Search the Community

Showing results for 'Generator box'.

-

The following was copied from a former post and provided herein to better consolidate progressive modifications to the Savana in regards to the opening statement: “Ultimately, two storage boxes were acquired to safely stow much of the cargo; specifically, underbody tool boxes.” Cargo Securement Assurance/General Discussion Posted December 14, 2024 When towing with a truck, the majority of ‘stuff’ brought along on a camping trip or road adventure is conveniently stowed within the various holds of the Oliver and bed of the TV. However, even though my former crew cab Silverado 1500 had a storage box under the rear seat, it was mostly used to accommodate service tools and supplies for the truck and thus, found myself utilizing the rear floorboards and seat as additional cargo space when traveling. There’s peace of mind knowing cargo carried in the bed of a truck is adequately secured, not so much for that behind the front seats! All one needs is something going on from behind when something tragic is happening up front, no bueno! We’re required to wear seatbelts for good reason, proper securement of vehicle interior cargo should be of equal importance. I would be interested in learning how owners with trucks/SUVs safely carry their cargo within. My awareness of cargo securement was heightened recently with acquisition of a converted cargo work van as my TV; specifics are detailed in a forum post last October under ‘Towing an Oliver’ and titled ‘2019 GMC Savana 2500 Cargo Van’, if interested. Unlike service utility work vans that generally have a partition or cargo net, along with containment shelves and boxes, to secure cargo and ensure personal safety; conversion and passenger vans are more designed for ‘people’ cargo. In the aforementioned forum post, I addressed cargo containment, but cargo securement was still under consideration. Here is what I did to address the subject matter: Maiden voyage to Texas Oliver Rally, Inks Lake SP; cargo contained, but not secured! DC CARGO E-Track system components were obtained via online purchases from Tractor Supply. Each of the Buyers Products boxes were fitted with six of these brackets, three at the top of each end. A 1/4” x 8” aluminum backing plate was used to attach and strengthen these mounts. Backing plate cut to size, holes drilled and tapped for mounting bolts. Containment boxes prepped for backing plate and E-Track bracket installation. Super Sliders affixed to bottom of containment boxes for ease of handling on interior carpet. Three E-Tract rails fastened to deck to accommodate securement straps. Aluminum plate at floor level is runway for folded e-bikes. This box was slid rearward once back box was removed for storage at COW Barn. It primarily contains items typically kept in the TV with additional storage space, as needed, a trunk per se. Ratchet straps best used for non-towing vehicle use. Box securement once e-bikes are deployed. Wider Cam straps best used for e-bikes and subsequent box securement when traveling. Rear box is for camping ‘stuff’, forward as a trunk and more ‘stuff’. Driver’s side box securement using ratchet straps. View of e-bikes ready for ‘takeoff’ on runway! Cam strap securing e-bike. Ratchet straps for spare propane tank, generator and other needs. Items too long for the containment boxes are stowed behind at side panel. Oliver-mounted hoist used to transfer box at storage facility. TV moved forward to enable box positioning. Cam straps used for the lift. Containment box lowered onto platform cart. Liking the modular containment storage.

-

We also have a Honda EU2200 in the bed of our F-150. When we need the generator, I remove it from the truck. It sets on the ground outside of our trailer or truck for "Just in Case" bad things that happen. Having it run in your TV or Tongue Box has several problems. One is that up front you have no line of sight to see a fire. At least if you put the generator on the ground and to the street side, if it cooks off, you have a chance of seeing the fire ball directly. Now I have never heard of a Honda generator "Self-Immolating"..... but if ours does, we will not be exiting the trailer about 4 feet from the fire. With it on the street side we at least could have an opportunity to see the fire ball and exit the trailer on the curb side. I would then grab the cord and disconnect it from the generator. Then use our awning crank as a hook to move the burning generator away from our Ollie. Or it could just sit in a box in the box at the front of Ollie and maybe the auto fire extinguishing system will overcome the leaking gasoline fire. Or if you run it in the TV bed, and it has a "problem", you would have a great excuse to buy a new TV. But then, what are the odds? Maybe something to really think about I suspect. 🙂 Safety John

-

We like the looks of the SeaBiscuit strange box. Yeah, a little pricey, but tempting. First major trip out - I lugged the Honda 2200eu (I think) along with us in the truck bed. Never used it once. I was thinking of the SeaBiscuit locking box for the generator - but figured it probably wouldn’t be worth the investment based on that non-usage. Our OEM Oliver storage basket is only used for picking up firewood when entering a CG, bag of garbage heading to the dump station, or staging my blocks, chocks, Andersen WD wrench, and San-T-flush hose. I never traveled with anything in it. Though I know it will likely reap howls of disapproval, I had been thinking that a locking SeaBiscuit box here would be a great place to have a -running- generator. Properly modified with large vents and fan for cooling and combustion air AND a suitable system for moving exhaust away from the trailer. Yeah, that’s the part that will make the hair stand up on the back of your head. That said, every generator-equipped motor home I’ve ever seen just routes the exhaust to the edge of the vehicle. Wonder if there’s any history of CO deaths for those guys. (Like I said guys - I’m not doing this - just brainstorming!) Of course, best practice is keep your running generator FAR from your RV. Unfortunately, the Honda generators seem to have “Steal Me!” stenciled on the side, so unless I’m sitting outside watching it - I’d never even be using it.

