GSMBear

Members-

Posts

30 -

Joined

-

Last visited

My Info

-

Gender or Couple

Male

-

Location

Great Smoky Mountains, TN

My RV or Travel Trailer

-

Do you own an Oliver Travel Trailer, other travel trailer or none?

I own a non-Oliver RV or Travel Trailer

-

What model is your other RV or Travel Trailer?

Airstream 23D

Recent Profile Visitors

7,623 profile views

GSMBear's Achievements

-

RecPro Houghton Interior Fan Mod v2.pdf

-

It's been a year since mine was out-of-the-box new and installed but it does sound familiar to the time when I did not have the compressor fan relay mod and relocated indoor temperature sensor in the equation. I just used mine this weekend (it's in an Airstream, not an Oliver) parked in full sun and low 90s for the highs. When set to auto, my fan will come on high for a short while and then taper down to low as it gets cooler inside. During the hot part of the day, it would run on low for quite a while (an hour?) which was fine with me. It's very quiet and it kept the inside temperature at a comfortable 74 degrees which was the set point. At night, I like it cooler. I would set it to 70 degrees and it would maintain that. On cycles during the night were frequent and short. I don't know what the interior humidity was because I've stopped measuring it as that problem seems to be solved. My application is different from yours, though. I do not have the timer mod installed in mine but I do have the fan relay mod. Moving the indoor temperature sensor was a pretty easy task with my RV but might be significantly more difficult in the Olivers and Casitas.

