Snackchaser

Member+-

Posts

215 -

Joined

-

Last visited

-

Days Won

11

Snackchaser last won the day on October 9 2025

Snackchaser had the most liked content!

My Info

-

Gender or Couple

Couple

My RV or Travel Trailer

-

Do you own an Oliver Travel Trailer, other travel trailer or none?

I own an Oliver Travel Trailer

-

Hull #

1027

-

Year

2022

-

Make

Oliver

-

Model

Legacy Elite II

-

Floor Plan

Standard Floor Plan

Recent Profile Visitors

1,625 profile views

Snackchaser's Achievements

-

Ron, You've had good advice to check the converter fuses. If that is not the issue, then iI's time to break out a voltage meter. 1) Disconnect shore power, and your battery tender, then check voltage at the battery (it's probably the 12.4 as you were seeing). 2) Reconnect shore power and check voltage at the same location, it should be higher which would indicate if your converter is converting and charging. If not, the converter is bad. Update: I looked at the converter manual link from above. The converter has 3 stages of output, each with a different voltage of 14.4, 13.6 and 13.2. One of those voltage values is what you should see when you test the battery on shore power. The manual also has a section that describes a simple test to absolutely confirm it's faulty before replacement. Be mindful that electrical problems are elusive and tricky, so the manual's test is important. As Jd suggested, the batteries are older and you could upgrade to lithiums. That would be a big improvement. However, unless there are pages missing from the manual, it looks like your converter is for lead acid batteries only. So if you upgrade batteries, also upgrade the converter. Fortunately, repair kits are available to replace the converter/charger section of the older PD units, and that also upgrades them to lithium chargers at the same time! Also, you would need to check/set your solar charger profile for lithium batteries. Looks like you're making good progress! Geoff

-

Okay, shore power looks good, but battery is dead! Sounds like you had been using outdoor solar to keep the batteries charged, then moved the trailer into the garage where there is no solar charging. If you didn't have shore power connected right away, then normal parasite power could have drained down the batteries and they just haven't had enough time to charge yet. A deeply discharged lead-acid battery looks almost like a short circuit to the charger initially. The battery voltage is so low that the converter/charger dumps maximum current into it trying to bring it up, which could cause brownouts both on the AC and DC power circuits. Deep discharge cycles and age can also degrade batteries, so they may not be charging, or they could be acting like a short. A faulty converter/charger can cause similar issues. It could have been weak or bad for a while, but un-noticed if you were solar charging. They can degrade and still work, but at a lower output. Where are you reading voltage? This could provide clues. To answer your question, yes a tender will charge both of your batteries at the same time. That would be a good next step.

-

Ron, 9 volts is critically low, you've got a dead or dying battery situation, and everything else is a symptom of that. Due to a lack of information, I'd guess your shore power is dead or faulty. This would result in battery not charging, and the TV (120vac or 12vdc) is not getting needed volts. Same thing with the 12 volt dc stereo, only it has different tolerance to low voltage and that's probably why either one or the other was working. If battery was dead, your lights and stereo should still work from the converter/charger that converts 120vac shore power 12vdc. More evidence of bad shore power. There could be other causes, but shore power is a likely culprit with the information provided so far. Geoff

-

Ron, From what you describe, this is a power issue, not an audio source issue. So you can rule out the HDMI ARC feature of many modern components that sends a signal to automatically switch the stereo to the active sound source. However, there is another HDMI feature on some higher end TV/Stereos that allows the TV to also turn on another component such as a stereo. If this is the case with your TV, then you might have a HDMI cable issue causing spurious signals. Try unplugging the HDMI cable to see if that resolves the problem. If it does, then try a new high quality HDMI cable with a Ferrite choke (little barrel looking thing that goes over the cable). This is a quick and easy check to eliminate one potential cause. If that doesn't work, then it could be something to do with the yellow Accessory trigger wire common on 12 volt stereos. I'd have to think on that one a bit more, so let us know what you find. Cheers, Geoff

-

If you like gadgetry, then the hardwired LevelMate PRO PLUS is highly recomended! Unfortunately, a lot of us bought the LevelMate PRO that is not hardwired, it's powered by a short lived button battery. No worries though, it can be hardwired with a simple DIY upgrade: Hardwire your LevelMate for under a buck Talking about gadgets and leveling, I heard a reliable rumor that some old fool built a completely unnecessary AUTOMATIC LEVELING SYSTEM for the Oliver's stabilizers! 🤫