-

When towing with a truck, the majority of ‘stuff’ brought along on a camping trip or road adventure is conveniently stowed within the various holds of the Oliver and bed of the TV. However, even though my former crew cab Silverado 1500 had a storage box under the rear seat, it was mostly used to accommodate service tools and supplies for the truck and thus, found myself utilizing the rear floorboards and seat as additional cargo space when traveling. There’s peace of mind knowing cargo carried in the bed of a truck is adequately secured, not so much for that behind the front seats! All one needs is something going on from behind when something tragic is happening up front, no bueno! We’re required to wear seatbelts for good reason, proper securement of vehicle interior cargo should be of equal importance. I would be interested in learning how owners with trucks/SUVs safely carry their cargo within. My awareness of cargo securement was heightened recently with acquisition of a converted cargo work van as my TV; specifics are detailed in a forum post last October under ‘Towing an Oliver’ and titled ‘2019 GMC Savana 2500 Cargo Van’, if interested. Unlike service utility work vans that generally have a partition or cargo net, along with containment shelves and boxes, to secure cargo and ensure personal safety; conversion and passenger vans are more designed for ‘people’ cargo. In the aforementioned forum post, I addressed cargo containment, but cargo securement was still under consideration. Here is what I did to address the subject matter: Maiden voyage to Texas Oliver Rally, Inks Lake SP; cargo contained, but not secured! DC CARGO E-Track system components were obtained via online purchases from Tractor Supply. Each of the Buyers Products boxes were fitted with six of these brackets, three at the top of each end. A 1/4” x 8” aluminum backing plate was used to attach and strengthen these mounts. Backing plate cut to size, holes drilled and tapped for mounting bolts. Containment boxes prepped for backing plate and E-Track bracket installation. Super Sliders affixed to bottom of containment boxes for ease of handling on interior carpet. Three E-Tract rails fastened to deck to accommodate securement straps. Aluminum plate at floor level is runway for folded e-bikes. This box was slid rearward once back box was removed for storage at COW Barn. It primarily contains items typically kept in the TV with additional storage space, as needed, a trunk per se. Ratchet straps best used for non-towing vehicle use. Box securement once e-bikes are deployed. Wider Cam straps best used for e-bikes and subsequent box securement when traveling. Rear box is for camping ‘stuff’, forward as a truck and more ‘stuff’. Driver’s side box securement using ratchet straps. View of e-bikes ready for ‘takeoff’ on runway! Cam strap securing e-bike. Ratchet straps for spare propane tank, generator and other needs. Items too long for the containment boxes are stowed behind at side panel. Oliver-mounted hoist used to transfer box at storage facility. TV moved forward to enable box positioning. Cam straps used for the lift. Containment box lowered onto platform cart. Liking the modular containment storage.

-

Hey Jim, My input- We are one of the first owners of many to install the SB cargo box. We absolutely love the amount of room it has, and it suits our set up gear with quick access perfectly. I use to secure our generator in the OEM Cargo box. After our 6000 mile trip out west last year and never using the generator, we reevaluated keeping the generator on the tongue and decided to just carry our Honda 3200i in the bed of our TV. The room in the SB cargo box allows me to keep all my immediate set up gear ready to deploy - 30 amp cord, chocks, Andersen blocks and levelers, 4 rubber chocks with lots of room for other miscellaneous items. Before the SB box install I was storing these items in the bed of our TV in an Action Packer box. The SB cargo box has made life easier just keeping everything right where I can get to it quickly vs unloading gear out of the bed. This box has continued to serve us very well even right now as we are out west again. We have not had any issues with water getting into the interior of the cargo box and we have been through some heavy rains on past trips. We always try and support USA made 🇺🇸 products and I think you will find David and Kristine Hess the owners of SeaBiscuit some of the finest people you will ever meet. David and his team take pride in what they craft and produce. I would also suggest you consider the moose rack he makes (pic below the hitch). It will keep your safety chains or cables stowed and off the ground. For what it’s worth, that is my input all the way from Cody, Wyoming now slowly headed home the long way round to North Carolina. 🇺🇸 Cheers and Happy Trails! Patriot🇺🇸

- 1 reply

-

- 4

-

-

First, I would say it would be easy to get help from friends at the rally for replacing batteries. A full inverter mod, the custom work of mounting the very LARGE Victron Multiplus II, stripping our all Xantrex parts (ATS and junction box) and related wiring changes may be a lot to accomplish at a campsite! I ran in and out of my garage/workshop 100 times while doing mine for tools and 4-5 trips to Depot or Lowes for hardware over a two-week period of time. If you study the mod threads, plan really well in purchasing parts, get very ready, have a lot of patience (new friends too), maybe, good luck! 🤣 You want the 12V inverter and do not need the UL-certified model (required by code for home installations only). I went with Inverter Supply for these parts for free shipping and no sales tax (see picture). You NEED the VE.bus to configure the Victron for charger/battery spec settings. There are two models (I purchased the USB-C model and there is also USB, depends on the laptop you would use to setup). You need an Ethernet cable also to connect the VE.bus to the Victron MP2. There are YouTube videos showing the configuration steps. You also posted pictures showing the Progressive Industries ATS (Automatic Transfer Switch) and the display which shows the readout of shore power stats. The ATS switches between the two shore power sources (side outlet and front outlet usually for generator in front basket). This will not change but the power coming out of the ATS, connecting to the 120VAC breaker panel has to be replaced with new 10-3 AWG cables to go to the inverter and back to the breaker panel (buy 15 ft to be safe, I used about 12 ft, it runs from streetside bed basement where our new inverter was installed up to the breaker panel under the rear dinette). The Victron MP2 has dual terminal bolts on both + and - sides. I ran the 4/0 battery cables, from batteries directly to the Victron MP2, removed from the 2KW Xantrex (I had the same older model) and all secondary 6 AWG cables that OTT had on the batteries, I also bolted to the Victron bus vs. out to the batteries. If you get this all done at the rally, that will be a great story! Take pictures and post...

