Chukarhunter

Members-

Posts

108 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Chukarhunter

-

Traveling between campgrounds when it’s freezing

Chukarhunter replied to RustyMD's topic in General Discussion

Don't forget about the Truma water heater if you will have one. Running the furnace while traveling will not protect the Truma in sub-freezing temperatures. Make sure the Truma is set to Eco when traveling in below freezing temps (propane) or alternatively, activate the electric antifreeze heating element in the Truma (preferred) if you ordered the option. Make sure OTT has actually installed the antifreeze kit when you pick up the trailer and make sure they explain how to insert the exhaust plug and set the control to electric antifreeze when you travel in sub-freezing weather. (And don't forget to remove the Truma exhaust plug before switching the Truma back to propane when you arrive at your destination.) -

My trailer is stored across town so I can't post a picture today but it sounds like your 2021 doesn't have an access plate hatch where my 2020 does which is located below and slightly left of the galley. That hatch is very close to the pex lines to the outside shower and distributes heat to that area well. I think you are on the right track and this is what I will probably do when I get around to doing a permanent, quality fix. First, your idea to make the existing return vent in front of the furnace on the street side smaller when you add other vents is a very good idea. I will probably close off that vent entirely. I will then ensure I add sufficient return vent area to replace it. The manual says something like a minimum of 50 sq. inches but I will probably make sure I have at least 60 sq. inches unobstructed with at least 8 sq. inches in the bathroom and at least 50 sq. inches on the streetside of the main cabin. I am leaning toward placing the bathroom vent immediately below the sink in the upper part of the recessed towel bar insert so that shower water can't easily enter. This vent should keep the bathroom warmer when the door is closed and also keep the plumbing area under the closet close to cabin temperature. For the main cabin, I will block the existing vent in front of the furnace and add two square vents of at least 25 sq. inches each to the streetside. I will place one of these directly across from the existing vent on the curbside to heat the garage/outside shower area and the second somewhere close to the front of the main cabin on the streetside. One other issue in my 2020 was that OTT shared the bathroom duct run with an adjustable duct in the main cabin. This is another design flaw as when the adjustable vent is closed (to try to force more air to the bathroom vent?), there is insufficient supply duct capacity (a safety issue) and the furnace overheats and short cycles. I tried to make sure that the vent was always adjusted open but found that the vent always closed itself when traveling. It is easy to remove the rotating closure ring from the back of the round vent cover which I did so now that vent is always fully open. This solved my short-cycling problem and the furnace heats the main cabin of the trailer much better (but not the bathroom).

-

I too have a 2020 LE II and I definitely bought mine new as a 4 season trailer and as I use it extensively through the winter in Oregon, I do not winterize it. I am extremely pleased with the LE II overall, but OTT completely failed when they engineered the forced air heating system. A forced air heating system does not distribute hot air throughout the living space, it has return ducts that pull hot air from the supply ducts across the living space to a one or more return ducts and back to the furnace. Oliver only put in one return duct and they located it immediately in front of the furnace itself. This means that there is no circulation of heated cabin air through the basement. It is dead air space. Even more inexcusable, OTT didn't put any return vent in the bathroom so when the bathroom door is closed, the supply vent in the bathroom pressurizes the bathroom space and warm air doesn't flow into the bathroom. Given the primary problem is a lack of properly sized and located return air vents, adding or relocating supply vents will not be very effective at warming the basement. I too spent did lots of testing with thermostats to get a good understanding of basement temperatures at various cabin temperatures. Like you, I found that no matter how hot I heated the cabin, the area around the outside shower would inevitably fall to around 5 degrees above the outside temperature. I determined the main reason was the lack of heated air circulating through the basement due to the lack of appropriately located return vents in the cabin. I also found that the tiny vents in the bottom of the trailer designed to drain any water that finds its way to the basement are a problem in cold weather given the flaws in the heating system. There are enough tiny air leaks in the cabin to create a slow convection effect which draws cold outside air slowly through the basement vents. Since there is no warm air circulating through the basement even when the furnace is running given the flawed design, this slow intrusion of outside air pools in the basement creating the dramatic temperature differentials between the cabin and the basement. I have not permanently fixed the problem yet, but found a temporary workaround that I am confident is good down to 15 degrees or so. If you have the inverter like I do, there is a large street side hole just behind the battery box (to access the inverter GFCI). When it gets cold, I just unscrew and remove the cover and create a second temporary street side return vent. Now more than 50% of the hot cabin air flows into the street side of the basement and across the water tanks and rear area stirring up the air. The area by the outside shower now varies less than 10 degrees from cabin temperature and the battery box stays within 5 degrees of cabin temperature (I have lithiums and have sealed and insulated the battery door). The furnace seems to run quieter and the cabin heat is more evenly distributed. The walls don't get quite as cold either. This winter if it gets real cold, I will also temporarily tape over the vents under the trailer to stop the convection currents from pulling cold outside air directly into the basement. For me, I think the permanent fix is to add a few return vents to the trailer. I will probably put one under the front dinette next to the CO detector and another smaller one in the bathroom. This should ensure that the entire basement enjoys adequate circulation of warm air when the furnace is running and that the bathroom is warm even with the door closed. You may want to try unscrewing the cover from the street side hole in front of the inverter and see if you experience the same improvements in basement temperatures that I did.

