-

Posts

390 -

Joined

-

Last visited

-

Days Won

20

Everything posted by DavePhelps

-

Nah! It's too big for my little Elite. But you have me thinking of other options. Thanks again! Dave

-

Wow that is a beautiful sink and install! I have never been all that happy with my sink/faucet combo. I was looking at getting at least a new faucet as mine does not reach far enough in to the sink. But the sink you found would be much more functional. So is your Franke Vector sink 17"wide x 22-3/8" long (flange to flange) x 9" deep? Just making sure. I'll be running out to my Elite to see if it will fit! Hope it does. Thanks for the post. Dave

-

Pete, Be sure to let us know how that 5.0 engine tows for you. I'm not yet sold on the Ecoboost for long term durability, but want to be sure the 5.0 has enough power-especially in the mountains. To the OP, my TV is a 1998 Ford E-250 Econoline with a 5.4 liter Ford Triton Engine/3.73 rear end. 10mpg towing. It has done well but it's 2nd gear and 35-40 mph over the mountain passes here out west. I really want to get a 1/2 ton crew cab with 4wd (gotten stuck once or twice with 2wd), but am having trouble making a decision. I like the Chevy/GMC trucks but they have only 26 gallon gas tanks (in the half ton)! Fords have a 36 gallon option, and depending where you travel, that is a good thing. Congrats on picking the finest Oliver trailer model! So easy to back up and you can slip it in to some tight spots. Don't go too small with your TV. The Olivers tow very well but you need to be sure you are within the payload and tow rating of your vehicle. Usually folks go over payload in smaller vehicles. Longer wheelbase is also more desirable for overall stability. Dave

-

What many don't realize (myself included until a few years back) is that tires can "age out" and still look like new or have decent tread left. There is a date of manufacture stamped right on the tire. It's a 4 digit number, the first two numbers are the week of manufacture and the second two are the year. I had a 10 year old snow tire explode in our basement while in storage. It looked almost new (until it blew up!). Where I now volunteer, all tires for the trucks are retired after 6 years no matter how "good" its tread condition. This is the rule I now follow, after 6 years, the tire is replaced. Here's a good bit of info if interested: https://www.edmunds.com/car-care/how-old-and-dangerous-are-your-tires.html Dave

-

Welcome Mmoren! Well I'm late to this party. Congratulations on your choice of an Oliver and especially the Elite!! Not many of us out there to be sure. We have two seasons experience in ours now. We seem to do most of our traveling in the shoulder seasons so we've had all kinds of weather and have been always so very comfortable and amazed at the shelter our little egg provides. After years of hunkering down under a tarp in pouring rain or blowing snow, I almost feel guilty being in there...I said almost! Options I am really glad we got: 1. Solar. OK this is a source of debate here, but our 200 watt PV/service has given us all the power we need. Yes the panels are fixed to the roof and not adjustable, but this really hasn't been too much of an issue for us. We aren't big energy users. The lights are LED, so the only other power need is the water pump (minimal) and the furnace fan (that can draw some power). Maybe a DVD now and then. We don't need extra power for medical or other needs. On my short list, however, is to add some remote panels like what Reed has done. Reason is that often we will be parked in the shade to stay cool, but there is full sun just 20' away, so a remote panel really makes sense. One thing to consider about solar is that the charge controller should be as close to the battery bank as possible for best efficiency. So if your remote panels have a built in controller, they are quite a ways away from your batteries and there will be power loss. Perhaps someone who knows more about this could chime in. If you get the solar package, with the plug in for remote panels, you will be operating at much greater efficiency. You also wont have to have to be pulling out your batteries and putting clamps on them every time you want to charge up. AM Solar sells a nice Zamp suitcase PV panel with no charge controller which is the way I will go. You'll find a ladder very helpful to brush the snow off your panels if you travel in the off seasons! https://amsolar.com/rv-solar-panels/solar-z120-f 2. Batteries. If you get the solar I would highly recommend upgrading to the AGM batteries. They have greater charge acceptance than the std batteries (charge quicker) and much greater capacity. They are a very high quality battery. The two fit like a glove in the battery box. Very glad I bought them! 3. Fabric upgrade. I found the commercial spec fabric Oliver offers a bit scratchy. So Anita told me how many yards they needed to do our Elite...16 yards IIRC. We went down to the local upholsterers shop and looked at many different materials. After we selected what we liked. They rolled it up and sent it off to Oliver's upholsterer. Couldn't have been easier! Then Oliver credited us for not using their fabric. In the end, the upgrade cost us an extra 75.00 and, really, I would have paid more. We love the feel and the look. The Oliver is pretty Zen inside, very simple, some may say stark. So don't underestimate the importance of the fabric you choose. Lots of other options we choose are now std., like the reading lights, which we use more than anything else. Porcelain toilet is now std. as well. We did spring for the Wifi and Cell booster. These have worked well. But when you are really out in the boonies the cell booster won't help you. Does work well in the fringe areas however. Did not spring for the counter tops. We were already over budget. Figured I could install something later if I felt the need. So far I haven't! If you can live without a microwave, absolutely delete it!! You will get a very useful cabinet in its place, and in the Elite, this is especially helpful as there is no real pantry like in the Elite 2. Can't imagine what a PITA it would be not to have that cabinet! Finally, get a fridge button guard for your Dometic fridge: http://www.rvwidgetworks.com/Photo-Gallery.html The Elite is narrower than the Elite 2 and sooner or later, you will bump the on/off button. Happened twice to me before I finally installed one. Luckily, I discovered the fridge was off before the ice cubes melted...God forbid...! You're going to like your Elite. Very easy to tow and back up. A pleasure to camp in, and you can put them just about anywhere where the big rigs can't fit. We sure like ours. Good luck!! Dave

