Chukarhunter

Members-

Posts

111 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Chukarhunter

-

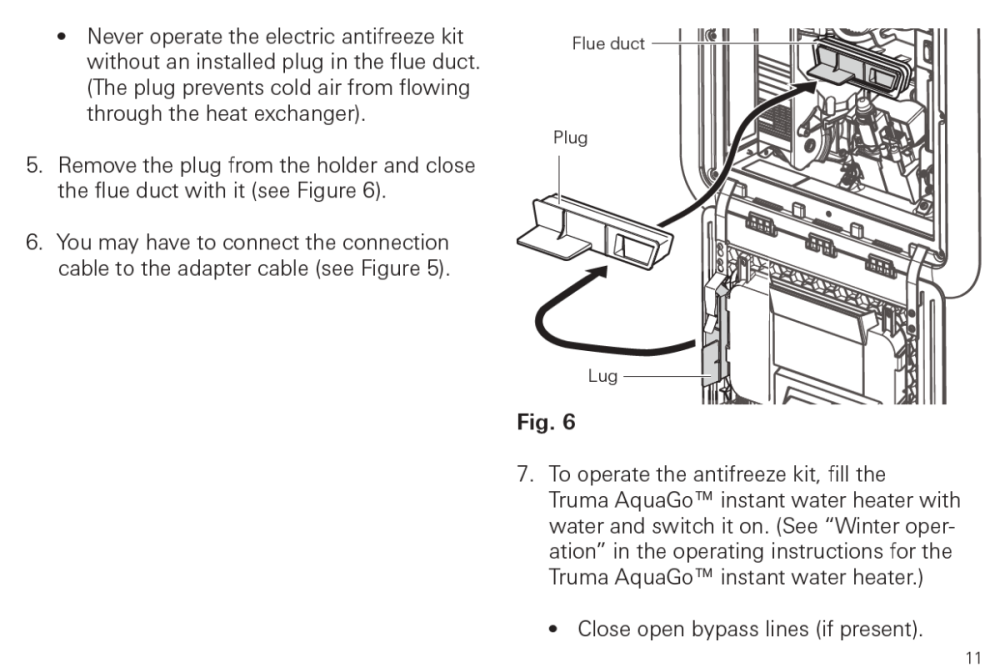

You should already have a plug clipped into a holder on the inside of the Truma door. It looks like every Truma comes with an exhaust plug even if no electric antifreeze kit is ordered. See picture below from the electric antifreeze instruction manual. I used the electric antifreeze kit several times before I realized that the plug existed and was supposed to be used. Oliver should really make a point of explaining how to install and use the antifreeze kit upon delivery. I had to teach myself.

-

CO detector goes off, ?? false alarm

Chukarhunter replied to Dave and Dana's topic in General Discussion

With the help of Mike Sharp at OTT, I think we may have identified why the Norcold control panel leaks outside air into the trailer around the upper front control panel . It is unlikely related to the combustion seal that seals the mounting fin of the refrigerator to the cabinet, nor is it due to an incorrectly sized cabinet opening. Norcold appears to have engineered an approximately one square inch penetration (hole) between the back of the trailer and the inside front of the control panel. Mike provided the following picture of what the backside of the control panel looks like before the refrigerator is installed. Note there is an approximate 1 inch square hole in the circuit board. This allows a direct path for outside air to enter the Oliver, basically negating the effectiveness of the combustion seal. Everyone's Ollie with this 3-way Norcold unit probably has this defect. A simple fix (hack) would seem to be to tape over the 1 inch hole on the circuit board. Unfortunately, there is no way to reach the back of the control panel to do so without pulling the refrigerator out. Mike was going to take this up with the engineering committee to see what, if anything OTT could do without running afoul of the Norcold warranty. Hopefully when Johnwen checks in with OTT next month, we will know more about what can be done about this, including whether Norcold will accept any accountability. OTT has gone to extraordinary lengths to make the Oliver a true 4-season (and safe) trailer. It is unfortunate that Norcold appears to have undercut OTT's best efforts. -

You said that you winterized the trailer when you got home and installed the Truma anti-freeze option. I am assuming you mean the 12 volt powered electric heating element into the Truma. I have installed the same option. If I am understanding you correctly, when winterizing the water system, you closed the water valve to the Truma and left normal water in the Truma to be protected with the electric antifreeze option (which is nothing more than the equivalent of a 12 volt dipstick heater). If that is in fact what you did, turning off the batteries would have cut power to the electric antifreeze dipstick heater in the Truma and it would not have protected the Truma against freezing. The electric antifreeze option in the Truma is really designed to protect the Truma while in transit during freezing weather when the propane is turned off while towing. To gain full protection from the electric option, you need to also install the provided plug into the exhaust port of the Truma when using the option, or cold air can enter the Truma combustion chamber while driving and potentially overpower the weak electric antifreeze heating element. If you later de-winterized the trailer and tried to start the Truma on propane before actually turning the propane on, and/or removing the plug from the Truma exhaust port, then the Truma would have tried to ignite a few times, and then it would have locked out. Just like the Norcold refrigerator, if the unit tries to ignite on propane when the propane is turned off, the unit locks out and must be turned off and then on again to reset the error codes. Same thing if the Truma senses a blocked exhaust port. When winterizing the trailer, it is probably best to follow the winterizing instructions in the manual that basically call for closing the water inlet valve to the Truma and then draining the water out. It only takes a minute or two. The electric antifreeze option will also work when winterizing, but then you will need to ensure that the batteries provide continuous power to the trailer over the winter to run the electric antifreeze option. Simply draining the water from the Truma when winterizing is a safer approach.

