-

Posts

2,306 -

Joined

-

Last visited

-

Days Won

65

Everything posted by Geronimo John

-

I'm a Wannabe and have been for awhile

Geronimo John replied to TravelWell's topic in Introduce Yourself

Hope you don't want to boondock in that kind of weather.......I can't even imagine! Welcome to our forum! Good luck on your quest. GJ -

And for sure this is the place to get the best options on how to do them. Especially now that we have a great search engine at our fingertips! YEA!

-

Double ditto!

-

The Saga of corroded brake wires on older trailers

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

Only if you needed them to work..... 🙂 -

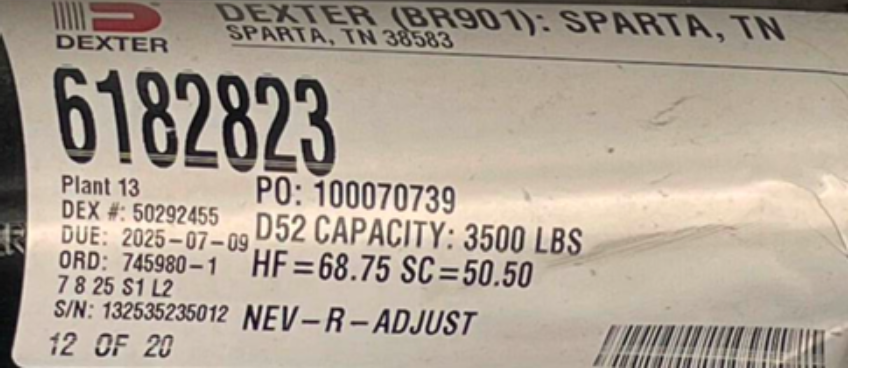

Yes with a minor edit. I copied this axle below: It IS the desired D52 axle which is designed for 5200 or 6,000 pounds of load depending on use. But it is also showing that it was derated for this use with the Dextre 3500 spring rating. With two per axle that tells us that it has the Dexter 1750 springs on each end. GJ

-

I think it would fit, but not when doing a minimum radius turn. Would also need a stone guard as the tank is made from PE. Will ponder this when I get back to Ollie in June. Thanks for the idea! GJ

-

I do as well, and would like to have the extra space and security over the OEM basket. At the 2025 Ralley I spoke to the Seabiscuit Team and suggested that they consider an enhancement for the Olivers. My suggestion was to increase the box depth (Fore and Aft) to include jack inside. That would gain about 5" of additional space less the volume of the jack. My only problem, and reason for not following your lead is that without massive solar and a nuclear power plant (600+ amp Litho's), I have to carry a gas can. Not good in a sealed box with stuff that could spark a leak. For safety reasons I would not be safe carrying one in my TV bed (with a sealed cover), in the cab of our TV,or on the back of Ollie. With your set-up would it be realistic to mount a 2 gallon fuel in front of your box in mini basked with a stone guard? Another mod could be to address the gas can issue dirctly. Since gas fumes are heavier than air, maybe having a wire mesh for part of the bottom of the box to keep the box fume level below the lower explosive limit should there be a gas can leak. What do you think? GJ

-

I would not bet my life on it, but I would bet a beer... especially if it one of Art's home brew's! Each magnet pulls 3 amps, or close to it. You should have 12+ volts at each Dexter drum brake. Measure current flow when energized. Start with measuring all four of them with a clamp on amp meter on the wire going back to the brakes. With the brakes energized, they should be pulling close to12 amps and have around 12V. If so, all is good. If not start inspecting current flow and voltage at each magnet. PS: An easy way to do the above is to just pull the emergency break away to activate all four brakes. But don't leave them locked up for long...... Somebody check my brain on this one. GJ

-

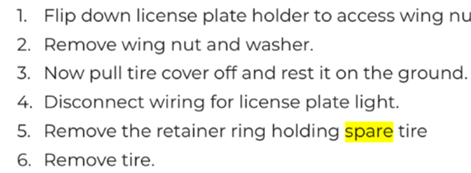

Well, I was waxing Ollie and had the spare tire cover off. Crazy Horse rode by and thought I was rotating the trailer tires. He asked "Will you be rotating the spare in the process". I stared up at him and with a serious face said "Well of course everybody does that!". He asked "Where will it go". I replied right where it is now, but I'll rotate it 180 degrees so the rubber does not sag". He rode off pondering that further. GJ

