-

Posts

2,470 -

Joined

-

Last visited

-

Days Won

155

Everything posted by jd1923

-

First highway roadtrip with Atmos 4.4 => MI to TN

jd1923 replied to rideadeuce's topic in Ollie Modifications

Should not matter to you or me. You already purchased a Houghton and I my Oliver sits outdoors! -

Elite 1 - What are the Solar Panel Dimensions?

jd1923 replied to Dirt Duff's topic in Mechanical & Technical Tips

Zoom in on pics #1-2 in my post above. They are bolted separately. You can see one bolt into the bracket and behind that 1 of 4 bolts into the L-support. That’s why I wrote a 24” angle support, commonly available, could be used. -

Nobody said that. 🤣 At your number, you two are petite! Gallup says the average weight Americans ‘“say they weigh” is 181 (average of adult men and women). Let’s add 10 lbs each for the little white lies and you have realistic 380 lbs AVERAGE for an American couple! Easily 400 for an older couple, those of us who eat well at home and at camp! I’m 6’ 2” and 220 LBS. Though I always weigh 230 at the doctor’s office, dressed with jeans and leather belt, hiking shoes size 12, with phone, and wallet, keys in pocket. At 318 lbs total, Chris would have to weigh only 88 lbs and that leaves zero lbs for our pup Charley (65 lbs) and ANYTHING else in the cab! Put the dog in the trailer to save GVWR!!! No, not our special pup. Do you have any bags up front? Phones, computers, camera, a smaller cooler, a packed lunch? I’m an industrial engineer with years of estimation experience. I’d say the 3 of us with our stuff in the cab in our truck is 450 lbs min, just plan on 500 being honest. I weighed all that in place at the scales and we have 1300 unused GVWR, the amount any 1/2 ton truck has to work with from empty! God bless @ScubaRx. He has every suspension upgrade in his E2 to carry 10K lbs max, likely 8500+ in his Ollie and room to visit several flee markets on his winter missions out west. Love you @Steve Morris, and love our discussions. You ever get that Pepwave mounted? 🤣 Can’t wait to meet you, and your pretty thin wife, on the Oliver trail. ”On the road again…” Best wishes, JD

-

I agree fully with @ScubaRx, except he underestimated the average weight of two adults. The truck picture shows it. These Toyo trucks sit with much more space between the rear tire and the fender vs the front. This pic the front gap looks a little larger than rear. That takes weight off the steering. The Anderson should be tightened some to help. Also see the pic showing what’s in the back of the truck, the plywood platform, the cooler, etc. wail until the shelf has stuff on it. Yep, overloaded.

-

That's why I took the recommendation of others to replace the OEM fan with a larger dual fan setup. You could change out the thermal switch screwed into the top RHS of the condenser. Given your fan works this is likely the issue. Note all the comments here. It's worth the $80 plus tax and a few hours and YES, run new wires to the switch or wire without the toggle switch on the lights panel. The Beech Lane fan product it very nice. I just purchased and installed a second one to cool the streetside bed basement area where I'm installing a 3KW inverter.

-

We stream most nights, but when there is no cell reception for the Pepwave we can always play a Blu-ray! Downloading movies reminds me of when I used to have to fly for business. Want to keep that a distant memory.

-

Monsoon rains all week! We love it since now we are at 47% RH and a month humidity it was down in the teens. 20 years ago, it was our last spring in Northern VA and Adam's little league season got rained out 7 of 12 games! The next year he joined a Prescott AZ team. We got rain one evening and all the boys were jumping up-n-down in joy, smiling faces looking up to catch the rain. The game continued. Last night this bad boy had all the look, but not enough energy to dump buckets of rain! Weather report says no rain this weekend, with monsoons coming back next week. 😂

-

Elite 1 - What are the Solar Panel Dimensions?

