-

Posts

3,137 -

Joined

-

Last visited

-

Days Won

227

Everything posted by jd1923

-

Upgraded to 6 in 1 inverter Microwave/air fryer/convection oven

jd1923 replied to rideadeuce's topic in Ollie Modifications

-

Replacw Xantrex Inverter/Charger DC Breaker

jd1923 replied to Gliddenwoods's topic in Mechanical & Technical Tips

It’s a real shame to have a 2-year-old Oliver with Lithium Platinum Power/Solar Package and have to replace a Xantrex 3000. Xantrex used to be the gold standard in inverter/chargers! As far as removing ALL power sources, I would also disconnect and follow the 4/0 cables from the batteries to the inverter. Reads here like they now use a breaker. Our older installation had a 250A ANL fuse and holder hidden between the hulls to the right of the pantry! At least 4 Oliver owners with older 2KW Xantrex systems have replaced them with the Victron Multiplus II. No reported issues. I’ve run mine at home for a couple months and field tested now 3 weeks on an AZ to TX trip. It really is a great product, about $1,100, will take a bit of work to install. More info here and a few other posts (search for Multiplus or MP2). Best wishes, JD -

Steve, this is an excellent mod! I had not heard of a 3-stage in one filter and shorter filter life is fine for us who travel occasionally. I spent double building a dual filter system with Clearsource components an it’s heavy / bulky. Your build is perfect! Your water pump is likely 50 PSI or more. I installed a variable speed pump at 60 PSI. You can run anywhere in the 40-60 PSI range. PEX is rated at 100 PSI. Our older hull has built-in pressure restrictors, not regulators, which can be seen in this picture. The plumbing diagram only shows back flow preventers, but it has both inline devices on Fresh and City water inlets. They truly impede water flow and I will remove ours eventually and add an external adjustable regulator like yours. if we use the City water connection, the water flow rate is poor due to the restrictor. When we fill the Fresh Water tank, it fills slowly, but the onboard pump delivers much better pressure. Not sure if all Olivers have the internal restrictor but something to look into since whatever pressure you’re setting it reduces the flow rate (GPM) at the faucets.

-

If it has a good power cord, doesn’t get hot to the touch, you’ll be good. I’ve used some old classics and usually replace the original cord with a cut-off #12 extension cord.

-

But then the Victron app will error again as SOC decreases again reading higher then actual, in my experience.

-

John @John Dorrer, when you install yours cut each length about 1 1/2” longer than the original piece you remove. This makes up for the shrinkage you have and the shrinkage that will occur to.the new rubber. Start at the bottom and push hard to compact the rubber to make room for the extra length. Be firm and patient. If some end up a little too long you can always cut a little off but you can’t add length. A hose cutting tool works well as it is hard to use a razor/box cutter when the piece is in place and it cuts square. https://a.co/d/gNDM9QE

-

Same price as when I bought ours in black last year. I bought 17 ft, they sent 18 and I had over a foot left over. Total shipped was $99. https://www.pellandent.com/Half-Inch-Glass-Vinyl-Seal

-

When the auto industry brings back a retired name it’s never the same. Case in point is Bronco, Camaro, Charger, even the Chrysler 300! Buy or restore a real Scout if you can afford one! (Pictures contrasting the 1960 Chrysler 300F vs. the 2000 Chrysler 300m.)

-

When the lid is open, fan running, and you key the OPN/CLS button it will close the lid and the fan stays running. @Mike and Carol thanks for the note of the fan blade. I will clean it when we get home. I’ll also study the wiring to see what can be done. I’m not going to carry an electric heater. We have an Atwood furnace. Prior owner wrote a service complaint re noise and had OTT replace the Suburban. The mods I made, running hard ducting the first 6 ft, eliminating the under bed duct, eliminating the dual outlets and adding a return air filter has made it even quieter! We ran our furnace for a week in the high country, mornings in the 40s. It was very quiet and it only blows in kitchen and bath. The overhead fan, even on 10%, bothers me more.

