-

Posts

2,261 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

YES. Here is Art's (MaxBurner) approach to adding space under the sink. I don't know if he was the first to do so, but I captured his post and used it. it DOES require mod and does provides significant additional storage space. When I did mine, lowered the floor to well below the bottom of the hatch, and extended it as far left and right to gain even more space. Not an easy project, but is one that is not all that hard to do if you are handy. GJ DIY - Art's Bathroom Under Sink Storage Mod.docx

-

You have a very good start. The odds of another deep freeze this weekend is likely 100%. From the forecast, it is already heading your way. I would suggest: · Pulling the bed mattress and vertically stacking them in the hallway. Then pull the fiberglass covers to expose the basement to the cabin interior. · Ditto for the dinette seating and covers. · In the bathroom if you have installed one of these you are golden. Open it. · If not, then consider removing the towel bar cubby from under the sink. · Open the basement hatch in the rear center storage if you have one. Open the wardrobe and bathroom doors. · Insulate the battery box and basement outside hatches. If you have shore power, acquire a small 120V desk fan to circulate air around the opened up cabin. The items above can easily be done very quickly. Of course the hatch takes a lot longer to do. But it opens up quite a bit of storage as a prime benefit. GJ

-

Cold weather rating for RVs?

Geronimo John replied to Steve and MA's topic in Mechanical & Technical Tips

Seems to be a design issue for a lot of us. I removed the adjustable fins on the kitchen and bath vents so they would run wide onpen. Then closed the one by the bed. Applied a dab of cement and it stay's at that setting. I guestimate (another GJ work) that it leaks about 5+% now. With the bed one closed, it forces more air "down the line" . Much more comfy sleeping. GJ -

Check your leveling jack feet!

Geronimo John replied to mountainoliver's topic in Mechanical & Technical Tips

Last season I lost one of my "Feet". I attached a small diameter SS cable thru a hole in the dome and put a crimp on it. Then made a tight loop with a crimp just large enough to accept a SS screw into the area just below where the jack sleeve ends. There is just enough room to do so. Have not lost another foot since. If the main bolt under the foot takes a walk, I 'll likely hear the tinkeling as it skips off the pavement. Would need a bolt and some touch up paint to replace. Much easier than having to find a replacement. GJ -

Inspectable Item: Propane Area

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

Ok, I can assume mine is dirty. How do you clean it? -

Inspectable Item: Propane Area

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

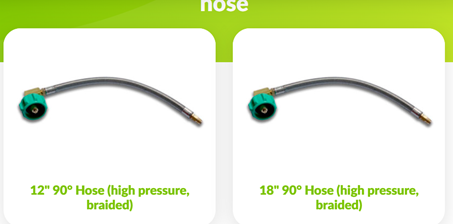

Ok, we have two solutions for the wing nut. If we were to use the Gas-Gear 90 degree hoses we could use these longer ones: Which would allow us to move the regulator forward well out of the way of swinging tanks as we change them. With the regulator moved out of the way (Forward), using one of these for security makes sense now as getting the lock on it would be eazy. Just need a simple bracket to move this forward out of the way: This is sort of turning into a cherry pick the best so far! GJ -

Inspectable Item: Propane Area

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

i tried that, and did't like the results. So I just added several inches of 1/2" cpvc pipe under the nut to get it up over the obstructions. Either way easy fix. GJ -

Inspectable Item: Propane Area

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

Now that's a good understatement. Your post has generated several concepts that frankly need a relook: The need to have the regulator higher than we had envisionated. (A Geronimo John word) Having enough hose to reduce hose stress especially during tank removal for refill. Using street elbows to get the hose traveling in the right direction from the regulator. Knowing that there is a second set of holes on the regulator. Creative security for our propane gear. Part of the service PITA is that the regulator itself is in the way as the tank installation centerlines are a bit too close. We have room to spare, but all the "OEM Purchased" components are set up for the "standard" set up where space is very critical. We have space to spare. Mount the regulator away from the threaded rod sufficient so as to allow the tightening of the rod handle without hitting or being close to the regulator! And now I'm thinking that the geometry of our OE2 dog house propane hoses and regulators may be space efficient, but it sure does not do us any favors when changing tanks when we have to do a Up and Over maneuver with the tanks. IMO, doing so always is a small PITA. I think we can concoct a better design as we are blessed with space under the hood of the dog house. My assumption is to reuse the tank base, rod, and horizontal tank tie-downbar. Then to focus on the regulator support. From almost 4,000 miles from our Ollie, I'm going to plant a seed to attract some flamng arrows. What if we: A. Modified the regulator bracket to attach to the verticle threaded rod to have two attachment points on the rod and a regulator bracket so as to put the regulator out of the way for service and high enough to be above the liquid level. Double nut one set of the attachment points on the threaded rod to do so. In effect the regulator's location would be fixed. B. Incorporate into the design a simple way to keep the tanks locked down that can be easily removed for service, light and uses a pad lock. C. Increase the hose lengths to facilitate service. D. Use street brass fittings to align the hoses to the direction needed to increase hose bend radius. GJ T Fromthe picture, the 30 pound tanks diameter has reduced a more restricted space for the regulator. -