-

CO detector goes off, ?? false alarm

Chukarhunter replied to Dave and Dana's topic in General Discussion

You said the propane was on and the fridge was set to auto and your Ollie was closed up tight for nine hours. One possible cause for the alarm could be combustion air seeping into the trailer through the Norcold refrigerator front control panel. I have evidence that Norcold has a design flaw that provides combustion air a clear path through the refrigerator control panel into the trailer. I am not the only one that has noticed this, which is only evident when the wind is blowing hard into the curb side of the trailer (In my case, the air was coming in hard enough to blow out a small candle). OTT has been great in trying to troubleshoot this with me, but Norcold claims it is not their problem and OTT has not been able to develop an aftermarket repair as Norcold claims that any modification would void the warranty. (It is definitely not a problem with the installation of the refrigerator by OTT as a repair shop told me that OTT's installation was far better than what they typically see). It is possible that there was a very slow seepage of combustion contaminated air (or propane) from the back of the refrigerator into the trailer over many hours. The Ollie is very tight when closed up and it wouldn't dissipate easily. You said you were on shore power so the refer may have been running on 120 volts and not propane. If there were a very slow leak in the propane lines in the back of the refrigerator though, this could also explain how propane got into the trailer. Propane is heavier than air and would immediately pool in the floor area under the dinette and even small amounts over many hours could have set off the detector. I would check for propane leaks outside the trailer at the back of the refrigerator. There have been numerous posts on this forum of the propane detector being too sensitive or going off for unexplained reasons. It is possible that the combustion air path through the front control panel of the Norcold refrigerator has been the cause of some of these false alarms. Maybe they are not all false. You may want to open a repair ticket with OTT so they are aware of your issue. In my opinion, Norcold should take this issue more seriously, because I believe Norcold may be selling a product with a safety related design defect. -

Generator consideration for the Elite II

Chukarhunter replied to Vic and Wanda Shumate's topic in General Discussion

A 2200 watt generator should run your air conditioner but with minimal to no headroom to charge your batteries as John pointed out. Assuming your LE II will have the inverter/charger and lithium batteries, even a 3,000 watt generator will likely NOT run the air conditioner as delivered, depending on how the inverter/charger comes configured when the LE II is delivered from the factory. The reason is the charger section of the inverter is probably set to a charge rate of 100 amps or higher. This means that the batteries will be charging at a 100 amp rate off the generator, which will require about 1,600 watts of continuous generator power not counting the air conditioner. If the inverter/charger is set to a 150 amps charge rate, it will require over 2,300 watts of continuous generator power just for charging the batteries. In both cases, a 3,000 watt generator would be unable to run the air conditioner and simultaneously charge the batteries without overloading. However, there is an easy adjustment that will allow you to run the air conditioner with either the 2,200 watt or 3000 watt generator. The inverter/charger allows the user to customize the charging current from zero to maximum in 5 amp increments. It only takes a minute to change the setting. If using a 2,200 watt generator, set the charging current to zero (i.e., turn the charger off) and start the air conditioner. If the air conditioner runs fine, you can turn the charger back on and gradually increase the charging rate from zero until the generator starts laboring or shuts off. Then you know how much is too much and set the charge rate accordingly. It may be only 10 amps. If you have a 3000 watt generator, you can do the same thing. Begin with the charger turned off and start the air conditioner, then increment the charging rate until the generator complains. You will probably be able to simultaneously run the air conditioner and charge the batteries at close to a 100 amp rate at the same time with a 3,000 watt generator. The best news is that the solar panels will continue to charge the batteries even if the inverter/charger charging rate is set to zero. My personal preference would lean toward the smaller, lighter, quieter 2,200 watt generator, turning off the charger section in the inverter temporarily, and relying on the solar panels to charge the batteries when I am running the air conditioner. Others please correct anything I got wrong here. Thanks. -

As has been pointed out on this forum in the past, it is not really advisable to routinely use the "Auto" setting on the Norcold 3-way due to the risk of accidentally drawing your batteries to empty accidentally. When set to auto and not hooked to shore power, the Norcold will automatically switch to propane. If propane is not turned on, then the Norcold will switch to 12-volt and you won't know. Even if set to Auto and you confirm that it is successfully running on propane, if the tank were to run out of propane and you didn't realize it, the Norcold would switch to 12 volt and once again, you would not know. The Norcold on 12-volt can draw up to 15 amp-hours per hour which puts a big draw on the batteries. If one manually sets the Norcold to gas but gas is not available, the refrigerator will generate an error message alerting you if the gas is not on, or if it runs out, prompting you to investigate why the Norcold is not getting gas. The choice of power source is best made as a deliberate decision. An exception might be if you were away from the trailer all day and wanted the security of 12 volt backup should the propane supply be interrupted to the Norcold while you are away.