- 53 replies

-

- 11

-

-

-

My 2020 LE II came with a factory installed bubble level installed on the upper left wall inside the rear storage garage. When unhitching, I first use the tongue jack bubble level along with Anderson levelers to get close. Then I go to the rear and fine-tune the port to starboard leveling using the stabilizing jacks while observing the factory installed bubble level. I will note that I didn't discover this factory installed bubble level in the storage garage until months and several trips had passed after picking up my LE II.

-

It sounds to me like the Truma AC has a soft-start capacitor built in to the unit by design which is why they will not honor warranty if a capacitor is added external to the Truma. I speculate that two uncoordinated capacitors in series may not always work well together. A soft start capacitor provides instantaneous reactive power reserves and it is reactive power that creates the electromagnetic field which allows any conductor to transmit real power. It is reactive power that supports voltage. Large generators on the bulk grid are designed to vary the amount of reactive power they generate in real time (simultaneous with generating real power or watts) to support grid voltage. Small generators like the Honda are rated at unity power factor and are not designed to inject or boost reactive power when faced with inductive loads like a sudden AC compressor load. Hence the need for a soft-start capacitor which minimizes voltage sag for the fraction of a second when the compressor starts. From the guidance out of Truma mentioned above, I expect that they have designed the unit with an integrated soft start capacitor that mitigates voltage sag on startup. (Just like the external soft-start capacitor that Oliver installed in my 2020 LE II does). I am reasonably confident that the Honda EU2200i, or any similar nominal 2,000 watt generator will start and run the Truma, or I don't think OTT wouldn't have made the switch.

-

Replacing the PowerTron Lead Acid Wet Cell Batteries

Chukarhunter replied to Frank C's topic in Ollie Modifications

Making the switch to LifePO4 batteries can be stressful because of the initial cost and because they are so new. It was for me, I can't comment on the Battle Born battery you are looking at as I have no experience with them. I have always liked that they are made in the USA and they have come down in price considerably in the last two years. I don't know that the particular model you are looking at would be your best choice though. You would probably be just as pleased with two of the 100 ah Battle Born batteries as they are over $600 less expensive than the single 270 ah model and because they are the same size as your current batteries (Group 27), you know they will fit in your battery tray exactly like your current batteries. You will still have considerably more usable capacity than you currently have with your flooded batteries and they weigh about 20 lbs less than the single large 270 ah Battle Born. Also, if one battery ever fails while boondocking due to a bad BMS, you still have one good battery. Do you plan to do the conversion yourself? If so, then it may be easier as well to go with the two 100 ah Battle Born alternative (like Mike and Carol) and since the battery posts are in similar locations so you probably can use your existing cables. The larger Battle Born appears to have the posts at one end which may require lengthening or shortening your existing battery cables. I do note that the Battle Born batteries don't have typical battery posts so you will likely need to re-terminate your existing cables to work with the Battle Born batteries in any case. Minor in the scheme of things. I wanted the lithium option when I ordered my LE II but Oliver didn't offer it so I changed out my 4 flooded batteries for LifePO4 as soon as I got back from Hohenwald over two years ago. Being particularly cost conscious after paying for our Ollie, I went with 4 Lion Energy UT1300 105 ah batteries I bought through Costco (420 ah total for $2800). They are Group 24 size and took less than two hours to change out and the cables only required one minor modification. It should have taken less than an hour, but I had to run to NAPA and get a new battery post clamp as for some reason the Lion Energy batteries came with both posts sized as negative posts (in typical flooded batteries the positive post is slightly larger in diameter than the negative post). They may have fixed that by now. I have been using the Lion Energy batteries extensively for over two years now with no problems whatsoever (they do have an outstanding warranty). Costco only carries them a few times each year as a special event. They have an event going on now that expires tomorrow (Sept. 11). Steve -