-

The entire interior of the cabinet is some kind of birch (or the like) plywood. That's just the lighting fooling the eye in the pic. All surfaces are the same color. There is also a rubber mat on the floor. Wine bottles fit nicely in there! Dave

-

We opted out of the microwave and am sure glad we did. The resulting cabinet has been an incredibly useful and much needed pantry for storing all kinds of stuff we use on a daily basis. In the Elite, there is just not a lot of storage, and this cabinet has really been useful. The interior dimensions are: 21-1/2"wide x 14" deep x 13" tall. The actual opening is a bit smaller because of the face frame and the door itself. That opening is 19-1/4 wide x 11" tall. Dave

-

Reed, I am also looking and researching a new TV. I really like the Chevy/GMC line of trucks. Although I was thinking more along the lines of the 6.2 liter. There are also rumors that Chevy may bring back the 4.5 Duramax for 2019 but this is purely conjecture at this point. They are working on a small diesel of some displacement for the 1500 however. The one thing about these trucks that has given me great pause is the size of the gas tank, only 26 gallons. Where we go, gas is often limited, and there have been a few times where I was sure glad I had a 35 gallon tank in my Ford van. Have you been caught short at all, or do you carry extra gas? 26 gallons at 10mpg is not so great a range. I agree with you that upping the octane in the mountains has made a noticeable improvement for me. Nice truck you have there. Can't wait to finally settle on one myself! Dave

-

It's Raining, it's pouring, all the windows....

DavePhelps replied to KarenLukens's topic in Mechanical & Technical Tips

Reed, I have the old style lights, but they leaked as well. They were "sealed" at the factory with silicone, which failed promptly. I cleaned and rebedded them with a very high quality butyl tape. This has worked beautifully. You don't need no stinkin' gaskets, just the butyl tape. The 3M 4000 would be my next choice, but it would be a far second. As for silicone....never. I posted a while back on the procedure I did. Just in case you missed it. I have not seen the new porch lights, and perhaps just squeezing some 3M 4000 in the screw holes would be enough in a pinch, but I think sealing the perimeter of the entire fixture would be best. If you do elect to just seal the holes, put a slight countersink on them, and make sure they are bone dry (hair dryer) before applying sealant. Good luck. Dave http://olivertraveltrailers.com/topic/porch-light-reseal-and-silicone-removal/ -

Yes, I just found out that there is a steel rod down the center of the Magnesium(?) anode (thanks YouTube). Saw a picture of a very spent anode but the steel rod was still fine so no worries about it falling off inside the tank. So do you folks also do the vinegar soak and rinse? I just am wondering how far I have to go with this. Is there a way to siphon vinegar through the winterization port (in back) so it just goes into the hot water tank? Or do I have to remove the T/P Valve and pour it in there (more likely)? Lots to learn here. Thanks Dave

-

Thanks Bill, I didn't want the anode to break off from the nut! Mine is two years old as well. Guess I'll give it one more year and see. I also recommend anyone doing this to flush their tank out with a wand made for the task. A lot of junk came out (the ring of granules in pic). Be sure to close the bypass valve behind the tank first so as to not accidentally blow any debris into the valve. Dave

-

Cleaning and winterizing today. Do you think it's time for a new anode? The bulk of the oxidation is at the nut. The rest of the anode is a little pitted, but in pretty good shape. Is this typical? First time dealing with this. Dave

-

So I guess Oliver needs to start including tarps with their send-off kit! Maybe white with their logo on it. Seriously....what is going on here? Dave

-

It's Raining, it's pouring, all the windows....