-

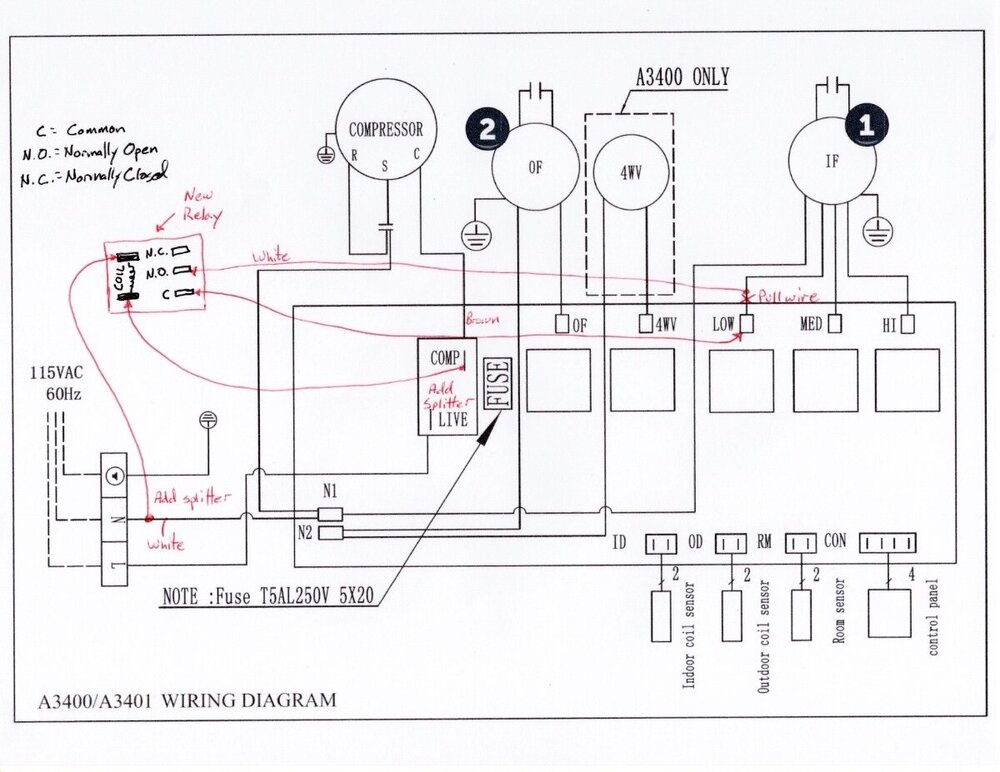

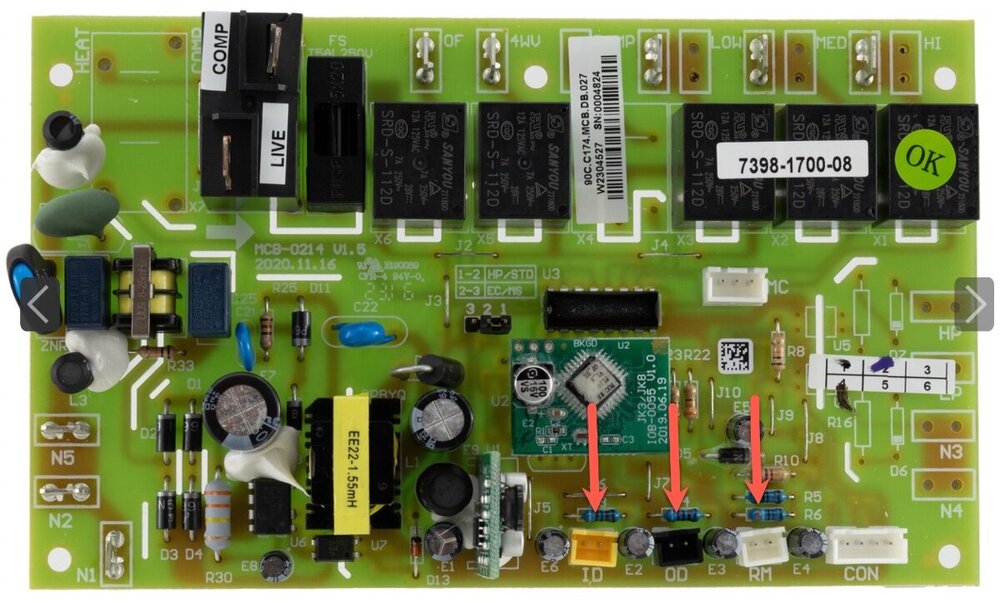

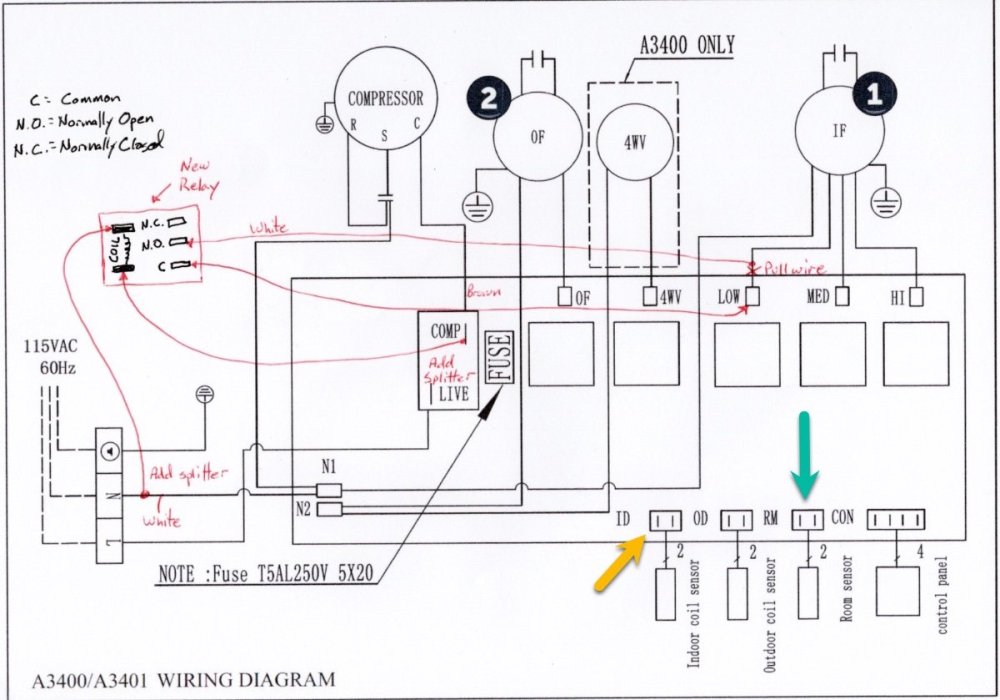

I apologize for unintentionally creating confusion. The schematic diagram posted above was meant to illustrate the ports for the coil sensors. It also has the conceptualized wiring plan for the new relay. The conceptualized plan was drawn prior to knowing what my wire color choices were going to be limited to based on my wire supply. Please ignore the wire color labels in that diagram. To be more precise about your question though. . . When you open the cover to this control box, you will see the thin white wire from the factory connected to the low fan speed blade. You want to remove it from that blade and reattach it to the COM blade on the new relay. Then, take a section of your own wire that you'll need to supply (about 10") and connect one end to the low fan speed blade and the other end to the Normally Open (NO) blade of the new relay. In the pictures from the v2 PDF document, both of these wires are white with the new wire that I had to supply being the thicker wire. Hope this helps and I apologize for creating the confusion.

-

The A3400 has separate sensors for the room temperature (the one I relocated), indoor coil, and outdoor coil. The room sensor is not used for detecting coil freeze-up. In my particular application, it was easy to disconnect the factory sensor from the main board and attach an auxiliary sensor with a much longer cable and route it to the location of the RV's original thermostat. This won't be the case in every application and I think your timer solution is a very valuable addition to the knowledge base with the non-desert applications of this otherwise fantastic AC unit. It's been in the upper 80's and low 90's in East Tennessee this week and I've been running the AC with a setting of 74 degrees. I keep the RV stored on my property where it is connected to power and internet. I've been monitoring the temperatures in the front and rear sections and it remains within less than a degree of the set point. My RV is 23' with no slides and was originally equipped with a 13.5K unit -- it is not an Oliver RV. EDIT: please ignore the wire color descriptions in the schematic below. The schematic is attached to show the connection points for the coil sensors.