Best Replacement for Lifeline gpl-4ct agm battery

Chukarhunter replied to roguebooks's topic in Mechanical & Technical Tips

Roguebooks, Yes, you could replace your two 6 volt AGM batteries (220 ah at 20 hour rate) with one 12 volt LifePO4 (lithium) battery (100 ah) and it would actually be an upgrade in performance under most conditions. Some reasons for this are: 1. The AGM's are rated at 220 ah when discharging over 20 hours which is an 11ah rate of discharge (220 ah/20 hours). At a 5 hour rate of discharge storage falls to under 190 ah of which only half (95 ah) is usable without dramatically shortening battery life. Lithium batteries do not lose storage capacity at high rates of discharge like the AGMs and can be discharged down to 15% without any significant voltage drop or shortening battery life. This benefit is very noticeable if one has an inverter and occasionally places large loads on the batteries (microwave, hot pot, etc.). 2. It takes hours to charge the AGM batteries the last 20 percent no matter how large a charger you use due to internal battery resistance that increases with state of charge. Lithium batteries can accept very large charge currents right up to the point at which they reach full charge. It can mean the difference between running a generator for 2 hours versus 5 hours. It also means that you will always be able to continuously store the full output of your solar panels unless the batteries are completely full. 3. AGM batteries perform poorly at cold temperatures due to significant voltage drop. At 32 degrees F, an AGM battery loses 15 percent of its capacity. The lithiums lose almost none. If you do have an inverter/charger installed in your LE , it almost certainly has a LifePO4 charging profile in which case there is nothing else to do to convert to lithium batteries besides removing the AGMs and putting the lithium (s) in and reconnecting the battery cables. Steve Here is a link to a testimonial from a mariner who made the switch and discovered the more obscure benefits of converting to LifePO4. He explains all this pretty well. https://panbo.com/lithium-battery-math-better-than-you-may-think/ -

We just ordered an Elite ll for pick up in April 2023

Chukarhunter replied to KetchikanKid's topic in Introduce Yourself

Welcome to the Oliver family Wendy and Steven. My wife Lornie and I (also a Steve) are also retired and live just a few miles north of you in close in SE PDX. We picked up our LEII in Hohenwald two years ago in August 2020 and came back via Missouri, Kansas, Colorado, Wyoming, Utah, Idaho then Oregon. We had planned to take our time returning home like you are planning to do but right after picking up the trailer we got word that Lornie's brother who had MS had gone into intensive care. We accelerated our trip home. I drove 400 miles the first day as a shakedown and and then another 1450 miles total on days 2 and 3. The LEII has such good towing manners that honestly I didn't find the long miles any more tiring than driving the interstate without the trailer. I also found the LEII to be much easier to back up than my 8 foot utility trailer or 14 foot popup. I never realized before how much nicer a well designed twin axle trailer tows compared to a single axle trailer. I don't know what tow vehicle you will be using but if you are at all apprehensive about the trip or towing, then I recommend that you order the Andersen hitch even if it is not really required for your tow vehicle. It really works well and they do everything to set it up for you when you pick up the trailer. I had a big scare the first day on a two lane road in Missouri when I launched off of a unmarked elevated railroad crossing at 55 miles an hour. It felt like the tow vehicle left the road and flew into the air (I probablly did not) and I braced for the porpoising and possible loss of control. There was no porpoising at all and the Andersen hitch dampened all movement after one bounce. I am sold on the Andersen mated with the LEII. The price of many of Oliver's options are approaching obscene, but the Andersen is worth every penny in my opinion. I have never had any issues hitching or unhitching with the Andersen and it only adds 2-3 minutes to the time it takes to hitch up and even less when unhitching. Lornie and I would be happy to meet you some time over food or beverage to share our Oliver experiences with you. Send a PM if you are interested. Congratulations on your Oliver purchase! -

I experienced the same yellowing of my window caulking after my first extended trip shortly after picking up my Oliver. It looked the same as it does in your picture. Turns out that it was just discolored from driving a number of miles on a gravel road with clouds of very fine dust. When the trailer comes out of the factory there is a very slight residual stickiness to the surface of the caulk that attracts fine dust like a magnet and holds on to it. A light wash and hard rinse didn't remove the dust/discoloration and it was still yellow looking. However, a fair amount of extra pressure with a soapy wash mitt on the caulk when washing the trailer a second time (and some use of a soft toothbrush for tight spots) made the caulk white again and eliminated the slight stickiness. It worked for me and I haven't experienced discolored caulk again.

-

I am very glad we ordered the rear view camera. With it, I have no need for extended side view mirrors. I can always see what is behind me and I can also always see when it is safe to change lanes as it is sometimes hard to tell if you have enough clearance when looking in the side view mirror (objects may be closer than they appear!). The rear view camera is especially handy when you need to change lanes quickly and/or merge in dense traffic. I don't find it all that helpful for backing up.

