-

Posts

434 -

Joined

-

Last visited

-

Days Won

18

Everything posted by mountainoliver

-

A weight distribution hitch and helper springs are two totally different things. The Andersen Hitch has two features built in. One is weight distribution, which shifts some of the rear axle weight towards the front axle. This by default also lifts the tow vehicle rear some. The second feature is an anti sway function. There is a friction cone system that dampens out sway. Helper springs or air bags and such only lift/level the vehicle rear. They don’t remove any weight from the rear axle. If you are over the rear axle or tire weight rating, that issue will remain with using helper springs/air bags. Remember, the weight on the rear axle includes EVERYTHING being hauled in the tow vehicle AND the trailer tongue weight on the hitch. It is better to over estimate this than to under estimate. The lightest your camper will ever be is when it just leaves the factory.

-

Interesting, my trailer is a 2017 hull number 208 and has two unusual patched holes between the two axles as well. I believe that one of my holding tanks had to be replaced due to one or both of these holes going through it. Interesting.

-

Having the truck/trailer level is ideal but, make sure that you’re not close to the rear axle weight rating or the tire max weight rating. Make sure that when you calculate/measure the vehicle loads that you include everything and it doesn’t hurt to over estimate the load. John Davies has a great description of estimating your weights and adding a percentage over for safety. That can be found in some of the other towing discussions. A weight distribution hitch not only just levels the truck/trailer but actually does the leveling by moving some of the rear axle load to the front axle. Leveling with helper springs does nothing about an overloaded rear axle.

-

I have three of the SensorPush sensors. We have the two twin beds so I have one under each bed. One just below the water pump down low next to the fresh water tank. The other sensor under the other bed just below the outside shower assembly. The third one hangs on one of the propane hoses under the front cowling. This appears to provide accurate information. The graph ability records trends and stores the information for I think 21 days if my phone is too far away to connect.

-

I have a fridge/freezer thermometer set like yours in my fridge and love how it works. However, I purchased a second set to keep tabs on the areas under the beds. They all worked great for a few days then all of the readings went weird. I found out that they were cross talking at random because of their close proximity to each other. I kept the ones in the fridge but purchased a sensor brand called SensorPush for under the beds and outside under the propane cover. The sensors are only about an inch and a quarter square by five eights thick. The batteries last for about a year and information is read by my smartphone by way of Bluetooth. They record both temperature and humidity and the information is in graph form along a time line with dates.

-

Inverter GFCI pops for no apparent reason

mountainoliver replied to geokeg's topic in Mechanical & Technical Tips

You said that you used a space heater this winter. Check inside of the metal junction box that’s close to the inverter. It’s a standard household 4in square galvanized box. Mine and a few others have had a similar problem as you. Mine turned out to be a bunch of loose connections inside this box. One of the wires and it’s wire nut completely melted into. Luckily in mine nothing touched the box. There are solid house type wires connected to stranded wire with wire nuts. It’s difficult to get a solid connection with solid and stranded wire together in a wire nut. Don’t just check the wire nuts for tightness but remove each nut and check that all of the wires are actually in the nut. There could be a short inside this box so make sure that ALL power is off before even touching the metal box as a hot wire may be against the box. This may not be your specific problem but it’s an easy thing to check. -

So what's the story on the Anderson WDH

mountainoliver replied to Trainman's topic in Towing an Oliver

Trainman, check out the good used Andersen hitches in the classifieds. -

Ok, new noticed thing. All propane appliances have been working great the last couple days with one tank about half full and one less than half full according to the Mopeka tank gauges. Yesterday I had both tanks filled and last night the fridge failed (shut off) three times. This morning the water heater shut down and restarted twice. I have had very intermittent water heater issues as well for a long time but way more seldom than the fridge so have not tied the two together. Furnace issues like this would be extremely difficult to detect because once the furnace is warm the air output would stay warm for a while. The furnace could fail and restart a couple of times without being noticed. The fan noise would cover the sound of the failure/restart cycle and there are no indicator lights to notify me of any failures. Any thoughts? Probably time to replace both propane tanks to rule out this issue?

-

Thanks, you are exactly correct! Oliver, and maybe rightfully so, is extremely resistant to throwing parts at it until it works. That said, Oliver has been more than gracious in allowing me to do just that but in a conservative manner. They have “eaten” certain costs that are in no way their responsibility and that I inten to try to pay back just to be fair about the whole thing. Jason has bent over backwards to help and has stayed after hours doing research as I’m traveling. Due to the extremely random nature of the problem the replace and wait and see approach will take months and I can’t use the camper in the process. If I change one parameter the current test becomes very questionable. This type of open discussion has really helped me in this issue. While in Quartzsite Steve (scubarx) and Lee both helped me in at least two days (we about drove each other crazy) of testing and allowed me to use their working campers as test subjects.

