-

Posts

2,252 -

Joined

-

Last visited

-

Days Won

64

Geronimo John last won the day on January 30

Geronimo John had the most liked content!

My Info

-

Gender or Couple

Couple

My RV or Travel Trailer

-

Do you own an Oliver Travel Trailer, other travel trailer or none?

I own an Oliver Travel Trailer

-

Hull #

342

-

Year

2018

-

Make

Oliver

-

Model

Legacy Elite II

-

Floor Plan

Twin Bed Floor Plan

-

What model is your other RV or Travel Trailer?

Sold Jayco UDST Pop-up

Recent Profile Visitors

Geronimo John's Achievements

-

Patriot started following Geronimo John

-

Geronimo John started following Patriot

-

Inspectable Item: Propane Area

Geronimo John replied to Chris Scarff's topic in Mechanical & Technical Tips

And very importantly as Hoosier brought to light, I was remiss in not adding to my list an important reason for our use not having an automatic switch over valve: We camp when it is warmer and we fully winterize when our trailer is in storage. As such, we have no need for it to burn propane to keep warm when it is lonely. That said, a significant number of owners do need/want/use these devices. And that's cool. GJ -

Inspectable Item: Propane Area

Geronimo John replied to Chris Scarff's topic in Mechanical & Technical Tips

Time for a left turn on this topic. The more I ponder my propane system, and the way that I use it, I'm questioning why I want or need an auto switch over valve. Rationale: I don't ever use the auto switch over part of the device . I want to know when I have an empty tank. It is a single point of failure. It is expensive to replace Why not just buy two regulators and two 18" hoses, attach oneset to each tank, and "T" their outputs to the supply line going into Ollie? Use one tank at a time. When it goes dry, open the small hatch and shut off one tank and open the second tank's valve. 100% redundancy with less points of failure for about the same cost. Your thoughts? GJ -

Inspectable Item: Propane Area

Geronimo John replied to Chris Scarff's topic in Mechanical & Technical Tips

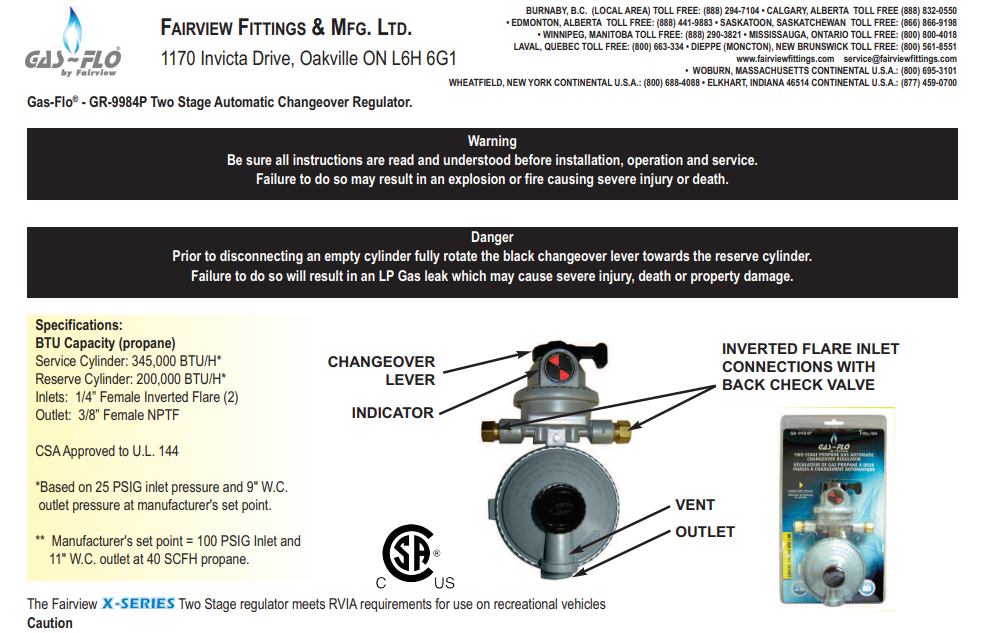

Drats you are correct. It appears that the American Copper and Brass have their wires mixed up. They are selling these two auto change over valves. Their left one shows 245KBTU and the one on the right is their 345KBTU model of another mfg. . Gut the Fairview Fittins and MFG web site says that the GRF9984 is a 345 KBTU model as I posted previously. The Fairview web site says that the GR9984 is rated at 345,000 BTU. Go figure????. Here is the link to the full manual: https://olivertraveltrailers.com/wp-content/uploads/oliver-university/Component_Manuals/Propane_Regulator/Fairview-GR-9984P-Propane-LP-Regulator-Manual.pdf GJ -

