Chukarhunter

Members-

Posts

96 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Chukarhunter

-

Generator Inverter Usage

Chukarhunter replied to Wandering Sagebrush's topic in Mechanical & Technical Tips

The only settings I had to change in my 2000W inverter/charger was to change the charge setting from flooded batteries to a LFPO4 charging profile. Our early versions of the 2,000 watt model did not have a LFPO4 setting to switch to so I selected the "custom" battery option. I then set the custom absorption voltage to 14.6 volts (as recommended by the battery manufacturer) and I was done. The main reason you need to adjust the absorption voltage to a 14.4-14.6 volt level (consult your battery manufacturer for their preferred setting) is that the LFPO4 batteries require a higher voltage than flooded batteries to reach full charge, compared to the flooded or AGM batteries. To be confident how to do this with your model of converter/charger, you really need to consult the "Optional Equipment" manual that came with your Oliver. I just looked on the Oliver University and the factory manual they have posted is apparently a mid-2020 updated manual that appears to reflect a firmware upgrade to the units we have, since the manual on the Oliver site displays a LFPO4 setting in the menu, which my 2020 version does not show in the menu and definitely did not have. I would post a picture of my settings table from my manual, but it is across town in storage. PM me if you want me to retrieve my manual and post a copy of the settings menu here. I would be happy to do so. -

Generator Inverter Usage

Chukarhunter replied to Wandering Sagebrush's topic in Mechanical & Technical Tips

The remote display I have is part of Xantrex inverter/charger model that I have, not the PD Charger/Converter. When I elected the 2000 watt inverter/charger option, the factory kept the PD Converter/charger in place to serve as the breaker/fuse panel, but disabled the converter/charger function and instead wired the 2000 watt inverter/charger into the PD circuit/fuse panel. You would not need to change any settings to use a 1,000 watt generator to charge your AGM batteries since your converter/charger is has its own built in charging limit of 45 or 60 amps depending on the model. A 1,000 watt generator should be capable of charging the batteries at 60 amps since this will effectively limit the draw on the generator to about 840 watts (14 volts x 60 amps = 840 watts.) I you upgrade to lithium batteries, then you have two choices. You can replace your existing PD converter/charger with a more up to date version of the same model that has a lithium ion charging profile option built in. This is the lowest cost option, but you will be limited to a maximum charging current of 60 amps split among all your batteries . A superior solution but more expensive solution would be to keep your current PD converter/charger but upgrade your inverter to a 3,000 watt inverter/charger. The 3,000 watt inverter charger that Oliver installs can charge your batteries at a rate as high as 150 amps, thereby charging your batteries 2 1/2 times as fast as a 60 amp charger when you are connected to shore power. To charge with a generator at the 150 amp rate, you would likely need a generator that outputs a minimum of 2200 MW continuous, more if you want to simultaneously use any 120 volt appliances at the same time. I hope this is helpful. -

Generator Inverter Usage

Chukarhunter replied to Wandering Sagebrush's topic in Mechanical & Technical Tips

Sorry that I may have added to the confusion. Apparently, the 2000 watt inverter installed in the 2018 Oliver was an inverter only without a battery charger built in. The 2000 watt inverter installed in my 2020 LE II is an inverter/charger. That is why I have a more sophisticated wall panel with led readout. In your 2018 Oliver, the batteries are charged by the Progressive Dynamics Converter/Charger under the dinette that also serves as the 12volt and 120 volt service panel (breakers and fuses). The PD Converter/Charger in your trailer has a fixed maximum charging rate of either 45 amps or 60 amps depending upon what model Oliver installed. The PD Converter/charger is perfectly adequate if you have lead/acid batteries or AGMs and charging at the maximum charging rate of 60 amps should not overtax a 1000 watt generator. If you ever upgraded to lithium ion batteries though, you would need to replace the PD converter/charger with a charger that offers a lithium ion charging profile built in. Progressive Dynamics makes one that is a drop in replacement for the one you have. Alternatively, you can install an updated combined converter/charger to charge your batteries and then bypass the charger in the PD Converter. That is what the factory did in my 2020 LE II. I do have a background in grid scale power and high voltage transmission, but the information above I learned the hard way when I switched out my lead acid batteries for LFP04 lithiums right after I picked up my 2020 LE II. Oliver started offering the lithium option in mid-model year about a month after I took delivery of mine so I had to figure it out myself. Information on this forum helped me out considerably. -

Generator Inverter Usage

Chukarhunter replied to Wandering Sagebrush's topic in Mechanical & Technical Tips