-

It never goes into a retry mode. It will be running and either when it gets to temperature and normally shuts off the check light comes on or as it is running it just shuts down and the check light comes on. It never tries to restart. The only time I have witnessed as retry is when in testing I have closed the little manual valve located on the gas manifold just below the solenoid. When I close that valve, the flame goes out and the refrigerator tries to restart and if I reopen the valve the refrigerator will restart and run. Also, Lee if you are following this, didn’t we witness a failure while checking the propane pressure? Didn’t we see no reduction in pressure at the moment of failure? Basically the fridge just shuts off and the check light comes on. Thanks again for the questions!

-

Thanks, our three way fridges don’t have a thermocouple. The flame sensing is accomplished through the igniter electrode and fed to the spark coil. Apparently a very low voltage is created in the electrode as it reaches incandescence. Electromagic, I don’t understand all I know about this setup. I have purchased propane from many different sources in different states as we travel. For example, while in Quartzsite, I buy my propane from the same vendor as everyone else. The most recent regulator is from Camping World and is different from the factory supplied part. In testing propane pressure/flow, the regulator was able to maintain around 11 inches water as different appliances turned on and off. We checked another Oliver that had all of the propane appliances working ok and it only had a pressure of 8.5 or so inches water! All specifications say that 11 is the target number. When the “check” light comes on nothing else happens. The fridge never tries to restart it just sits there. When I turn the power off then back on it always starts and runs fine. It will run for a few minutes or a few days, or anything in between. Completely random. Thanks everyone for the sanity check questions. They are causing me (and should) to rethink everything I’ve looked at so far. Keep asking! Thanks!

-

Completely new fridge. First real boondocking use in our new camper was at Quartzsite last year. I guess that is where I first noticed the problem. With the issue coming and going it’s been difficult to pinpoint. Issue became more noticeable the end of last year while traveling in southwest Texas. This year on the way to Quartzsite I stopped in Hohenwald to have Oliver look at the fridge. Two weeks later I had a completely new fridge. Finally got back on the road and sure enough still had the same problem. Thus all of the trailer input tests, propane and power. Inputs to the fridge all look good. Interestingly, through all of this I have been able to obtain a Dinosaur control board which works with propane but unfortunately does not communicate with the eyebrow board, so the fridge will not work on either AC or DC and I can’t easily control the temperature setting. The Dometic boards work great on AC and DC but have intermittent issues with propane.

-

Sorry, as questions are coming in I realize that I have forgotten a little detail. I’ve been through this thing for so long old details seem to blur. On the eyebrow, when the fridge “quits” or “fails” all lights go out except the “check” light. At this point the fridge just sets in limbo until I turn the fridge off then back on. I have actually seen it fail and immediately turned the fridge off then back on. It always will turn back on and run great. Sometimes for several days or just a few minutes or anything in between! It has failed while we were taking a propane pressure test at the fridge solenoid test port and saw no pressure fluctuations. Thanks for the input!

-

Brand new refrigerator. It will run on occasion for days at a time. Original refrigerator had the same problem. Oliver folks tested the original fridge with Dometic directing all of the testing. After a week Dometic said that they couldn’t figure out why it wouldn’t run so they sent a new one. Totally does not make sense. Thanks for any and all suggestions and questions.

