Snackchaser

Member+-

Posts

210 -

Joined

-

Last visited

-

Days Won

11

Everything posted by Snackchaser

-

Rear Electric Stabilizer Jack adjustment - help?

Snackchaser replied to tallmandan's topic in Mechanical & Technical Tips

I totally agree that the mounting bracket was probably welded in the wrong position, and I’m sure that they will somehow make it right for you. But I also think this could be fixed with a drill and angle grinder without disturbing the weld. The jack needs to be lowered about 1” to match the other jack, and probably less than that to clear the lid. On my trailer, it looks like there is enough room to achieve that. There is plenty of space to drill new holes in the 3-1/2” x 2” angle iron to lower the jack by up to 1”. However, there is limited room to lower the jack before the welded bracket hits the floor. It looks like the jack could be immediately lowered about 1/4 to 3/8 without any interference, but then it’s hindered by a fiberglass fillet where it transitions from the frame rail to the floor. This could be enough to gain the clearance you need, but you'll need more drop than that so the proposed new holes don’t overlap with the existing holes. Or fab a new piece of angle iron, I'm sure you could source it locally. You could probably gain another 1/8” or more drop by re-positioning the angle iron and (outside) aluminum bracket to clear the obstructing fillet. The mounting holes of both brackets are elongated, and the hole though the fiberglass is oversized, to allow for truing the jack angle. These brackets are held by the long bolts that go through the frame and you can loosen them just enough to tap the brackets over to help clear the obstructing fillet. If still more drop is needed, to avoid overlap of the new holes, then you can slightly trim the bottom edge of the welded bracket with an angle grinder to make up the remaining distance. Before drilling the new holes in the angle iron, I’d experiment lowering the jack to assure you can get adequate drop and hole separation. This shouldn’t impact the structural integrity and it I personally wouldn’t hesitate doing it. I'd ask Oliver to reimburse me for fair value of a new jack. Sorry for the crappy drawing, but hopefully it helps clarify my suggestion. Cheers, Geoff -

DC fuse for the Rear Camera Switch/Circuit

Snackchaser replied to EurekaJ's topic in Mechanical & Technical Tips

Eurekaj, To use the camera switch for your TPMS Signal Booster, you will have to tap into the "switched" camera power circuit, not the fuse. Check out the modification titled "Turning on the rear camera automatically." It has instructions and pictures for tapping into the camera circuit inside the attic, which is easier than running a wire to the camera switch. It also shows how to connect directly to the Electronics fuse if you decide against the switch and just run a hot wire. https://olivertraveltrailers.com/forums/topic/10461-turning-on-the-rear-camera-automatically/ Cheers! Geoff -

I was also looking to extend that hose, but couldn’t find a hose to fit it. Instead I lengthened the existing hose by sliding the weight down and adding a spring to prevent kinking. I got about an extra foot. This was described in a post titled something like “ Better toilet rinsing “ I also extended the shower hose by adding a second section. Those fittings are common to most showers and hoses are readily available. That post is titled something like “Washing dishes outdoors.” Sorry if those titles are not exact, but it should be close enough for the search engine. Good luck! Geoff

-

Yes it's the correct fitting, except that it's a low pressure fitting that has to be modified. It has "coarse" threads that will not fit into the stove's "fine" threaded high pressure propane inlet. So you need to buy the (linked) Regulator/Green Bottle Holder to scavenge the fine threaded part that threads into the stove. That fine threaded part will replace the coarse threaded part on the 90 degree fitting. The (linked) video demonstrates how to do it. Be sure to also buy the (linked) adjustable regulator (with hose) that will fit any standard size propane tank, including the 5 pound tank. You can adjust the regulator to around 10 LBs pressure, or whatever provides a nice flame, you can also dial it down for a fire pit if wanted. There's been miss-information in this thread, so for the benefit of those who don't know, the Oliver's quick disconnect propane outlets are fed by the main low pressure regulator on the propane tanks. This works for most BBQs, grills and fire pits. Some of these appliances, such as BBQs, come with their own regulator which will have to be removed to use it with the already regulated Oliver gas outlets. However, most cook stoves work on high pressure and they use different thread sizes to prevent mix-ups. The typical regulator/green bottle holder is usually stamped "10" to denote that it's 10 PSI. Cheers, Geoff