I have the Xantrex PROwatt 2000 inverter in my 2020 LE II. It has Charge Current setting just like the 3000 watt version. The max charge current in the 2000 watt inverter is 80 amps (as opposed to 150 amps in the 3,000 watt inverter.) To set the charge current limit to less than the factory default of 80 amps, you just need to go into the inverter panel on the wall of the Oliver, enter into configuration mode, scroll to setting # 24 Charge Current, and change the setting. It only takes a minute or two. It is certainly not as easy as using a bluetooth app and I often have to refer to the manual again because the exact sequence of button pushing is easy to forget. But it works just the same as in the 2000 watt inverter. -

Generator Inverter Usage

Chukarhunter replied to Wandering Sagebrush's topic in Mechanical & Technical Tips

With no offense intended, I believe there is some questionable advice in this thread. In particular, it is counterintuitive to me that reducing the input amperage to the inverter is the best way to limit the level of charging current that the inverter is delivering into the batteries, especially when the inverter has a setting (#24) designed specifically for that function. Wandering Sage Brush is apprehensive about using the smaller Honda 1000 to charge his house batteries while boondocking. There is nothing to be nervous about as many of us do it all the time. The only issue you need to be aware of is ensuring that the combination of trailer loads (120 volt loads and 12 volt charging load) is less than the maximum output of the generator. If you try to run higher loads (i.e., greater watts) than the generator can produce, the generator will overload and shut down. The table above showing inverter settings are for a 3,000 watt inverter. Setting 28 is factory defaulted to 25 amps because 25 amps * 120 volts = 3,000 watts. If you lower the amperage limit in Setting 28 down to lets say 15 amps, you are turning your 3,000 watt inverter into an 1800 watt inverter because 15 amps * 120 volts = 1800 watts. There is no need to do that. If you want to charge your batteries with a 1000 watt generator, then you need to limit the draw on the generator to less than 1,000 watts. If you want all the available 1,000 watts to go into your batteries, then there are two steps you need to take when you decide to charge. First is to turn off your inverter and any 120 volt loads if you want to all the generator output to go into your batteries. You don't want any 120 volt trailer loads drawing on the generator at the same time you are charging the batteries. Second, you need to reduce the amperage limit in Setting #24: Charger Current. The charger typically charges at about 14 volts when the batteries are getting close to full. Since volts x amps = watts, 1000 watts into the batteries is going to require 71 amps of Charge Current (14 volts * 71 amps = 1,000 watts) . Adjusting for losses and generator derating at altitude and in higher temperatures, you should probably limit the watts from the generator at no more than 900 watts which equates to 64 amps (900 watts / 14 volts = 64 amps). So whatever inverter/charger you have, set the max charging current at 60 amps and your Honda EU1000 will probably charge just fine without overloading. If you are running the Honda 1000 and you are also getting 20 amps from your solar panels at the same time, then you will be putting 80 amps into the batteries (60 amps from the generator and 20 amps from the solar). This is equal to 1,120 watts (80 amps x 14 volts = 1,120 watts) You can leave the Charge Current setting at 60 amps all the time if you want unless you want your batteries to charge faster when you are on shore power. If so, just increase the max charging amps in setting # 24 before you go back on shore power. -