-

There is no doubt John that pleated paper filters do a better job filtering the air than the oiled filters like the K&N. I will admit that often when I have gone hunting or off-highway driving in dusty conditions I would switch in an OEM paper filter for the trip. I really can't remember why I decided to go with the oiled filter 20 years ago for everyday driving but I think it was based mostly on cost saving of not having to replace the filter every few months. Maybe I have just lucked out as my engine has not appeared to suffer any issues that could be attributed to dirty combustion air. I wouldn't recommend anyone switch to an oiled filter though. But if someone is like me pulling an Ollie with an older marginal tow vehicle like the Tacoma, etc., they may want to try a high flow air filter out. Rivernerd, I don't know if changing the filter caused the engine sensors to modify the engine combustion parameters. Your thought though triggered my memory that before heading up the pass, I also filled the engine with non-ethanol premium which I rarely use. It is certainly possible that the change in fuel affected engine performance. One would speculate that non-ethanol fuel would increase the performance, but maybe not the case at all. Others may have insights on the differential effect of non-ethanol versus E10 fuel in older vehicles like my 4Runner under heavy engine loading. I just don't know. And no, I do not intend to keep towing with my 4Runner too much longer. I truly wish I could have switched it out by now but live in the heart of Portland, OR and I cannot fit a full sized pickup in my "less than normal height garage". I originally bought the V8 4Runner because it was the beefiest tow vehicle I could fit in my garage. I rebuilt the garage 8 years ago and was able to squeeze a few more inches of height out of the door in the process, but still not enough for a full size pickup. Based upon preliminary specs of the 2003 Sequoia, it appears that even the new Sequoia may be an inch or two too tall as well. The Rivian SUV will fit nicely in my garage but the long range version is well beyond a year in the future by which time I hope there are more options for me. To the extent that I am abusing the 4Runner, it is probably the transmission that is suffering the most abuse although when towing, I almost never let the automatic transmission pick the gears or downshift on its own, and often shift gears manually. I never use the top (overdrive) gear when towing the Ollie. And I try to keep my GTW under 5,500 lbs even with full water tank and full propane tanks. Living on borrowed time I know.

-

If one asked me this question a year ago, I would have said probably not. I have a different opinion today. Depending on the vehicle, I have anecdotal evidence that some vehicles may benefit from a high performance air filter when towing. This includes my vehicle. By way of history, I have used a washable K&N air filter in my tow vehicle since I purchased it in 2004, only substituting a stock pleated air filter when removing and cleaning my K&N. I switched to the K&N only to save money on replacement air filters. I never really believed in the claims of more engine power. I was somewhat concerned in the beginning that the K&N wouldn't protect my engine as well as the stock air filter but I was wrong. My decision paid off as I went almost 200,000 miles on my first K&N filter. I now have 225,000 miles on the engine and the engine still burns less than 1/2 quart of oil every 5,000 miles between oil changes. I have saved $100s of dollars over the last 20 years by being able to periodically wash my air filter rather than buying a new one. But I never bought into the "more engine power" hype. Until recently. Almost any tow vehicle rated to tow the weight of an Ollie will perform acceptably on flat highways at sea level. Where the marginal vehicles like mine struggle is climbing hills and performance can decline rapidly as ambient air temperatures rise and/or altitude increases. This is simply due to the fact that warm air is less dense than cold air and air density (i.e., air pressure) drops as altitude increases. Less dense air means less oxygen in the combustion chamber and lower combustion temperatures. Of course, no air filter will compensate for lower air density (that is where turbochargers come in). However, if the air filter is at all restrictive of airflow required to achieve the full compression ratio in the cylinder, then that engine will lose even more power on top of the power loss due to the air being less dense. In most driving situations, even a clogged air filter will still pass all the air that the engine requires because most driving conditions (cruising on the flats in overdrive) don't draw on much of the power or torque capabilities of the engine. Marginally under-powered tow vehicles on the other hand occasionally seek to draw on the full capabilities of the engine when climbing grades and accelerating to the speed of traffic. This is largely because the engines in marginal towing vehicles often need to access the full torque capability of the engine on hills which means by definition that they need to operate at higher engine revolutions per minute (RPM). As engine RPM increases, the volume of air that must pass through the air filter increases linearly. For example, an engine that requires airflow of 50 cubic feet per minute (cfm) at 1500 RPM will require airflow of 100 cfm at 3,000 rpm, or twice as much airflow. in this case, if the air filter is restricting airflow to a little less than 100 cfm, the engine will be starved of oxygen at its factory designed compression ratio and it will have less power. This is not really a problem on flat roads at sea level, but can impair power on hills, especially at higher altitude and ambient temperatures which further reduce oxygen due to less dense air to start with. Last summer I spent time up in the North Cascades of Washington and got ready to pull my LE II over the North Cascades highway from east to west. Thinking that I was way overdue to wash my K&N filter, I stopped at a NAPA store in Winthrop, WA and bought a brand new OEM style pleated filter. In fact, I upgraded from standard NAPA filter to their "Gold" filter that claimed better engine protection (probably with greater restriction in air flow). I then started up the pass and it was like I was driving a different vehicle. I didn't notice a difference until I had to slow down for 30 mph curves on a 4%-5% grade and found if was more difficult to accelerate on the grades from the lower speed. I was baffled that the engine wasn't performing as well as expected, considering the ambient temperature was only in the upper 50's and altitude was under 5,000 feet. When I got home, I installed a new K&N filter and my performance was restored on my next trip towing the Ollie. Was this all in my imagination. Possibly but I don't think so. Might other marginal tow vehicles benefit from using a high performance (high flow) air filter? I don't know. The air filter in my vehicle is pretty small to start with. I am convinced though that my vehicle's performance suffers under full load when using a stock media air filter. Those Ollie owners that have more than adequate tow vehicles are unlikely to notice any real difference from a high flow air filter, but those Ollie owners out there with under-powered tow vehicles might want to try out a high performance air filter, especially if you are heading to the mountains. At best, it will help. At worst, you will save some money over time by not having to replace your air filter again in the future (just wash it). If I have got something wrong here, please chime in. If anyone has also switched from an OEM pleated air filter to a high flow air filter in the past, or does so in the future, I would be interested in learning of their experience.