-

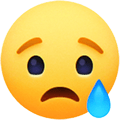

Hello from another HAM. I have used the existing "Furrion brand" Cable TV inlet ports, and added a third one, for an RJ45 pass through and for a 12 volt outlet. They can probably be drilled out to fit your SO239 connectors. This is detailed in my posts "Don’t cut your Starlink Cable! There’s a better way to install Starlink…" and "Starlink Mini, breaking the 12 volt barrier" There is a wide spot between the trailer walls on the street side attic next to the AC drain tube that you can fish wire into the attic. My other posts describe this too! Cheers Geoff

-

I hear you brother, we also searched in vain for a decent stove that would work off the low 2-3 LB pressure trailer gas connections. No luck, so we decided to stick with our favorite Everest stove from Camp Chef that uses the more common 10 LBs pressure. It's a really popular stove that can blast BTU's or be turned way down to a slow simmer. We converted our stove to use a 5 LB propane tank instead of the annoying 1 LB green gas bottles. You can probably do the same modification to other stoves that use the common 10 LB regulator/green bottle system. To be able to use a larger propane tank, you need an adaptor to fit a long hose to the 10 lb pressure regulator/green bottle support. . . but that’s kind of janky. There is a YouTube video that shows how to easily eliminate the awkward green bottle regulator, and convert the stove to a quick connect hose that’s way more convenient and better looking. We bought a quality padded case for our 5 LB propane tank that it makes it easy to carry and stow. We also got a 5’ hose with adjustable regulator and parts for a quick disconnect. We saved the stoves original regulator/green gas bottle holder as a backup, and bought a second one that can be taken apart to get the propitiatory stove connector piece that's needed for the quick disconnect as shown in the video. In all honestly, we now prefer having a portable stove instead of being tethered to the trailers low pressure gas connections as we originally wanted. We often put the stove on a picnic table or bring it to group cookouts. Since the Oliver's awning can't be used in the rain, we carry a canopy that can go over picnic tables so we can now cook and eat outside when its raining, which is does an awful lot around these parts. If anyone wants to go this route, Iv’e linked the stove and padded tank, with all the parts needed to convert it to quick disconnect. Cheers, Geoff https://a.co/d/4wh0e5k https://a.co/d/66t3la0 https://a.co/d/0U67u5X https://a.co/d/6zcM88m https://a.co/d/7VNUJ9d https://a.co/d/7VNUJ9d https://a.co/d/fSQMj0G https://youtu.be/QI3TZYfKDEU?si=pH_B9Z9l3SnksOdR

-

JT, I'm not sure which connector you have, or how you're installing it, so forgive me if I state the obvious. I think you might be trying to put the nut on the inside wall of the trailer, that would probably be too thick. The nut goes on the back of the Furrion cable TV port after it's drilled out to fit the Rj45 panel mount. It's assembled on the bench, then installed on the trailer with the 4 mounting screws. The hole through the Oliver might need to be enlarged a little, this is best done with a step drill bit. I sure hope this helps you out!

-

Dc to Dc charger Victron Orion 12 I 12 - 30

Snackchaser replied to johnwen's topic in General Discussion

No. My 30 amp Orion only powers up, and shows in the App, when it's connected to the truck. That’s the proper operation per the manual and it's a good thing otherwise it would be another tiny parasite draw when not in use. I don’t know about the 50 amp. Its ability to be used as a power supply, or that it's non-isolated could have something to do with it. Or if you have it connected through VE Direct it would probably show up on the App. -

Inexpensive Helpful Modifications

Snackchaser replied to Wandering Sagebrush's topic in Ollie Modifications

John, I'm fairly sure that I found the following Moen part number in an old forum post. I bought them on Amazon, but they were a bit larger and the mounting holes were different (vertical verses horizontal.) My wife actually liked them better, so I relocated one of the original hooks so that the size difference is not noticeable. I looks factory🤙 https://a.co/d/fdl5a9h -

I guess technically speaking, it’s correct that Gree does not have a built-in SoftStart, but that might not be the whole story. The Gree website says: “Proprietary compressor technology eliminates the need for an add on "Soft Start.” This seems to be a new industry direction. Good discussion! I’ve been slowly building an AC spread sheet over the last few months and trying to capture information. Sound levels are not usually specified so Its good to hear actual comparisons in an Oliver. I think your probably right about 45dB being too low, some vendor claims are dubious:

-

I received a reply from Greenland this morning and I'm still on the fence with its viability, despite its other excellent attributes. Customer service has been very responsive though: "Turbo Customer Service Thank you for your patience and continued interest in our products. The ambient temperature needs to be lower than 109 degrees is designed to protect the compressor's longevity. Regarding the low-temperature threshold, the design of this product does not include electric auxiliary heating so it does not heat when the ambient temperature is below 20°F."

-

Hi Derek, Good question, I'm also curious what folks think about the Greenland Turbo Inverter. It could be my top choice except that it’s only rated to operate in temperature ranges from 19.4℉ to 109.4℉. I asked the manufacture if that related to the inside or outside temperature, and they said both. I reached out to them again for more perspective because temperatures over 109℉ are common, and that’s when the AC is most needed. I’m hoping to hear some better explanations next week because that could be a non-starter. Another potentially controversial issue is that the Greenland is designed to slowly ramp the compressor up-and-down - continuously. The starting/running current looks like a smooth sine-wave, unlike conventional compressors that turn on with a large inrush starting current and then a steady run current. The Greenland runs continuously when in use, cycling the compressor from high-to-low to maintain temperature. The conventional AC compressor constantly turns on-off when in use. Our Penguin sometimes does that every 30 seconds. I was skeptical of the Greenland at first, but after more thought I think it’s a good design because it doesn't have frequent starts and stops, and there is less temperature fluctuation. They supposedly have lower energy consumption, and are very quiet at 45db. They come with a remote control thermostat where I’d prefer a wired one to replace the existing one. Another interesting AC is the Eco Cool by Gree. It’s also a heat pump with a built-in SoftStart. The manufacture claims its the quietest. I like that it has “intelligent” dehumidification, a 3-speed fan, and both remote and wired thermostat. The Houghton and Dreiha Atmos are on the table too, they are getting good reviews! From what I understand, the Truma is unavailable for DIY. Cheers! Geoff

-

Yea after miles of dirt road the dust gets everywhere. We missed cleaning under the caps but I'm not concerned about it. To get the ethernet cable from the attic to the outdoor garage, you will need to remove the attic's street side wall panel, it's held in by two hex head screws. Also remove two screws to partially pull back the garage side panel. From both locations, you will see the clear poly drain tube for the air conditioner. The gap is wider here, and I was able to snake a fish rod along the side of the tube straight down to the garage without restriction or obstruction from the insulation. A cheap Amazon sectional fish-rod works well here. Always pull an extra string with the cable because it gets harder to get the rod through with each wire added, and you may want to add wires later for my "Turning On The Rear Camera Automatically" modification😁 https://a.co/d/fl9XvxS

-

Yea this stuff could drive anyone nuts! Forgive me that Iv’e showed this before, but it still might help you save $$. I looked at the SmartPort way back when, and was appalled at the price. Also it would stick out like a sore thumb on the Oliver. You can buy another matching Furrion outlet for $9 and a RJ45 panel mount (two) for $16. Just have to drill the Furrion hole bigger and the RJ45 panel mount will fit right in. It’s a double female, so any Cat 6 RJ45 patch cord will work on the inside, just fish it up the wall into the attic. There is a clear path next to the AC drain tube. Gosh, that photo looks like it's mounted crooked🫢 A female 5.5 mm barrel connector will screw into the Furrion without any drilling if you want to go that route. You can even make your own Starlink Mini power cord from cable, at least #16, and run the Mini without boosting the voltage. https://a.co/d/6ZfCA1Q https://a.co/d/5YNGSrP https://a.co/d/9p1RQpP https://a.co/d/hszApCd

-

There are battery isolators for charging, but I've never seen one that would work for your purpose of using both sources at the same time to power your Mini. You would be essentially wiring the batteries in parallel, and it's also a no-no to mix lithium and lead acid. I'm sure you could rig up a diode affair, but that's not very realistic. I'd keep them separate with a "On - Off - On" toggle switch to feed the Mini from one source or the other . . . or off! The common terminal goes to the Mini, the others to the starter battery and tow harness trailer battery respectively. Ground to the chassis. You can get toggle switches up to 30 amps. A relay will work too, but overkill in this case. Just fuse it properly. 🤙