-

Furrion Chill Cube – Product Review and Installation

Snackchaser replied to jd1923's topic in Ollie Modifications

Jd, have you looked into running wire for a DC unit? I'm fairly sure I could get a couple #4's into the attic space, although I v'e yet to actually confirm it. I've read comments that some people have been unable to fish wires down the wall. However, Iv'e done it a good number of times. The trick is to use a stiff fiberglass sectional rod made for this purpose (Ace or Amazon). They won't follow the curve and go off track like the flexible fish tapes. The gap on the corners is a little wider, one just has to make sure the rod tracks straight down, and add rod sections as you go. It might be harder to get the wire from the attic to the unit. Although it certainly wouldn't be hard to put a small hole through the attic ceiling/roof, then 3-d print a short/shallow wire channel/cover that could be caulked to the roof right up to the unit. But I'm curious to hear from someone like you who's had the unit out. Is there's enough gap between the ceiling and the roof where a couple #4 wires could be fished from the attic to the unit? Then there's the bigger question. Has anybody has done the research to know if there is any significant advantages to a 12 volt unit over a 120 volts? Happy new year's! Geoff -

Greenland Turbro 13.5k Inverter AC / Heatpump install.

Snackchaser replied to CRM's topic in Ollie Modifications

Jd, so sorry to hear the bad news, what a drag! I'm still biding my time waiting to see how this all plays out with the different brands. . . well actually, wifey put an end to my new AC dreams; "we don't need no #&@! AC around here, buy a bigger heater!" We did get one of those $79 dehumidifeirs though, I set it up with a Temp/Humidity gauge on top, then I saw your photo using the same gauge! Had to laugh🤣 -

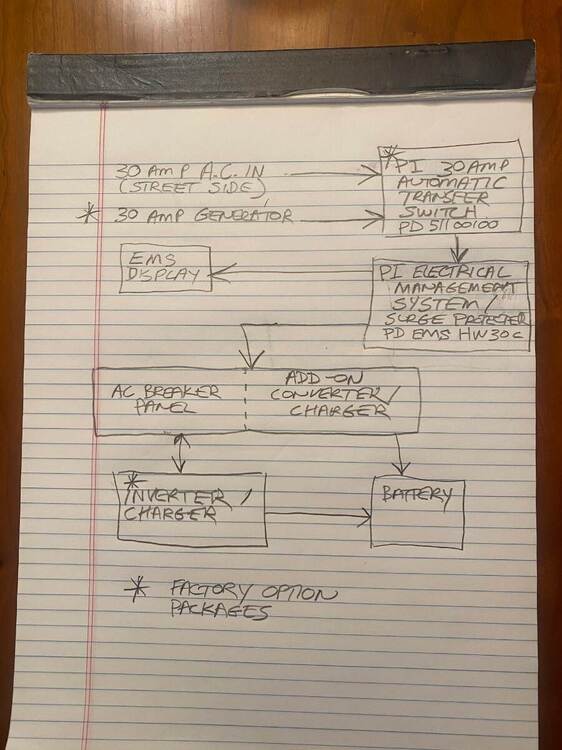

Wayfinder, you are correct, this thread got convoluted and confusing. You mentioned that you plan to upgrade your power converter/charger to handle lithium, and that you already have the Xantrex 2000 inverter. I have good news for you! I'm pretty sure all the Xantrex inverters already have a built in converter and charger. Your PD converter/charger is redundant. You don't need it and should probably take it out. A made a little sketch of how a lot of the Olivers are set up. This shows the configurations with and without the optional inverter, and the front generator receptacle with Automatic Transfer Switch. Different years may vary. Cheers! Geoff

-

The charging voltage profiles for lithiums are critical, and consequently most lithium chargers have very tight tolerances, typically within 0.1 volt. PD's are considered good, and their output has been reported to be from 14.4 up to 14.6 volts. There is also tolerance of whatever measurement device was used, a typical DIY multimeter has a tolerance of 0.5%. With this information, it looks like you are safely within the margin of error, and the battery company info. However, It wouldn't hurt to measure voltage with a known precise meter for peace of mind.

-

Stay away from the cheapies! We live on the coast in a very wet redwood rainforest and have tried several Peltier electronic type portable dehumidifiers from Amazon that were absolute garbage. We found that the Afloia Q3 Portable 20oz was the least worthless Peltier, but it's no longer available in Amazon. I wouldn't recommend any of the Peltier's anyway. They're rated in Ounces of water compared to compressor type dehumidifiers that are rated in Pints... it's a bit of a giveaway! The Peltiers are cheaper, smaller, and lighter, and most compressors are too large and heavy for the Oliver. But I've been eying the Ivation 14.7 pint compressor for under $200. The Ivation is the smallest compressor I've seen at 7x7x18 inches, 2 lbs. It has a drain hose so it doesn't have to be emptied all the time🙏 I'm thinking it will fit on the counter and drain into the sink. It's even advertised for RVs! Hope that helps! Cheers! Geoff.