-

@Just Joe There are many available options out there for front storage boxes. In 2023, we did an epic 42 day loop out west and had our Honda 3200i mounted in the front basket. We never used the generator. During the trip, we quickly learned that storing a gen in the basket was not best use of this valuable storage space for our travel needs. The first thing we always found ourselves needing were chocks, blocks, 30 amp cord, LP grill hose, extension cord, and just all things go to gear. This meant opening the tailgate and unloading this gear out of a storage box in the bed of our TV. After returning home and doing a little research, I opted to order and install a front storage box from SeaBiscuit in Johnson City, Tenn. We actually went to their shop and picked it up as we do not live that far away from JC, Tenn. David and Kristine Hess, owners of SeaBiscuit, are some of the nicest people we have ever met. The quality and craftsmanship of their USA 🇺🇸 made products are excellent in our experience. On this year’s 47 day trip out west, the SB cavernous water tight storage box was a great decision for us and has served us well. It sure was nice to have quick access to set up gear instead of opening our tailgate and pulling out our gear at each base camp. We now store/carry our rarely used 3200i gen locked down in our TV bed. Everyone’s budget, storage and travel needs are different. This storage box works for us and is how we roll. If you decide to attend the 2025 Oliver Rally at Lake Guntersville State Park in Ala, David & Kristine Hess and their staff will likely be attending with products to display. Hope to see you there! Welcome to the forum! Patriot🇺🇸

-

That said.... I like your mounting concept. But in an adverse situation the short height will foster spilling contents out of the storage basket. This is a major reason that the OTT box and all the options above have height enough to ensure stuff in the basket stay in the basket. If you were to:: Match the size and shape of the Oliver Box foot print, this would mitigate the Basket/TV interference damage issue somewhat. Ditch the hanging fuel containers outside the basket. Reduce the fuel load and mount a fuel container inside the frame of your basket. Would require vertical tang. Ditch the blue straps and get some STRONG ones. These plastic strap ends will fail under impact. The larger picture below seems to indicate that the blue straps are run up and to the flanks of the generator handle. IF this is the case, a better solution would be to "X" them on the front and back big sides of the generator, running them through the handle. I would also increase the bottom width distance to help reduce movement port/starboard directional movement. Or add another strong strap port/starboard also passing through the generator handle. Combined the above would significantly mitigate the situation. GJ

-

Maybe a political protest? Though NO mechanical device is completely foolproof and inherently safe, I’d tend to trust Honda before some of the Harbor Freight fly-by-night brands out there. I had a no-name discount store open-frame generator for a season. It kept my freezers going during a week-long power outage, but I wouldn’t trust it as far as I could throw it. I suppose if one were gonna design and install a ventilation/cooling system in an enclosed box on the front of the Ollie, they may as well go whole-hawg and design a system that monitors CO, temperature, etc and shuts down the gen and triggers the fire suppression system if parameters were exceeded. I wonder if folks in motor homes with built-in Onan or Generac generators running -inside- the body of their RVs give it so much thought….

-

@Blain, Champion Power Equipment offer a number of dual fuel models, including a 3400 watt model, which can produce a maximum of 25.5 starting amps and 23.3 running amps when running on propane. The downside of this larger capacity generator is a weight slightly over 95 pounds. In contract my 2500 watt generator (Model 200961) approximately 40 pounds. Check the specs of these generators to ensure they will fit into the front storage box. You should also check the allowable tongue weight of your tow vehicle to ensure a heavy generator does present too much weight. How did you determine you need a generator capable of producing 30amps? I suggest this is overkill for an LEI. Do you really want to carry gasoline in your tow vehicle? As @dewdev pointed out, our LEII does not have the Truma AC unit. From what I have read on the OTT forum, I expect Oliver will confirm the Truma AC unit has lower power requirements than the Dometic Penguin. I suggest you add details of your tow vehicle and LEl below your signature, which will help other owners to make appropriate recommendations. Don

-

Alternative Front Storage Basket

Shawna and Scott replied to Just Joe's topic in Ollie Modifications

I don't have a generator box, just a rubber maid container to put my chocks and stuff in that goes into the front tray/box Oliver provided. I was just putting an option out for others who visit this thread as I mentioned I know several who have the products from Sea Biscuit. Everyone's needs and budgets are different. -

Sea Biscuit Rear Basket and Storage Boxes

Steve and MA replied to Steve and MA's topic in Ollie Modifications

We've been very pleased with the basket and boxes. Now that we've had them for almost 6 months we can give more feedback. First, many have asked about their weight limit. As @Patriot mentions, this is a question better answered by Oliver. Sea Biscuit doesn't provide a weight limit, but the basket and boxes are very robust. Oliver has a 150 lb limit on their optional bumper receiver. Our unladen receiver weighs 26 lb, so we're looking at a maximum of about 176 lb hanging on the rear bumper. The Oliver receiver could probably handle more weight, but you also have to consider front/rear weight balance. Our Sea Biscuit basket and empty boxes combined weigh 74 lb. If we observe the Oliver weight limit, we can carry 102 lb maximum in the boxes. We only carry about 30 lb of bulky/dirty items in the boxes: chocks and blocks in one rear box and a (very) small grill in the other. We also have the Oliver front basket, sometimes loaded with 70-80 lb of gear (e.g. generator and fuel) which helps offset the weight on the rear. Access to the dump hoses stored in the bumper is a minor inconvenience, but less so if you keep the hoses attached. Since we have the Nature's Head, we only have to deal with gray water. If we had a black tank, then we wouldn't want to troubleshoot a leaky hose or connection while the basket is attached. That brings us to another access issue. The basket must be pulled out about 4-5 inches to remove the spare tire cover. This isn't a big issue though. We can just pull the pins holding the basket on the bumper and slide it back a little without removing it from the mounts. No tools required. Fortunately, we haven't had to use the spare, but the basket won't be a problem if we do. Besides the convenient storage, especially the easy access to the chocks and blocks, an unexpected big benefit is that the boxes are at countertop height when parked on level ground. We always have an outdoor table set up. The boxes are also strong enough for a 225 lb person to stand on, making it easy to visually check things on the roof. Steve- 11 replies

-

- 10

-

-

Generator box - Has anyone made their own and if so any suggestions? It is my intent to put this box where the storage box from Oliver goes. I want the generator completely enclosed with a cover that opens. It will have vents for air to come through and exhaust to get out. Our generator runs on gas or propane.

