legacy Elite II

-

Floor Plan

Twin Bed Floor Plan

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

tallmandan's Achievements

-

Removing shelf under bathroom sink for plumbing access.

tallmandan replied to Mroth's topic in Ollie Modifications

Hello Marc, Yes. There is a phillips screw head under that plastic cap. A gentle but firm pry should pop them off. I think I used a plastic putty knife but a small standard screwdriver should work, being carefull not to damage the fiberglass. You will also have to carefully break (slice) the bead of silicone caulk around the edge of the access panel to remove it. A new sharp plastic razor blade should work without damaging the fiberglass. Suggest adding your Hull number to your posts so folks know what year your trailer/equipment is. Hope that helps -

In April of 2025 I asked for a quote from Calmark for a cover. I was quoted $1450 including shipping and also informed that they changed their fabric resulting in cutting the warranty from 6 years to only 3 years. I spoke with Natalie on the phone and she was very nice. They were not able to source the same fabric anymore (as of then) and could no longer warranty it for 6 years as on previous covers. I told her I live at 6300ft elevation in Colorado and the UV sun exposure is absolutly brutal. I store the trailer at an RV lot where it is uncovered and it takes the sometimes intense wind and wind gusts we have here. I'd like to have a Calmark cover but just couldn't stomach almost $1500 with only guarantee for 3 years. I decided to contiue with the much cheaper cover I have been using. It's good quality compared to most of what's out there, which is a lot of cheap junk. I do think it's caused light rub marks on the fiberglass in a few spots from the whipping wind even though it does secure down pretty tight. They seem to buff out with some McGuires one-step compound and wax, but it's obviously not ideal. I decided this was the lesser of two evils compared to the damaging sun exposure. The 15-18 foot size fits the LEII pretty well even though it's cut for a trailer 8ft wide. It reaches to cover all the way up over the front jack. Hopefully Calmark will be able to revise it's offering. But in the meantime, this is an alternative with caveats... IMG_3362.HEIC https://www.amazon.com/gp/product/B01KHX27HS/ref=ox_sc_saved_title_6?smid=ATVPDKIKX0DER&th=1 IMG_3362.HEICIMG_3362.HEIC

-

Day/Night Window Shade Questions

tallmandan replied to rideandfly's topic in Mechanical & Technical Tips

Can I ask those of you that have done this — how did you access and tie the new cord to the spring inside the channel? Seems very difficult to thread the cord and tie a good knot when it’s tucked in there and under tension from both sides via separate cords. Am I missing something? Just trying to plan before I have it apart in 9 pieces. Thanks! -

Ran across this video just posted to youtube... They are clearly targeting Oliver LEII and Airstream FlyingCloud 23fb as their competitors. Starting price on their website is $88,900 but it looks to be inclusive. Several things are appealing. The larger sink and upright fridge/separate freezer would sure be nice. Don't think I like the vinyl flooring. Those manual scissor jacks at the back make it look cheap. Above them are copy-cat 3-piece Oliver-style tail lights - just tunred diagonal 🫤

-

Day/Night Window Shade Questions

tallmandan replied to rideandfly's topic in Mechanical & Technical Tips

Ha! Yes I have the same concern! Just curious, did Oliver give you a price for the new shades? Looking for motivation to try this DIY project 🙂 -