-

JD is right, your numbers seem too low. This can be caused by several things. Most frequently it's low gas pressure in the burner caused by a restricted orfice jet clogged with debris. If fan runs without heat then could be the Sail Switch sticking. They can get corrosion on the pivot and need to be cleaned. If the gas sounds like it's pulsing, and you hear clicking, then it could be a failing Limit Switch. Then there is the flame sensor, looks like a thermocouple rod, they can get sooty from a poor flame. Take a look and listen while the furnace running; you should hear the gas roaring with a good steady burn. If it's weak or whistles then check the orfice. Flame should be steady and strong, not yellow. If it cycles about every minute-- with a burn then a click, then it's likely the limit switch. There are videos for all of this. I'd recommend shutting off the gas, opening the unit up from the outside, and just doing a thorough inspection and cleaning of things that you can easily access. Then you can try it again and see how it works. Stay warm and check out the Borrego Springs underground visitor center. I helped build it about a half a century ago. Cheers, Geoff

-

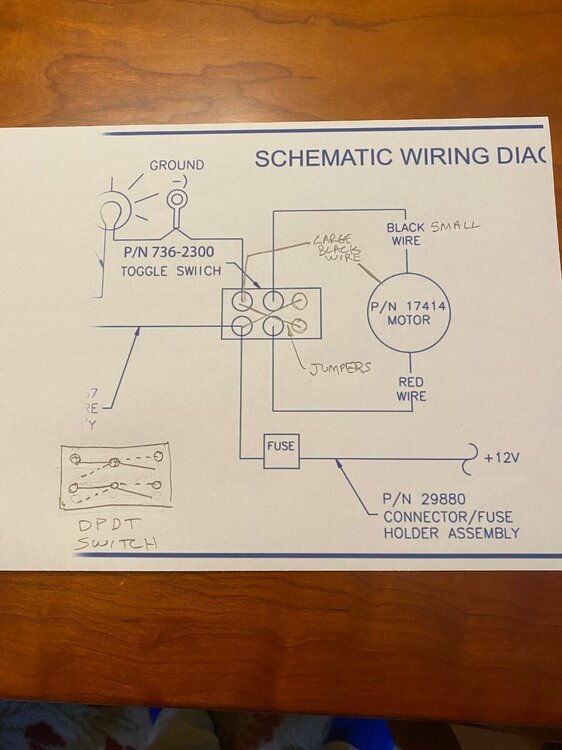

Hi Chris, I’m sorry to read about your jack issues on the road! I’m a little late to the party, but I can offer some switching information and a troubleshooting procedure. Or I could swing by your house if you still need help when you return. I read back on this thread and noticed that the question of why the motor has 3 wires was never answered. Per the Barker schematic, it looks like the jack motor should have only two wires, so the third wire creates confusion. The smaller gauge black (-) and red (+) wires are the motor leads, the larger black wire is a second ground to ensure good grounding of the motor. The toggle switch is wired to reverse the polarity of the motors leads, which reverses the motor for up-down travel. I’ve never actually looked at the jack’s toggle switches, but a reasonable guess is that they are DPDT (Double Pole, Double Throw) switches with a spring-back neutral (off) center position. They would have external jumpers that are’t seen in the Barker schematic. I filled-in the “likely” missing detail in the Barker schematic and included a sketch of the internal switching of a DPDT switch, the center row of terminals are common. Your rear jack doesn't include the head unit with the light, but the toggle switch should be the same. The fuse will be on the + feed wire, and the - ground terminates on the main ground bus with all the yellow wires. Oliver choose yellow for ground wires, but I don’t know if that holds true on older models too. Test across the two center (common) terminals with a multimeter in the dc volts setting. Use pointed probes being carful not to short across the switch terminals. You will need a second person to operate the switch: With the switch in center off position - 0 volts With switch down - around 12 volts With the switch up - around 12 volts (FYI - the polarity will be reversed). This will tell you if the switch is working, and if there is voltage to the switch. If the switch works, then the trouble is in the wiring between the switch and motor, or the motor itself. If there is no voltage on steps 2 or 3, then recheck the fuse and /or the wiring between the fuse and power source, or look for an open ground wire. Hope this helps ! Cheers! Geoff

-

Sure! Each laptop is working independently so it only comes down to the internet "Bandwidth," which simply means how much data can be transmitted over time. Typical Starlink connections are very fast, usually greater than 100 Mega bites per second (Mbps) so you can easily stream video on more than one device at a time. That's why trailer park internet can be so slow; the more users means less available bandwidth.

-

Run 12v System w/out Batteries in Oliver 1

Snackchaser replied to GeoffChapman's topic in Mechanical & Technical Tips

With all other loads turned off (as to not overload the Jackery) just hook your Jackery neg to the ground buss with all the yellow wires, and the Jackery positive to the big red wire input of your 12 volt fuse panel . Your pump will then operate as normal. Otherwise you will have to cut the wire splice at the pump to feed it. -

Thanks! But I might have some involvement with it being there😉