jd1923 replied to Dirt Duff's topic in Mechanical & Technical Tips

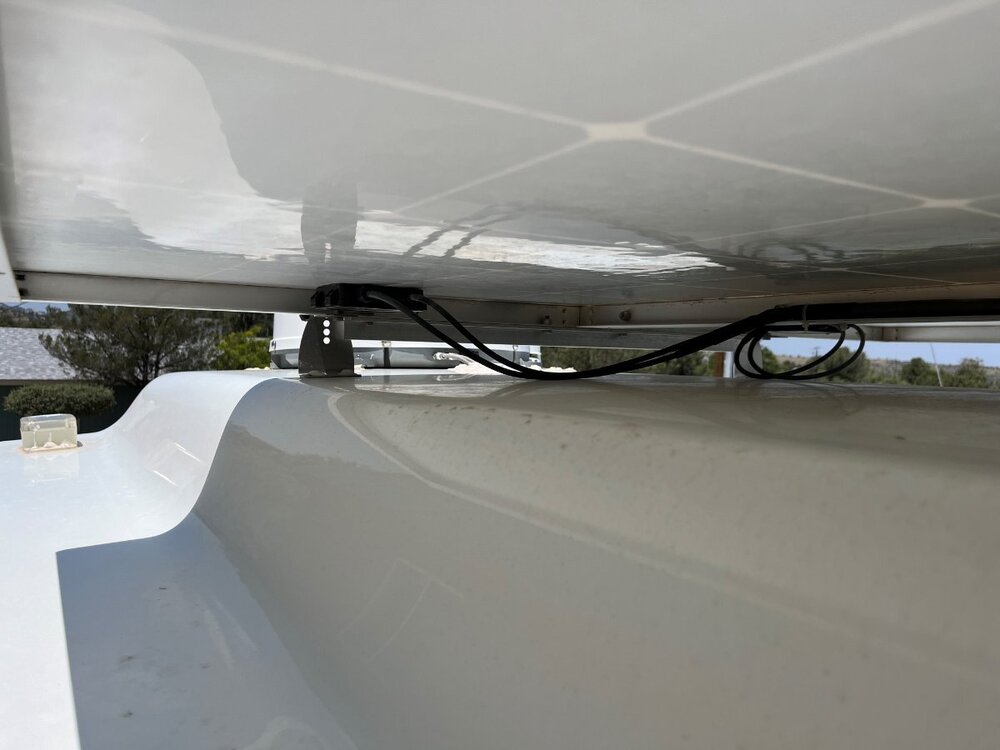

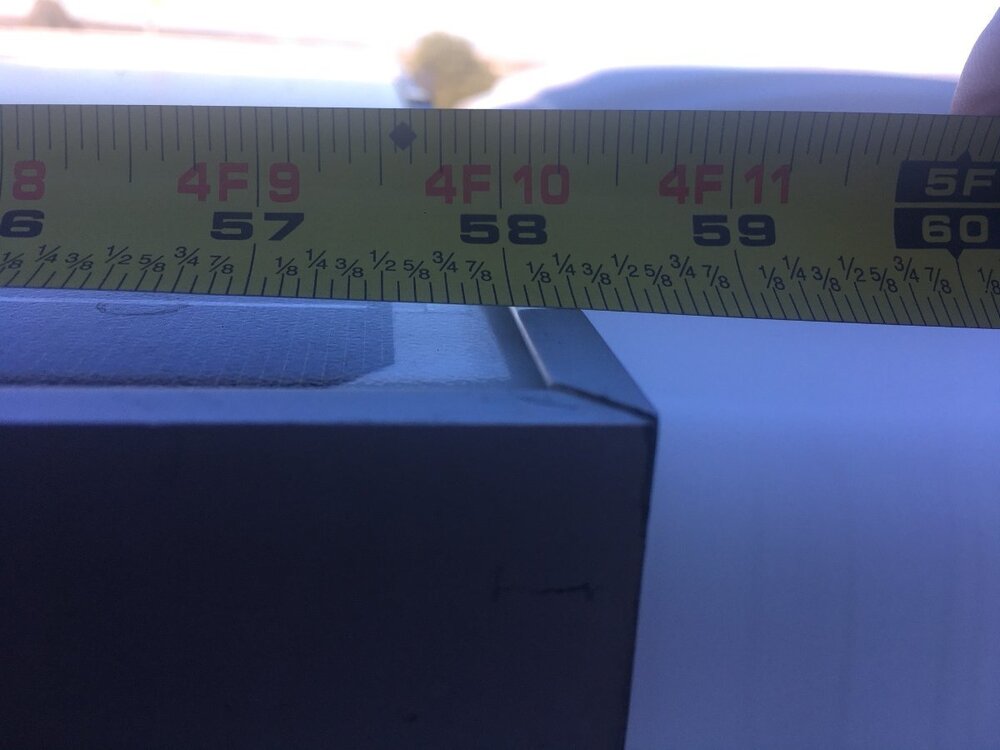

As usual Steve and @mossemi are correct. It is 1" Aluminum angle. mine measured 25", Mossey wrote 26". There is no reason at all (two) 24" pieces would not work. The T-shape I noticed in the above picture was an illusion seeing the mounting bracket. I just climbed up and measured. The mounts are 27" center-to-center and if yours measure the same (and about 59.5" front to back) then your installation was likely the same as mine. Good time to CLEAN the roof! 🤣 With these pics you could rebuild yours to match. The two panels do not have a center support. They are just bolted in 5 places, looks like 1/4" HW. Since you're build from scratch, not sure if angle mounts make real sense, but check out this post: HOW TO: Solar panel extension arms. - Ollie Modifications - Oliver Owner Forums (olivertraveltrailers.com) -

Elite 1 - What are the Solar Panel Dimensions?

jd1923 replied to Dirt Duff's topic in Mechanical & Technical Tips

Ours is an Elite 2, but also older 2016 hull. Maybe solar on E1 vs. E2 was not different, not sure, but the width is the same, only length differs in the hulls. Your E1 appears to have the same 4 mounts to the roof. I took some pics recently. If you zoom in on picture Solar3 below you can see the support bar on ours is T-shaped but an L-angle would work fine. I also show measurements. Another pic shows a Zamp serial number. I believe ours are two Zamp 170W panels for 340W total. The 58.25" measurement is the length and the 52.43" is the width of two panels. This item is likely the current replacement: Amazon.com: Zamp Solar Legacy Series 170-Watt Roof Mount Solar Panel Expansion Kit. Additional Solar Power for Off-Grid RV Battery Charging - KIT1009 : Patio, Lawn & Garden Not sure why Zamp is so expensive! I would replace with Renogy or Newpowa (bought these for a Class-C and was very happy with them). Hope this helps! -

Anyone replace Norcold fridge with Isotherm?

jd1923 replied to Kathy Tewart's topic in General Discussion