It looks like your Ollie and those winding roads got a lot of snow and several days of hard freeze too. I hope that you will be able to get back safely after the roads get cleared and the thaw allows. Glad you reached out to optimize your rig from being damaged. We all wish you a safe return to your Ollie. GJ

-

Inspectable Item: Propane Area

Geronimo John replied to Chris Scarff's topic in Mechanical & Technical Tips

JD: Your regulator may be undersized for the load. Past posts indicate that the gas regulator size likely should be in this range: · The OEM Hull 505: GR-9984XF with 345,000 BTU · Possible Smaller Replacement Part if above is not available: GR-9994XF has 262,500 BTU If you are using a high demand outside stove, grill or fire ring especially with the furnace running; then for sure go the larger regulation. Hope this helps with the moonlight harmony you are getting from your regulatior. GJ PS: The Fairview gas regulators are designed in USA and made in North America. I have purchased them from American Copper and Brass for a lot less than most posted prices on the net. Worth checking them out. -

The "Where do we go from here" statement is on point. If Dragon Fly is not going to honor their warranty without fees, then the answer is: Class Action. I am starging to think that Dragonfly took the Ford approach to Phasers and not the Toyota approach to their EcoBoost head problem. GJ

-

Geronimo John started following Alcan Spring shackle failure , Local web page to search Oliver forums via Google , Winterizing in below freezing temperatures and 1 other

-

Local web page to search Oliver forums via Google

Geronimo John replied to Chris Scarff's topic in General Discussion

Thank you Zodd! I was starting to get a headache with all the above stuff flying by me at Warp 10. I'm glad Chris, JD and Ollie are on top of this for us. I'll remain confused and happy, GJ -

Winterizing in below freezing temperatures

Geronimo John replied to RVK's topic in General Discussion

JD Unless I'm messing up my boat terms: The boondocking port is close to the furnace, aft starboard. The fresh water and city water are aft port side near the outside access to the basement. But you are correct in ensuring that the furnace (vs. space heaters) was being used. It circulates air in the basement and helps prevent problems with freezing. However there is a limit to how cold it will do so. Something that I'll hopefully NEVER NEVER even come close to knowing first hand. See video posted on the other cold related thread. 🙂 GJ -

I have a tough decision on this beautiful blue sky day in Hawaii: Go paraglidng or go surf kayaking..... Another tough day for a RoF (Retired Ole Fart)! I’ll not encourage even more flaming arrows by posting a typical blue skies and bikinis picture, but will share my favorite Hawaii weather forecast. Here is Trumpet the Weather Dog talking about our weather in Hawaii: GJ

-

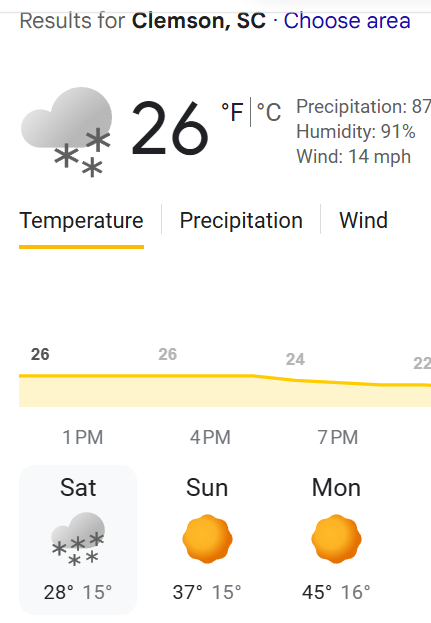

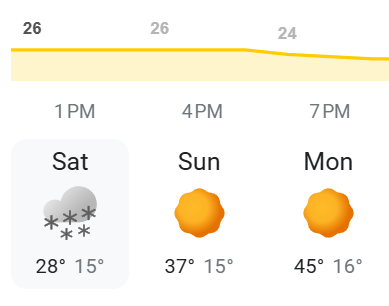

JD: I admit that my living in Hawaii makes me a "Weather Woosie", but the current weather lows at Clemson SC of 15, 15, and 16 degrees are three nights while he was gone each with hard freeze conditions pending. Below cut and pasted for reading enlightenment. So not being winterized while away, with hard freezed inbound, with the furnnace on low..... opening the basement up to the cabin is easy insurance with such conditions inbound. GJ