-

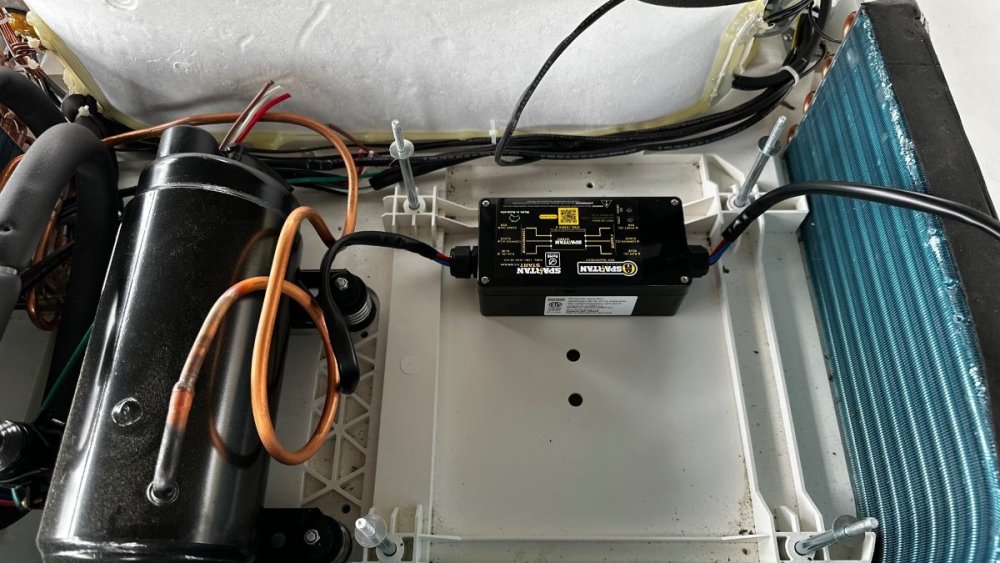

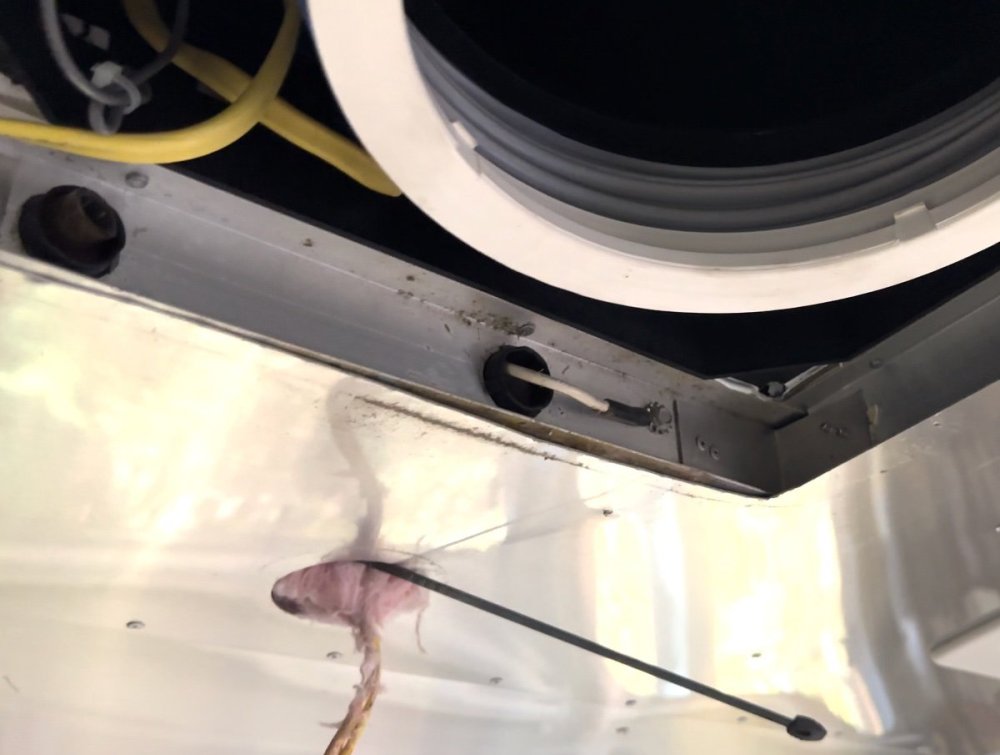

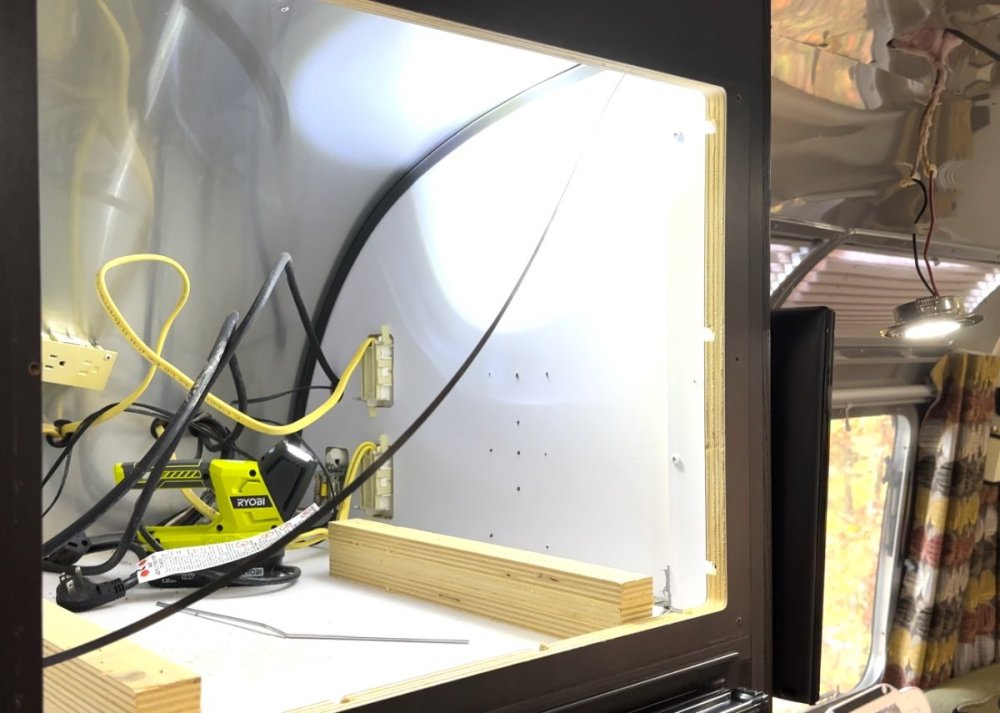

Yesterday, I installed a Spartan Power Soft Start in my RecPro/Houghton A3400 air conditioner. It's identical to the one RecPro sells and is $100 cheaper on Amazon at https://a.co/d/cvYZV39. The wiring method on this one is different from other popular models. I've done both now and this one is much simpler. I removed the fan and found a place mostly out of the way underneath it on a flat surface. All you have to do is use your finger to trace the wrapped set of wires coming out of the compressor to a point where you can cut them. There will be 3 wires: red, white, brown. After snipping the wires, the 3 that are still connected to the compressor get connected to the "compressor" side of the Soft Start. The 3 remaining wires on the other side of the snip location get wired to the "supply" side of the Soft Start. Red-to-Red, Blue-to-White, and Black-to-Brown. Button it up and let it run for 30 minutes with the temperature set close to the interior temp so that it will cycle on/off a few times. Then good to go! I had no trouble when mine cycled on while the microwave was running. The combination of these two puts me near my limit of 30 amps so it will depend on what else might be running. The refrigerator was off and if it had been running, that might have put me over the limit. It's a balancing act, for sure. The picture with my fingers shows the snipped wires that lead back to the compressor. The other end of the same snipped wires represent the "supply" side. The other picture shows the mounting location which is accessed by removing the 4 nuts that secure the large black fan. Clean the surface with some rubbing alcohol first then peel the double stick tape and press it down.

-

GSMBear started following FORD SUPER DUTY TRAILER MOUNTED CAMERA

-

FORD SUPER DUTY TRAILER MOUNTED CAMERA

GSMBear replied to Wandering Sagebrush's topic in General Discussion

I'm also interested in this. I believe there is something similar for the F150. And I'm wondering if a lower mounting location -- such as license plate level -- would still offer good multi-views on the dash display. -

I kind soul over on the AirForums has brought to my attention a discrepancy in the original PDF document I shared about the fan mod that I did on the RecPro/Houghton AC unit. Steps 5 & 6 are correct when viewing the pictures but the narrative I added was incorrect. I've updated the narrative and I will try to post the v2 document here. RecPro Houghton Interior Fan Mod v2.pdf