This phrase caught my eye. If the LP line is in the area of the fridge that vents ONLY outside, then this is OK not best. I've read some about this fridge needing an interior vent, then not OK at all. Best installation would be to remove the gas line T-coupling down at the frame below the cabin and replace it with a straight coupling. This way there is absolutely no chance of LP leak into the cabin interior. -

First highway roadtrip with Atmos 4.4 => MI to TN

jd1923 replied to rideadeuce's topic in Ollie Modifications

This was asked and answered in another thread titled, "AC upgrade conundrum." At that time, I checked and the Atmos is spec'd at 0.9" taller than the OEM Dometic Penguin. Given OTT specs the EII as "Outside Height To Top Of A/C: 9' 8" call it 9' 9" with an Atmos which should not make any real difference, even for a 10' garage door. -

I've seen pictures of the Oliver rallies. Oliver owners that easily have twice the outdoor gear than we do, extra tables & recliner chairs, camp lights, screened rooms and so much more! Can't get a 35-gal water tank in an SUV and we don't leave home in the SW w/o extra water. We don't pack an extra fridge, no generator, lots of available space in the bed. We love our GX470 too and the two cars and two other trucks we have on the property. I have not spent a year (cannot) without a pickup truck since I bought my first one 40 years ago. My best friend from high school said at the time, "What took you so long?" I always get a chuckle watching SUV owners load up at the Depot! 🤣 As they are busy making room, I quickly load my purchases in the bed and drive off. Ya gotta admit the back of your truck is quite full near GVWR and you could not get me or my wife to spend one night in that other camper! After we pack for a trip, our TV has 1300 LBS available GVWR and our Oliver sits under 6400 LBS. It's easier with a pickup and safer not to push the limits.

-

Arches NP has an online reservation system. We could only reserve a 4PM entrance, which worked out fine as the sun was softer and the day was nice cooling off. Drove all the roads and made two short hikes to Landscape and Delicate Arches. Left after 7PM to enjoy a late dinner at Dewey's in Moab. Next door is the Moab Diner. Had great breakfasts there a couple mornings!