-

You may have already checked this possibility out but if not, you may want to check the wiring on the back of your thermostat. The wire to the furnace fan seems to be working fine but if your thermostat has a separate wire that goes to the furnace igniter, this wire connection could possibly be loose or corroded. In that case, you will get higher resistance across the wire terminal on the back of the thermostat. It could be that 12.7 volts from the battery is insufficient to overcome this higher resistance. When you plug into shore power, the converter (or inverter/charger) will immediately send 13.4 volts or more to the battery and will pass that higher voltage through to all the 12 volt circuits in the trailer including the thermostat. This may be just enough of a voltage increase to overcome the resistance of a bad thermostat connection and would explain why the furnace works on shore power and in warmer weather. It is a long shot, but cleaning and re-tightening the wiring connections on the back of the thermostat might solve your problem. If nothing else, it rules out yet one more possibility.

-

I can't give you specific advice as my LE II is a 2020 and when I ordered mine, Oliver did not offer any lithium options (they announced availability three weeks after I ordered mine). After purchase, I immediately upgraded to Lithium. The upgrade was painless . Having said that, I would probably order the full Oliver lithium package if I had it to do over again just for convenience and the bells and whistles of Oliver's battery choice. As a point of reference though, I will explain my experience in which I easily upgraded later. Since Oliver had no lithium option and I planned to convert to lithium right away, I asked Oliver to add the solar system and inverter, but I would stick with the standard 2 flooded batteries when I ordered. Oliver said I had to upgrade to 4 batteries (flooded were fine) if I ordered the solar/inverter system because they needed 4 batteries to test out the whole system before delivery. So I upgraded to from 2 to 4 flooded batteries. When I got the trailer home, I replaced the four flooded batteries with 4 Lion Energy UT 1300 lithium batteries through Costco (113 ah each for a total of about 450 ah). They were $700 each (Costco has specials on these batteries a couple times a year) The UT 1300 lithiums (only 23 lbs each) are group 24 size which is the same footprint as the four flooded batteries (Group 27) that came in the Oliver. That made it easy. All I did was remove the four flooded batteries and replaced them with the 4 lithiums. They were an exact fit and I didn't have to change out any of the wiring. Truly plug and play. It took about 2 hours. It would have taken half that time except that the posts on the UT 1300 lithiums were both sized the same as a negative terminal on a flooded battery so I had to run to NAPA and buy a replacement negative terminal for my positive battery cable so it would fully tighten onto the postive post of the first lithium battery. (The positive terminal post on the flooded batteries is slightly larger than the negative terminal post I learned.) That was not an issue with the remaining three batteries because the cables attach to screw posts with wing nuts.) I now have 18 months of experience with my lithium batteries and at least 12 boondocking trips. No problems whatsoever, knock on wood. The UT 1300 lithiums don't have bluetooth or heaters but that hasn't been a problem. Each battery has a button you push that will light up a row of 5 LED's when the batteries are above 70% state of charge (SOC), when you get down to only 2 led lights lit, the battery is down to about 20% state of charge. While crude and not particularly accurate, they work and I always have a good idea of how much juice I have left. The Battery Management system (BMS) in the UT 1300 seems to work fine, and has all the important safety systems built in (e.g., won't charge if the battery is below freezing, etc.). I store my trailer outside and the solar system keeps the batteries fully charged all the time in the summer. In the winter, I am connected continuously to shore power which makes sure the batteries are brought to a full charge each day. I know this is not recommended for maximum battery life, but the Lion Energy warranty is 8 year replacement with no pro-ration if the batteries drop to less than 70 percent capacity in the first 8 years. We'll see.

-

Depending on how you intend to use the handheld GPS, you may want to take a look at OnX Maps ( onxmaps.com ). They offer a free trial. The app loads on your phone and works off the internet. You can download satellite maps of any area you know you will be in that doesn't have cell coverage. Originally developed for backcountry hunters, they now have a "recreation" version (trails, campgrounds, ski reports, etc.) that is pretty amazing. It won't give you driving instructions, but if you want something that works anywhere you can see the sky and has impressive mapping and GPS features, you may find OnX maps and your phone to be preferable to a handheld GPS. I do.

-

Basement access door under the nightstand.