Oliver batteries not charging with generator

Chukarhunter replied to chiwald's topic in Mechanical & Technical Tips

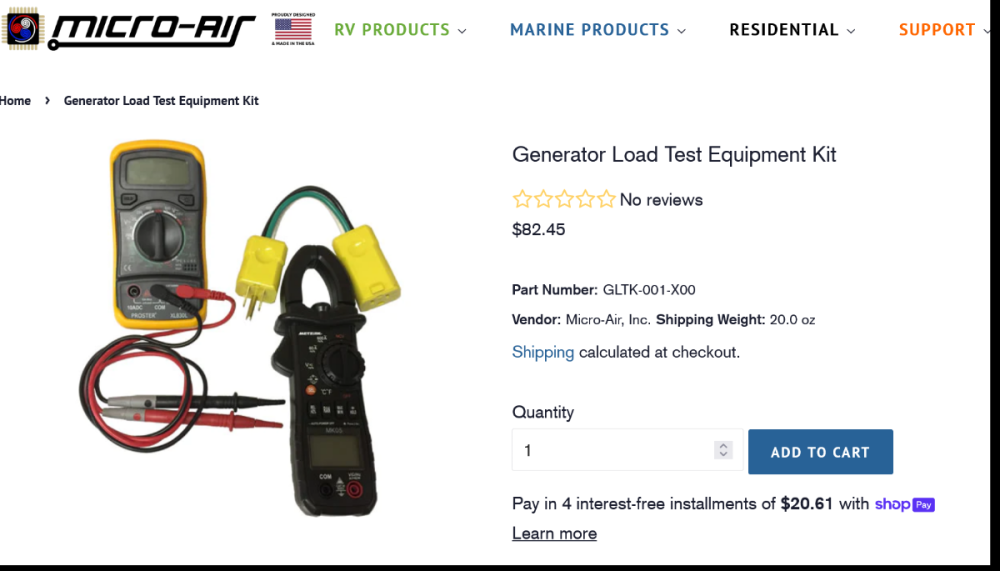

I picked up one of these relatively inexpensive generator test kits a while back. It lets you verify both generator voltage and also how many watts and amps the generator is actually generating at site conditions (altitude and temperature) with the clamp meter. This can help you rule out generator issues. It comes with a test pigtail to make measurement easy. (see pictures below). You can find it at Microair .net -

I worry about Oliver owners with the Suburban furnace that close any heat vents (supply vents) in the trailer. This is almost always detrimental to the functioning a an HVAC system but in the case of my generation of the LE II it can be dangerous. According to my furnace manual, the furnace requires 25 square inches of unobstructed hot air venting to work properly. Even a few feet of lightweight flex duct will restrict airflow and any bends in the flex duct will restrict airflow even more. The two 4" round supply ducts in the Oliver total exactly 25 sq. inches at the furnace so technically, when the runs of flex duct are considered, Oliver has not ensured sufficient airflow for the furnace to operate at its best as it is. (An analogy would be someone that exceeds the GVWR of their tow vehicle). Closing one of the two cabin vents inevitably causes a sharp increase in back pressure against the furnace fan with the result that the fan cannot move as much air across the heat exchanger and into the cabin. The result is hotter air coming out of the remaining open vent but less Btu's in total flowing into the cabin, and the likely overheating of the heat exchanger resulting in the furnace shutting down prematurely (short cycling). In milder weather, this might not be noticeable but it is dangerous in colder weather because if the high temperature limit switch in the furnace ever fails, there is a serious risk of a fire. The only safe way to increase the flow of hot air into the Oliver's cabin is to increase the number or size of return vents, which will reduce cabin pressurization when the furnace is running and thereby enable the furnace to move more air (and Btu's) through and out of the supply ducts. In my experience, the key to comfort and balanced heating in the Oliver along with a warm bathroom is to ensure that all the hot air from the cabin must flow through the entire basement on its way back to the furnace, thereby heating the entire basement as well as the cabin. This requires additional return vents in the middle and front (bathroom) of the cabin.

-

Your observations on the inferior design of the HVAC (furnace) "system" is spot on. I think Oliver has maybe not given this issue sufficient design attention because a large proportion of Oliver Owners probably winterize their trailers and don't care much about the furnace. I use my Oliver throughout the year, store outside, and do not winterize. My primary concern is the ability to keep the plumbing from freezing even when the cabin is warm. I have placed internet connected thermometers in the basement by the outside shower hoses and other spots, and found that the basement temperatures can fall to 30 degrees or more below the cabin temperatures when outside air temps drop into the low 20's or teens. I found that if the outside temperatures go very much below freezing, I have to keep the cabin at least 65 degrees to keep most of the basement areas (except for right around the furnace itself) above freezing. I determined the problem is insufficient warm air circulation through the basement (i.e., no return air vents in the front of the trailer (bathroom). Oliver did add a small return air vent in the bathroom in more recent models. I have resisted running new ductwork or cutting holes in the trailer to address this while I studied the issue in the field. Finally, and just recently, I tried a non-invasive hack that appears upon initial testing to work quite well. The outside temperatures last week dipped into the mid-teens for several days, yet my basement temps stayed within 15 degrees of the cabin temps (the Oliver was in outside storage). I am heading out next week and will test the cabin and bathroom comfort in temperatures expected to be just below freezing, and I expect to find a much warmer bathroom and more comfortable trailer, as well as the warmer basement temps. What I finally did was easy. I removed the "front bottle plate" from the bathroom vanity and disconnected the flex duct from the bathroom vent, creating a 3'' (or 4") return air vent in the bathroom. I then left the disconnected air duct loose under the sink to put extra heat into the front of the basement. Combined with the new return air vent in the bathroom, the warm cabin air flows forward into the bathroom and the warm air bathroom air is pulled under the bathroom and shower to be slowly circulated from front of the basement to the back of the basement when the furnace fan is running, more effectively heating all the plumbing and battery box. I do need to keep the bathroom door cracked (but not open) for this to work, unless or until I install a vent between the bathroom and main cabin. I am not sure if a functional return vent like this would cause problems in Olivers with the composting toilet. I have the standard toilet.

