-

Posts

390 -

Joined

-

Last visited

-

Days Won

20

Everything posted by DavePhelps

-

That is "two Falls ago"... Damn auto spelling.

-

Glad you made it back safe and sound! Sounds like quite an adventure. We had a similar drive back from Red Rock Lakes NWR two For ago... Being chased by a major early Winter storm. The Oliver sure was/is a cozy shelter to retreat to when the weather gets ugly. And they do tow like a dream. Glad you made it home safely. Dave

-

Man those reveals are pretty bad. When I get home I'll check my window and get back to you. That shouldn't have left the factory like that.

-

George, Did you take off the AC shroud on top of your trailer and make sure all the weep holes in your AC pan are clean? Also did you remove the interior AC cover and make sure the mounting bolts are good and snug? Finally, When Oliver installed my AC, they forgot to connect the condensate drain tube coming off the AC unit to the long drain tube that exits the trailer. So make sure that is in place as well. I bring this up because I'm wondering if that window, as it is, could be the cause of all that water intrusion. You may be able to tweak the hinge a bit to equalize the reveals between window and frame. But first I would for sure tape it off from the weather and see if water is still coming in. Instead of taping the seams, I would tape some 6mil plastic across the top and sides of the entire window on the gelcoat. Don't cover any marker lights or the Oliver logo light, you'll have to eliminate entry points one at a time. That way you know for sure if it's the window or something else. Good luck, I feel your pain! Dave

-

Frank, I know you asked for a regulator with a gauge, but this unit has worked very well for me. It is simple, bombproof, and as far as I can tell, has a much higher flow rating than the cheaper units: https://www.rvwaterfilterstore.com/Fixed.htm If you still need or want to have a gauge, this store also sells those, although they are expensive. I've been very happy dealing with this outfit and their products are top notch. Dave

-

Just got to wondering if maybe kerosene lantern wicks may do an equal if not better job than pipe cleaners. Plus no metal wire to poke you or leave rust stains. https://www.amazon.com/Paraffin-Kerosene-Lanterns-Genuine-Superior/dp/B01BYLYQYY/ref=cm_wl_huc_item I might give it a try. Dave

-

Hey Scotty, Glad it worked out for you. Mine still looks like new and has worked great! Dave

-

Jaque, Having the Elite1, I can not fit the 30# tanks so I figured I'd just carry an extra tank for early and late season, or extended trips. The three 20's will carry a little more propane than the two 30's. Yet another option, although very expensive, is to go aluminum tanks. IIRC, a full 30# aluminum tank weighs about the same as a full 20# steel tank. Vintage Trailer Supply has them, and you can order them with gauges as well: https://www.vintagetrailersupply.com/Aluminum-Propane-Tanks-s/1.htm You'll find that propane really goes a long way in an Oliver. The extra insulation and the double hulls really make a tight unit. At least in my small Elite1, I barely get in to the second tank after two weeks of cold weather use. If you are still worried about running out, I'd just get an extra steel 20# tank. Much cheaper than going aluminum or composite. I always refill my own tanks. I feel it's a far better option as far as safety and value. Propane is everywhere and easy to fill. Good luck! Dave