Chukarhunter replied to John and Debbie's topic in General Discussion

Lornie and I also travel frequently with our dog and two cats. The basement access door is the perfect solution for the litter box. Oliver should really market the basement access door option to prospective Oliver owners that intend to travel with cats. Elegant solution to locating the litter box outside of the living space but easily accessible at all times. -

I faced a similar decision as you when I finally pulled the trigger on my 2020 Oliver II. I purchased my current tow vehicle many years ago, choosing the most capable tow vehicle at the time that would fit in my low height urban garage. When it came time to buy an Ollie, I could not find a better tow vehicle that would fit in my garage aside from a few $100,000 plus vehicles like BMW, Toureg, etc. They wouldn't work for me because I need a very capable off-road hunting vehicle on many of my camping excursions. My current vehicle has a GVWR of 5,720 lbs, 7,000 lbs towing capacity, 700 lbs max tongue weight, but only 1,120 lbs cargo capacity. The engine develops 320 lb-ft of torque at 3,200 RPM. It has a towing package and auto-height adjusting rear air springs. From the numbers you give for your current tow vehicle, you should be safe towing an Oliver II and you will likely feel safe when towing, but only if you have the discipline to pay attention to how you load the trailer and how well the Andersen hitch is set up. The sway control built into the Andersen is not really needed in normal towing, but could be invaluable in an emergency maneuver. The real benefit of the Andersen hitch in a marginal tow vehicle is the ability to actually achieve the rated cargo capacity which requires precise weight distribution between the front and rear axles. If you are under the GVWR of the tow vehicle when towing, but the rear axle is 300 lbs over its max axle rating (and the front axle is 300 lbs under its max axle rating), safety will be compromised and you will be out of spec even though you are at or under the vehicle GVWR. I suggest that you load your tow vehicle how you would normally drive without camping gear (i.e., driver, passenger and dog?) with a full gas tank, and then weigh it, recording the weight on each axle. Then put a known wight (say 200 lbs) into the front of the truck bed and re-weigh to determine how much of the additional 200lbs falls on the front axle and how much falls on the rear axle. Now look at the headroom left on each axle (how much below max axle weight rating). Lets say for example that after weighing the vehicle with 200 lbs cargo in the truck bed, you have 800 lbs cargo capacity left (GVWR minus combined weight on both axles) with 300 lbs of headroom on the front axle and 500 lbs headroom on the rear axle. If you expect to run your Ollie II with 600 lbs tongue weight plus 50 lbs for the Andersen hitch (total 650 lbs), you will need to shift at least 150-200 lbs from the rear axle to the front axle. The Andersen can do that. If you need to shift much more weight than that to the front axle, then your tow vehicle probably won't work (can't be set up safely) without running with an empty truck bed. As many have said here, you will have issues associated with the under powered engine as I do. That said, I have never found that to be a trip killer based upon the way I have used my Oliver. I don't mind occasionally dropping to 55 mph on long hills and I have become used to the noise and poor gas mileage associated with the frequent need to operate at the higher RPM of the engine's torque band. I also typically tow almost exclusively at 5,000 ft altitude or lower. If there is a 30 plus mile an hour headwind, I may just put off travel until the wind changes I would never choose my current vehicle to tow the Oliver II and you wouldn't choose your current one either. However, if it comes down to starting with the tow vehicle you have and upgrading later, or not getting the Oliver, my vote is choose the Oliver if the current tow vehicle you have can tow the Oliver safely. Lot's of great new tow vehicles will come on the market in the next few years including SUV's like the 2003 Sequoia and hybrids and electrics. I am very much looking forward to upgrading my tow vehicle, but it is not urgent.

-

I have owned my 2020 LE II for 18 months and towed about 10,000 miles including 2,400 miles from Hohenwald to Oregon when I picked up the trailer. My vehicle is rated to tow 7,000 lbs. Horsepower is about 245 and torque about 320. Payload is a dismal 1,120 lbs. I couldn't afford a new tow vehicle and the Oliver at the same time I have been mostly satisfied with my towing experience but certainly look forward to getting a beefier tow vehicle at some point. I definitely feel safer towing the LE II with my current vehicle now than I did towing my former 3,000 lb tent trailer with terrible towing manners. If you can afford more tow vehicle, then don't hesitate to get a new one. If it comes down to no Oliver, then you can start out with your Tacoma with the Anderson hitch and upgrade your tow vehicle later. It seems that many have done that. Oliver will set up the Anderson hitch properly when you pick up the trailer. If you pay close attention to loading and leave the toys at home to stay within all specs, you will not be unsafe on the road. The double axle LE II tows extremely well without sway. Look to adjust tongue weight to no more than 9% and plan on a mostly empty truck bed. Pack any extra weight in the Oliver on the floor or bunk centered over the axles as much as possible. Move this weight to the pickup when you set up camp. And don't travel long distances without first emptying the blackwater tank which adds considerable tongue weight. When loaded for a week of camping, my LE II weighs about 5700 lbs with 520 lbs tongue weight (plus 60 lbs for the Anderson hitch) and my tow vehicle is usually pushing its GVWR of 5,700 lbs. I limit tow vehicle payload to one driver, one passenger, one dog and less than 100 lbs of cargo. (If I had young children, it wouldn't work). And yes, I need to stop for gas every 200 miles or so. Note that to achieve the full GVWR safely, it is critical that the weight be properly distributed over the front and rear axles of the tow vehicle. That is what the Anderson hitch is for. My current tow vehicle is a 2004 4Runner V8 Limited with 220,000 miles. The 2004-2006 V8 4Runner is the only 4Runner ever built with a V8 engine and a towing capacity of more than 5,000lbs. I am the original owner. Eying the 2023 Sequoia as a possible replacement.