-

Humor notwithstanding, I believe this is the correct answer. It is not complicated. First, lets look at what happens when you connect to shore power 30 amp receptacle. In this normal situation, the 30 amp shore power outlet will pass a maximum of 3,600 watts continuous power to your Ollie (30 amps x 120 volts = 3,600 watts). If you turn on too many appliances in the Ollie (including battery charger and air conditioner, fridge, etc.) such that you are consuming more than 3.600 watts, then the 30 amp breaker on the shore power receptacle will likely trip. It is difficult but not impossible to to draw more than 3,600 watts in the Ollie but could happen if the batteries were charging at a 150 amp rate consuming 2,100 watts (150 amps x 14 volts =2,100), and you turned on the microwave at 1,000 watt setting, and turned on the air conditioner all at the same time, you would be trying to draw more than 4,000 watts from the 30 amp shore power outlet and the 30 amp breaker in the shore power post will trip. The only thing different when you connect to a 20 amp shore power outlet is the shore power outlet will only pass a maximum of 2,400 watts before the 20 amp breaker protecting the shore power outlet will trip. In this case, you need to be diligent to keep your continuous consumption in the Ollie to less than 2,400 watts. This is easy to do if you change the charger setting to something lower than 150 amp maximum charging rate. I almost always choose to connect to the 20 amp shore power outlet when I am just stopping for the night somewhere and not unhitching. It is less work than to having to dig into the back of the basement to retrieve the heavy 30 amp cord and put it away later. Instead, I quickly plug in using a 25 foot lightweight 12 AWG extension cord with a 20 amp to 30 amp adapter. It allows me to simultaneously charge the batteries at 80 amps (1,120 watts, the maximum my 2,000 watt inverter will do) run the air conditioner or microwave at reduced power, and watch the 120 volt TV all simultaneously without drawing more than 20 amps of shore power. I can also run all 12 volt loads (e.g., furnace, lights, water pump, etc.) that I want without increasing the draw on shore power since all 12 volt loads draw their power from the batteries. The next morning, it takes me only two minutes to disconnect and stow the 12 AWG extension cord in the back of the TV. As Rolind said above, you will probably need to back down the maximum charge rate limit setting on your charger if you connect to only 20 amps, depending on what other 120 volt loads you want to run simultaneously in the Ollie.

-

ICE engines will fade from vehicles, but hopefully ground based ICE generators will expand in rural areas to support grid-independent DC fast charging facilities. Using technology available today, these hybrid renewable EV fueling complexes can be built with a combination of on-site solar and/or wind power, some flow battery storage, and ICE generators with on-site fuel storage. The ICE generators would burn locally produced renewable diesel (not biodiesel) made with agricultural or forest biomass. All at lower cost than today’s grid-connected fast chargers that rely on expensive, increasingly unreliable grid supplied energy. And unlike every charging station in place today, these chargers would continue to work when the grid goes down. Rural economies would be the big winners.

-

Looks like my Gold 4Runner pulling the LE II. Gonna have to try that!

-

I would be concerned if the GFCI on a house outlet tripped when connecting the Ollie, period. The inverter/charger by itself will not cause a GFCI outlet to trip at the house. A properly functioning GFCI will only trip if it detects a current leakage to ground, a situation that is not wise to ignore. Your problem may be with the GFCI receptacle you are otherwise using. You mentioned that your GFCI is only rated to pass 15 amps of current. Your GFCI is not rated to pass a 20 amp current to the Ollie. I would suggest you install a 20 amp WR (outdoor rated) GFCI and see if that solves the problem. It worked for me. This is the 20 amp WR GFCI that I installed to connect house power to my Ollie. https://www.amazon.com/Leviton-GFWT2-W-SmartlockPro-Weather-Resistant-Tamper-Resistant/dp/B013OVCTBO/ref=sr_1_1?crid=21PT35NK7I73G&keywords=outdoor%2Brated%2B20%2Bamp%2Bgfci%2Boutlet&qid=1699985721&sprefix=outdoor%2Brated%2B20%2Bamp%2Bgfci%2Boutlet%2Caps%2C124&sr=8-1&th=1