-

Setting the grid limit at 15 amps on generator power seems correct because the EU2200I is rated at 1800 watts continuous which equates to 15 amps continuous current at 120 volts (120 volts * 15 amps = 1800 watts.) However, I don't think you need to set the charge current as low as you are doing, especially if you have the lithium batteries. Remember that the charger is supplying its charge current at a nominal charging voltage of 13.5-14.5 volts, not 120 volts. One amp of 120 volt current delivers 120 watts of power, whereas 1 amp of charge current is only delivering 13.5-14.5 watts of power to the batteries (volts * amps = watts). The Eu2200I is capable of 1800 watts continuous at 120 volts. If the battery charger is the only load and you assume 15% losses through the inverter charger, then the EU2200I is capable of charging the batteries at a rate of 1,530 watts (1800 watts * 0.85 = 1530 watts). If the charger is charging the batteries at a rate of 1530 watts at a charge voltage of 14 volts, then the charger is delivering 109 amps to the batteries (1530 watts / 14 volts = 109 amps). I would think you should be able to set your charge rate at 100 amps and the EU2200I would supply the 100 amp charge rate just fine if there are no other 120 volt loads. (My inverter charger has a maximum charge rate of 80 amps which is what I have it set at when charging with my EU2200I). I don't know how many watts your air conditioner draws with the compressor running, but lets say it is 1200 watts. That leaves 600 watts of generator power to charge the batteries (1800 watts continuous from the generator minus 1200 watts to the air conditioner = 600 watts). Assuming 15 percent losses through the inverter charger, you should be able to run the air conditioner while simultaneously putting as much as 510 watts into your batteries (600 watts * 0.85 = 510). If the charging current is 14 volts and power into the batteries is 510 watts, then the charger is putting out 36 amps of charge current (510 watts / 14 volts =36 amps). This means you should be able to set the charge current limit as high as 30-35 amps while running the air conditioner with the EU2200I without overloading the generator. This will result in a 6-7 times faster battery charge rate than the five amp setting you chose. When not running the air conditioner, you should not have to reduce the charge current at all from your 50 amp normal. In fact, you may want to increase the rate to 80-100 amps to take full advantage of your 1800 watt generator and thereby reduce your generator run time needed to charge your batteries. I may have calculated something wrong here. Others please chime in if I have. All this is not really intuitive.

-

Sounds like your issue is solved. Charging batteries at 14 volts at a 60A rate means you are putting 840 watts into your batteries (volts x amps = watts). If you are seeing 9A current at your 20 amp wall outlet, and assuming the utility company is delivering 120 volt power,that means that the inverter/charger is pulling 1,080 watts from the grid (9A x 120 volts = 1080 watts). This means that your energy losses between the house outlet and the batteries is 240 watts lost, or about 22%. This seems unusually high and cannot be easily explained by losses through the inverter/charger alone. There are two very possible causes for this: low voltage (below 120 volts) at the 20 amp outlet and/or an undersized extension cord. You can't do anything about voltage at the outlet, although if it is too low into your house, you should complain to your power company. Even when nominal voltage in hours of low area power consumption is 120 volts, this voltage can drop noticeably in the afternoon when everyone in the neighborhood is running their air conditioner. You can also get significant voltage drop between the breaker and the outlet if the circuit distance between the breaker and outlet is more than 50 feet which of course the power company can't do anything about. A 20 amp breaker doesn't know how many watts it is passing; it only sees amperage. If voltage at the outlet is 120 volts, then the breaker will trip if it is passing more than 2400 watts (120 volts x 20 amps = 2400 watts). If the outlet is only seeing 110 volts, then the breaker will trip if it is passing more than 2200 watts (110 volts x 20 amps = 2200 watts). The size of the extension cord is very important. Using an extension cord no smaller than 12 AWG should allow a 50 foot extension cord with no more than 3% voltage drop. Never use a smaller 14 AWG extension cord as it will result in greater than 3% voltage drop even if it is only a 25 foot extension cord. If you must go longer than 50 feet, spend the money on a 10 AWG extension cord or heavier. Voltage drop increases exponentially as the length of an extension cord increases. (see table below) Low voltage into the trailer shouldn't be a problem with charging the batteries through the inverter other than maybe having to reduce the rate of charge. On the other hand, low voltage is not good for the air conditioner and can cause premature failure of the compressor.

-

Can’t get help. Electrical/voltage problem.