-

Enclosed Aluminum Box Front Mount

mountainoliver replied to Tim and Christie's topic in Ollie Modifications

I purchased a generator box from the KSH folks while we were in Lake Havasu this past winter. I particularly wanted a box for my Honda 2000 generator. For the past five years I’ve kept the generator in the Oliver basket (the older expanded aluminum version which weighed 35 pounds empty) and covered with truckers tarp material. This has worked great but the tarp has aged and would have had to be replaced in another year or so. The stock KHS box has three openings covered with removable aluminum plates so that the generator can be used inside the box. This setup is not at all water resistant and I’m not interested in using the generator so close to my trailer. I ended up getting them to make a box without the three cutouts. The box came with two hold down brackets welded in place which I removed because they were exactly in my way where I needed to mount the box. I was able to use the existing holes in the fiberglass cowling and the original stainless u bolts. The back part of the box is mounted to a 1/4 inch thick by 6 inch wide aluminum plate. The front is mounted to a 1/8 wall 1 inch by 3 inch rectangle aluminum tube. This allows the box to be level. I made two 1/4 inch aluminum spacers for the u bolts to clamp against for inside of the box. The u bolts can also be used to strap down the generator inside the box. I made two 3/8 thick by 1 1/2 inch wide brackets for under the frame. As you can see in the photos, the front bracket was made so that I can hang the safety chains on it as well. -

There are so many great projects on these forums that I felt obligated to document mine (partly so that others can avoid my mis-steps!). We dry camp the majority of the time. During the winter (until the snow flies) that is not a problem, but summer time on the Eastern side of Washington State can be uncomfortably hot. When we bought the Ollie we knew that the solar system would take care of most of our needs, but that we really wanted a generator capable of running the A/C. We specified the optional soft start add-on for the A/C so that the trailer would be ready. A bit of research showed that the new Honda 2200 would run the A/C, even if it was running on propane. We chose “Hutch Mountain” as the best propane conversion for the Honda 2200. After 10 years of putting generators into and out of the truck I knew that some kind of generator carrier attached to the trailer was a must-have. We chose “Generator Box” as they have one sized perfectly for the Honda 2200. I asked Hutch Mountain if they would do their magic by installing all needed gear inside a Generator Box. They said they would be glad to do so. I had “Generator Box” directly ship the box to Hutch mountain. They did an install and then shipped to us. Perfect !! I did the install of the Hutch Mountain conversion kit into our new generator. BTW Honda service centers get very twitchy about propane conversions. There was/is a recall of a circuit board in the 2200. My local shop will do the recall, but will not even start the generator afterwards. I may have to school them about modifications NOT invalidating an entire warrantee. In my case the engine is now out of warrantee, but the generator section is still fully covered (federal law on this subject is well established). We bought the storage box on our Ollie. I wanted to save as much space in the box as I could for lightweight things, so I designed a frame to support the Generator Box. I initially intended to have the box dropped down into the storage unit by about and inch and a half. That was a bad idea as the latching assembly which secures the box to the mounting plate will not operate with more than about 3/8” of drop below the edge of the storage box. I used aluminum flat stock and 70 durometer Sorbothane to raise the box and give a little vibration dampening. Parts list, purchased or modified by me: Honda 2200 Companion generator to get the 30 amp locking connector 5 feet of aluminum 2” C-channel, ¼” wall thickness 5 feet of aluminum 1½” angle 10 1” SS ¼” x 20 screws with NyLock and two flat washers each 6 1½” SS ¼” x 20 screws with NyLock and two flat washers each 30 1” SS 10x32 screws with Nylock and 2 flat washers each I made a 69” section of Marinco 10 ga power cord Hutch Mountain made a 69” connection hose to hook-up the front end trailer propane supply to the Generator Box quick disconnect. Pictures follow… Any questions, please ask! Bill and Dorothy

-

There I go again, quoting myself! 🤣 By chance I found the individual electrical runs for the 110v outlets and microwave. This may not be true in newer hulls, but on ours there is one breaker for both. Good news is the run to the microwave is separate and can be wired to a separate breaker, given one available in the panel. Since I will soon eliminate the PD converter/charger I could use its breaker or install a thin double in its place. I already wired the panel in this way but need the PD converter while I have no batteries in ours, working on the new inverter/charger installation. I removed the Xantrex 2KW inverter yesterday. Ours is inverter only, no charger and it also has the Xantrex PROwatt SW external ATS. The freed-up space is perfect to add a DC-to-DC charger or other needs. I also plan to move the solar ON/OFF switch from under the streetside bed to rear dinette. I already upgraded to motorized ball valves so no pulling of the curbside bed, and I want absolutely no reason to move either bed when camping. OTT really needs this as a future design goal! I sure hope the MP2 does not have some kind of manual reset button! What hokey wiring OTT did. Though I'm thinking back in 2016 the solar inverter option was a rare add-on. When I built an inverter system in our past Class-C, I created a split bus in the panel, one side served by the inverter and the other side having A/C and converter/charger breakers only to be powered by shore power. PD actually makes panels with a split bus for this reason, but mine was hand-cut! OTT wired the microwave and 110v outlets into a standard electrical junction box using only wire-nuts to connect these runs to both shore and inverter. These only went through the breaker on the panel when on shore power, otherwise are protected by the GFCI outlet on the inverter. I removed everything you see in this picture, and you can see the junction box at the top of the picture. The second picture shows the two cables that were wired into the box. They are the two white cables you see lose above the panel which I wired into the panel afterwards. Also yesterday, I purchased my Victron MP2 and VE.bus for programming and Bluetooth connection from Inverter Supply, at a good OTD price, no additional costs: Victron Energy PMP122305120 - Inverter Supply The second picture also shows the main shore power cable (heavy black 600V 10-3 cable on LHS). This will be removed. A new 10-3 cable will be wired from the EMS as input to the MP2 and another from MP2 output to the panel so that the inverter handles all loads including air conditioning. When on shore power from either input (grid or generator) it will allow pass-through 120VAC and/or Power Assist when needed. No generator on our rig, just 600AH Epoch and 3KVA MP2. If this doesn't do it, though it should, I can always add more batteries in the basement!