-

There appears to be some confusion around setting number 28 which is a dedicated internal circuit breaker for the 3000 watt inverter. The factory setting must stay at 25 amps because it requires at least 20 amps of 120 volt input current to charge the batteries at the factory default 150 amp charging rate. Stated differently and ignoring losses, the inverter requires a minimum of 2,100 watts of 120 volt shore power to achieve the 150 amp charging rates (150 amps x 14 volts = 2,100 watts). 2,100 watts of 120 volt power results in a shore power draw of 17.5 amps (2100 watts / 120 volts = 17.5 amps). If setting #28 is set to only 15 amps, I believe that it is guaranteed the inverter will shut down and not charge the batteries. Once the battery charging stops, the inverter will after awhile reset, restore shore power and start charging the batteries again. The inverter starts charging the batteries at a low rate initially and slowly ramps up the charging voltage until it reaches a steady state 150 amp charging rates. If setting #28 remains at 15 amps, then it will never reach 150 amps charge rate because shore power will shut down again and the cycle will repeat itself over and over. OTT should verify the above, but I don't believe there is ever a reason to reduce the AC input limit in the inverter/charger to below 25 amps. Rivernerd's advice to use an extension cord with a higher amperage rating is excellent advice in all situations. The reason is to reduce voltage drop. The footnote to the table above that rich.dev posted states that the inverter will trip shore power and switch to battery power if the shore power voltage drops below 106 volts. An undersized extension cord can cause significant voltage drop. For example, assume the voltage into the house from the utility is 118 volts. Further assume that there is an unusually long 75 foot run of 12 AWG romex from the breaker box in the house to the wall outlet feeding the extension cord to the trailer. In this example, the voltage at the wall outlet has already dropped by 6 volts to only 111.96 volts, merely due to the 75 foot run from the breaker box to the wall outlet, assuming a 20 amp current draw at the outlet. Now lets assume that you use a 12 AWG (20 amp) extension cord between the wall outlet and the Ollie. Adding the additional 50 feet of 12 AWG extension cord will further reducevoltage at the Ollie by an additional 4 volts to only 108 volts. Everything should still work fine. However, if one were to use a 14 AWG extension cord instead of a 12 AWG extension cord, the voltage at the Ollie will drop to only 105.8 volts and will cause the inverter to cut off shore power (and battery charging) because it is less than 106 volts. While this situation is unusual and situation specific, everyone should probably own a "kill a watt" or similar meter to quickly eliminate voltage concerns. This can be inserted between the extension cord and the Ollie plug to observe real time voltage and power consumption into the Ollie. They are only $30 or less and have many beneficial uses around the house besides measuring voltage. https://www.amazon.com/P3-P4400-Electricity-Usage-Monitor/dp/B00009MDBU?th=1

-

Add a Device to the Rear Camera Switch

Chukarhunter replied to GeoffChapman's topic in Ollie Modifications

I too found it necessary to hook up the signal booster to my Tiretraker to prevent "lost signal "alarms. I attached a 12 volt male cigarette lighter plug to the signal booster and when I tow, I plug it into a receptacle in the rear of my vehicle and secure it to the side with a piece of velcro tape. It is easy to remove and store when not towing. This approach should work in any of the cigarette lighter ports in the Oliver as well and only takes a few minutes to set up. No trailer wiring involved. -

Norcold refrigerator when not level

Chukarhunter replied to John Welte's topic in General Discussion

Iphone owners can use the built-in app that measures slope in all directions and reads out the degrees of slope. It is accurate. -

Gliddenwoods, If I didn't have the access port below the pantry, I would probably add a second return vent even farther forward, probably under the forward dinette. That is because I believe return vents should be placed as far as reasonable from the supply vents. This causes the best mixing of warm supply air as it is pulled across the cabin and into the return vent, and also causes the best mixing of warm cabin air throughout the basement on its way back to the furnace intake. It is important to have warm return air-flow flowing across as much of the basement as possible on the way back to the furnace to eliminate dead air spots which can become very cold in sub-freezing weather. Another easy way to add some "as needed" additional return paths for warm cabin air into the basement is to slightly open a drawer or two. Since the wall behind the drawers is open to the basement, cracking open one or more drawers by an inch or less will provide another path for warm cabin air to be pulled into the basement, warming the sink plumbing at the same time. The best solution I believe is to provide a decent sized return vent in the bathroom which will allow warm cabin air to warm the entire length of the cabin as it is pulled into the bathroom and also the entire length of the basement on the way back to the furnace intake vents. I believe that Oliver started putting in a return vent in the bathroom in 2022 (although I think it is very small). After three years of patient observation of my furnace's performance under all sorts of weather conditions using multiple thermometers, I have decided to add a return vent to the bathroom but not cut any new holes. Instead, I am disconnecting the bathroom flexduct supply hose from the existing supply vent in the bathroom which will turn the existing supply vent into a return vent. I will re-terminate the flex duct supply hose inside the vanity in the front of the basement which will place warm air directly under the bathroom and closet; common cold spots. The combination of warm air flowing across the cabin and into the bathroom and then into the basement and back to the furnace should make the cabin and bathroom more comfortable and substantially reduce the temperature differentials between the cabin and basement. I have multiple remote thermometers and will report on the results of my simple modification after thoroughly testing it this winter. The good thing is If it doesn't work satisfactorily, I can easily restore everything to its original configuration and try something else.