-

BTW, I did get a return authorization on the KISAE and just got refund less shipping yesterday. I have not heard if they tested it to determine the issue. Twice for me it would not recognize shore power, so the A/C would not run and later it ran fine for 2 weeks in bypass mode from shore power before I removed it. The combination of lead-acid batteries, 2KW Xantrex inverter (older model w/o charger) and old Dometic Penguin (according to the EMS draws 15A on shore power), did not add up to a viable solution. I wired the A/C back to the breaker directly. I received 600AH Epoch LiFePO4 batteries, waiting on shipment of a 3KVA Victron MP2 inverter that of course has the built-in ATS (shore or inverter) that will power all Oliver 120VAC needs.

-

Yep, you were editing. I'm on this site too much! I need to get out, work on the Oliver and get some yard work done today. Lunch break is over! Now that you have the highly capable Victron charger, if it were me, I would bypass the Xantrex charger if at all possible. Use its inverter function only. As you wrote, "soon after showed erratic output." This could be caused by the Victron charger sensing amperage supplied by the Xantrex charger.

-

Don't know Kodachrome. Loved out visit to Dead Horse and wish we would have camped there. Do that for sure! I agree with @SeaDawg, where she wrote, "Zion is beautiful. So is Bryce. Don't know if I'd be up for a week at each." I would spend a week in St George area, so many things to do and we've made it an annual trip for us. You are a close commute to Zion. April is better than later, as it will get more and more crowded. The shuttle system gets full and you can wait at some stops for a while. For me 2 days at Zion is enough due to the crowds. Separately I suggest camping somewhere up between Bryce and Capital Reef NP, weather permitting. This is all 8000+ FT elevation. Leaving Zion you can drive Hwy 9 east, the Mount Carmel Highway for more great views. Then take Hwy 89 N to Bryce. So many options!

-

I had this thought too and then there I was in our local Walmart, a box full of thin noodles! Chris is creating an Americana-Patriot theme for our interior decor, and she came up with the flag idea! I found a cheap 18" wide poly flag on Amazon. Had an old broomstick in the shed. Cut it to size and just a little sanding for the correct diameter. Used 3M spray glue and rolled it tight. Can't drill cloth, so first I used a needle tool to puncture and a center punch to widen the hole. Measured the first hole and mounted it to get the exact point for the second hole, two screws go through the wood center. It sure beats the ugly old burlap brick! Turned out pretty good. When I find a quality cotton flag, I'll do it again in a couple years. I have enough leftover noodle! 🤣

-

Honestly, I don't how any of you manage, towing with SUVs! Go back to @John E Davies posts and you will see the custom shelving and everything else he did to store just a few small items. We feel inside storage of the Oliver EII is good with ample room for kitchen, bath, clothes and personal items. Where do you put all the camping items in an SUV? The Oliver has little outside storage. The front bin for generator (we stow a fire ring and cooking grate there). Then you have the awkward trunk. All we keep back there is the shore power cord, hoses, an accessory bag, empty jugs for fuel and radiator emergencies and our campground blanket. Back of the pickup is needed for lawn chairs, grill and stand, a folding table, tools and much more. To allow boondocking for a full week, we bring extra water too (35-gal tank). The only constraint is the black tank (will just last a week), but no, we're not composting poop. 🤣 Get a pickup truck eventually and make it a 2500! Still use the Anderson, unless you purchase a modern beast of a truck. It will make setup and tear-down quick and easy and if you find something you want to buy along the road, you'll have the room to bring it home.

-

I will disconnect for sure. It is designed for lead-acid and to run LiFePO4 you need the upgraded model as Chris @Wayfinder had installed. I will use that end fuse for the microwave, now our Emeril Air Fryer, to separate it from all the 110V outlets. Wondering if it's worth just leaving there as a backup, in case of Victron MP2 failure. Charging with a LA pattern is better than nothing. But with solar, I will likely pull it to save 2 LBS! That spot then becomes a vent. 🤣

-

I want to thank all that provided good feedback here! Always helpful. Want to show you my first step with a platform for the Victron Multiplus-II (see pics). More on this in a couple of weeks as I will start a new build thread. I'm waiting on the MP2. The Florida company Inverter Supply must receive shipment from the manufacturer and then ship to me. Thought I would get it this week, but it will be another week. I'm getting installation parts here and there. Love how this first step turned out. I had to put a steel cutting blade in my power miter saw. One mounting ear had to be cut back to slip it under and the two mounting brackets had to be cut to fit side-by-side. This base will hold the weight of the MP2 and I will build a 6x24" platform above it. It will just sit on the floor since I will not drill into the bottom/outer hull. The MP2 will also be strapped above. Much more later in mod post! 😂