-

Battery problem Or Other ?

Chukarhunter replied to Alberta and Randy's topic in Mechanical & Technical Tips

Another place you could check for a phantom draw is the light in your rear storage garage. I am kind of embarrassed to admit this but recently while camping I opened the streetside rear storage hatch at night and it was lit up inside! I had never really thought about there being a light in there. It could have been on for over a year since I picked up our Oliver for all I know. -

It is interesting that Truma markets their units by specifying "watts of cooling capacity" on their website instead of Btu's of cooling capacity. Stating the input power in watts only tells you the maximum input Btu's for the unit, but tells one nothing about the output (cooling) Btu's, i.e., the maximum BTU's of heat the unit is capable of removing from the trailer over a one hour period. In the case of the Truma, it appears that a 2,400 watt cooling capacity corresponds to 15,000 Btu/hour of cooling capacity. As Geronimo Joe correctly points out, 2,400 watts input is 8,189 Btu's so the Truma converts 2,400 watts of input Btu's into 15,000 Btu's of cooling. This relationship is commonly referred to at the Coefficient of Performance, or COP. In the case of the Truma, the COP is 15,000/8,189 = 1.83. This is really, really inefficient. This past summer I installed a high efficiency Lennox unit in my home (to replace a failed air conditioner). The unit modulates between 30% to 100% capacity based upon cooling demand. At the minimum 30% capacity and a 15 degree differential between outside temp and inside setting (80 degrees inside and 95 degrees outside), the unit will supply 10,700 Btu of cooling while using only 730 watts of input power for a COP of 4.3. Under the same ambient conditions at 100% power, the unit will supply 35,000 Btu's of cooling while using only 2,700 watts of power, a COP of 3.8. Unfortunately, one-piece RV air conditioners are already pushing the limits of achievable efficiency, given the one piece design and requirements to be ultra compact. They must be designed with smaller heat exchangers/coils and fans due to space limitations that in turn requires high velocity fans to work well, hence the noise. I don't expect the Truma will be all that much quieter than all the others out there today. I expect what is needed to achieve a breakthrough in much quieter operation (and much higher efficiency) would be the development of a two piece rooftop air conditioner for RV's, much like home air conditioners (and heat pumps) that have an outside compressor unit and an inside air handler and coil. The same size inside unit as installed in the Oliver today could then have the space freed up to use a larger coil and a quiet, low velocity, high volume fan, gaining higher efficiency and much quieter operation.. The compressor itself could be mounted on the roof immediately behind the existing inside unit and be connected to the internal air handler (inside unit) with small refrigerant lines, just like today's outdoor units designed for the home. The result would be a quiet, more powerful and more efficient air conditioner (or heat pump) that could be easily run with an 1,800 watt generator or battery power. Of course, it would also probably cost a lot more than today's units but my guess is there is a large, untapped market for a truly quiet, higher performing two piece unit, even at a significantly higher price.

-

Oliver under a full moon in front of a large campfire (No flash used). Boondocking in the Owyhee country of Oregon.

- 162 replies

-

- 10

-

-

-

1000cc Generator for battery backup

Chukarhunter replied to Ralph Mawyer's topic in Mechanical & Technical Tips

Thanks for sharing your experience with the smaller 900 watt EU1000i and the Progressive Dynamics 60 amp converter/charger. I checked the specs on the PD60 amp model and it requires a 1000 watt input to deliver 60 amps to the batteries at 13.6 volts which means it has a conversion efficiency of less than 82%. Since the charging current is not adjustable in the PD60, anyone with a PD60 must use a generator rated at a minimum of 1,000 watts continuous to charge their batteries and the EU1000i will not work. So to summarize: If your Oliver has the Progressive Dynamics 60 amp converter/charger, then you cannot use an EU1000i to charge your batteries. If one has the PD45 (45 amp converter/charger), then the EU1000i is more than adequate and moving to a larger generator would not provide any charging benefits. Finally, if one has any one of the inverters (2000 watt or 3000 watt), the EU1000i will definitely work because the maximum charge current is user selectable. Also, because the inverter/chargers are more efficient (rated at 91% nominal efficiency versus 82%), the EU1000i should be able to comfortably charge the batteries at a 55 amp rate and possibly even 60 amp. -