-

If your 2019 LE II is the standard bed model (like my 2020), then yes, it is (unfortunately) normal and reflects a design flaw on Oliver's part. I would speculatgethat NCeagle's 2020 LE II has the twin bed option which would explain why NCeagle hasn't observed the same phenomena. In our particular vintage of LE II's, Oliver placed only a single air return duct in the very back on the curbside immediately in front of the furnace. When the standard bed is set up and the furnace is running, most of the hot air blowing out the supply ducts can't escape the cavity under the bed and is immediately pulled back through the return duct and into the furnace. This hotter air into the furnace in turn causes the supply air temperature to become even hotter which in turn causes hotter return air into the furnace which increases the temperature of the supply air, etc. Meanwhile, the air temperature in the cabin takes forever to increase because the hot air from the supply vents is immediately pulled back into the furnace and doesn't mix well in the cabin. As the intake air around the furnace (i.e., water pump) gets hotter, the heat exchanger in the furnace gets hotter and eventually overheats and triggers a safety shut-down of the furnace flame before the cabin actually reaches the temperature set point; referred to as short-cycling. From your pictures, it looks like your furnace started short-cycling badly when you increased the thermostat set-point just before 8 in the morning. It appears that it took over an hour to raise the cabin temperature by 10 degrees quite probably due to the short-cycling. I doubt this is an issue in the twin bed model because the hot air from the supply vents can freely mix into the cabin air and doesn't get trapped under the bed to be fed immediately back into the furnace. The quick fix for standard bed owners is to open another furnace return vent on the street side of the trailer forward of the bed. This helps pull hot air out from under the bed and returns that hot air to the furnace via the street side basement opening and over the water tanks. My 2020 LE II has a nice round access hatch on the streetside below the pantry (to access the Inverter GFCI). In the heating season, I just remove that access cover to that streetside hatch and the short cycling problem is solved, the furnace runs quieter, basement temps are more even throughout, and the furnace/thermostat do a much better job keeping a constant temperature at the set point chosen.

-

Unlike many satellites that are geostationary, the satellites used by the InReach are continuously orbiting the earth. That is why the InReach works almost anywhere in the world. The InReach has to wait until one of the orbiting satellites passes overhead in a line of sight before it can send and receive. In the middle of a miles wide open flat field, the InReach can see so much of the sky that it can almost always locate a satellite quickly. However, in a narrow canyon for instance, it will eventually see a satellite, but it may take considerable time before a satellite passes over the narrow window to the sky above the canyon. If you carry it on your waist or in a backpack, your body will be blocking part of the sky as well. I have found that the fastest way to get an important message out when you can't see the whole sky is to place the InReach wherever it can see the most sky, then move away from it for awhile.

-

When troubleshooting your thermostat, you may want to take time to plug the large hole on the wall behind the thermostat that the three conductor wire comes out of. You can see part of the hole in the picture above. I found that in colder weather, cold basement air can exit this hole directly into the thermostat and trick the thermostat into thinking the cabin temperature has fallen causing it to start the furnace when in fact the cabin is still at the preferred temperature. Once the furnace starts, the airflow reverses as warm air comes into and through the thermostat and into the basement through the hole, causing the furnace to shut off in short order and then the short cycle repeats itself. Merely covering the hole with a piece of tape is a quick and easy fix. This hole is not necessarily a design issue with OTT but rather a poorly designed thermostat. Well designed thermostats have sealed backs with the wire terminals located on the back of the thermostat. The Dometic has a hole in the back of the thermostat with the wire terminals located on the inside of the thermostat. Cheap design. I swapped my Dometic thermostat out for a "Easy Touch RV" thermostat from Micro Air, primarily to allow me to monitor cabin temperature and adjust the furnace remotely via wi-fi because I store my LE II outside many miles from my house and unwinterized. The Wi-Fi feature allows me to turn on and/or turn up the thermostat from home when a freeze event is forecast. I am also alerted if the propane runs out. Unlike the Dometic, the Easy Touch has a sealed back with terminals on the outside back of the thermostat. You may want to consider the Easy Touch as a replacement if in fact your Dometic thermostat continues to be balky and ultimately needs to be replaced. Micro Air makes a model that is an exact replacement for the Dometic thermostat in the Oliver.