-

Wow, that's a lot. Given we are nearby, it took us 3 April-May trips to see all that! April 2022, we visited Mesa Verde, Canyonlands and Arches. Spent too much time in Moab (more for young people in Jeeps) and should have gone through Telluride and Ouray on the way instead (future trip). Spring 2023 we went to St. George Utah, visited Zion and Bryce Canyon. St George is a great town, and we went back this year and camped Snow Canyon and since the weather was hot headed north to Cedar City and made it to the viewpoint at Cedar Breaks. What a climb from Parowan to the top! It can be extremely windy out here during April-May, so be ready for that. Some evenings it's hard to light the grill or fire ring. Also, some roads and locations are still closed for the season. For example, the North Rim of the Grand Canyon and even the road to it opens May 15th. Most of the Utah parks are open in April, but you cannot do The Narrows of Zion (water flow to high) and hiking at Bryce would be on snow-packed trails. Zion is low elevation and April is good there. But at the north end of Zion, the road to Kolob Canyons will be closed for snow. Hope this helps. You trip looks like the trip of a lifetime! 😂

-

OMG! How are you getting from Florida all the way to Sedona, AZ? I almost do not know where to start! 🤣 You're staying at the best park near Sedona. The City of Sedona has created the Red Rock Pass that you need to buy to even drive down any dirt road within 20 miles. The city is not camping friendly, again this park is the best place within 30 minutes of Sedona and not much else up there to camp. I love everything Arizona, but only go to Sedona when out-of-town friends visit. Not being into overpriced art and things spiritual, it's not for me, but my son being religious and spiritual goes there monthly to hike and meditate. It is a special place, but the tourists, the crowds, the cheap stores and nowhere to park keeps me from more than an occasional visit. We can drive to Sedona in one hour traveling up Hwy 89A over Mingus Mountain, the best part of the trip! Cathedral Rock is my favorite Sedona site. It's south of town on Hwy 179. You cannot miss it coming off I-17. However, we always visit from the backside (of Hwy 89A) where there is nobody but us most of the time (see our pics which is the backside view). I love this place, would not drive to Sedona without stopping here again! Suggestions yes, spend more time in Cottonwood and Clarkdale. Book the Verde Canyon Railroad (Verde Canyon Railroad | Train Ride in Clarkdale Arizona (verdecanyonrr.com)) for a train excursion up to Perkinsville AZ, the head waters of the grand Verde River and back (we drive to Perkinsville often from our home). I love the little town of Cornville. Eat lunch there and take in some town views along Oak Creek (very short drive). Don't let the name get you, what a cute town! BTW, the best drive in ALL of Arizona is Hwy 89A heading north out of Sedona towards Flagstaff. This is the Oak Creek Canyon, just amazing. During April everything should be in bloom, and the water will be running strong. The birds are amazing, with thousands of butterflies everywhere if your timing is right! Drive up the mountain to Jerome! What was the largest copper mine in history, booming 100 years ago and a cute cliffside town with great local restaurants and shops (no chains, more bikers than other tourists). If you want to climb Mingus Mountain, on the same road another 600+ higher, you could then drive the beautiful descent down to Prescott Valley! Stop by and see us for an overnight. Fill your tank with mountain fresh water and plug into 30A service. You are certainly welcome. Great drives, hikes, restaurants, real stores and the famous Whiskey Row for drinks and dinner. You can camp anywhere in the Prescott NF and BLM lands. We have Thumb Butte and the Granite Mountain Wilderness. Prescott was founded in the 1860s by the Union Army as the capital of the Arizona Territory (in competition the Confederates founded Tucson). A day trip to Payson is an amazing drive... But you only have a week! If you like, you can pull your Oliver on every road I have mentioned. Have an amazing trip! 😂

-

New axles may not fit all older sub-frames

jd1923 replied to Wayfinder's topic in Mechanical & Technical Tips

This is an outlier. It appears every other hull 2016 and older has the 50” axle. If this is true and Dexter can build either when ordered, why would OTT start with 50.5” then use 50” and then back to 50.5. It’s not what Henry Ford would have done!