1000cc Generator for battery backup

Chukarhunter replied to Ralph Mawyer's topic in Mechanical & Technical Tips

All really good information in this thread. I am bumping it because I have also considered getting a 1,000-watt generator (Honda or Yamaha) to use for topping off my batteries instead of my current generator which is the Honda EUI 2200 Companion. My LE II charges the batteries via the 2000-watt inverter/charger so while boondocking last week, I decided to determine how many charging amps I could deliver to my batteries with a Honda 1000-watt peak generator (900 watt rated) before overloading the generator, after accounting for electrical losses through the inverter charger. The 2000-watt inverter/charger in my Oliver can be set to a maximum charge current limit of 0-80 amps in 5-amp increments meaning it is capable of delivering 80 amps to the batteries IF the batteries can accept 80 amps. I have the lithium phosphate batteries so they will always accept 80 amps charging current up to full state of charge with my EUI 2200, but the smaller generator would not be able to deliver 80 amps to the batteries without overloading. It is straightforward though to calculate how many watts a generator must deliver at 120 volts for the converter/charger to deliver any given number of amps to the batteries at 14 volts, ignoring losses. What I did not know was how many watts the generator must deliver to also make up for the losses in the converter/charger and wiring. Using the formula volts x amps = watts, I knew that the minimum watts that a generator must deliver at 120 volts to provide 80 amps to the batteries at 14 volts would be 1,120 watts. 14 volts x 80 amps = 1,120 watts. The Honda EUI 1000 is rated at only 900 watts continuous so I knew it could not support 80 amps charge current to the batteries, but I did not know what the maximum charge current that a 900 MW generator could support when accounting for losses. The maximum charge current with no losses would be 64 amps 14 volts x 64 amps = 900 watts. While I was charging the batteries at 80 amps with the EUI 2200 last week, I read the 120-volt input amps to the inverter from the panel, and it showed that the generator was supplying 10.2 amps of 120-volt power to the inverter. This meant that the generator was supplying 1,224 watts to the inverter including any bypass current to any other 120 trailer loads. 120 volts *10.2 amps = 1,224 watts I did have my satellite receiver operating on 120-volt power at the time, so I assume that the inverter/charger itself was requiring approximately 1,200 watts at 120 volts to deliver 80 amps to the batteries at 14 volts. This implies that inverter/charger losses were about 7% meaning 93 percent of the 120-volt input power was reaching the batteries. (1200 watts - 1,120 watts) / 1,120 watts = 7% losses Now, using the loss factor of 7%, a 900-watt generator could be expected to deliver a maximum of 837 watts to the batteries in my Oliver. 900 watts x 0.93 =837 watts This means that the I would need to set the maximum charge current in my inverter/charger to no more than 60 amps, or the 900-watt generator would overload and shut down. 14 volts x 60 amps = 840 watts For me, this means that if I switched to the 900-watt Honda generator it would take about 33% longer to top off my batteries than it does now with the larger EUI 2200 at 80 amps charge current. For example, if it would otherwise take 3 hours of generator operation to top off my batteries with the EUI 2200 at an 80-amp charge rate (i.e., 240 ah into the batteries), it would take 4 hours to get the same 240 ah into the batteries with the 900-watt generator. Some with the inverter/charger may find this longer run time unacceptable. I personally think it is a reasonable tradeoff when boondocking, given the much lower weight, quieter operation, and lower fuel consumption of the 900-watt generator. (of course, it would not run the air conditioner) If I can ever find the Honda EUI 1000 in stock anywhere again, I will probably pick one up. It also explains why SeaDawg has been more than happy with their Honda 1000. I assume they have the 45-amp converter/charger so there would be no charging benefit for them of using a larger generator. It would not charge their batteries any faster. I am not a professional and may have made mistakes in this assessment. Please correct me if I have. -

Elite II Average Tongue Weight w/ Solar

Chukarhunter replied to Islandgrl's topic in Introduce Yourself

I have paid close attention to tongue weight as I have a marginal tow vehicle. My 2020 Elite II came out of the factory at about 5,500 lbs with full fresh water tank and a tongue weight of about 550-570 lbs (Shurline 1000 lb scale). It had the front cargo carrier (since removed and stored) and 20 lb tanks plus the solar option. I do not have a composting toilet. Since every pound of cargo capacity in my tow vehicle is precious, I have endeavored to reduce my tongue weight to no more than 9% of fully loaded trailer weight which for me is about 520 lbs, and succeeded. (I agree with others on this forum that 9% tongue weight is just fine for the LE II). All I did to reduce tongue weight was remove the front basket (-35 lbs.), switched from 20 lb steel tanks to 17 lb composite tanks (-20 lbs) and switched to four 105 Ah Lithium Ion batteries (-100+ lbs). As others have said, how one loads the trailer for travel can have a large affect on tongue weight. Anything loaded behind the door has a negligible affect on tongue weight, or even positive effect if loaded in the very rear of the trailer. Anything loaded in the bathroom or closet has a significant effect on tongue weight, as do the contents of the black water tank. I suspect those reporting tongue weights in excess of 600 lbs carry at least 50 lb. in the front basket, and have the 30 lb propane tank option. This alone would add close to 100 lbs. of tongue weight on top of the 520 lbs that I now typically see when pulling my LE II. -

My 2021 LEII came with 4 of the Brightway flooded batteries. They fit snug but easily in the tray with enough room for thin padding on the sides.

-

Lornie and I have owned our LEII for a year and have traveled quite a bit with our two cats (and our dog). We have the standard floor plan and we ordered the optional inside access hatch to the outside rear storage compartment without really knowing whether we would ever use it. We quickly discovered we could place the cat litter box in the back storage area (i.e., outside the living space of the trailer) and leave the inside access hatch open to the storage area. Cats go in and out to use it and as a bonus, only kick litter into the storage area and not onto the trailer floor. Less odor as well. Works perfect for us. When we ordered our LEII, the inside access hatch option was only available on the standard floor plan but that may have changed.