-

LE1 Generator Selection

My Imagination replied to My Imagination's topic in Mechanical & Technical Tips

Thank you both. I’m hoping to find a generator that will fit the front storage box and will generate 30 amps. We intend to travel mostly, boondocking along the way. The LE1 air conditioner will require either shore power or a generator during the summer months. The battery bank is not sufficient. Again thank you for responding. -

Enclosed Aluminum Box Front Mount

mountainoliver replied to Tim and Christie's topic in Ollie Modifications

The trip that we just returned from last night was a month long road test to make sure that the box was weatherproof before I put the generator in. So as requested, I put the generator in the box this morning. The nylon strap that KSH supplied seems more than sufficient to hold the generator solidly in place. The original strap anchors that were welded inside the box may not have been sufficiently strong enough to hold the generator. I removed them because they were in the way of using the original Oliver supplied basket anchoring u bolts. If I were to buy this box again, I’d ask that the welded in strap anchors not be used. There is enough space for my extension cords and rope lights (pack rat deterrent) as well. I draped a piece of indoor/outdoor carpet over the generator to prevent any damage from the cords, etc. I’m very pleased with the results! The extra plus is that the generator box is about six inches narrower (front to back) and eight inches total narrower (side to side). This gives me a little tighter turning radius and a little less worry while backing up. I’m also saving about 15-18 pounds on the tongue. I would have liked to use a “store bought” triangular shaped aluminum tongue box but I never could find one of reasonable size that my generator could fit into. -

Oliver batteries not charging with generator

rich.dev replied to chiwald's topic in Mechanical & Technical Tips

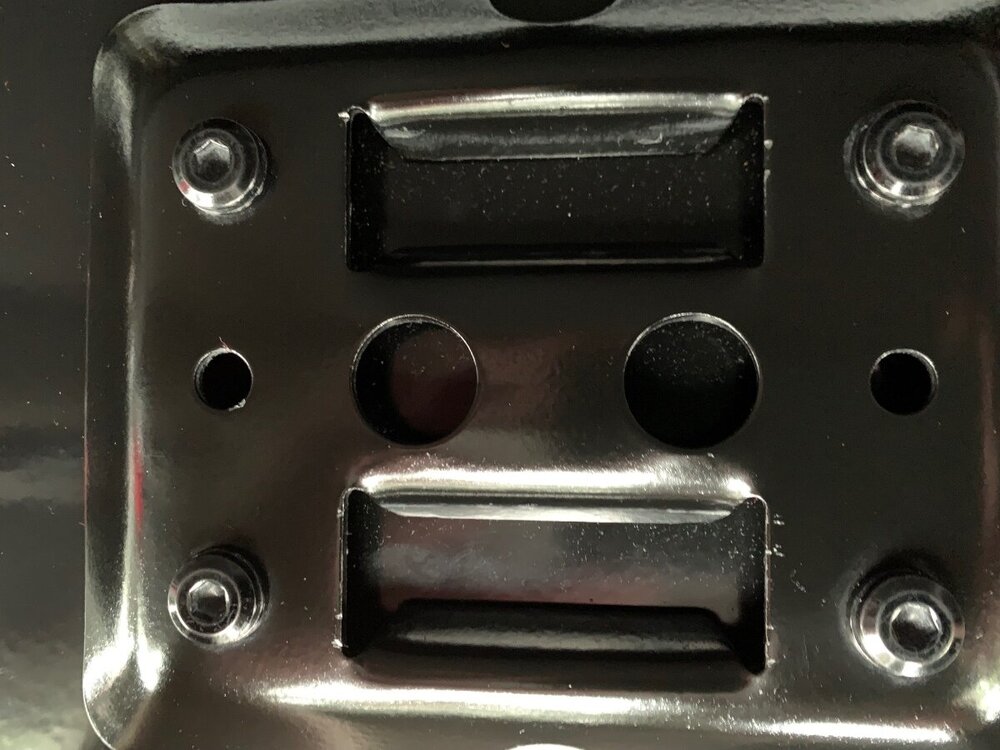

You should have a breaker for the inverter under the street side bed on the wheel well, looks like this. Some suggestions... 1) Did you check if the ground bonding plug is seated properly in your generator? 2) Are you running your 3500W generator on gas or propane. Because it generates only approx. 2800 continuous running watts on propane, which at 120V is approx. 23A, which should still be enough power to run your trailer without changing the Xantrex settings. Try changing the Xantrex AC input settings from the factory 25A to 20A, that would be #28 setting in the Xantrex "FXC Control" app. This setting is set to 25A at the facory because the breaker size for the inverter is 25A and the main power supply is 30A which is greater than the breaker size. When you connect to a generator or house receptical that supplies a lower amps, you need to adjust setting #28 down to match the current incoming power supply. Your smaller generator could have messed it up. 3) Like @topgun2 suggested, take a rubber mallet and tap the transfer switch box 4) If you trust your generator turn off the EMS and see if it works. -

Not good advice, especially for a new Oliver. You will be supplied with brand new tanks with warranty, date coded for 10 years of use. The swap tanks are often abused/damaged. I got one once where the O-ring was missing and the LP would leak. Also, it’s expensive. I just got one 30# and one 20# we use at home filled from empty for $29.80 which is the price of a swap tank at our local big box stores! Our local Ford dealer charges $2.50 per gallon Keep your original tanks for cost savings and your safety. We’re on a 3 1/2 week trip and will likely only use one 30# for furnace, cooking and we love our LP fire ring. Years ago we ran out on a trip in a Class-C and best price nearby in the Phoenix valley was $5/gal. We have enough batteries/inverter/solar to keep us fine and can run A/C for 3-4 hours when needed. If I was going to run a generator for A/C, I’d have more than enough LP, would look to fill one 30 when starting the second. If the E1 can only hold 20s, I’d buy a 3rd tank at a local HW store and have it filled up ready in the truck bed.

