-

Posts

490 -

Joined

-

Last visited

-

Days Won

6

Everything posted by Wayfinder

-

Day/Night Window Shade Questions

Wayfinder replied to rideandfly's topic in Mechanical & Technical Tips

We have wood workers, mechanics, electricians, IT folks. What we need is a person to make nice shades for less money, that looks nice, and easy to maintain, and replace when the time comes. -

Day/Night Window Shade Questions

Wayfinder replied to rideandfly's topic in Mechanical & Technical Tips

In May of 2024 Oliver charged me, and you best sit down for this, $906 to install new shades. I suggest you get a quote with shipping, and install yourself, but honestly, it won't be much less these days. Not too many people seem to like the new, simple shades, me included, but you know what, I bet they're easy to replace. Has anyone seen the new shades up close? Thoughts? -

Local web page to search Oliver forums via Google

Wayfinder replied to Wayfinder's topic in General Discussion

I'm getting there slowly. Updates I've come up with so far. Only 1.5 minutes long. Ideas are welcome. camper-document-indexer-v008.mp4 -

Local web page to search Oliver forums via Google

Wayfinder replied to Wayfinder's topic in General Discussion

I've been using this local html document more lately. Man, I'm searching on things, but then finding so much more that I had missed over the years. I should call this page the Oliver Squirrel Search (OSS). Good stuff. I'd love any feedback, I might be able to add in more options, or "check boxes" to filter more!? -

I had to take one of my pins off the ring, put it on the workbench, and I used WD-40 over and over again to work it into the pin, standing up on end (locking-balls) facing down, and worked the button until it would stay freed up. I kept flushing it until about 40 gallons of rust came out of the pin and I saw clear WD-40 flowing. I then used to dry lube and worked it into the pin, constantly pushing the button to work it through. That was 2 or 3 years ago and that stubborn button pin has been fine since. Might be one of those annual things-to-do to put on the list, that I don't have yet. LOL

-

Alcan Springs Quote for Jan-2026

Wayfinder replied to Wayfinder's topic in Mechanical & Technical Tips

I only have 1 day before I depart for the Eggs & S'Mores rally in FL. No time to install springs with the need to work today. oh well. The UPS guy, who was quite large, carried both 50 lb boxes of Alcan springs in a bear-hug style. I was impressed. I'm ready with some awesome new tools. -

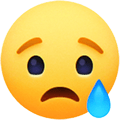

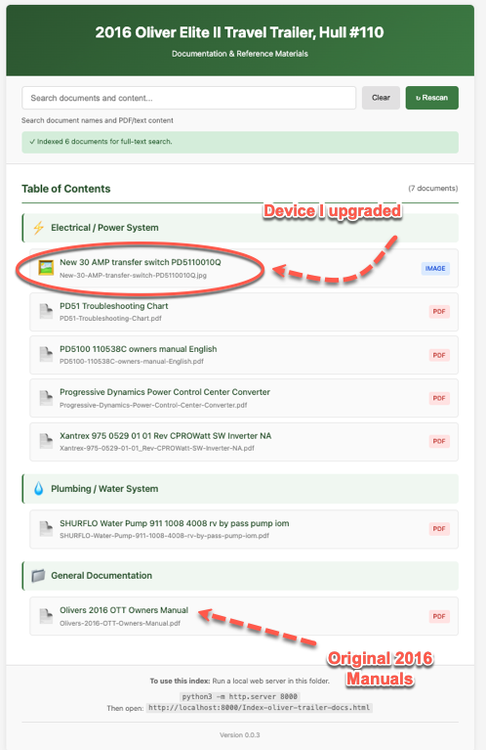

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

Let's see if I can upload the short video of my proof of concept. I've spent more time on this video than I did creating the indexer. LOL oliver-specific-document-index-tool-v005.mp4 -