-

Inverter Generator Trivia - Warning - Nerdy Engineering Post

Chukarhunter replied to Frank C's topic in General Discussion

I see you have a 2019 LE II. Oliver only offered flooded/AGM batteries and the 45 amp converter/charger in 2019. Do you still have the flooded batteries with the 45 amp converter charger? If so, then anything larger than the little Honda EU1000i would be overkill for battery charging. A 45 amp converter charger will only be able to charge your batteries at a maximum rate of about 650 watts (45 amps charging current * 14.5 volt maximum charging voltage) regardless of how large your generator is. Assuming 10 percent losses in the conversion from 120 volts from the generator to the 14.5 volt charge current, the maximum generator size needed to charge your batteries is about 725 watts (650 watts / 0.9). If you have only two flooded batteries, then they won't even be able to accept a full 45 amp charging current. Even after adding the tri-fuel conversion kit to the EU1000i, it should still put out a continuous 800 watts when running on propane. More than enough to charge your batteries at the fastest rate possible while simultaneously running the furnace and a few lights. Any larger generator will not charge your batteries any faster (unless you convert to Lithium batteries and an inverter/charger with a higher charging current capability). If the above accurately describes the configuration of your Ollie with the original 45 watt converter/charger and flooded/AGM batteries, you may want to consider the little Honda EU1000i with the conversion kit. It is significantly lighter and much quieter than even the Honda EU 2200i. (I know because I own both). It is expensive though. -

I agree and it is all good advice. I spent hours and hours on this forum agonizing over whether my tow vehicle could tow the LE II safely. In the end, the many wise and experienced members of this forum convinced me that I could do so while staying within all limits as specified in my owners manual and placard on the door pillar. The wise advice of J.D. actually gave me the confidence to pull the trigger and I am grateful. I have been frowned upon in this forum more than once for my choice of tow vehicle but nobody on the forum has ever accused me of being a terrible danger to my family and everyone else on the road. Should the mystery owners of the subject Kia ever identify themselves, I suspect this is what they might say….. "Our very low mileage KIA (with tow package) is rated to tow 5,500 lbs with the Anderson hitch and 550 lbs tongue weight. It has a cargo capacity of 1,325 lbs. We spent a lot of time on this forum and paid particularly close attention to J.D.'s posts about towing with his Land Cruiser 200. We noted that the wheelbase on the KIA is a few inches longer, and the front and rear track width are the same but the KIA has a lower center of gravity and the distance between the rear axle and the receiver is shorter on the Kia than the Land Cruiser. Our tow package came with auto leveling rear shocks that allow us to always tow flat which increases safety without affecting rear suspension performance the way aftermarket air bags can. We then noted that J. D. successfully travels with a tongue weight under 500 lbs and thought that if we followed all the guidance on the forum, we wouldn't be putting ourselves and others on the road in danger. We are empty nesters with a small 20 lb dog. The combined weight of my wife and I and the dog is 325 lbs, our hitch weight typically 520 lbs (with half full fresh water tank), and the Oliver loaded with provisions is 5300 lbs and we carry less than 200 lbs of cargo in the car. So total actual payload is typically 300 lbs below the limit and gross trailer weight is 200 lbs below limit. Engine performance is definitely marginal on long grades but we have no trouble maintaining over 50 MPH climbing over the Siskyou pass on a hot day. We bought and use a tongue scale and occasionally weigh on commercial Cat scales to make sure we don't get careless or complacent. We have thoroughly enjoyed our Oliver in the brief time we have owned it, and had no idea what a danger we have been to others on the road. Now we are confused. Where did we go wrong?"

-

For the first year of ownership, we never used the patio lights at all because we didn't want to blind ourselves on the curbside, much less the neighbors on the streetside. Like other Oliver owners have, we ended up adding amber film over all the patio lights and the light is now warm and subdued. I agree that Oliver should provide separate switches for street and curbside lights, but we found that adding the amber film to the lights is an easy, low cost way to mitigate those annoyingly bright lights for everyone affected.

-

Ditto for me. On rural interstates though, I usually adjust my speed to match the predominant speed of most truckers. Out in Oregon that seems to typically be around 67-68 MPH. If I catch up to a trucker going at least 65 MPH I will follow it. If I start getting passed by trucks (which I hate, especially in the rain), I will speed up a little bit and drive with them. And I will admit that under ideal conditions in remote stretches of Interstate, I will cruise at 70 MPH. On two lane roads I drive 50-60 MPH depending on conditions and I don't try to keep up with the trucks. I will typically slow down in heavy crosswinds/headwinds but only to save on fuel. I find the LE II to be almost impervious to crosswinds.