-

This is a great idea and when we get back to high speed internet I’m looking forward to reading the PDF and trying it! Thank you. At Inks Lake in a sea of Olivers I noted a few things. First off, if you have $1650 to spend, get the Atmos A/C! @Ronbrink’s system is amazing. In 15 minutes at the noon hour in Texas 80+ heat and humidity it cooled the interior at a whisper! Humidity dropped 11% on the gauge and I felt cool and dry before we looked at the numbers. We run our Dometic only when necessary and set it in Auto so the fan is on only when the compressor is on. The majority of noise is inside from the loud fan at high speed. Outside it’s not near as noisy. We had a neighbor who runs theirs fan ON always. Their outside noise was double ours, likely from running it 24x7! Theirs was not only louder but I could hear bearing noise, on top of noise! Maybe, but likely with the fan at 50-60% it would be fine. Most A/C systems allow for multiple fan speeds, but set on AUTO ours only runs fan on HIGH. Worth a try! What are you chancing, a poor Dometic model where w/o modification needs replacing anyway?

-

I can’t afford $3K on an older hull which has set and will sit in the AZ sun year after year. I’m getting less work annually on my job and inflation adding to 30% over the last 4 years makes it worse. Given two young men at 1 1/2 days that’s 24 hours. Say $120 for buffing compounds, this comes to $120/hr. I’m not getting near that with a MSIE degree teaching professionals for PMP certification. It’s a crazy number for manual labor! I can see $75 max. This comes to $1,920. Another example: OTT wants “on special” $1000 labor only to wire the Oliver, not the TV too, for a DC-DC charger, equally crazy. Call it 6 hours and it comes to $167/hr. Glad I do my own electrical and mechanical work, though buffing/waxing is not worth taxing my body! The CGI young men are so nice, witnessed by them serving us dinner at Inks Lake! If I was in my 20s making over $100/hr I’d be grinning ear-to-ear too! Love when my wife Chris says, “Why does a trailer have to be so shiny?”

-

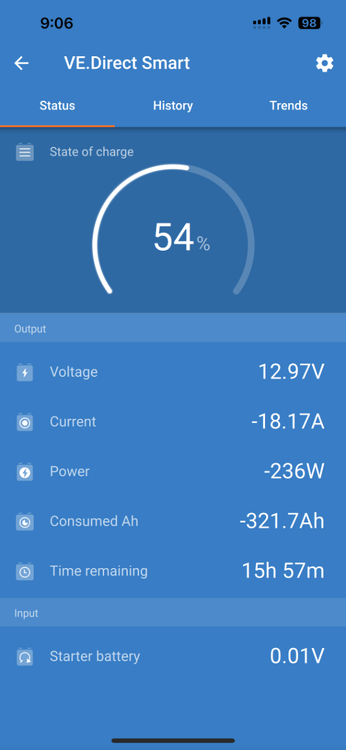

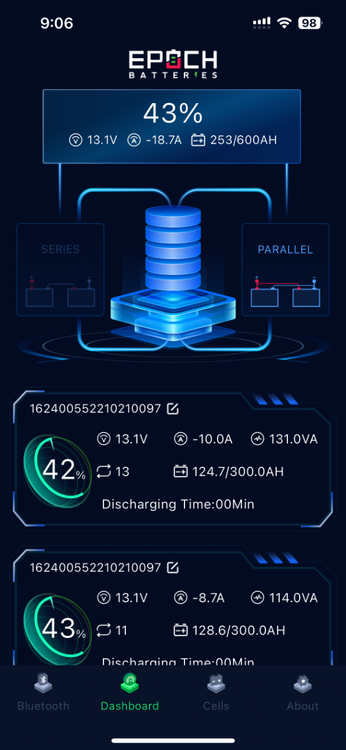

We have to get to the bottom of this, as I have also found the Victron app or the Victron SmartShunt to be unreliable. i do not have the OTT installed Lithionics but instead self-installed 600AH Epoch batteries. We also have an Epoch app that regularly shows a lower SOC reading. Note the two pics. The Victron app states we have 54% SOC but it also states AH consumed at -321.7A. This is more than half of our 600 AH which calculates to 46% SOC. The Epoch app (y’all have a Lithionics app) appears to be more accurate showing 43% SOC. Since the battery app is a more conservative reading and appears more accurate, we count on this number when traveling! Hope this helps!