-

Battery Box Separation

Geronimo John replied to Mike and Carol's topic in Mechanical & Technical Tips

Pretty neat device. Problem I see is that there will be times that the structural "post" will be in compression and tension. This fixture only withstands compresson. So it could be used for that purpose, then a means such as straps or other means to take care of the tension. Not as efficient as jacking it up, drilling a couple of holes and bolting it in place. Cost = 2 bolts/nuts, locktite and time. I have grown to not be a fan of Nylocks. Frankly they can be impossible to take apart when torqued hard. Only way to get them off then is to tighten them until they break or heat them and melt out the plastic. Nether of which I want to do while stand on my head in an enclosed space down there. GJ -

Welcome to our OTT Family! As questions arise, do your homework as mentioned by Patriot in his post above. Do down load the new search tool by Wayfinder below. And always be encouraged to ask questions here on the forum. I am just starting to poke around Wayfinder's search tool and all I can say is WOW! GJ

-

XDR: This axle is rated at 5200 pounds. It is an excellent axle that well over 200 OE2 owners have upgraded to in the past couple of years. We specifically like it's 12" brakes and the long life maintenance free bearings. Better stopping power, especially in mountains and way easier maintenance! The only down side is that with a lot of miles (And typically 6+ years of sevice), we have had some of the 1750-pound springs flaten out. Those owners, myself included, were looking at spring replacement and the cost of upgrading to your 5200 Dexter axles to 100% renew our entire suspension system. The huge discussion was to go with the Dexter 2400-pound rated or the American made Alcon heavier duty rated springs. The vast majority of the cost to do so is the axle, not the springs. By comparison the springs are cheap. Should that happen down the road to your trailer, the good news is that you would already have the higher rated axles. So I echo Patriot's thoughts, and that OTT is moving in the right direction by exclusively using the higher rated axles on all their trailers, and that the Oliver Trailers are the best on the road. Geronimo John

-

Gosh Golley HD. You need a bucket of Lucky Charms to turn around your bad luck streak!

-

For my D35's I/We run from 8K to 15K miles per year. Lots of interstate and BIG mountains for sure. A suspension failure where we spend time would be a PITA for sure. So like many owners, we service our Timken Bearings and National Seals annually. Since Day 1 with our OE2, I have had to run 8 - 9 on my F-150 brake controller to get the braking needed. I have several times checked the voltage and 3 Amp flowing to all four brakes. So it is what it is, and I have no complants with the Dexter 10" system. But I am running it at the upper end of it's design. And I often pull over with the truck to zap the drum/hub to check on over-temp. I would rather have the Dexter 12" brake system for our use. Just to be clear, I agree with JD on the service frequency for the bearings. But one would still need, IMO to annually check in on the brakes if you are running the mileage that JD, Art, and I run. My observation is that the Dexter Never Adjust "Automatic" adjusters are in the trust but verify zone. See John Davies post about them if you would like an independent opinon. (Spoiler Alert: He HATED them!) This is the exact situtation that many owners are facing with their OTT's that have mileage and years. My intent was to FULLY tear down my D35 brakes before our 2026 Tour. Checked into the prices of brake shoes, magnets and turning the drums. It was high. I found that replacement of the entire brake assembly and turning the drums was not all that much more expensive. Then I looked into the cost of the D52's with Alcan install and I was hooked. Sure I could save a bit less than a grand, but the rebuild would not improve my Ollie's braking situtation in mountains. And I end up with a totally new suspension system with more capacity. I sent Alcan a check last month for my 1 JULY 2026 D52 axles install. (Oh, yes I will be reusing my one season old Dexter 2600# four leaf springs.) GJ

-

I agree with both of the above. With a 5 year old trailer, replacing the OEM bearings is suggested. A difficult task if not experienced in doing so. But with some mentoring it is actually not all that difficult. Temken bearings and National/Temken races are the preferred choice here in Ollie Land. Here is Frank C post with the same mileage as yours and likely the same OEM bearings: GJ

-

You gotta love this forum! Frankly it was a primary reason we bought our LE2.