-

Electrical fault, dinette A/C receptacle

mountainoliver replied to Rleog's topic in General Discussion

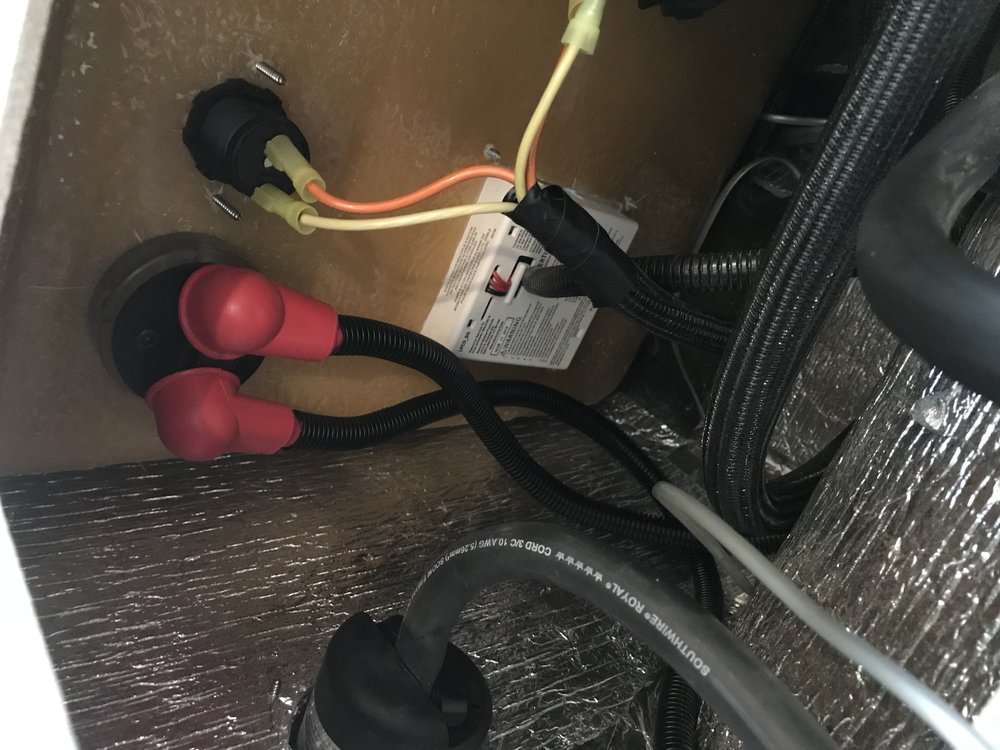

Definitely check the junction box under the driver’s side bed. It is just aft of the inverter and below the inverter/shore power switchover relay box. I had a similar problem a couple months ago with the wire nuts in the junction box being loose and one melting completely. Not saying that this is the problem but is a known issue and being that it’s difficult to connect solid wire and stranded wire with a wire nut and achieve a guaranteed connection, it’s a good place to check. -

Anyone experiencing issues with their RM2454 failing intermittently on propane? When running on propane mine may run for several days or just a half hour or anything in between. This is a new fridge and failing very intermittently same as the original fridge. The fridge runs flawlessly on both 110 volts AC and 12 volts DC. I have checked propane pressure at 11.1 or 11.2 or so with nothing running, checking at the rear main manifold quick disconnect. With fridge, water heater, furnace all running, pressure ranges from 10.6 to 10.9, tested either at the rear main manifold quick disconnect or at the fridge test port. These pressures are in the good range. I have run two number 12awg 12volt supply wires directly to the batteries (through the 20A fuse) both positive and negative. Thus the fridge is not being fed through any of the factory wiring. This has been tested both connected to shore power and not, with and without 110 breaker off. I have run the fridge on both propane tanks both one at a time and both on and switching the changeover valve. The original regulator was changed out by Oliver a year ago and I changed it again during our current trip. The rubber hose under the propane tank cowling that forms a sort of “p” trap has been flushed out with solvent to remove any possible oil blockage. Both the main and eyebrow circuit boards have been exchanged with known working/bench tested boards. And as said before this is a new (now three week old) refrigerator. Thanks for any suggestions or questions! I’m at a total loss as to why two different refrigerators built close to two years apart have the same problem with running on propane!

-

Took a photo of the information cast into the back of my hull number 208 LEII wheels. 110 psi is listed as a maximum. I run 60 psi in all four tires. I could be wrong but, I would think that it is harder on the bearings/tires when making a tight turn with really low inflation pressures.

-

Who hates those @#$&*! chip sealed highways?

mountainoliver replied to John E Davies's topic in Towing an Oliver

I ran into this type of mess last year in Michigan. Never had seen it before so was unaware of the absolute mess it causes until it was too late. Took most of a day to clean it off of my truck and trailer. I 100% agree with John, from now on I’ll go miles out my way to avoid it! -

Sorry, I meant that the disconnect switch is only for the jacks. I just used the term that is used on the packaging for the switch. The manufacturer calls it a master disconnect switch because it is typically used for race cars and boats etc to completely disconnect the batteries from the vehicle. I choose this because they are cheap, can handle high amp loads, readily available, and reliable because their construction is so simple. I may have misunderstood the original question. Also, the amp draw through the switch is only what one jack motor would draw. I only operate one jack at a time. I feel that the 300 amp capacity master switch will more than handle one jack at a time or even all three at once. I also forgot to mention that the red key is removable so unauthorized use is difficult to say the least. I always “disconnect “ the jacks when camping or any time the camper is unattended to prevent the jacks from “accidentally” being moved. Wink

-

First trip since Dec 12, 2018 Delivery

mountainoliver replied to dbp05ret's topic in General Discussion

The first picture is the refrigerator defrost drain. -

Spike, I guess you will need to answer that. Check your “ready to camp” tongue weight. If it is greater than what Toyota recommends then you’ll need a weight distribution hitch. Tongue weight should be tested with the camper on a level surface with the camper level as well, otherwise the axle springs will affect the reading. That is they will make the reading look greater or less than it really is. Ready to camp weight needs to include everything like water, food, clothing, everything. You can also weigh your ready to camp rig. I use the CAT scales. The truck front wheels go on one platform, truck rear wheels go on another platform and the trailer wheels go on the third platform. All these added up gives gross weight, that is truck and contents (including passengers), and camper and camper contents. This is all still really confusing to me but I think this will give all the information needed. This will tell you how much weight is on your trucks front and rear axles. To get true camper gross weight you’ll need to unhitch and let the camper free stand on one of the scale platforms. Any other input is appreciated. Hope this is of some help.

-

Spike, I’m guessing that your tongue weight is over what Toyota allows by not using a weight distribution hitch. I don’t remember, but I think it was 500lbs. (but could have been lower). My 2017 Tundra used passenger car tires as well so I know that I was also close to their limits. I think that it was someone on these forums who wisely said that if you’re close to a limit in one or two areas, that you’re probably over limit in another area. I have found that to be mostly true.