-

I may have stumbled on a simple cause for your frequent furnace cycling, especially when it is colder. I had not been very pleased with the Dometic CT thermostat in my 2020 LE II and had at one time experienced the clicking noise but only when I tried to change the deadband from 2 degrees down to 1 degree. I occasionally experienced erratic performance from the thermostat and more so when the temperature dropped rapidly outside to temperatures below 45-50 degrees. I recently decided to change out to a new wifi thermostat (Micro-air Easy Touch RV), primarily because I store my trailer outside across town at my son's house and his wifi reaches the trailer. It now allows me to turn the furnace off and on, monitor the cabin temperature and change the temperature setting from my home or anywhere else. I can also monitor when the furnace is actually running or not from anywhere. When changing out the Dometic OEM thermostat, I discovered that there is an almost 1 inch diameter hole behind the Dometic thermostat that the thermostat wires come out of and this hole is directly behind a big hole in the back of the thermostat. The hole is large enough to allow a significant air exchange between the cabin and the basement/hull cavity between the outer hull and the inner hull. I think what is happening is when the furnace is running, the return air into the furnace is naturally creating low air pressure in the basement that pulls return air from the cabin through any penetration between the cabin and the basement/hull cavity. Most of this warm cabin air is pulled into the basement through the return vent at the rear curbside floor, but some air is pulled out of the cabin into the basement through other small openings such as around the drawers, etc. It will also pull warm cabin air through the thermostat and out through the hole behind it. This is not a problem although it could cause the thermostat to occasionally turn off earlier than it should. The real problem occurs when the furnace shuts off and warm cabin air starts exiting the cabin through the max air vent if open or other small air gaps around closed vents and the windows creating convection air currents. This creates a low pressure situation in the cabin which will cause much colder basement air to be drawn through the basement scuppers and into the cabin through any and all penetrations between the basement and the cabin, including cold air from the basement exiting the hole behind the thermostat and through the thermostat into the cabin. It is not unusual to have the basement temperature be 20 or more degrees below the cabin temperature. I believe that as soon as the furnace turns off when say the cabin temperature is 65, almost immediately a small current of much colder 45 degree air starts flowing out the hole from behind the thermostat, through the thermostat and into the cabin. This sudden inrush of much colder air into and through the thermostat causes it to quickly restart the furnace again and once again warm air gets pulled into the thermostat causing it to quickly turn the furnace off, which causes cold air to almost immediately begin entering the thermostat from behind and the cycle repeats itself. You can test my theory by unscrewing the Dometic thermostat and let it hang away from the wall and put a piece of tape over the hole behind it. If the rapid cycling doesn't happen anymore, you may have found the cause of your issue. Me, I am going to seal the hole in the wall behind the thermostat to seal off the air flow, and then put some little pads on the back of my new thermostat to hold it about 1/4 in off the wall to break the thermal coupling between the thermostat and the colder wall.

-

Those of us that occasionally or frequently encounter very cold weather when pursuing our passions with our Oliver can benefit immensely from the experiences and insights of others on this forum. Those that never do, or that always winterize, probably don't care as much, especially those that never boondock. Let's face it, if you have full hookups, you can put two electric space heaters in the basement and run the propane furnace at 70 and not worry. Absent shore power, cold weather can be stressful. I would like to see the Moderators expand the category of "Oliver Boondocking" and call it "Oliver Boondocking and Cold Weather Camping" so those of use that do find ourselves in frequently in cold weather and unwinterized can share our questions and insights in one place. I have spent over two years trying to figure out the eccentricities of the Oliver when it comes to balancing temperatures throughout the trailer in cold weather and I wouldn't trade my Oliver for anything else. However, what I have learned or not learned can't be shared in one giant post. And I haven't figured it all out either. After two years of moving remote wifi temperature sensors around to different places, changing out the thermostat, and opening different pathways for return air to enter the basement, I have learned a lot. Importantly, I have come to the tentative conclusion that the biggest reason that the basement temps can drop so far below the cabin temp in places is due to the fresh water tank. Heat travels through water 20 times faster than it does through air. Conventional wisdom would say that the fresh water tank would act like a hot water bottle to help keep the basement warm. However, the fresh water tank in the Oliver appears to sit on a rubber mat on the floor of the basement and that creates a direct coupled path for the heat in the water tank to be lost through the bottom of the trailer at a rate up to 20 times faster than heat is lost through the rest of the shell. This sucks heat out of the basement faster than the furnace can replace it. Even a small air gap under the fresh water tank would slow this heat loss dramatically. Unfortunately, insulating under the fresh water tank is not an option for us, although Oliver should consider doing something like it in future builds. The rapid heat loss from the fresh water tank could explain why the basement temperatures drop so much compared to cabin temperatures, unless the furnace runs constantly. I am wondering if it would help to add 2 inch or 3 inch rigid pink foam panels to the underside of the trailer between the ribs of the frame to reduce the heat loss from the fresh water tank. Am I crazy?