-

I am too. What usually gets me to actually read the instructions is I run into a brick wall. Just as you did. Then I'll post it to the forum. Just as you did. So no worries. Please do post a pick, one of us out here will figure it out. GJ

-

Yep, that's the way it's done by about 1500 of us. (1500 is my guess as to the number of us with 16" tires.) Some thoughts come to mind. With the downsize of the tires from 16" to 15" was the design changed for the tire removal that would cause your difficulty? If it was, if you were to reduce the pressure in the spare tire to allow a slight reduction in the diameter would that make a difference in your situtation? Was your spare tire changed to a larger size? (Not likely with a 2023 OTT. I believe that from about 2018 to the rim size change, the spares were the same tire as the 4 on the axles. But that is just an assumption.) Best of luck. GJ

-

That's a new one. It certainly was designed to just lift the license plate and remove the big nut. The cover can then be removed with the spare tire still attached to Ollie. Kindly post a picture. GJ

-

For most tents, stakes they would work fine. But for our awnings and higher wind areas, I would consider increased diameter and length. Love the 20V impact to drive them idea. For our OTT awning, we carry two milk crates. One in the basement and the other in the basket. For high wind areas, we primarily rely on them with "locally sourced" rocks as anchors. One lesson learned is to emply quick disconnect so that in emergencies one disconnect and retract quickly. I have some ole D-rings that are over 100 pound rated and use them with mil-spec 550 cord as the connection means. Additional weight for two is less than a pound or two. GJ

-

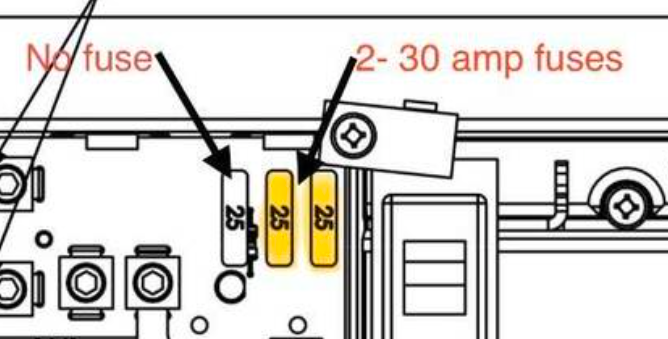

We know that most of the older PD's had two RP fuses, and likewise some had the Lithium switch. I suggest testing the unit amp output to definatively end the discussion. Just turn off the solar controller, turn off the Inverter (If installed) turn on the Converter, and either check the SOC reading at the SOC display (If available) or use a clamp-on-amp meter at the battery to measure voltage and amps. Hopefully you see higher voltage and amperage when you think the Converter is on. If not, cry.

-

-

That is good. I'm sure you already have, but out of an abundance... Since this is taking some time, recommend you periodically monitor battery water and top off as necessary with distilled water. GJ

-

The manual I posted above is for our 2018 OE2 and his is older than ours. Our units do/did not have the lithum switch... unless it was upgraded by someone that bought 12V LA's.... not likely.... So if going Lithium, at a minimum, an updated master board would be needed. If purchasing one, and going lithium I suggest upgrading from the 4045 (45 amp converter) to the 4060 (60 amp converter). That extra 15 amps makes a nice reduction in charging time. Or if budget allows, an upgrade into the Victorn lines if you are into neat gizmology. DBL-R: Not necessarily. Without a smart charger, a trick simple test will tell you very clearly. Both tests are founded on Watt's Law: Watts = Volts xAmps?) It says for a given wattage, with in reason you can power up a load with various voltages and amperages so long as their product = the Watts of the load. If your battery is surface charged, it may flow the optimum amps and volts off the surface initially. But then seconds later the voltage drops, the load in watts does not change, so the amps must increase. In your case you are looking at a voltage that can change, a fixed load, and variable amps as a result. As the volts decrease, the amps must increase.... until the buse blows. Two ways to test your battery for load carrying ability and health: If you have an Inverter (Changes 12V DC battery power into 120V AC power): First, unplug from shore power, turn on the inverter and hook up your volt meter to your batteries. Have someone start your microwave while you monitor the voltage. If the microwave tries to run but shuts off quickly, you have a surface charge. Only hope is to try using a smart charger to desulfate as mentioned above. If you don't have an Inverter, just cycle the front jack. If the batteries can raise and lower a full cycle then you may just be the lucky guy of the day. But if it slows down and stops, or blows the 30 amp jack fuse.... Time to desulfate.... Also keep in mind that a fully charged deep-cycle LA battery typically tests at 12.7V to 13.0V (for 12V systems) after resting for several hours. So more charging is also needed. Just be careful not to boil the batteries with too much charging amps or time. GJ GJ

-

Battery Box Separation

Geronimo John replied to Mike and Carol's topic in Mechanical & Technical Tips

For David and Gail's case, you nailed that one! How? My guess is it was a long week and on Friday late the installer laid the bolts on the floor with a "I'll get it Monday". GJ