-

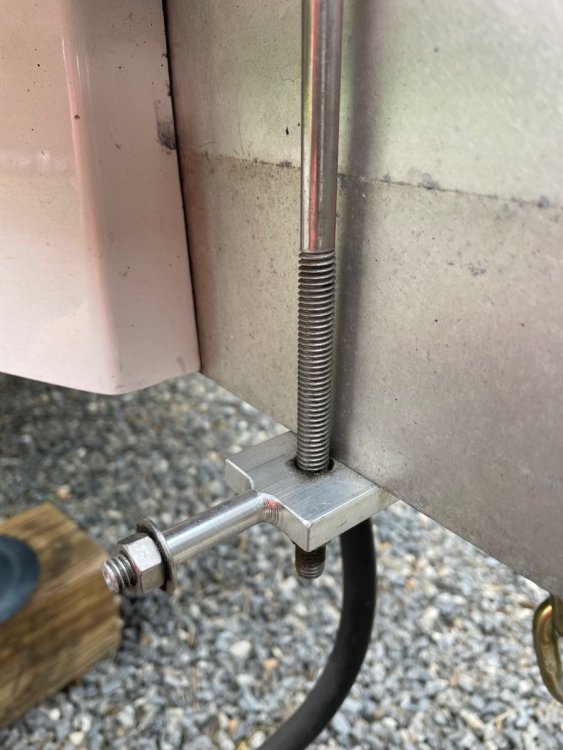

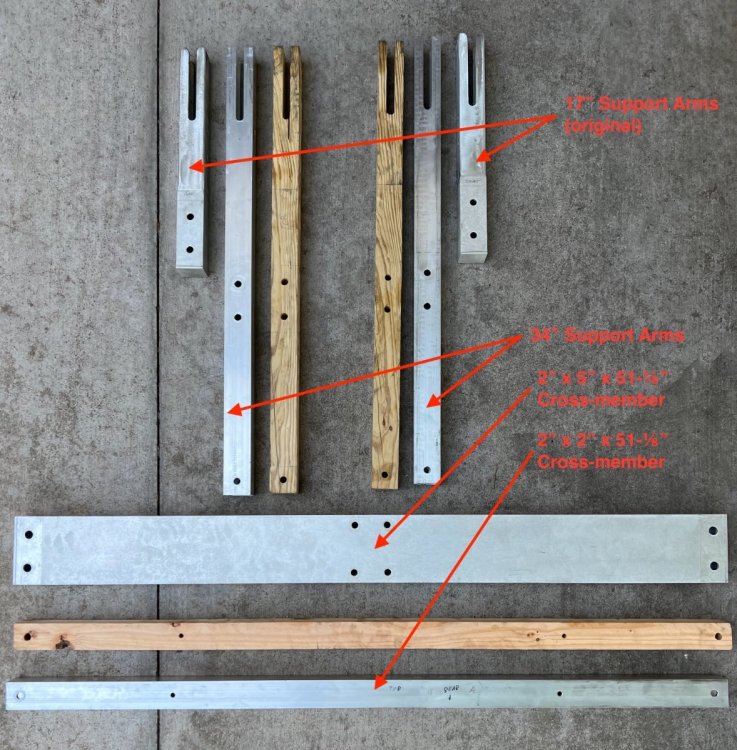

Summary I have installed a rear mounted cargo carrier, with lights, to our 2022 Oliver Legacy Elite II (LEII) travel trailer. We recently completed a two week, ~2000 mile trip, using the cargo carrier, which performed flawlessly. Below are photos of the installed cargo carrier, which are followed by a detailed description of its installation. Storage Constraints Prior to ordering our Oliver Legacy Elite II (LEII) travel trailer I knew we would need additional storage space on the trailer. We are using a 2014 BMW X5 35d (diesel) as our tow vehicle, rather than a pickup truck. Thus, we could not plan to use the pickup bed for supplemental storage. We also needed to stay within the tow vehicle's cargo capacity of 1100 lbs and maximum tongue weight of 600 lbs.. Expecting a tongue weight of approximately 500 lbs. plus two occupants at approximately 300 lbs, we could only accommodate a maximum of 300 lbs. of other cargo. The available payload will be partially used by our camera gear, which must be protected from exposure to moisture. A tongue mounted cargo carrier was not viable, given the tongue weight limit for the tow vehicle. Storage Requirements I anticipated needing additional storage space for the following items: Champion Dual Fuel Generator- 2500 watt (~45 lbs.) (too large for basement storage) Napoleon TravelQ™ 285 Portable Propane Gas Grill and hose (~35 lbs.) (too large for basement storage) Anderson Ultimate Leveling kit (~25 lbs) Harbor Freight rubber chocks (4) (~20 lbs.) Camco Stabilizer Jack Supports (3) (~10 lbs.) Miscellaneous accessories All of these items can tolerate some exposure to moisture, which is likely when stored in any external cargo carrier. A closed and reasonably secure cargo carrier was needed. Searching the owners' forum, I found examples of rear cargo carriers/bike racks and found several examples, including: Oliver's original bike rack design using twin receivers and extending approximately 3 feet beyond the rear bumper; Various rear mounted metal cargo boxes, including custom designs; Rear mounting of an Oliver tongue cargo box by John E. Davies. I also looked extensively at aluminum cargo boxes from various manufacturers, trying to find options which could accommodate the cargo items listed above. I already owned a cargo carrier which we had used on the BMW X5 tow vehicle. This carrier has a heavy steel swing-away frame which mounts to a standard 2" receiver. Mounted on the steel frame are a polypropylene tray and an enclosed container with 13.5 cubic foot capacity. The tray and enclosed container interlock. This cargo carrier also is equipped with fully functional lights (running, brake, turn, flasher). Interlocking pins on the enclosed container mate with the tray. Locking latches secure the container to the tray. Solution Approach I decided to re-use the polypropylene tray and enclosed cargo container, but not the heavy steel frame. Instead, I would use a design similar to the original Oliver bike rack. I ordered the current optional Oliver bike rack when we placed our LEII order, planning to utilize some, but not all, of its components. The current Oliver rear hitch (photo below) utilizes twin receivers that are 11" long, constructed to receive 2" x 2" X 0.25" (wall thickness) T6061 aluminum square tube support arms, which are 17 inches long. The receivers are each mounted to the LEII frame by two long 0.5" diameter stainless steel bolts and nuts. The other components of the rack are a 2" x 5" x 0.25" T6061 aluminum cross-member, 51-1/8" long (with end caps), and a 1-1/4" receiver for connecting a bike rack. I planned to use the twin receivers, and the cross-member, but not the support arms, nor the 1-1/4" receiver. Instead, I would replace the 17" long original support arms with longer equivalents, whose length was to be determined. I would utilize the original 2" x 5" x 0.25" T6061 aluminum cross-member and add another cross member, this one 2" x 2" x 0.25" T6061 aluminum, also 51-1/8" inches long with end caps. The cross members would be bolted to the support arms, in the same manner as on the Oliver rear hitch. The tray and enclosed container from my existing cargo carrier would be mounted to the cross-members. Note the clevis pins circled in the photo below, there are two 0.50" diameter horizontal clevis pins securing the support arms in their receivers. Each clevis pin has a washer on either side of the receiver. Removing the clevis pins permits the support arms to be pulled to the rear, enabling removal of the spare tire cover and spare tire without dismount the support arms. Solution Model A critical dimension to be determined was the length of the 2" x 2" x 0.25" support arms. The new support arms need to be long enough to: Support the polypropylene tray and enclosed cargo box and attach using the molded mounting holes in the tray; Allow the lid of the enclosed cargo box to open without striking the spare tire cover; Permit removal of the spare tire cover and spare tire without removing the cargo carrier and support frame; Permit access to waste water hoses stored behind the bumper; Minimize the additional length of the cargo carrier and support frame to the LEII's length. I fabricated 2" x 2" wooden support arms, approximately 40" long. Using woodworking equipment, I cut slots into one end of each support arm to fit around the bolts holding the twin receivers to the frame. I also drilled horizontal holes for the clevis pins which retain the support arms in the receivers. Positioning the Cargo Carrier on the Cross-members The wooden support arms were inserted into the twin receivers and secured with the clevis pins. Then the 2" x 5" x 51.125" T6061 cross-member was placed across the support arms near the bumper. The additional 2" x 2" x 51.125" wooden cross-member, was also placed across the support arms, but further from the bumper. Clamps were used to hold the cross-members in place on the support arms. The polypropylene tray and enclosed container, latched together, were positioned on the cross-members, centering both to the trailer's width. I opened the lid of the enclosed container and adjusted the spacing (fore and aft) between the lid and the spare tire cover to ensure they did not contact each other. Once I had located the joined tray and enclosed container in what appeared to be a desirable position, I adjusted the positions of the cross-members fore and aft to establish alignment with the mounting holes in the tray. The 2" x 5" cross-member engages two mounting holes on each side of the tray. The 