Day/Night Window Shade Questions

tallmandan replied to rideandfly's topic in Mechanical & Technical Tips

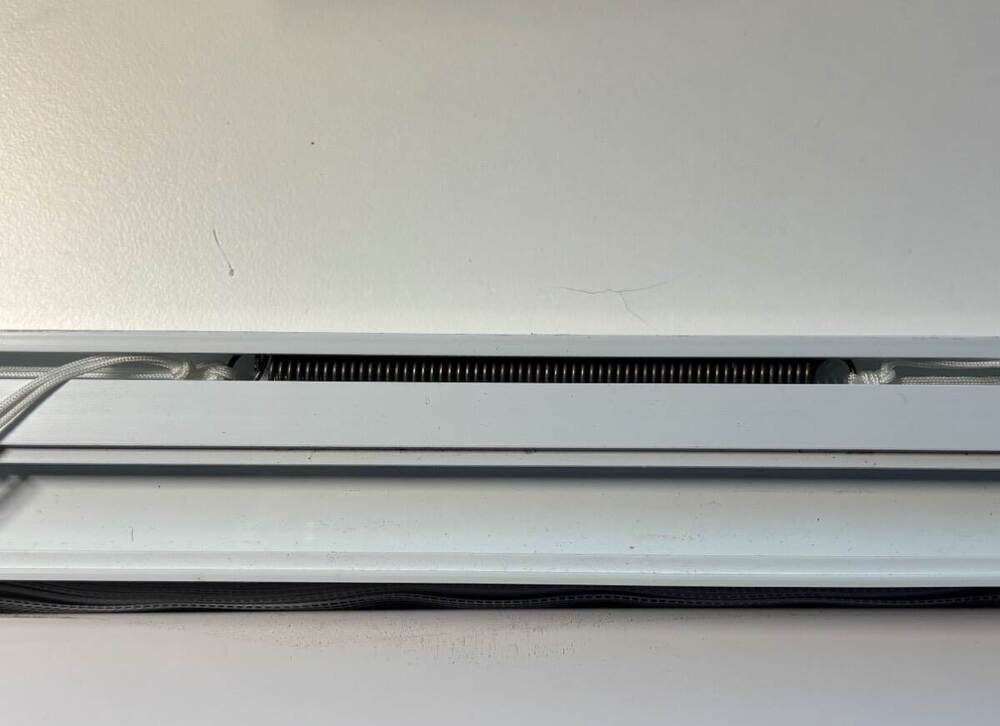

One of my window shades developed a problem. The outer nylon covering of one of the cords has separated from the inner core and is bunching up between the pleats, preventing the shade from collapsing/folding completely (see photo). I can only collapse the night shade partially now, leaving a quarter to a third of the shade unfolded. This thread has been very helpful to understand what I need to attempt and how. This does seem difficult and potentially frustrating to tackle... Thank you to those who have shared info and tips! ? Question to those that have replaced broken cords: Can I dissasemble the shade frame and replace just one of the four cords and leave the others in place? Do I have to release tension on all four cords and take everything apart and start over? IMG_3759.HEICIMG_3759.HEIC -

This is a good start but leaving the battery door open/unlocked is not a real good idea. The mods and installs shared on the forum are allways impressive and helpful! Just an FYI - I have the Renogy 200w Solar Suitcase with attached solar controller (link below). I am able to simply use the alligator clips on the battery terminals and route the cable to the lower right corner of the battery compartment. As I close the door, I shift the cable just a bit so it's below the weather seal and next to the hinge - the door will just close without pinching. https://www.amazon.com/Renogy-200-Watt-Monocrystalline-Controller/dp/B07RFQVB9M?th=1

-

Wow JD! You've gone an one-up'd those of us that have installed the 2 300 Ah Epochs. Very impressed and good to know that this can be done. I've been very happy with my upgrade to 600 Ah with the these two Epoch batteries but if I ever decided to upgrade to the 3000w inverter and try to run off-grid a/c then this would be the way to go! Thanks for sharing and thanks again for all the help and advice you share on this forum.

-

When we are traveling together, my wife calls it our little Cannellini Bean. When I’m solo, I call it my MFC (mobile fishin’ cabin)

-

Agree. Levelmate works well and another benefit over using bubble levels is that you can monitor the trailer degree of level while moving into the campsite. I camp in boondocks sites where the gravel/dirt is uneven and I can monitor from the drivers seat while moving back or forward to find best level spot.

-

Epoc Lithium "Keep-It-Simple" Upgrade Advice

tallmandan replied to tallmandan's topic in Ollie Modifications

Yeah, I was suprised to find a residential-type galvanized junction box for the 7-pin connection....but it was located close to where the 7-pin trailer wire comes into the hull behind the propane tanks. My 7-pin cable was damaged and I found it easy to replace it with a new one while I was in there. It seems to work just fine... -