-

geO, This is interesting. On my 2015, all the windows, maxxair vent, bathroom fan, plumbing vent, and all the other penetrations were factory sealed with 3M Fast Cure 4000 UV. Oliver uses this all over the trailer inside and out. The porch lights and the markers were factory sealed with silicone. Many of those sealed with the silicone have failed. I would not use silicone over the 3M 4000. I had a few gaps here and there in the window trim that I redid. And I also cleaned up some "less than adequate" joints on the interior, especially in the bathroom and around the kitchen sink. The only issue with the 3M 4000, other than it's cost, is that once opened, it has a very short shelf life. So get all your spots lined up and do the inside and outside all at once. Cut the tip on your tube sparingly! Clean your rig well to remove any dirt and wax. Give a quick pre-wipe with acetone or MEK (my preference) on a rag around where the joint is. On the inside, I then tape both sides of the joint with thin blue tape (delicate surfaces). Carefully squeeze a fine bead in the joint and smooth out with your finger. Immediately pull the tape and lightly swipe again to get the ridges from the tape to blend in. You may not like to, but I wipe a little paint thinner on my finger to lubricate it a bit, works good. Too much sealant in the joint and you'll have a mess. Use the sealant sparingly. The first wipe should be tight to the tape edge, not going over the top. It's a judgement call depending on the size of the fill. The 3M 4000 can clean up with paint thinner so if there is some that gets away from you, you can carefully clean up with that. The stuff skins over pretty fast so be organized, work small areas, and don't forget to breathe! On the outside, I just very carefully apply the bead and smooth it out with my finger. If the sealant line gets messy, some thinner on a rag drawn along the edge of the sealant cleans it up nicely. Warning though: don't use thinner or any other solvent around your chromed plastic light fixtures, it will mess up the finish! I don't know why Oliver recommended silicone to you when most of what you'll be sealing was done with the 3M product. Good luck! RE: the marker lights, I would like to hear how others have sealed those as I think I have a few leakers, and yes they were factory sealed with silicone! Can the chromed escutcheon ring be removed somehow for sealing? Dave

-

Donna, I have not found the Google Maps ETA function to be accurate, certainly not for someone towing a trailer at responsible speeds. Maybe a for a Porsche on a warm summer day! Definitely add time to their estimate. That has been my experience anyway. With regards to the WDH. My TV is a 3/4 ton van so no need to have it. For you, you will have to check. Many Unibody style cars are not rigid enough to handle the forces the WDH creates. Yours may be OK but check. I'd get one if it will handle it. From E-trailer: https://www.etrailer.com/question-241876.html Dave

-

Donna and Duane, I live in Portland and made the trip you are talking about when we picked up our Elite1. Let me tell you, it is a long way out there to Hohenwald TN!! Just a quick look on Google Maps will tell you that from Portland it's 2370 miles out there and another 2370 miles back. In the winter, your average speed towing, if you're lucky, will be around 50 MPH. And those are not going to be easy miles. At 50 MPH average, that is 47.4 hours of driving, and I think that is very optimistic. Potential snow/ice, rain and wind, backups, crazy drivers.... Days will also be short and you will be driving in darkness for several hours each day. I've towed in these conditions (thankfully for not very long!) and it is quite exhausting. To attempt this trip in just 3 days would be most unwise IMHO. Another option that hasn't been talked about, which is what we did, is to delay your pickup until early Spring. Our Ollie was completed about the same time yours will be, but we had them hold it for us until April, when we made the trip out to pick it up. Much better this way! And gives you time to enjoy and learn about your new trailer while taking in the wondrous early Spring throughout our beautiful country. I wish you the best of luck on your trip whenever you decide to go. Be safe! Dave

-

We have the smaller Elite1 with the full size rear bed. We had been just throwing a sheet over the seat cushions and putting our sleeping bags on that. Worked OK for two seasons but recently ordered this 100% latex foam topper from Amazon and it has been incredible. In fact, we like it so much we bought another one for our home bed. I took the foam to a mattress shop to get cut to match the curves of the Oliver (I made a template), they didn't even charge me. It's 2" thick and we just put it on top of the seat cushions. I also had the single piece of foam cut down the middle to make it easier to take up and store in the van if I need to set up the big table for company. Just another option for those wanting a little cushier bed. https://www.amazon.com/gp/product/B00UYGAH4O/ref=oh_aui_detailpage_o03_s00?ie=UTF8&th=1 Dave

-

I would underscore everything that Sherry said. We love the size of the Elite. You can tuck them in just about anywhere, and it is a very cozy shelter. But.... If you are much over 5'10", you might feel a little cramped for headroom. I'm 5'10" and can stand tall in the main cabin with maybe 1.5" clearance. In the bathroom I have to stoop a bit to take a shower, but not so bad. For two folks, you learn how to move within the trailer. It's like being on a boat. The Elite is also narrower than the Elite2 so if you're more on the plus side, you may appreciate the extra width of the Elite2. Since this is our first trailer, we decided to go smaller and am glad we did. Everyone has different requirements and are of different sizes! We don't travel with pets so that is not a concern for us. Best to visit one or both if any are near by. The Elite will also be quite a bit lighter (but still pretty hefty) and have less tongue weight if you have a smaller TV. Good luck. Dave

-

Toyota Tacoma and Elite II ??? Anyone tow with this combination?