-

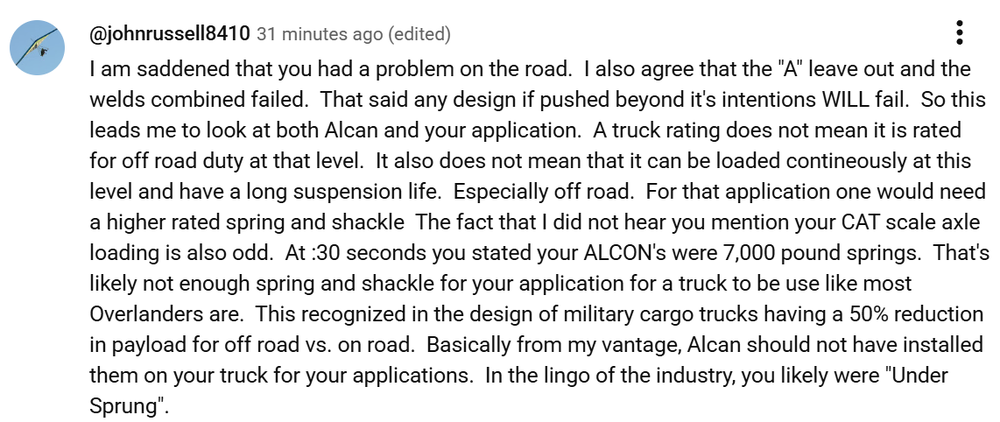

Alcan Spring shackle failure

Geronimo John replied to rich.dev's topic in Mechanical & Technical Tips

I'm in your court on this one for sure. Yes it was a less than optimal design. Ultimately everything fails if the use is pushed beyond the design limits. I think this is the case for this young couple. The fact that THEY INSEALLED the system from Alcan concerns me. If so, was Alcan advised of the end weight of their vehicle during the purchase or was it a "Send me XXX" and I'll install it transaction. More "Paul Harvey Questins"..... Crazy Horse has warned me about flaming arrows at times seeking me out.... but I can assure you that I don't intentionally try to be such a target. Here is my response to the couple left on their comments section of Youtube. GJ -

New fiberglass RV manufacturer

Geronimo John replied to Steph and Dud B's topic in General Discussion

Yep! I suspect many OTT owners would like a rubber backed woven vynal floor cover. Suggest you consider asking this to be a new thread under Mods. GJ -

Readers should be aware that you live in AZ. And equally important you generally are in relative proximity of your Ollie should weather turn terrible. Those who have their trailers where hard freezes HAPPENl and can't always get quick response to their Ollie easily..... may want to consider your approach as not being ideal for their location. But for your situtaiton it is easy and effective. GJ

-

Alcan Spring shackle failure

Geronimo John replied to rich.dev's topic in Mechanical & Technical Tips

There have been a few, but they were resolved. In the case of the Overlander and the shackles, it appears that vanity got mixed up in the design with physics. On the surface, it appears that the shackle design with the "A" cutout was a weak point. Alcon's actions to change the design is proof that they thought so as well and commend them for doing so. On the other hand their welding inspector's statements were believeable. My heart goes out to those owners. But who pays is still up in the air. Not knowing the weight of their load on those shackles is not normal for someone who has built the truck. Odd actually. Also not being clear as to how and where they used the truck is not useful. Were they heavy on the springs. Were they abusing their suspension by doing "jumping jacks" with their Overlander. Both could damage the suspension but not yet break it. In time it came apart "for no apparent cause" on the highway. Were there other trucks with the same issue? Bottom line, we need the "Paul Harvy" on this story. ("The Rest Of The Story") GJ PS: I just sent Alcon $$$ for a couple of 5200 Nev-r-Lube's to go with my 2400 Dexter springs. They were $400 less than a great firm in Tulsa. And have the experience on this upgrade for sure. A no worries upgrade. . -

Moving Stabilizer Jack Switches

Geronimo John replied to Tony and Rhonda's topic in Ollie Modifications