Chukarhunter replied to Katjo's topic in General Discussion

This does not sound right. The lithium batteries should read no more than 13.6 volts when fully charged. I expect the tech did not realize that when he checked the voltage of all your batteries, he was reading the solar charge controller's charging voltage of 13.9 volts, not the battery voltage. If you have a charger hooked up to a battery, the voltmeter will be measuring the charging voltage and not the battery voltage. The only way to accurately check the voltage of a battery is to disconnect the batteries from the system to ensure they are not receiving a charge or seeing a load. If they had been charging before disconnecting, then let them rest awhile and then check the voltage of each battery. This is known as the "open circuit voltage". If you haven't checked the open circuit voltage of your batteries, this is the first thing you need to check. It could save a lot of unnecessary troubleshooting if it turns out you actually do have battery problems. Don't give up. 🙂 -

Can’t get help. Electrical/voltage problem.

Chukarhunter replied to Katjo's topic in General Discussion

It is possible that you have problems with your Lithionic batteries. This older thread discusses severe under-voltage with the Lithionics even when the app says everything is fine and is describing the system in a 2021 LE II like yours. Lots of useful troubleshooting information in this thread. -

Can’t get help. Electrical/voltage problem.

Chukarhunter replied to Katjo's topic in General Discussion

This makes sense but it sounds like you may have a problems with 120 volt system and unrelated problems with the 12 volt system. When you are connected to shore power, you say the inverter/charger is charging your batteries at 14.2 volts. This is consistent with flooded or AGM batteries in absorbtion mode which means they are almost full. If you have lithiums, then it means they are basically full and will probably drop the voltage to float setting (around 13.6 volts) soon. If the solar charge controller is also saying the batteries are full, then it would seem that the charger section of the inverter/charger is working correctly. That means that the charger section of the inverter is getting 120 volt power, but the inverter is not passing 120 volt power to the 120 volt outlets and appliances. Have you checked the GFCI on the inverter itself to see if it has tripped? It is accessible through the round hatch below and to the left of the Galley. I believe power to all 120 volt outlets and appliances is always passed through the GFCI in the inverter at all times, whether connected to shore power or running a generator. If the GFCI on the inverter is tripped and won't reset, then you have a bad GFCI on the inverter itself. Do you have the accessory 30 amp convenience connection at the front of the trailer? It would be on the curb side below the propane tanks. If a tripped GFCI on the inverter is not the problem, you might try moving the shore power cord to the auxiliary 30 amp connection to see if that restores power to your 120 volt outlets and appliances. As I understand it, there is a transfer switch that prevents power from flowing into the trailer from both outside receptacles at the same time (i.e., shore power and a generator). If you do have the auxilliary 30 amp connection and moving the shore power cord to the auxiliary connection (or vice-versa) solves the 120 volt issues, then you may have problem related to the transfer switch. You have received good advice on troubleshooting the 12 volt system but I find one thing you said interesting and a possible clue. You said that the lights sometimes dim and other times don't work at all. Do all the lights dim together or just occasionally one or two. All the lights in 2021 Oliver are led lights. Unlike incandescent lights that will dim when voltage drops, led lights either work or they don't. If voltage drops, they stay at close to full light until voltage drops so low that they just go out. If it is just one or two lights that occasionally dim, then the electronics in those individual bulbs are failing and you can just replace the bulb which contains the electronics. If all the lights are dimming together, then you may have a bigger problem then just low voltage on the 12 volt side. -

So I had a driving condition pulling the Oliver Elite II

Chukarhunter replied to Trainman's topic in Towing an Oliver

You are so right. I stand corrected. Thanks for your response. -

So I had a driving condition pulling the Oliver Elite II

Chukarhunter replied to Trainman's topic in Towing an Oliver

If you had not had the Anderson hitch, you may have experienced less than perfect control in that high speed maneuver. The weight distribution functionality of the Anderson is important for towing stability at all times with many tow vehicles, but the anti-sway functionality built into the Anderson is really only important in emergency maneuvers because of the ability to instantly dampen any sway induced by sharp turns at high speed. This extra safety is even more important with short wheelbase tow vehicles like mine. The anti-sway feature of the Anderson works well as you experienced. I think the reason Anderson recommends never greasing the ball is to prevent any possibility of grease working its way into the anti-sway friction cylinder which would compromise performance. Sort of like greasing the surfaces of your brake shoes on drum brakes. If/when I get a tow vehicle that doesn't require the weight distributing feature of the Anderson, I will probably remove the whale tail and chains on mine but may continue to use the Anderson ball because of the extra margin of safety provided by the anti-sway functionality. -