-

There were all these white egg shaped objects all over the park and behind the moving truck. A polar white Tesla would have hidden better given the park landscape! 🤣

-

To Central Texas from Central Arizona the Slow Way

jd1923 replied to jd1923's topic in Campgrounds & Parks

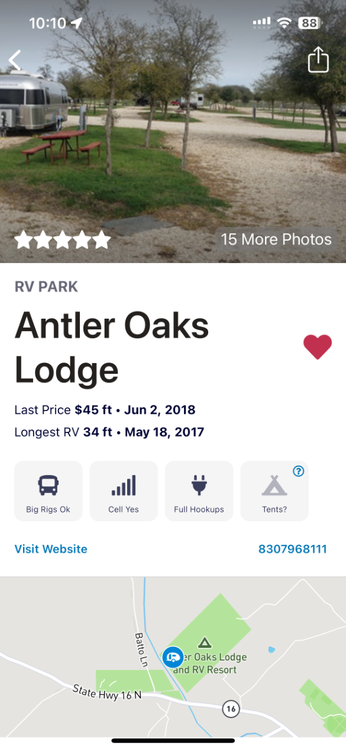

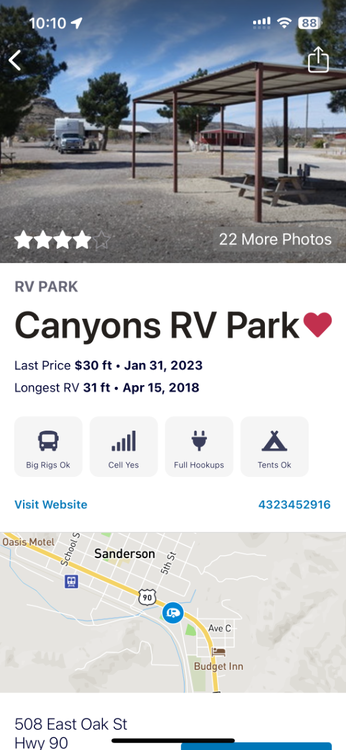

Update on our return trip… Given the goal of staying off Interstates, we wanted to see South Texas w/o I-10 travel. Left Inks Lake for lunch in Kerrville and spent a night in Bandera at Antler Oaks lodge. They are $59 plus tax! But with a soft sales call, I talked them into $40 cash and we would not hook up, no costs for them. The RV park was nice enough, but one tenant scared us. They were up all night, lights on at 2AM, where 4 pickup trucks parked around their large travel trailer. One thing my Dad told me, “Nothing good happens after midnight.” I’m sure they were involved in trafficing or drug running. We stayed quiet pin the trailer and they kept me awake most of the night. Thought to head straight south to Uvalde. The largest town out that way and they were in the news for a major school shooting a couple years ago. Uvalde also has the cheapest fuel around. Another part of planning is where to buy fuel. We use Gas Buddy and with the map view you can look ahead at prices along your route. Highest gas price we paid was $2.99 for diesel and the lowest was $2.79 at H-E-B Uvalde, $2.43 for regular, nice! Wanted to see Del Rio, stopped for lunch there and had many great views of the Amistad National Recreation Area. On our route west. just woke up in Sanderson TX. Not much of a town or RV park. Got another $10 discount for my “no hook-ups speel” some light road noise and we slept well. i was too tired yesterday to push another 2 hours to Davis Mountains SP, so will leave for there as soon as I stop typing this! Looking forward for a few days there! -

Certainly is! Wow, great repair and upgrade all for $49! We need to travel to Hohenwald one day!

-

Saw one at Inks Lake in green-camo which made it look a bit better. Was leaving too quickly to get a picture.