Inspectable Item: Propane Area

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

PS: It appears that one of your hoses is relatively new and the other is likely a 2016 OEM. May want to update the older one. GJ -

Inspectable Item: Propane Area

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

Chris: Many of us fully remove the tank hold down bar when filling our propane tanks. I would prefer not to have the regulator support angle above the tank hold down bar. Doing so would subject the hoses to additional stress at every tank fill. That said, I appreciate your warning. I think that I will add two jamb nuts below the tank hold down bar (One on each side of the regulator support angle) to "fix" the location of the regulator thereby reducing stress on the hoses during survice. Do you think that would solve the concern? GJ -

Moving Stabilizer Jack Switches

Geronimo John replied to Tony and Rhonda's topic in Ollie Modifications

I keep it simple and fast: 6" torpedo level, slap it on the entry door threashold for fore/aft. For starboard/port move the level 12" into the entrance. 1/4 bubble is close enough for us. If the refer decides not to work at 1/4 bubble, then it will be my excuse to get an inverter one. Gizmology is great, but can be a PITA too. My torpedo has yet to sink our Ollie! GJ -

Moving Stabilizer Jack Switches

Geronimo John replied to Tony and Rhonda's topic in Ollie Modifications

Hey JD! I resemble that slight! I use a 6" torpedo level. Don't need the accuracy of a foot long torpedo! Besides the only foot long I get is at COSTCO for $1.50. LOL -

Moving Stabilizer Jack Switches

Geronimo John replied to Tony and Rhonda's topic in Ollie Modifications

If so, we are a minority of two! GJ -

Exactly! But short cycling is not the same as Power OFF and then Power ON on a regular basis. Short cycling does not shut down the mother board. Power On Power Off takes the mother board all the way OFF. It would be like the difference of starting a car, letting it cool, restart, let it cool forever. Something will give out sooner. For this unit, my concern would be the unknowns to the mother board and start/run capacitor with so many power on/power off cycles. Will it age it at an accelerated rate? Will it be fine? Only time will tell. GJ

-

Custom Mud Flaps for the Tow Vehicle and Oliver

Geronimo John replied to jd1923's topic in Ollie Modifications

In our trailers there is very little that is level, square or symmetrical. And it is amazing how well it is done. When Art and I were making front wardrobe shelves for our OE2's, I "Ass-U-M'ed" that the template for his would work in mine. Nope. I failed to remember the above mantra. GJ -

Roger on the newer sliding trays having double latches. Likely more new ones than older ones like ours. On the deletion of the aluminum angle: Don't know as my Ollie is on your side of the pond. But possible. But I seem to recall that the geometry of the area was such that just a bolt and nut was not doable. My guess is that for our vintage of sliding trays Horace figured it out and needed the aluminum angle to make it work. I would wager one of Art's home brews on that! On using a bolt and wing nut: I would prefer using a Rev-Nut if it will fit. One less thing to not get lost (nut), Besides when leaving Ollie for some time, I would like it taking some time to open the drawer from an anti-theft perspective. Kind of like removing the fuse from the front jack. Make hooking up a 600# tongue a PITA.... go next door to the SOB and steal that one. GJ

-

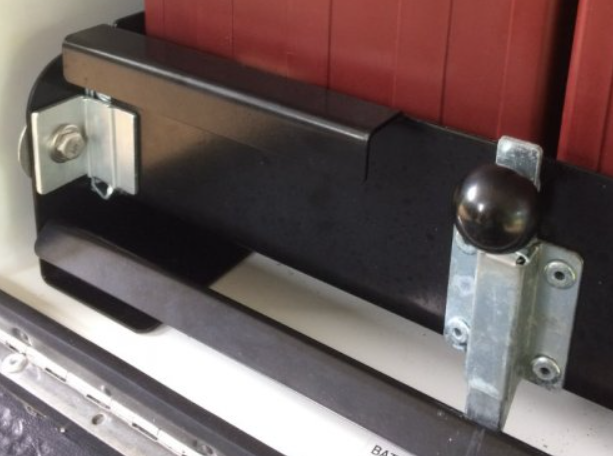

Owners: Mike and Carol’s “Battery Box Separation” thread well addresses the battery box structural securement to the frame and hull. My intent of this post is to re-look at the battery tay and straps and their securement. Despite our OEM straps being VERY tight, twice I found one of them had gone slack and come loose from the tray hook hole. Not good. I am starting this separate thread to focus on how to ensure that our OEM tray and batteries “stay put”. So basically, I would like to learn more about how the tray is mounted and then how to super contain our batteries in the tray. I would very much appreciate your sharing your thoughts on how the battery box embed plate and straps do their job. Some questions follow: · How is the battery box embed plate attached to the structural member below? · What’s you guess as to the dimensions of the embed plate? · Are all battery sliding tray fasteners buck-stopped by the embed plate? · I assume that the embed plate is aluminum. Can it be tapped for additional hold-down bolts. If yes, what bolt length will work best? · Can you share your DIY solution? GJ PS: As far as the tray slide coming open, I like Horace's (Hull 93 Maverick) Dec 17, 2020 idea. A couple of these would increase security and would prevent movement should the slide fail. My upgrades to his idea would be to use a Riv-Nut in place of the nut and washer. Maybe also pop rivet the aluminum angle to the tray sheet metal. Combined, less parts to get lost when doing battery checks and service. Thanks GJ