Mysterious shore power outage

Chukarhunter replied to ThomB87's topic in Mechanical & Technical Tips

Trainman, I agree with others that low voltage at the post was likely your problem. Voltage drop is a function of wire size, current (amps) and nature of the load itself; resistive, or inductive. Were you the last RV site in the park? The longer the wire run, the more voltage drop there will be. And the higher the current in the wire, the more voltage drop there will be. I'd speculate that the closest trailer to the power source had plenty of voltage, but everyone in front of you on the bulk circuit was running their air conditioner and everything else which will cause voltage drop at each site along the circuit so by the time the power got to you, voltage was getting pretty low (the definition of a brownout). The bulk power system adds capacitors every so often along the overhead lines to support voltage. Your electric water heater is a resistive load like an incandescent bulb, so if voltage into the water heater drops, the water heater just consumes less watts and doesn't heat the water quite as fast. The air conditioner is a motor (i.e., inductive) load which like John said will increase current draw as voltage decreases. As voltage drops , the current increases to the AC as the AC continues to draw the same number of watts. The increase in current will act to drop the voltage even more which increases the current draw which drops the voltage, etc. Reactive power devices (like the soft start capacitor in the Oliver) might be able to intervene somewhat to break this cycle but can only do so much. Beyond a point, the voltage collapses and the EMS will open the circuit preventing the AC compressor from burning up due to the high current draw resulting from the low voltage. The soft start capacitor in the Oliver acts to prevent this voltage collapse when starting the air conditioner with a generator. Like others, I expect that you were experiencing unusually low voltage at the post to start with and your air conditioner was operating on the bleeding edge of low voltage. Turning on the water heater increased the current draw from the power source past every RV site ahead of you on the circuit and caused further voltage drop at your post and on into your trailer. That caused the air conditioner to draw more current (amps) which further dropped the voltage which caused it to draw more amps and it reached the low voltage cutoff of the EMS. Just a theory. If it happens again, you might try turning the air conditioner to low (the compressor should draw fewer amps on low) and you may be able to run the water heater in combination with the air conditioner on low long enough to get the water hot. Worth a try. I don't think plugging into 50 amps would make any difference as I believe 50 amp RV posts are still only 110 volts into the Oliver. A heavier gauge and/or shorter cable from post to the Oliver would reduce voltage drop a bit, but if you are using the beefy cable that comes with the Oliver, there is not much more you can do there. The RV park probably had an under-designed electric system. I have read that the electrical code says that an RV park system need only supply 41% of the sum of the maximum rating of each site on the theory that in aggregate, the RV's will never be using more than 41 percent of the capacity of all the posts. Probably not a very good assumption on hot afternoons since just about everyone has an air conditioner and compressor fridge these days. -

Using the formula “Volts x Amps = Watts” it is relatively straightforward to estimate how much using the convection/microwave will draw down your batteries. If the convection microwave is 1,450 watts, then the formula is: Volts x amps = 1450 watts If you assume that your lithium batteries will reliably deliver 12.5 volts to the inverter under heavy load, the formula becomes: 12.5 volts x amps = 1450 watts, which is the same as (amps = 1,450 watts divided by 12.5) 1,450 watts divided by 12.5 volts = 116 amps The last thing you need to account for is losses through the inverter which are typically around 10% or less. Assuming 10% losses through the inverter: 116 amps divided by .9 = 128 amps. So, if the oven runs at full power continuously for 1 hour (which it won’t), you will use about 128 amp hours from your batteries, or about 2.1 amp hours per minute. (128 amp hours/60 minutes) A microwave on high will draw continuous power, so if you microwave something that takes 10 minutes to cook, it will consume about 21 amp hours. (2.1 amp hours per minute x 10 minutes) If you bake something for an hour, the oven will run continuously until it heats to temperature and then will cycle on and off to maintain temperature. Assuming the oven is actually heating for 30 minutes of that first hour (complete guess), then the oven will use about 63 amp hours over the course of an hour (2.1 amp hours x 30 minutes). So Topgun2’s popcorn, potato and hot tea at 9 minutes total probably consumes a little under 20 amp hours (9 minutes x 2.1 amp hours per minute = 18.9 amp hours)

-

Convection oven, love it or hate it

Chukarhunter replied to John and Debbie's topic in General Discussion

I am happy with our choice of the convection/microwave oven, although I have not used the convection feature all that much. Upon heading home to Oregon after picking up the trailer, we stopped in Utah after a 700 plus mile day of towing and I was too tired to even hook up to power. I only had the basic 4 flooded batteries at the time, but I proceeded to bake a couple of pork chops for a little over a half hour at something like 350 degrees. Worked well and they were nicely browned and delicious. With the lithium pro package, you should be able to use the convection oven while boondocking without giving it a second thought. Just don't use any other power hungry appliances at the same time. Makes great nachos. -