-

The advantages of lithium-ion batteries over flooded/AGM batteries are numerous, although the relative importance of each benefit to some extent depends on how you plan to use your trailer. I have owned my 2020 LEII for one year now and almost always boondock. Oliver didn’t start offering a lithium package until one month after I placed my order and the first thing I did after arriving home from Hohenwald was to swap out the 4 lead acid batteries it came with for four 105 amp-hour Group 24 Lithium-Ions. Since I already had the 340 watts of solar and 2000-watt inverter/charger, it was a simple swap to make as Galway Girl points out. No changes in cabling required or anything else. For me, the greatest benefit is the much higher rate at which the lithium-ion batteries will accept a charge. If you go with AGM batteries and solar, Oliver will require you to use four 110-amp hour AGM batteries weighing over 200 pounds, even if you don’t want or need that much battery storage. I was told that this is so Oliver can test the performance of the solar system before it leaves the factory and that explanation makes sense. This is because the maximum charging rate of an AGM battery roughly 150 watts (12 amps) up to 80% charge and only about 60 watts (5 amps) between 80% and 100% charge. A single lithium-ion battery, on the other hand, can accept a charging rate of over 1,000 watts (100 amps) all the way to 100 percent charge. The 2000-watt inverter/charger Oliver installs can deliver about 1,000 watts (80 amps) to the batteries and the 3000 watt inverter/charger can deliver about 1200 watts (100 amps) to the batteries. This can all be confusing so I will explain what this means in the field. If you remember one simple rule, it becomes much easier to understand this. The rule is: volts x amps = watts. My Oliver solar panels are capable of 340 watts on a sunny day. At an average charging voltage of 13.5 volts (controlled by the solar charge controller), the panels are capable of delivering roughly 25 amps to the batteries, ignoring losses (340 watts / 13.5 volts = 25 amps). If you have 4 AGM batteries, once they reach 80 percent charge, they can only accept about 20 amps of charge current (4 batteries times 5 amps each) which means the solar panels are throttled back to only produce about 270 watts (13.5 volts *20 amps = 270 watts) to protect your AGM batteries. This slow charging between 80% and 100% means you are wasting potential solar energy and your batteries will likely never recover to full charge after you have started your trip, (this is true even if you use a generator unless you want to run the generator for 6 hours/day). With my lithium-ion batteries, my solar panels always deliver their full capability, unless and until my batteries reach 100% charge. I am a high desert bird-hunter and so I boondock in the fall/winter. The solar panels are not always adequate for longer trips in the winter due to shorter daylight hours, sun much lower in the sky, and cloudy weather. For winter trips more than 3 days I reluctantly take a generator and hope I don’t need to use it. If I do need to use a generator though, I only need to run it for an hour to put 80 amp-hours into my lithium-ion batteries. One would need to run a generator for 2-4 hours to put 80 amp-hours into four AGM batteries. A bigger generator doesn’t make a difference since the limitation is in the batteries and not the capacity of the generator. In fact, I can put 70-80 amp hours into my lithium ion batteries in one hour using the smallest/quietest /lightest inverter generator made (Honda EUI 1000 at 28 lbs). The newest LEII has a 3000 watt inverter/charger that can put 100 amp hours into lithium-ion batteries in one hour, but will still only put 20 -40 amp hours into AGM batteries in the same hour. One other consideration is that with lithium-ion batteries, you can get by with fewer than 4 batteries and still have more usable battery storage than you get with 4 AGMs. When you factor in the difficulty of charging the AGM’s above 80 percent with solar in the field, you really only have 40% of usable storage with AGM’s (50% to 90%) whereas the lithium ions give you up to 85% usable storage (15% to 100%). Translated to amp hours, the AGM’s give you about 170 usable amp-hours/day before charging is mandatory (40% of 420 amp-hours), whereas the lithium ion’s give you over 350 usable amp-hours/day before charging is mandatory (85% of 420 amp-hours). My understanding is that the Oliver lithium-ion package comes standard with two 220 amp-hour lithium batteries at roughly $3,000 more than AGM’s. For those that don’t need 420 amp-hours but still want all the benefits of lithium, I think Oliver should also offer a lithium package with only one 220 amp-hour lithium-ion battery at a savings of about $2,000. This would mean the upgrade to lithium-ion would only be about $1,000 above the four AGMs instead of $3,000, while still providing more usable battery storage than four AGM’s. Hope the above makes sense. I am no expert and welcome corrections/clarifications from other forum members.

-

Anyone have experience with this trailer dolley?

Chukarhunter replied to Chukarhunter's topic in General Discussion

Thanks for sharing your experience on with using a trailer dolly on gravel. I think I will pass this one by. I will definitely look to putting on a front hitch when I upgrade my current undersized TV. My current backing maneuver would probably be impossible to do if my TV was a full size pickup. -

Anyone have experience with this trailer dolley?

Chukarhunter replied to Chukarhunter's topic in General Discussion

In my current situation, I would only use it on the level. The only place I can store the LEII is in the backyard off of a one-way alley. I have to back the LEII about 200' down a very narrow alley and then cut it through a slightly angled 14' gate and then curve it to achieve a 90 degree turn before I hit the neighbors side-yard fence. Making the 90 degree turn without my tow vehicle hitting the side of the gate opening is a challenge. I am reasonably proficient but it would be much easier if I could just back it in through the gate, unhook, and then move it into the final parking spot using the dolly. The working surface is gravel and I am concerned the small wheels could be a problem.