-

My typical problem with the Mini is "partial" obstructed view, where the connection continuity is impacted when the satellites pass over the blind spots. It depends how big the obstruction is, whether it can be buffered-out without disruption or too much speed loss. I have a Dishy pole mount on the front and rear of the trailer for that reason, and sometimes only that much movement can make a big difference in an obstructed area (See my "Tacky Starlink Dishy Mast" post). Often the obstruction is on the low horizon and a long mast is the ticket. That's another advantage with the lightweight Mini because my heavy Gen-3 Dishy is too wobbly on a long pole. The Starlink App has an interesting feature that maps the sky and shows obstructions. I think it works even without having a Starlink connection if you want to play around with it. It might help you answer the question how well the Mini would work laying flat. Correct, I think mobil cords are around 15-20 feet long compared to the standard 50" cord, so there is no need to boost the voltage. Cheers, Geoff

-

JD, I devised my Victron Starlink Mini power supply because there were no other options available at that time. Now that there are other options available, I’d still prefer the Victron for my setup with the standard 50’ Mini cord. It’s a quality power supply, and I haven’t felt the need for a different router yet. The PoE injector has benefits too. It’s a good option if you want have the Mini more than 50’ away and/or use a separate router for a stronger WiFi signal. The Mini’s built-in router’s WiFi signal can weaken the further away it gets. This hasn't been a problem for me so far, the problem is always obstructed view on the upper horizon from trees and hills. In your setup, with the Pepwave router and Mini mounted permanently on your truck, then you don’t need the Victron or PoE injector. You can simply power the Mini with a shorter 12 volt mobil cord (Amazon). The Mini's connection to the Pepwave can either be a short Rj45 cable or the Pepwave WiFi interface. If you ever want the flexibility to move the Mini away from the truck for clear sky view, then I’d consider either the Victron or PoE injector. It really depends on how you want to connect to the Pepwave. Remember, if your in that situation where you need to move the Mini away from the truck, then you don’t have to connect it to the Pepwave every time. . . or it will still connect through WiFi. . . or carry a longer Ethernet cord and run it parallel with the Mini power cord. You have options. Cheers! Geoff

-

Since you asked; I needed to have a ground pass-through jumper for the "optional" automatic switching using a digital "ground open" trigger😁 Otherwise the jumper isn't needed. And you're right, the jumper un-isolates the Victron but it's a non-issue for this application. Cheers, Geoff

-

JD, unfortunately it’s true that the DC to DC charger does not pass current in the opposite direction to back-feed the truck, otherwise the trailer battery would try to equalize with the truck battery and it could act like a charger in reverse. This is also why the DC to DC charger uses an engine-on sensor to turn it on, otherwise the truck battery would try to equalize with the trailer battery when the engine is off. If you want to use your DC to DC charger cables to run your Mini/Pepwave from the trailer battery, then you would need a relay to go-around the charger on the trailer side, and another (50 amp relay) to isolate the battery on the truck side. Then you would need switches for both with an interlock for safety. It’s rather complicated and expensive, not to mention relay parasite current. A better idea is to use the +12vDC wire from the 7-pin tow harness. It should be spared already on the trailer side, and you would have to isolate it on the truck side to use it as a trailer power feed for the Mini/Pepwave. I used that same wire to automatically turn on the rear camera. Otherwise, I’d recommend adding a separate #12 or 14 circuit in parallel with the DC to DC charger cables. Hope that helps, Geoff

-

I was conservatively using the 300 horsepower rating of our Tesla verses the Honda generator at 2.5 hp. It's actually way less than 1% because the Cyber truck is rated 600 to 800 hp. They say that regenerative braking re-captures about 20% charge, and that's already factored into the range estimates. Our Tesla has never registered an increase of charge even on the longest downhill grades. It sure registers discharge going up them through. 🫢 I see this technology working well for long haulers where they can stop for hours at charging stations. But I think there is still a ways to go before it's practical for campers.