Hide Interior Blemishes Using Decorative Emblems

Wayfinder replied to jd1923's topic in Mechanical & Technical Tips

Yeah, I do want a new A/C too. Darn it. -

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

No no, I'm good. I now have all the tools I need to make job easy, and, fingers crossed, no more than say.... three hours?! Will be my second set to install, and shocks are already in, saving a few minutes. Brake wires are good now. Sooooo, we'll see. Neuhaus might come down to help too. I told him I'll take him to my daughter's Italian restaurant. I sort of get a discount there. LOL -

Hide Interior Blemishes Using Decorative Emblems

Wayfinder replied to jd1923's topic in Mechanical & Technical Tips

I'll need to do research on that remote thermostat. Not sure how they "separate" between furnace and A/C. Lots of digging into things, learning more and more. -

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

@jd1923 when I'm near Arizona next, I'm taking you out for dinner. -

What is Towing "Level" and Does It Matter?

Wayfinder replied to Sam Heumann's topic in Towing an Oliver

I think we all missed the most important part about @Sam Heumann initial post.... He spelled Andersen correctly on the first post. He's okay in my book. LOL -

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

I'm thinking an iPad, with all the docs, doc-apps, Bluetooth apps to talk to everything in the new Campers, etc. You know, Batteries, Smartshut, Tire monitors, radio, Inverters, whateva. I would LOVE a remote for the Dometic thermostat, so I would not have to get out of bed in the morning to turn up the heat. Or at least wire it near the bed. LOL A Smart Oliver Pad (SOP) -

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

Those cups fell apart last year. LOL. A shame. -

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

Okay, I have to go to "yucky" work now. But this is what I have so far. Run's on my MacOS, and if someone is s Linux person, like me, it runs there too. Windows (windoze) is to come later if someone can convince me. LOL -

Convert Old Paper Manuals into Digital Format

Wayfinder replied to Wayfinder's topic in General Discussion

@Steve and MA this was very helpful. You'd think I had looked there before after all. these years. It's not perfect, for the 2016 as some equipment might have been different, AND much is certainly different now with newer components. I'm well into creating a program that will simply search a folder, maybe called Oliver-manuals/, and the web page will scan that and be ready to search in a few seconds. Pics to come. -

I'm considering converting my old paper manuals to digital format. I'm not looking forward to the task, but if done well enough, might be a useful task, as least for the next owner. One thing I just thought to do, was to find as many original manuals online first in good PDF format. Saving tons of time. I might be able to create a stand-alone we page that points to the individual manuals and include a search function. That would allow me to search through just my manuals for key words or phrases. I'll keep pondering this. Has any of the owners of older campers done this - digitize? My 2016 only has a nice leather ring binder of documents. I suspect new Ollies come with a copy in digital format, but not sure how well done it is - have any reviews? I've seen some nicely bound books of Ollie manuals too. Cheers,

-

I'm not sure how useful this would be to others. I got tired of typing into google site:https://olivertraveltrailers.com/forums/ "some search term". This little html file works fantastic, but I had my Claude.AI create a page I could keep on my local computer, maybe on the desktop, where I can simply type in my search term and all the results only come from the forums pages, but via Google Results. Try it out. It's a single HTML document. Download it and type in something you wish to search for in these forums. I use Claude AI for work and find it to be the best in coding. oliver-forum-search.html

-

I put my new Bulldog HD shocks on yesterday. I'm not sure if I had THE original Monroe shocks, but I suspect I did. All four were shot/dead. Quick vid I posted in my Brake saga post. https://olivertraveltrailers.com/forums/uploads/monthly_2026_01/Old-Oliver-shocks-verus-new-bulldogs.mp4.db543c0ab47c29eb24a5c9c0373392a5.mp4 When the sun comes up, I will confirm that I snugged up the nuts well enough on all the shocks. Pro Tip: I kept two nuts, four plates, and two rubber bushings.... just in case I, or someone else I run into, needs them on the road. 😉 Also, I will "attempt" to randomly check these annually, since we do not yet have too much life-data on these. I'm "shocked" that they are so much less expensive than all other replacements. But, they seem fine so far. Better than 10 year old Monroes. LOL