Your question sounds straightforward but the answer is complicated and multi-dimensional. Cooling a hot trailer to the preferred set temperature is a function of the capacity of the AC expressed as the hourly maximum Btu's of heat that the AC can extract from the inside of the trailer versus the heat gain into the trailer from the outside. My AC is rated at a maximum of about 13,500 Btu/hour so I will use that as an example. If the trailer is absorbing heat from the outside (heat gain) at a rate greater than 13,500 Btu/hour, than the air conditioner will not be able to cool the inside of the trailer at all. It will be doing well just to keep the inside from heating to warmer than the outside. If the outside temperature is 95 degrees and the heat gain is 7,000 Btu/hour, then 7,000 Btu/hour of AC cooling capacity will offset the heat gain and the remaining 6,500 Btu of cooling capacity is available to actually cool down the inside to the preferred temperature setting. If the outside temperature is 105 degrees and the heat gain is now increased to 10,000 Btu/hour, then there is only 3,500 Btu/hour of cooling available to actually lower the inside temperature and it will take longer to cool the inside. As the inside temperature falls relative to the outside temperature, heat gain will continue to increase. Heat gain is a function of the several factors, the most important being the difference between the outside temperature and the inside temperature. The good news is that compared to most trailers, the heat gain in the Oliver is on the low side if the user cooperates. This lower heat gain is a function of many design attributes including the insulation between the hulls, the white outside color, the tinted windows and the "tightness" (very few penetrations of the hull) that minimizes the number of outside air exchanges per hour. To get the most out of your air conditioner, you must park your trailer in the shade, make sure all windows and vents are closed tightly, and don't open the door unnecessarily. If shade is not possible, extending the outside awning can help reduce heat gain in the trailer somewhat as can closing window shades. The speed with which one can actually cool down a hot trailer is a function of how warm the inside is to start with (stored heat in the thermal mass of the trailer itself) and the excess cooling capacity of the AC remaining after offsetting the ongoing heat gain from the outside. There are things you can do to achieve the best performance upon arrival on a hot afternoon. After minimizing heat gain to the extent possible by parking in the shade, etc. , make sure that the trailer is closed up as tight as possible by closing all windows, hatches, doors and vents to the outside. Then turn on the AC and set the thermostat down as low as it goes, and open all the inside vents on the AC itself to maximize airflow through the heat exchanger. You will want to turn the thermostat down way low because you want the compressor in the AC to run continuously until the trailer cools to the desired temperature after which you can reset the thermostat higher to hold the desired temperature. I have concluded the Dometic thermostat in my Oliver does not work very well. It will cycle the compressor off and on unnecessarily, even when the inside of the trailer is still well above the set temp. By setting the set temperature down to say 60 degrees initially, the hope is that the compressor will run continuously until the trailer is cooled . Any cycling will greatly increase the time it takes to cool the trailer. While the trailer is cooling down , stay outside if possible and try not to open the trailer door unnecessarily until it has cooled down inside. A human body adds several 100 Btu's an hour and two persons inside can easily add 500 Btu's an hour to the cooling load. Opening the door several times can do the same. Once the trailer has cooled inside to your desired set temperature or below, you can move inside, raise the thermostat setting to your preferred set temperature and the AC should cycle normally to maintain the inside temp you want.