-

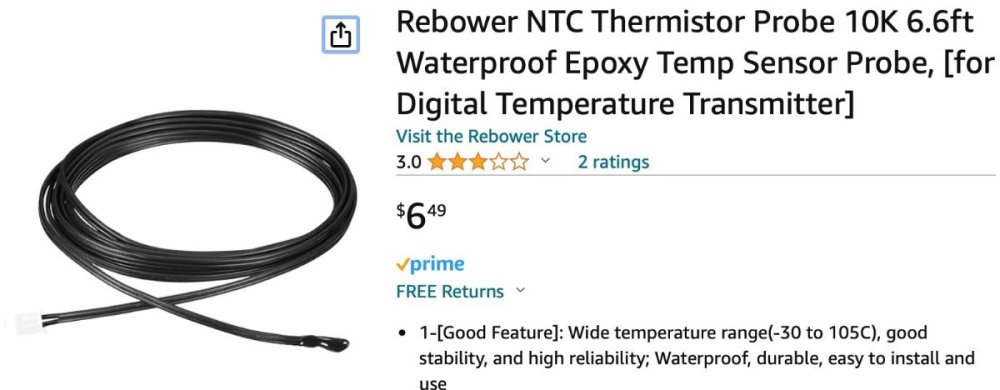

This is the one that I used: https://a.co/d/ceHt1sT. That's a suspicious looking link but I guess that's how Amazon creates them so that they're short. I followed the link and it does go to the correct place. Or search for this item in the picture.

-

I was browsing the RecPro website the other day and noticed a new addition to their Quiet AC lineup. They now have an AC/Heat pump model with a condensate pump for retrofit installations that have existing drain management to whisk away the condensation. Unfortunately for Oliver owners, the 15K size of the unit is probably too much for the space. It is also their higher profile unit which might not be appealing to some. Perhaps it will be an expanded offering someday in their low profile units.

-

Ah, I see. Very clever how the former wires were put to good use. But as a former co-worker used to say: "Your problem is very clear to me." Unfortunately, I'm coming up short on solutions. But tinkering and just sitting in the space and thoughtfully observing - and then repeating as necessary - is likely what lead me to find a solution that worked my situation. When you ask about intercepting the drain tube in the basement area, are you saying this would require cutting out a section of the fiberglass skin to (hopefully) find the tube located behind it? Akin to cutting away drywall to find a pipe or wire inside the wall? I can understand your concern about that, if so.

-

John -- having another thought. . . Your Houghton is a replacement to an original Dometic, right? Is there still an RJ-45 cable that runs from the air distribution box location to the location of your original thermostat? If so, might that wire be the ticket to relocating the thermistor? If I recall correctly, that's not exactly a phone wire. Can't recall where I read it but I think the gist of the message was that two of the wires have their positions swapped from one end to the other which makes it different from a phone wire. The wires are color coded so that should be enough to identify which ones (there are 4, I believe?) are being used to extend the thermistor. And I don't think the concept of polarity is involved -- meaning, I don't think it matters which wire gets connected to the two on the other end.

-

Great minds think alike? 🤔 What I did ended up being similar to this. The final location where I wanted the thermistor provided some good shielding from airflow. It's also at a more reasonable vertical level. My initial testing had the thermistor pretty close to the ceiling because that's as far as the original wire would reach and still get it around the corner of the cabinet. I took a big gasp and snipped the end of the thermistor wire about 8 inches from the tip. Then I added several feet of supplemental wire to extend the length so that it would reach where I wanted it to go. I tucked it behind the cover of the ugly mechanical thermostat that now controls the gas furnace. At first I had it poking out the other side so I wouldn't see it but that appeared to provide too much shielding. I switched it to the side you see in the picture and it seems to have the perfect balance. The short cycling stopped. I didn't time it but I'd say the on cycle was about 10 minutes and felt very comparable to the original Dometic unit. The off cycle was a little longer. Two wifi-enabled temperature sensors provided temperatures of 68.5 at the front by the panoramic windows (in the airflow path) and 70 directly on top of the mechanical thermostat where the sensor is (shielded). I probably had this kind of temperature difference with the original AC but I never measured it. It was too warm to test the heat but I'll get that done later. (If our theories are correct, those fins still would have had a lot of moisture on them.) Pictures below show the path the thermistor wire took: 1) from a factory wire access hole to a nearby ceiling puck light, then 2) across to the top of the interior of the microwave cabinet, then 3) down the side of a closet and under a shelf and through an existing wire access hole for closet lighting to 4) the ridiculously large and off-center hole from the Dometic CCC2 to 5) the final location! In the first picture you can see the snipped drain tube from the Dometic in the top left corner. In my Airstream, this runs directly down the side of the wall and it exits in the street-side wheel well. Would have been nice to integrate this somehow with the Houghton. I'm not sure how this is different in an Oliver RV so I've not commented on your question about this. I'm not understanding how this might provide a path for the wire but I'm sure it's because of my lack of familiarity with your setup.