DavePhelps replied to doc foster's topic in Towing an Oliver

So I'm trying to figure the CAT scale readings. If the Rumline's trailer axle weight is 5560 lbs, and if his tongue weight is indeed 620 lbs, would you add these two together to get the total weight of the trailer?? To answer the OP's question, I personally like the Taco but do not think it would be a good TV for the Elite 2. Most E2 owners seem to be weighing in 5000 to 6000 lbs. This is pretty close to the Taco's max 6800 lb. max. tow rating (this figure is reduced with options like crew cab, 4WD, bed length, and other options). More importantly, it's max payload is too low, 1120 to 1620 lbs. If your tongue weight is 500 -600 lbs, you have a 200 lb canopy, 300 lbs passengers: that's over 1000 lbs just for that. Plus only a 21 gallon gas tank. You will also absolutely need a WDH with any midsized truck. I have an Elite1 and am going through all this. I would dearly love to have a mid sized pickup as it would also be may daily driver, but I just would not feel comfortable using one in the Inter Mountain West where I mostly travel. If the new Chevy/GMC 1500 with the new 3.0 Duramax Diesel has an exhaust brake like the 2.8 does, I would be very tempted to go that way. If no exhaust brake, then I think the F-150, HD payload pkg./max tow 3.5 Ecoboost will be the truck I get. It also has a 35 gallon gas tank and comes with LT tires. Good luck on your truck quest. Dave -

Nice truck! Out of curiosity, what is the payload rating (located on sticker on the driver side door jamb)? Could be just right for my Ollie1....maybe....hopefully. Dave

-

I really like the Canyon with the 2.8 Duramax. In fact it is high on my buy list. Just waiting to see how the larger Silverado with the new 3.0 Duramax plays out. Just remember with all trucks that the tow capacity is hardly ever the issue, generally speaking. It's overloading your payload capacity where people can get in to trouble. The Canyon in 2WD, Crew cab, and short bed has a 1507 pound payload limit. 4WD and long bed options would reduce payload further. Ollie2 has a tongue weight of 460 lbs (from website). The tongue weight would be even more if you option the twin 30# propane tanks and have other stuff in the front like a generator. Add 2 passengers, say 300 lbs, that's 760 lbs minimum payload and you haven't begun to load your gear. Pack water? 8.34 lbs a gallon... Firewood? Fiberglass topper? etc. In this scenario, you have 740 lbs to work with before you're technically overloaded. I totally agree with what Overland said, some folks don't mind creeping up to the edge or even going over it, others like to have a large, maybe even an extreme safety margin. I will say however, from what I have read online regarding these issues, is that if you were ever in an accident and it was determined that there was an overload situation with your TV, you could held liable for all damages, and/or receive no support from your insurance company. The Canyon is a great and capable truck within it's design parameters, you just need to figure your payload needs and the tongue weight of your trailer, and then assess your personal risk tolerance. Personally, I take this towing stuff pretty seriously. I want my hitch to be setup properly, and I want to keep within the weight requirements of my TV. Be safe and happy travels! Dave ps Really looking forward on hearing about how your new Canyon does ScubaRx. With all the payload details.

-

Windows? There has to be a better way, seriously.

DavePhelps replied to routlaw's topic in Mechanical & Technical Tips

Routlaw, the screen is tough to remove, but doable. You have to really compress the springs on the bottom edge of the screen frame, and they are stiff. Then the top will pull out. I also have to pull off my shades to get the screens off. Cleaning the window tracks is no fun! I assume ScubaRx is talking about removing the exterior gaskets to remove the window sash?? Haven't tried it yet. But it sure would be nice to get that sash out of there for the best job. Dave -

Raspy wrote: Any chance you’ll be at the Oregon Coast Gathering at Bullards Beach this month, or Winnipeg next month for the Boler anniversary? No I won't be at either. The summer has filled up fast. Bullards Beach was booked out quite a while ago. Have fun though! Like your setup Pete! Dave

-

Windows? There has to be a better way, seriously.