2" x 2" cross- member engages only one mounting hole on each side of the base of the tray. Six 5/16" carriage bolts will fasten the tray to the cross-members. Only four carriage bolts attached the tray to its original steel support frame. I used a mason's string stretched across the width of the tray with weights on either end to aid in aligning the mounting holes in the tray with the positions of the cross-members. I also used carpenter's squares to verify the cross-members were perpendicular to the support arms. Another check of squareness was made by measuring the distance from the trailer bumper to the cross-members. Once I was satisfied with the position of the tray and enclosed container on the support structure, I marked the locations for the holes to be drilled for the six mounting bolts to secure the tray to the cross-members. The tray overhangs the rear cross-member at the rear. With the cargo carrier tray and enclosed container in place on the clamped cross-members, I wanted to determine if the spare tire cover could be removed without removing the entire cargo carrier and support assembly. I found I could remove the clevis pins and pull the support arms aft approximately 7 inches out of the twin receivers and enable removal of the spare tire cover. With the tray and enclosed container positioned on the cross-members, I could now determine the required length of the support arms, which is 33.75 inches. The location of the rear cross-member determines the length of the support arms. After locating the mounting position of the tray and enclosed container I marked all key positions and hole locations on the wooden support arms and wooden rear cross-member. I cut the wooden support arms to the desired final length. Material Sourcing and Machining The required T6061 aluminum components required are: 2" x 2" x 0.25" x 33.75", square tube, quantity 2 (support arms), cost= $110.18 2" x 2" x 0.25" x 51.125", square tube, quantity 1 (cross-member), cost= to $99.08 2" x 12" x 0.125", flat bar, quantity 1 (to be cut into 2" squares for end caps on the support arms and rear cross-member), cost= $6.86 Sales tax= $17.83 No shipping charge. I picked up the materials at the local Metal Supermarkets warehouse Total cost= a $233.95 The above T6061 aluminum components, cut to specified length, were obtained from: Stainless steel bolts and nyloc nuts were obtained from: I was referred by Metal Supermarkets to a local machine shop: When I received the materials I took them and my wooden mockups of the support arms and cross-member to Air & Earth. I also took one of the original support arms. I discussed the machining needed: to cut the slots in one end of the support arms and to drill the needed 0.50 diameter holes for the clevis pins and mounting bolts. I also asked them to cut the 2" x 0.125" flat bar into 2" x 2" squares. I did not ask them to drill the smaller holes for mounting the cargo tray to the cross-members. I was quoted $220 and turnaround of the job within a week. They did an excellent job within the promised timeframe. Finishing and Assembly of the Support Structure After Air & Earth completed the requested machining, I performed the following finishing steps, which included: Rounding the edges of the 2" x 2" square tubing on the slotted end to be inserted into the receivers. I used a 3" wide belt sander with 100 grit sanding belts to round the corners of approximately 12" of the tube which would be inserted into the receivers . The original Oliver support arms also had the corners rounded to more easily slide within the receivers. Several trial fittings were required to verify smooth insertion and removal to/from the receivers. The support arms and the rear cross-member were sanded with an orbital sander using 200 grit disks. This sanding removed markings on the tubes and made the surface textured, similar to the Oliver rear hitch components. The support arms were inserted into their receivers and fastened with the clevis pins. The cross members were aligned with the mounting holes on the support arms and bolted into place. The cargo tray was positioned on the 2" x 5" cross-member at the previously determined mounting position and holes drilled to mount the cargo tray. Holes were then drilled in the 2" x 2" rear cross-member. Carriage bolts, flat washers and double jamb nuts were used to secure the cargo tray to the cross-members. Once all test fittings of the support assembly were completed, lithium grease was applied to the ends of the support arms which are inserted into the receivers. 2" x 2" x 0.125" caps were attached to the open ends of the support arms and the rear cross-member, similar to the end caps used by Oliver. These were attached to the square tubing using JB Weld epoxy. Cargo Carrier Lighting The cargo carrier partially blocks visibility to the taillights of the trailer, which is most noticeable when viewed from close behind the trailer. At a distance the taillights are largely visible. The cargo tray is fitted with two LED light fixtures and a wiring harness with a 4-pin flat connector. A corresponding 4-pin flat connector was installed on the LEII to integrate the lighting on the cargo carrier with the trailer lighting. Details of the installation of the 4-pin connector in the trailer are covered in a separate article. The lights on the cargo carrier ensure the trailer is quite visible from behind. A license plate mount was added to the cargo carrier tray, since the license plate mount on the spare tire cover is blocked by the cargo carrier. Lighting for the license plate mount is provided by adding a Y connector to the license plate light cable under the spare tire cover and adding an extension cable routed to the cargo tray mounted license plate mount. I also added reflective tape to the support frame members. I used the following reflective tape: https://www.amazon.com/gp/your-account/order-history/ref=ppx_yo2ov_dt_b_search?opt=ab&search=reflective Conclusion This addition to our trailer provides significant benefits, with no significant disadvantages. It does add approximately two feet to the length of the trailer. Besides the additional storage space, the cargo carrier and its load slightly reduces the tongue weight. I measured the tongue weight, using a Sherline scale, at 450 lbs., with no water onboard. Tongue weight seems sufficient, as no swaying or other handling issues have been observed. This project had a successful outcome due largely to the information I was able to glean from the Oliver Owners Forum. I hope this information is useful to others on the forum. Comments and suggestions welcome. Regards, Don