-

Question on Removing the Winegard Roadstar Omni Directional Antenna

jd1923 replied to csevel's topic in Ollie Modifications

-

Thank you Jerry & Kathy for both answers! I turned the tabs, why didn’t I think of that, and I have the screen out now. Thanks again. I’m hoping for a procedure to turn off the fan without closing the vent cover. Chris wants the fan on when going to sleep where it’s just cool enough to go w/o A/C. When I wake up, middle of the night, it’s much cooler and I want to turn it OFF but keep the hood/vent open. The motorized lever mechanism is soooo noisy late at night! I muffle the sound with a pillow on the fan, then OMG have to do that again to open the vent, no fan. I’ve got to find the procedure, or I promise I’ll pull it apart and wire a dedicated toggle switch for this simple purpose.

-

Upgraded to 6 in 1 inverter Microwave/air fryer/convection oven

jd1923 replied to rideadeuce's topic in Ollie Modifications

Good to hear from you Mike. Another great upgrade in your list of many. Good work and I especially like your thin insulation fabric. Thanks -

There is a certain brand appeal for Redline, but I contend ANY reputable oil co that makes the red-type high-temp NLG #2 automotive wheel bearing grease will do equally well. Can be Valvoline, or Lucas, or many other brands, take your pick. I chose base on price vs. reputation. If you do not remove all the grease, clean parts with solvent (I used spent gasoline drained from my dirt bikes and yard tools), get all new grease UNDER, yes under the main gear, you are truly wasting your time. Just leave it alone or do it right, as you would be doing more harm than help. The OTT maintenance video is a joke. All he does is a visual inspection. Adding like grease on top is also doing absolutely nothing. Drives me crazy watching this! The NLG-2 grease is better than OEM. Do it as I had illustrated on page #2 of @John E Davies’s original post. I even received accolades from him which in probabilities is near wining the lottery! I pray @John is doing well! If you do it like I have demonstrated below, I promise it will last for many years, like 3+ years for full-timers and 6+ years for the rest of us. Our hull is now 9 years old. When I did this service last year, I could tell from experience, it had never been maintained in 8 years and was working fine. The ONLY thing that will damage this quality leveler jack is raising or lowering it beyond the upper (happens more often) or lower stops, which damages the drive gear attached to the motor. IMHO, those of you with Hull #s >1000, leave them alone until you have minimum 40K miles or 5+ years use, and then do it right. Show your mechanic my post and ask for like service. Or you could just look at it annually as “suggested by the manufacturer” and buy a new VIP3000 eventually. It is a great jack, will likely last 10 years if you want to forget-about-it! 🤣

-

Q1: Is there a way to turn the fan off while running and keep the vent from closing? We have this fan and remote (pics). Q2: How do you get the screen off for cleaning. Ours has one broken tab and I don’t want to break another. Thx

-

I use something similar to the one centered in the your picture for almost everything automotive, must be high-temp NLG #2 for bearings. This red grease is the toughest. Given you researched this, I’m thinking you are good on your choices!

-

This may be the answer!

-

So many bad roads in these United States as well as Canada. For some reason today an Infrastructure Bill is passed and then monies are spent on perceived social issues. First line item re infrastructure is building roads. Hopefully .gov will spend necessary monies to replace all the roads and bridges damaged or destroyed by Helene. President Eisenhower RIP would be ashamed of his interstate system, except for in Texas and a few other states. I moved from Chicagoland (always potholes for decades) to Tidewater VA in the late 70s. Driving on I-64 back then was like floating on glass! We drive highways, back roads and dirt roads throughout the SW, roads not so good. Keep tire pressures on the low per the chart, drive slowly. It be a shame fear would keep you from this dream trip, IMHO. You have to ask what’s more important, the trip or the trailer. Yep, have a pair of replacement leaf springs.

-

Yes, and fresh in the dairy section! Chris and I were born and raised in Chicago where Bays started and didn't know of the other name brand until we traveled east. About Bays | Bays English Muffins