DavePhelps replied to routlaw's topic in Mechanical & Technical Tips

I have tried but can't get that window out. That would make it so much easier! I lift the moveable sash up in to the frame but no matter how hard I try, I can't get the bottom to kick out. Any secrets?? Dave -

Windows? There has to be a better way, seriously.

DavePhelps replied to routlaw's topic in Mechanical & Technical Tips

Hey Routlaw, how about these? They look intriguing: http://www.truckcamperadventure.com/2016/01/the-dometic-seitz-window-pros-cons-and-a-few-tips/ And this: I agree with you, Oliver could do better with the windows. Dave -

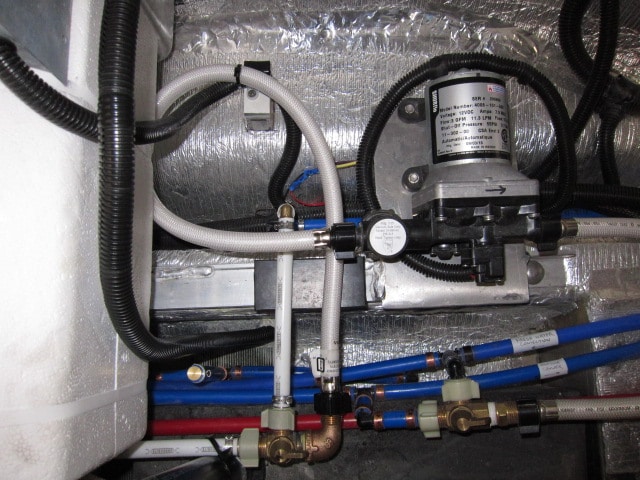

Well I may be kicking a dead horse here, but I finally got around to adding the siphon tube to my Ollie's FWT. Thanks to Raspy and Reed and all others for their input which was of great help to me. I modified Raspy's design just a bit by using a PEX suction tube instead of copper. Don't know if one is better than the other but they do have some subtle installation differences I thought I'd point out. The heart of the setup is the same, the 1/2" brass compression fitting that has been carefully drilled through with a 5/8" bit to remove the internal stop so the copper or pex tube can be pushed through the fitting. The important difference here with PEX is not to use the brass compression ring, but a nylon ring made for that purpose. Here's a pic of the siphon tube setup with all the fittings: Of course the part that gave me the greatest worry was spin welding the fitting on to the tank. I used the same HD fitting that Reed used and I bought 6 of them so I could practice on a piece of scrap plastic I got at a local tank factory (they gave me the scraps). I bought the fittings and the driver from here. They have all the fittings and drivers for that particular fitting that you need, and are very fairly priced. I oversized the fitting and also got the HD version for strength. I oversized because I wanted to screw the brass compression fitting into a bushing and not directly into the spin weld fitting as a hedge just in case! Did I need to? Maybe not, but I felt better doing it. The difficulty on my Elite is that it is crowded down there in between the hulls! I'm no stranger to routers, they are powerful, can impart tremendous torque, and things can go South in a hurry if you don't respect that. Reaching down in there with the router was dicey. My grip was tenuous at best, I needed an extra elbow! I could get a reasonable hold and turn it on, but had to change my grip for the critical turning off stage!! I did not want to change my grip with the router running and court disaster. So finally I put two short extension cords together and had my wife at the ready to pull them apart when I yelled out to her. We practiced a few times until we both felt good about it. Four seconds of terror later the job was done....perfect weld! For those used to using routers with wood and who know what can happen, I would say that spin-welding plastic fittings is pretty easy and forgiving. Timing is the most critical factor. I was glad though that I did a few test tries first, and at only .35 cents a fitting, it was cheap to do so. The rest was easy. Since using a PEX suction tube, I did not cap it but cut out 2 tabs on the bottom on my table saw to keep the tube 1/4" above the tank bottom. Everything else was just as Raspy and Reed did in their video. Here's the pic of the installed suction tube. It's actually straight, camera was tilted a bit. Here's a pic on the pump side: The pickup tube came out just next to the water heater where I strapped it to the drain pipe to the GWT. You can see the brass pulg in the old pickup tube next to the water heater. While down there, I added a brass elbow to the valve on the left for the flex line to the input side of the pump. Originally, there was none and the flex line was badly kinked having to make such a tight turn: So all is well now. Instead of loosing prime at 36% full. The pump just barely makes it to 6% full. That's a lot of water! Things are looking up! Dave