-

Battery Box Separation

Geronimo John replied to Mike and Carol's topic in Mechanical & Technical Tips

I SUSPECT that the lean out is to facilitate water drainage should a seal fail. I support your thought that the advantagee of a slight lean in would out-weigh potential negatives of a seal failure. The amount of the lean out could for sure facilitate the failure of the rivets. The support member as you have: with just one bolt (as pictured) could easily allow the top of the "stiff leg" to move out there by increasing lean and failure. Suggest adding a second bolt above the shown one to better fix (Lock in) the angle of tilt once properly adjusted. GJ -

About 2 miles. Ben there done that 20 years ago. I now do a FULL bearing and brake service before each season. Hint. 🙂 GJ

-

Battery Box Separation

Geronimo John replied to Mike and Carol's topic in Mechanical & Technical Tips

Reallly good idea! Yep weight and G-forces will tend to find weak parts. At least your Litho weight is way under what the OEM's were. We now have seen frame fractures and battery boxes being damaged by trailers likelly exceeding their design limits in one way or another. Just a reminder that stiff Frames/Springs/Shocks and high tire pressures are things to avoid or at least mitigate where we can. GJ -

Battery Box Separation

Geronimo John replied to Mike and Carol's topic in Mechanical & Technical Tips

Crazy Horse asked if by chance you have Alcon's? I told him to mind his own business. GJ -

New fiberglass RV manufacturer

Geronimo John replied to Steph and Dud B's topic in General Discussion

My wife and I had purchased a lightly used Jayco UDST pop-up with a single torsion axle. We completely rebuilt all the systems above the axle. We departed SLC for a month long tour along the west coast and northern tier border and back to SLC. As part of our rebuild, I had new tires and a pro inspected the torsion axle. Axle appeared good. Probem with torsion axles is they look good until they are not. Ours failed 100 miles from Reno NV on a Thursday before a 3 day holiday weekend. When they fail, they scruffed off our new tires the no time at all. No warning, on side of road, with 100 miles of nothing. No options but getting three replacement tires at a Super Walmart and scruffing them all to bare cords to get to an axle shop. Limped into Reno just before the axle shop was to close. Learned that a new torsion axle would be 7 days out. Saw they had lots of steel and welders so while waiting until Tuesday for the shop to reopen, I designed a replacement axle subframe to support an in stock Dexter 3500 axle. With annual bearing service, it is a lot easier to tell when a standard axle is going south and to leave you on the highway. Torsions....... not so easy. Hence my dislike for torsion axles. GJ -

Alcan Springs Quote for Jan-2026

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

Chris: Some thoughts about the standard wet bolts vs step bolts for trailer springs: Standard bolts generally used for light duty trailer shackles using a 9/16" diameter shackle bolts without a zirk fitting. Step Wet Bolts Bolts are used for heavy duty axles where the step is necessary for proper function with bronze bushings. I believe that all of the OTT trailers, and the most other heavy duty trailer spring shackle bolts are step bolts. Yet Alcon is using a standard bolts. This got me wondering about the topic. Wet bolts sandwich the springs between the subframe mounting "tabs". With the step, the step bolts mechanically limit the clamping of the springs. The result is that the bolt head is prevented from turning in the mounting tabs by two means. First, the splines. Secondly the friction on the tabs by the step and the nut itseld. As a result of the design, the spring always has some clearance allowing it to more freely rotate relative to the bolt center line. My concerns are: The Alcans could easily be over tightened thereby forcing the mounting tangs against the springs. This process would result in the spring binding in the tabs and facilitate the stripping of the bolt splines thus creating a "spun bolt". A spun bolt will act as a crude bearing causing the mounting tab holes to quickly wear. And the repair is rather difficult. Been there myself. Use of Nylock's in high torque situtations often results in the Nylock becoming impossible to remove with hand tools. To do so, one will likely want access to air tools or electric grinders to literally cut the nut off. Trying to do so with a hack saw and punch will be tedious, especially it appears that their bolts are very high quality grade 8. As such, failure of a wet bolt will complicate life a lot. The only way I would want standard bolts for a splined application is if the bolt head head was fixed using a Hex Capture Washer. After two years of working with OTT Jason, this approach ended up being the only acceptable repair for such a mistake. DIY - Dexter EZ-Flex Center Bolt Spline Repair (20 APR 2024).docx What are your thoughts about Alcon not using step bolts on our springs? Thanks GJ