2026 YM Oliver awning style windows and other changes

tallmandan replied to Patriot's topic in Ollie Modifications

Not a fan of wallpaper/texture look on the wall. I've always hated the cheap, dingy wallpaper look on the interior of so many other RVs. Always loved the clean, nautical feel of the bright white fiberglass in the Oliver. Its a double hull fiberglass trailer so embrace that! Leave it to individual owners if they want to cover the fiberglass with something. I'm not sure I like the new windows either, which sure seem to have less airflow. On the plus-side, it does provide rain protection. My trailer is usually my basecamp and I often leave the windows open when I leave for the day's adventure to keep it cooler inside. I worry that if a rainstorm comes up before I return then it can get wet inside the trailer (Colorado is notorious for quick-forming afternooon thundershowers in the summer). I wonder how much more privacy the new windows add with the dark tint? Assume it is significant and the new roller shade is a full shade only? Does the dark tint result in less light transmission and a darker feel inside? I like light-and-bright! -

Disconnecting Tow Vehicle charging circuit to the Ollie?

tallmandan replied to routlaw's topic in Mechanical & Technical Tips

I'm not sure if this will help as I don't know if a 2017 trailer was wired the same way as my 2020 trailer. I disconnected my charge wire when I upgraded to lithium batteries a few months ago. Mine did not have a bus bar. I couldn't find anything under the seats or bed. Inside the bathroom access panel under the sink I found that my 7-pin cable entered a standard galvanized steel junction box containing all of the connectors. Each was connected with a Wago lever connector and then wrapped with electrical tape to safeguard the lever coming undone from vibration. I just found the black charging wire, unwrapped the tape and lifted the lever on the connector to pull the wire. I capped it, taped it and then put everything else back together. Oliver's electrical connection design was less than elegant but it made for an easy disconnect once I found the junction box. -

Sure hope you plan lots of extra time for stops! I used to live in Vancouver, WA and went to the Oregon coast many times with my family. Here is a quick list that I put together for a freind a while back that I copied here in case it would be of value. It's in South to North order so just reverse the list for your trip... Some good stuff working your way North... 1. Depoe Bay. Cool little town. Whales are frequently spotted here in the bay from shore. 2. Cascade Head Trail. I never did do this but understand it's great if you are up for a longer hike. 3. Neskowin is a nice little town and beach 4. Pacific City beach is great! Cape Kiwanda State Natural Area is just to the north of Pacifc City Beach and is outstanding. Park your truck in the parkting lot of Pacific City Beach and hike up the giant sand dune to your right (North). At the top of the dune you can then hike along the cliffs and the views are superb. It's a steep but short hike up the big sand slope with no "trail". Most folks don't realize how great the landscape and view are if you go up and hike around. This is amazing at sunset! Must do. 5. Cape Lookout Trail. Excellent easy hike out to the point on high cliff. Highly recommend! 6. Cape Mears Lighthouse. Short walk to historic lighthouse. beautiful. 7. Tillimook Cheese Factory. This is a tourist trap but it is the original main cheese production of Tillimook cheeses and ice cream. Worth putting up with the crowds to go in. Can do a factory tour if you want. Get ice cream cones. Try the cheese curd - my favorite! 8. Highway 101 from Manzanita to Cannon Beach is the most scenic stretch by far. Great views from the cliffs above the ocean 9. Oswald West State Park. Park at the trailhead for Short Sand Beach. Take the easy trail down under the highway and through a valley to a secluded stretch of sand and surf that is pinched between cliffs on each end. Great beach and popular spot for surfers. 10. Hug Point. Cool beach. Walk along the beach going North to a small waterfall and shallow caves in the cliff that are on the beach. 11. Cannon Beach. This is a very popular and busy beach town. The main street has lots of shops and restaurants. Expensive, more high-end little town on the coast an easy drive from Portland. Great beach with the famous Haystack Rock. 12. Ecola State Park. You can spend all day just exploring here. Hikes and views and beaches. Drive through the park out to Indian Beach Day Use Area. Beautiful area.

-

Rear Electric Stabilizer Jack adjustment - help?

tallmandan replied to tallmandan's topic in Mechanical & Technical Tips

Alright, time to close this out. I received the replacment jack post assembly from Barker which they shipped to me at no cost. The picture below shows the new unit next to the old unit. As I knew, the mounting bracket on my existing jack sleeve was welded the the incorrect location by about one inch. The swap out was easier than I expected and I now have plenty of clearance under the hatch as it should be. I want to thank Bob Asher at Barker for his help with the free replacement and with swap/install instructions! Great customer service! I also want to thank everyone who responded in this thread in a effort to help! The collective knowledge and experience of this group is really valuable.