-

Windows? There has to be a better way, seriously.

DavePhelps replied to routlaw's topic in Mechanical & Technical Tips

Yep, the window wells are a pain to clean, but a very necessary part of maintenance and keeping water from overflowing the wells and into your trailer. After trying a few methods, this is what I have settled on. 1. Completely remove all the exterior gaskets. Don't get them mixed up between windows. 2. Remove interior bug screens. You may have to remove shades as well to completely remove the screens. 3. Open windows as far as you can. 4. Remove as much of the rubber slotted track as you can from the window frame. IIRC, the bottom track goes under the sliding window and is captured, so I pull up as much as I can. 5. Then with shop vac and a duster brush (3" paintbrush) I remove all the debris, brushing it into the vac. I find doing this dry is way better than trying to clean with water and washing out the debris that way. It just turns into a gunky mess with water. 6. Once all the major junk is out of there, I'll finish cleaning the frame with a damp rag and Citrisolve (or the like). 7. Last step! While all the gaskets and rubber track are out, I clean them as well with the damp rag and cleaner and finish them off all sides (once dry) with a good wipe down with 303 Protectant before re-inserting. The 303 makes the windows slide real easy and also protects the gaskets from UV degradation. Seems like a lot (and it is) but that's what I do once a year. My trailer is a 2015 so not that old, but the windows haven't leaked and the gaskets look new. YMMV depending on the roads and environments you travel. Hope I didn't forget a step. A lot of the work becomes apparent as you move along through the process. If someone knows a easier way to do this I'd sure like to hear about it! I'm with you though about finding the ultimate RV window. Maybe the frameless types I'm seeing on the new super rigs out there? Not sure how they function though, or if they don't have their own issues. Happy trails! Dave -

First thing I would do is get up on the roof, pop off the AC shroud, and have a look at the fan and condenser fins. These fins can be easily clogged, especially if you're using the AC around Cottonwood trees when they're seeding (like now). Dirt and pine needles also get in there. I blow mine out carefully with compressed air (I have a radiator blow wand), some use water. Just be careful not to flatten or damage the fins. With my Mach8 unit, I have the fan on low and that is plenty! Don't know about the Dometic units they now use. If it was working before, then that's where I would start. Good luck and keep us posted. Dave

-

A/C maintenance and Condensation tube

DavePhelps replied to DavePhelps's topic in Mechanical & Technical Tips

OK, just saw the other thread, been gone for 2 weeks so missed it. Still wondering why I can't blow air out the condensate tube though. Dave -

I am trying to figure out if my condensation tube is plugged. I pulled the cover off and you can see the condensate pump and tube in the pic. I tried blowing some mild compressed air into the clear tube and then in to the pump but no air came out the discharge tube at the driver side rear of the trailer. Anyone know which is the discharge side of the pump and shouldn't I be able to blow air through it so air comes out the drain tube at base of trailer? I have the older Coleman Mach 8 model. I also rarely ever use the AC. I have also been having a few drips come in to the trailer during heavy rain. I suspect the AC is involved. Water appears to be running down the tube to a low spot and then dripping between the hulls on to my solar monitor wiring, where it drips out right on to my face when sleeping! This water caused the monitor to fritz out. Luckily I was able to disconnect it and let it rest for a few minutes, then plugged it back in and all was good. Stuffed a washcloth up there to intercept any more water making its way to my monitor. As far as general maintenance, all I can think to do is keep the pan clean and blow out the fins clean. Anything else I may be missing? Thanks Dave