- 22 replies

-

- 19

-

-

-

-

-

Enclosed Aluminum Box Front Mount

Patriot replied to Tim and Christie's topic in Ollie Modifications

After some thought of how little we used our 3200i generator in the cargo tray on our last 42 day trip out west, we decided to move forward with a custom all aluminum cargo/storage box from Sea Biscuit metal fabrication shop. My wife and I took a 3 hr drive up to Johnson City, Tenn and visited the Sea Biscuit metal fabrication shop. We met David and Kristine Hess the owners. Some of the nicest folks you will ever meet, and they are campers as well. After seeing the high quality of the Oliver storage boxes that David and his team craft we decided to purchase one. The fit and finish is excellent. We like supporting small companies and their products made right here in the USA 🇺🇸. We know we will get a lot more use from our cargo box each time we set up camp. It has lots of room for all things for initial set up. Our gen will be secured in the truck bed. I custom ordered and installed the XPLOR metallic silver graphics from https://lettering.com/ another excellent customer service experience. Had a buddy of mine install XPEL PPF on the front and sides of the box as it sits in the road rash blast zone. For questions on custom boxes and pricing reach out to -https://seabiscuitmetaldesigns.com/product/oliver-box/ a few photos - PPF - I bought and trimmed a fatigue mat to fit from HF to line the shelf and bottom. Added graphics- Moose rack holds our cables off the ground. Plenty of storage for all initial set up gear- XPLOR graphics installed- -

Atmos 4.4 vs the Dometic FreshJet 3 (13,500BTU) vs Penguin II

theOrca replied to theOrca's topic in Ollie Modifications

ADB is the "air distribution box" on the inside side of the roof. My install dealer and I are still working out the ramifications of they having installed a 15K BTU FreshJet3 instead of my requested 13.5K BTU version. There is now some question as to my Honda 2200 being able to run the 13.5 version. I can attest to the fact that it is NOT able to run the 15K version. 😒 Measured data 15K Dometic FreshJet 3 (with the Dometic Easy Start) and a Honda 2200 gen: Sea level, 73F. Low setting on the A/C - 13 amps. Generator runs fine Medium setting on the A/C - 15 to 16 amps, gen running hard, evidently right at it's max wattage output. High or Turbo setting on the A/C - 18 to 19 amps - Gen shuts down immediately due to overload. I am having difficulty getting my mind around the fact that Dometic claims that the amperage draw of the 13.5K unit and the 15K unit are the same. If they are the same, then why is one de-rated to 13.5K? in my mind, BTU = energy = watts = amps.... 🤯 -

We used Two 100 Watt Costco Solar Panels that they sell new in the box for just under $100. I bought three. Two to use and one as a spare. Each panel comes with instructions and wiring. The Airstream had an external connection for Solar on the Battery Box that holds the two 12 volt AGM Interstate Batteries that now can be purchased, also at Costco. I am not an electrician. I am not a Solar Installer for a Travel Trailer lot. You connect the + to the + side of the battery and the - to the - of the battery with the +/- of the Solar Panel. Diode is yellow when Charging and Green when batteries are charged. I could run a long thin pair of wires to place the Solar Panel against a milk crate with some rocks added, and move it with the Sun. Then I bought a second panel added it and charged faster. I sold the 25 foot Airstream and gave them one panel and now have Solar on the Roof of the Oliver and the Airstream. Easier for sure... but the Costco panels I have two left and if I need them in the future... repeat what I did previously. My rooftop Solar Panels provide us with all the 12 volt power we need. If they do not keep up with our simple needs for minimal power... add a panel, lean it against a Milk Crate and back in business. If anyone is curious I will try to find some photographs of our Portable Solar System for $100 and double it for $200. Better than the Honda that came with the Oliver that we never use. No Air Conditioning or TV while Off the Grid Boondocking. If you NEED Air Conditioning and Television... look into an expensive Generator that needs to be hauled around with gasoline. Been doing our own Solar since 2006. I am a Neanderthal, but common sense and two thin wires was MAGIC to ME. You may want to explain how you managed to ADD portable Solar for the price of a roll of wire and some wire connectors and go Human Bean. Like me.