-

The milage increase would be insignificant. The Honda is less than 1% of the horsepower of a Tesla and Energy conservation law states “energy cannot be created or destroyed, but can only be transformed from one form to another.” As Tesla owners, we love the performance and safety aspects of it, and it's defiantly energy efficient. However, I’d never consider one for travel trailer tow vehicle because of the range and charging challenges. I’ll stick with the 2500 RAM.

-

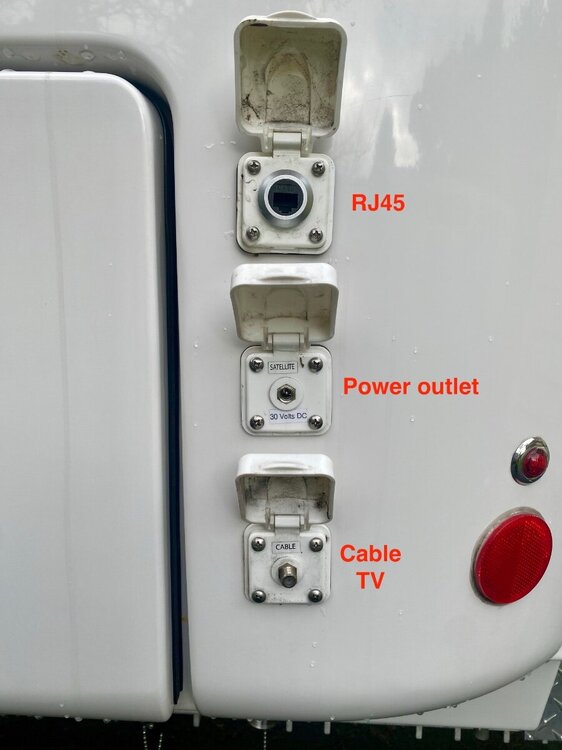

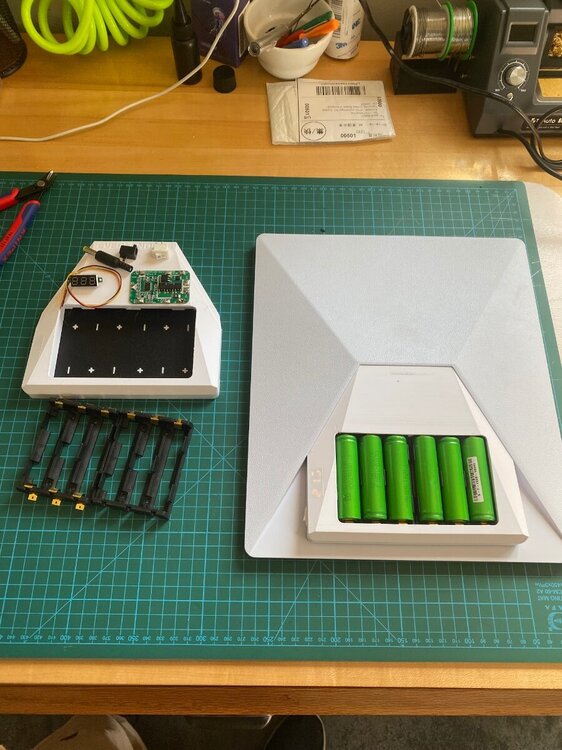

Thanks for your kind words @GaRambler, I hope to get to a rally and meet other Oli owners too!! You folks with the Starlink Mini may also be interested in this compact, self-contained Starlink power supply. It gives the Mini extra portability so you can take it to the campsite of an internet-needy friend, or hiking, or a remote picnic. It uses six common 18650 rechargeable batteries that will power the Mini for several hours. This DIY “StarSled Go” was cleverly designed by @Everlanders using a 3D-printed case and electronic components from AliExpress. It has a power switch, voltage meter, and built-in BMS/equalizing charger. The case can be printed for a couple of dollars’ worth of filament, and parts are so ridiculously cheap that I built extras for fun and gifts. Message me if you’re interested in one. Cheers, Geoff

-

SeeLevel sensors integrated with Victron system

Snackchaser replied to rideadeuce's topic in Ollie Modifications

That would be a "Single Pole Double Throw" (SPDT) switch. I buy my switches from DigiKey company, PN CH876-ND. If you message me privately, I can send you an extra one I have.