DavePhelps replied to KarenLukens's topic in Mechanical & Technical Tips

So for those who have reset their windows because of leaking issues. Did you set them in butyl tape and finish off around the perimeter with a bead of 3M 4000? Or...? Just curious as to the best procedure. Personally, I'm not a fan of silicone at all, in any shape or form. Really sorry to hear of these issues. Best leave it at that.... Dave -

Cold weather/ winter camping tips

DavePhelps replied to SeaDawg's topic in Mechanical & Technical Tips

So regarding draining the outside shower hose. Since there are no inline shutoffs in the hot/cold pex lines that feed the ext. shower, I assume that "by draining the outside shower hose", one is just letting the chromed flex line drain by gravity and that's it? It would be nice if all those water lines in the back corner of the trailer could be drained when needed as this is probably the most vulnerable area in freezing weather. The brass backflow valves are at particular risk. I know because one of mine was busted open when we picked up our rig in late March. It had been out in the weather for a month or two before we could get out to pick it up. Luckily, the leak showed up right away during our shakedown at Fall Hollow, and was replaced. Dave -

One last effort! Since the system works great in our 2015 Elite, something is being missed here. Just in case that you were not aware, the volume control for the TV when setup as described above is through the Furrion, not the TV remote!! We have to get up and adjust the volume by turning the volume knob on the Furrion unit. You probably already knew this but just in case.... Sometimes the most simple things elude us. If this isn't it, definitely give Oliver a call. Dave

-

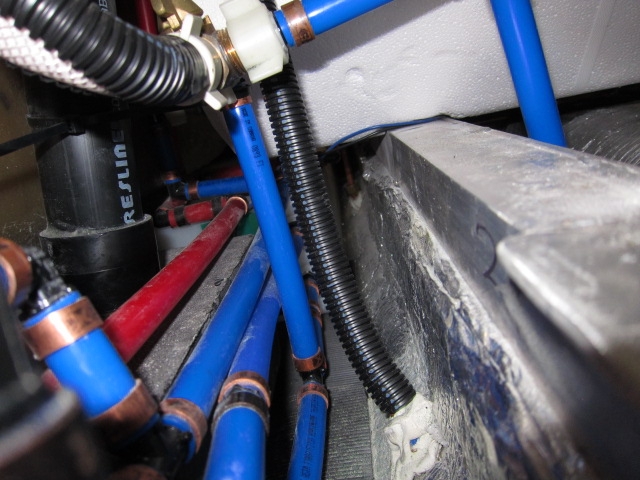

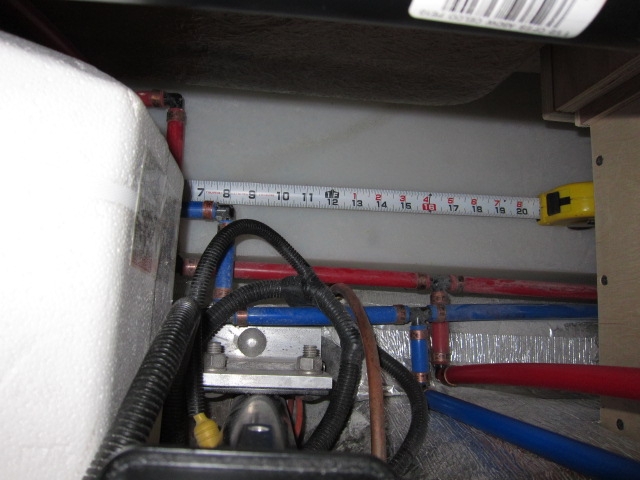

I've been learning a lot here. Lots of great ideas and techniques posted and many thanks to all who have contributed. Having looked hard at my Elite and considering all that has been presented here, I can say for certain that the only way forward for me is to spin weld a fitting on top of the tank. There is just no room at all to work with the existing fittings, even using John's technique. The water heater tank mostly centers on the back of the FWT, completely covering its fittings, there is no room. Even if I was to remove the hot water tank, which would be a huge project for me, there still would be minimal room with high chance of failure. You can just make out the back of the FWT in this pic: There is a clear area on top to spin weld a fitting but it is about 12" forward from the rear of the tank. I guess this means I would have to use a longer siphon tube that would reach to the back of the tank, which is where I believe it should be located. Tape is hooked on back of FWT above fittings. I sure wish Oliver was a little more supportive about this issue. At least identifying shops that could do this work for us folks who live very far away from Hohenwald. I told them about this issue 04/15 when we kept loosing prime on our trip home. It didn't take long to discover the problem. I still am in disbelief that, as well conceived as the Olivers are, that this PITA water system ever got off the drawing board. Sure glad we all have each other to help make our Olivers what they should be- the very best! Dave