-

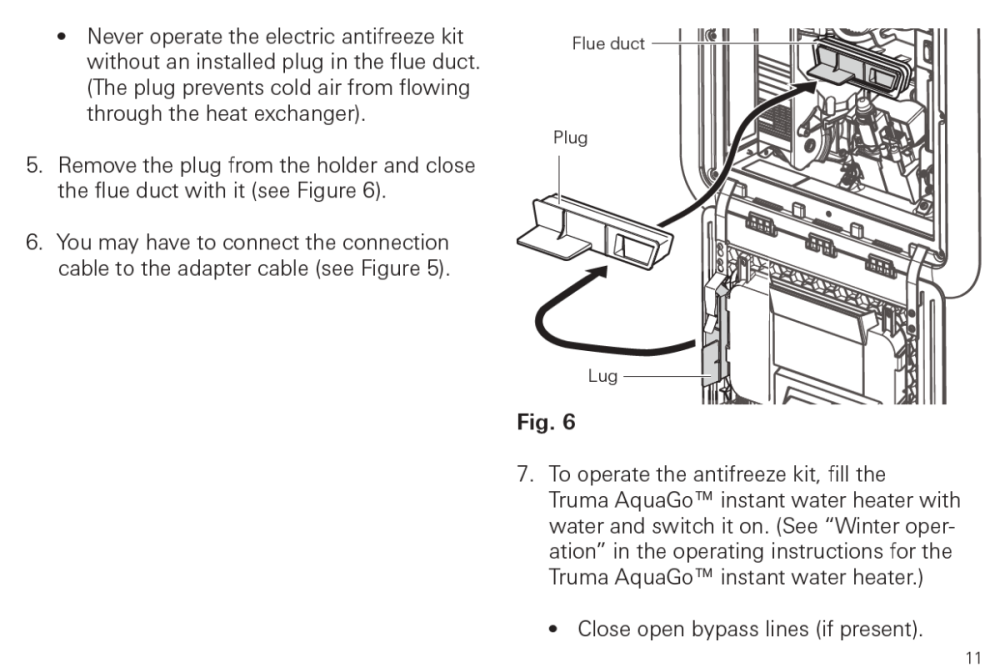

One other caution concerning the electric antifreeze kit that is not really explained in the manual is that the electric antifreeze module should never be energized if water has been drained from the Truma. It would be like turning on the heating elements in a home hot water heater that was emptied of water. The heating element would overheat and fail. There is no need to remove the electric antifreeze module when draining the Truma, but to be safe, one should probably unplug the 12 volt wires into the antifreeze unit when winterizing, so it cannot be accidentally energized after the Truma has been drained.

-

You should already have a plug clipped into a holder on the inside of the Truma door. It looks like every Truma comes with an exhaust plug even if no electric antifreeze kit is ordered. See picture below from the electric antifreeze instruction manual. I used the electric antifreeze kit several times before I realized that the plug existed and was supposed to be used. Oliver should really make a point of explaining how to install and use the antifreeze kit upon delivery. I had to teach myself.

-

CO detector goes off, ?? false alarm

Chukarhunter replied to Dave and Dana's topic in General Discussion

With the help of Mike Sharp at OTT, I think we may have identified why the Norcold control panel leaks outside air into the trailer around the upper front control panel . It is unlikely related to the combustion seal that seals the mounting fin of the refrigerator to the cabinet, nor is it due to an incorrectly sized cabinet opening. Norcold appears to have engineered an approximately one square inch penetration (hole) between the back of the trailer and the inside front of the control panel. Mike provided the following picture of what the backside of the control panel looks like before the refrigerator is installed. Note there is an approximate 1 inch square hole in the circuit board. This allows a direct path for outside air to enter the Oliver, basically negating the effectiveness of the combustion seal. Everyone's Ollie with this 3-way Norcold unit probably has this defect. A simple fix (hack) would seem to be to tape over the 1 inch hole on the circuit board. Unfortunately, there is no way to reach the back of the control panel to do so without pulling the refrigerator out. Mike was going to take this up with the engineering committee to see what, if anything OTT could do without running afoul of the Norcold warranty. Hopefully when Johnwen checks in with OTT next month, we will know more about what can be done about this, including whether Norcold will accept any accountability. OTT has gone to extraordinary lengths to make the Oliver a true 4-season (and safe) trailer. It is unfortunate that Norcold appears to have undercut OTT's best efforts. -

You said that you winterized the trailer when you got home and installed the Truma anti-freeze option. I am assuming you mean the 12 volt powered electric heating element into the Truma. I have installed the same option. If I am understanding you correctly, when winterizing the water system, you closed the water valve to the Truma and left normal water in the Truma to be protected with the electric antifreeze option (which is nothing more than the equivalent of a 12 volt dipstick heater). If that is in fact what you did, turning off the batteries would have cut power to the electric antifreeze dipstick heater in the Truma and it would not have protected the Truma against freezing. The electric antifreeze option in the Truma is really designed to protect the Truma while in transit during freezing weather when the propane is turned off while towing. To gain full protection from the electric option, you need to also install the provided plug into the exhaust port of the Truma when using the option, or cold air can enter the Truma combustion chamber while driving and potentially overpower the weak electric antifreeze heating element. If you later de-winterized the trailer and tried to start the Truma on propane before actually turning the propane on, and/or removing the plug from the Truma exhaust port, then the Truma would have tried to ignite a few times, and then it would have locked out. Just like the Norcold refrigerator, if the unit tries to ignite on propane when the propane is turned off, the unit locks out and must be turned off and then on again to reset the error codes. Same thing if the Truma senses a blocked exhaust port. When winterizing the trailer, it is probably best to follow the winterizing instructions in the manual that basically call for closing the water inlet valve to the Truma and then draining the water out. It only takes a minute or two. The electric antifreeze option will also work when winterizing, but then you will need to ensure that the batteries provide continuous power to the trailer over the winter to run the electric antifreeze option. Simply draining the water from the Truma when winterizing is a safer approach.