-

The Saga of corroded brake wires on older trailers

Wayfinder replied to Wayfinder's topic in Mechanical & Technical Tips

Well, it was a good day, I now have some new toys tools to help do all this type of work, and WoW, what a different they made. I finally got a creeper, a set of ratcheting wrenches, and an off-road hydraulic roller jack which reaches 29 inches in hight. It's nearly 21 inches to the Oliver frame from the pavement. Man, it was a breeze to do now. I think putting the wheels on the creeper took half the time of the entire project. LOL The ratcheting wrenches were SUPER handy for the new Bulldog shocks - I've wanted a set for years. My new high-end crimper made great crimps on the new brake wire now running along the rear axle. I have not gotten to the front axle yet, got rained out. My old shocks were all dead, which "someone" at Oliver said were "good" just two summers ago. All four shocks would not open on their own and had to be pulled apart and were much easier to push closed than the new Bulldogs. I'm now ready for next week's trip to Florida's Eggs & S'Mores Rally at the Suwannee Music ground in Live Oaks. Can't wait to see "the gang". We'll have at least 4 or 5 Ollies in our group, along with Casitas. My Alcan springs should arrive next week, but no time to put them on yet. I used heavy duty exterior zip ties to secure the double insulated, 12-gauge, 2-wire brake wire to the axle. The eTrailer part number from eTrailer is C46GJ. My new mini heat-gun with wire shield did the trick nicely on the shrink tube butt-connectors. I was also able to find the serial number to the rear axle for future replacement - thank goodness for the new creeper. IMPORTANT: I did find a bad area on the wire I pulled out of the axle, which appeared to have been "calked" over, or something odd like that. Also found a break in the wire insulation of the brake assembly itself - it's getting brittle. All brake assemblies will be replaced after Alcan spring installation, or best yet, just get the axles replaced with new brakes. Then, the entire under carriage should be good-to-go. Passenger-side voltage is now at 2.98v. Very nice. Here's a quick video of the new -vs- old shocks, a short race to the finish. Old-Oliver-shocks-verus-new-bulldogs.mp4 -

What is Towing "Level" and Does It Matter?

Wayfinder replied to Sam Heumann's topic in Towing an Oliver

Yeah, my 2016 #110 is also smaller to fit in the housing. No biggy to me. Except if I don't have room to put the bad tire. Hmmm. -

Alcan Springs Quote for Jan-2026

Wayfinder replied to Wayfinder's topic in Mechanical & Technical Tips

@Tideline77 I forgot. I ordered them from 4 STATE TRUCKS. https://www.4statetrucks.com/ -

Alcan Springs Quote for Jan-2026

Wayfinder replied to Wayfinder's topic in Mechanical & Technical Tips

@Tideline77 It's above, but here it is again with current pricing. (edited): Ordered from 4 STATE TRUCKS https://www.4statetrucks.com/ Item: 19-050000007: Bulldog HD Shock Absorber Replaces 555001 For Trailer Leaf Spring Retro Kit As of January 2026: Qty 4 = $154.40, shipping to GA just over $14. -

Alcan Springs Quote for Jan-2026

Wayfinder replied to Wayfinder's topic in Mechanical & Technical Tips

I just received my shocks, thanks @Galway Girl and I know @jd1923 has used these too I think I saw in another post. Can't wait to get started, but I have another rally in a week. LOL -

Alcan Springs Quote for Jan-2026

Wayfinder replied to Wayfinder's topic in Mechanical & Technical Tips

Alcan has already shipped the springs. Shipping was $175 via UPS. Final cost was $1291. I suspect that would be nearly the same cost having them installed by Alcan themselves. Give or take a few bucks. Can't wait to get started. I love the experience. This will be my second install of Alcans. It also keeps this "aging" body moving more. Too much desk work as a career in Information technology. 😜 PS: Lew did confirm that their shackles are NOT splined, but the wet bolts are. I'm not sure why they have decided this, but as we did Steve's camper, I will mark the bolt ends with a scratch, in order to know where the grease hole orientation is upon installation. It's the best we can do I think, in this situation. I explained that to Lew, and they don't seem to see an issue with splineless shackles. Just FYI.