-

Sorry that didn't fix you up. Should have looked at the video first.... I'm pretty sure that audio between the TV and the Furrion is through the HDMI cable (someone please correct me if I'm wrong). If you are still not getting sound and have a connection at the TV, then the connection at the Furrion needs to be checked. On my Elite, there is no access port in either of the overhead storage compartments next to the Furrion. Not sure about the Elite2. You may have to remove the Furrion's trim ring to access its mounting screws and remove the unit enough to inspect all the connections. Never done this so can't advise. I'd call Oliver about the best way to proceed. Good luck! Dave

-

OK, try this. I also have a 2015 Oliver. You will need the HDMI cable. Check the back of your TV for it. Turn on your TV and with the TV remote, press the MENU button. Scroll over to AUDIO, then scroll down to TV Speaker, then turn the TV speakers OFF. Go back to main menu. Scroll over to SETUP, then to AUDIO OUT, change from Variable to FIXED. On your Furrion (not the remote) set Sterio to AUX. That's what I did and it works great. Use the A, B, C buttons to select which of the trailer speakers you want to use. Hope this works for you. Dave

-

So if there was a small amount of water in the tank, say an inch or so and it froze solid, would that really hurt anything? There is plenty of room for expansion. I just wonder about this as we use large plastic tanks (250 gallon) for watering trees and there is always some water in them through the Winter. It does freeze here, though not probably as hard or for as long as other parts of the country, and the tanks are fine come Spring. I just hate having to put AF in the tank the way it is currently designed. It's just too hard, if even possible to get a complete drain and flush. I know they say it's non toxic but, well, I prefer not to use it in that location. Traps yes, tank no. The rest of the water lines I carefully and thoroughly blow out with compressed air. Dave

-

Wow, quite a thread John. Thanks for diving in to this. Still not sure why you decided to swap the intake/outtake lines out. Wouldn't it have been just as easy to put the new siphon tube in the lower hole? Or were you worried (as I am) about access down there. Curious to see how well your setup will work when it comes time to drain the tank. You may have to get under you Ollie and suck on the exterior drain port to get it all going! But hopefully not. Curious also about your pic of the factory spin weld fitting. It appears to be of a different design than the one that was sent to us. Can't figure out why there would be any tank showing inside the fitting as there has to be that collar on the weld side of the fitting to key in the fitting for spinning. That collar is larger than the FPT part of the fitting. To have to file the tank out to get the tube through is a real PITA. I asked Oliver about months ago as I was worried about this very thing. They assured me that 1/2" pex or copper would go through. Hmmm. Finally, do you think in hindsight that you could have gotten a copper bend in your tank instead of the PEX bend you made? I'm a little worried about the PEX in a compression fitting that is unsupported by the little support sleeve that came with that fitting. I think copper would better resist deformation by the compression ring in a pass through situation. But perhaps with the pressures we are talking about, the PEX will do fine. Thanks again for the write-up. It must have taken a bit of time and is appreciated. Dave

-

Hey John, Thanks for posting this! I was just getting ready to do the same after receiving my "kit" a few days ago. I received the same stuff you did. No instructions or diagram. No spin weld tool or suggestion of where to get one, or tank prep/tips for installation. No mention of the best place to weld the fitting on my tank (Elite1). No mention of the notch in the base of the pickup tube someone posted a picture of.... Also, doesn't that compression fitting still need to be drilled out so the pex can pass through it? Yes, I am a wee bit frustrated. Guess I'll be calling in about it soon. Still hoping to somehow use the original outflow fitting. My thought is to place the pex in the rt. angle bracket they sent and gently heat it up so it maintains that shape. Then slide it through the comp fitting and attach it to the tank. Access is the big issue for me. But spin welding the fitting won't be a piece of cake either in my little trailer. Maybe with a laminate router there is enough room.... Am I going to be a happy camper when this project is done! Dave

-

Full cabin-length clothes line: need your ideas please!

DavePhelps replied to John E Davies's topic in Ollie Modifications

John, How about a simple D-ring like this. Mount two of them and rig up a length of parachute cord with a sliding tension knot at one end. You could add hooks or tie directly to D-ring with a quick release hitch on one side and your tensioning knot on the other. Maybe too backwoods for you but how often will you be setting it up? This D-ring is stainless steel with a welded ring so very strong if properly mounted. Dave -

Glad you heard back from Oliver. I would still recommend weighting up your Taco to 360+ pounds in the rear and measuring the drop. I suspect it will be more than 1". Consider how much weight you plan to carry in the bed as well as that will drop it even more. Sounds like you're zeroing in on it though. Good luck! Dave

-

Reed, This is the exact truck I have been drooling over!! Curious if you took the 6.2 out for a spin, and more curious to hear how the 5.3 does pulling your trailer. I was pretty set on the 6.2, but if the 5.3 is up to the task, then the mileage would be better. I've heard that the new 8 speed transmission has greatly improved the performance of that engine (well, both of them actually). Congrats on your new rig! Dave