-

Good News! I am happy to report that the auxiliary thermistor I bought from Amazon works as a replacement to the factory thermistor. These two things are critical to the success: locate the new thermistor away from the air distribution box and away from the airflow. For me, this will be around the corner of a cabinet and likely in the same location as the original Dometic CCC2 thermostat that controlled the original Dometic AC and gas furnace. I tried multiple experiments with the thermistor in the same area as the air distribution box with varying degrees of shielding from the airflow. But it just wasn’t good enough to suit me. This would have been the simpler solution and I wanted to rule it out before moving on to something more involved. I think there’s just too much air movement everywhere around the distribution box and it tricks the thermistor into thinking it’s a different temperature than it really is. The test that pleased me the most was when I stretched the cord out as long as it would go and I taped it in a location near where I hope to set it permanently. The cord isn’t long enough to get me there right now. But when taped to the wall around the corner from the airflow the AC set temperature of 70 was reached and three other temperature devices in the RV measured between 70 and 72 in different locations. The on/off cycles were fairly short which concerns me a little bit and I’m hoping this will improve when I have the thermistor in the final location which will be more shielded from airflow and at a more reasonable vertical location. In heat mode this morning, there was a greater difference between the set temperature of 66 and the actual temperature of 72. Cycles were short and I think if I had let it continue the interior temperature would have gone higher than 72. Perhaps this will also even out more once the thermistor is not as close to the ceiling. I’m less concerned about an accurate reading with heat than I am with AC. I use the RV more in the warmer seasons than I do in the cooler ones. Also, when I turned on the heat this morning, there was a great deal of humidity pumped into the living space. The windows fogged and the moisture on the interior aluminum skin (this is an Airstream instead of an Oliver) was visible. I was surprised to see this and I wondered if it was due to residual moisture still on the evaporator fins from the prior day’s AC testing. Overall, I’m pleased with the testing knowing that I can relocate the thermistor elsewhere and get reasonably good results. If I have to adjust the settings to reflect the differences between set temperatures and actual temperatures I’ll learn that over time and adjust. I feel like the two major wins in this obsession of mine are: 1) getting the additional relay installed to allow the interior fan to cycle with the compressor (solves humidity issue with AC), and 2) finding an easy path to get an auxiliary thermistor from the rooftop control board location to the interior sealed area without much effort. For those interested, this is the thermistor I am using right now. It has the two-pin connector on the end that fits the control board. https://a.co/d/dV31de2

-

Hi John -- that extra wire is the connector to the air distribution panel for the limited control functions offered there instead of from the remote. None of those pins (4, I believe?) involve the thermistor. That wiring clip appears unused in the picture because the air distribution panel has been removed to access the innards. When it's all assembled, there is a corresponding end for that wiring harness on the air distribution panel side. They get connected together upon assembly so that the display panel and controls will work. The "hot poker stick through the Styrofoam" approach wasn't hard and it allows the factory thermistor to remain in place as a backup. I'm going to test the auxiliary thermistor more on Saturday and report back here once that's done. Fingers crossed!

-

Ah, methinks you're onto something! Your remark about the heat pump not sensing that warmth is being produced made me look at the wiring diagram. I'm now pretty sure that I mistakenly unplugged the interior coil sensor instead of the room sensor. I know it was a yellow connector and the attached picture of the control board positions this one in the location of the interior coil sensor according to the schematic. This adds up! Without the interior coil sensor connected, the fan would continuously wait for the signal that the coils are warm enough to start blowing -- so the fan would never start! OK, so stupid mistake on my part but there's hope left. I will give it another try next weekend and report back.