-

Posts

2,261 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

Three way selector switch to the 712. One in, three options out. Would of course need three of the temperture sensors. GJ

-

For sure we KNOW where to put that temp sensor. B+ Terminal!!! Now which one. The Back of the battery bay, the middle b+, or the outside B+ .... That's a question for the Battery Smarter Owner to answer. GJ

-

Here to date, there has not been any reason to connect the free port on the 712 system. I even have the temperature probe in my spare parts onboard. Looks like the Victron folks did us a favor. GJ

-

And that Krea was the percise point of my above "Let's Ponder" post. Well said. For most of us with three BB's and a 300 Amp Fuse, we likely will not have a problem. The following uses some WAG's such as inverter efficiency (75%) and disscharge voltage of 12.5V. Both of which are just numbers are WAGS. But for illistration the following provides a basis for "Pondering Further" for a single 100 AH BB install: A 2,000 watt inverter overloaded could draw for a moment at least: (2000W / .75 ) /12.5V = 211 amps. . A 3,000 watt inverter overloaded could draw for a moment at least: (3000W / .75 ) / 12/5 = 320 amps. Neither likely would blow the 300 amp fuse. But over time, repleated again and again, then it is more than just possible that the BB design would become a problem for such installations. Yes we all could blow holes in the above "Hypothetical" example. But the underlying concept likely explains why some installs out there are having problems. Dragon Fly likely will be redesigning their B+ terminals as is obvious. But do I see a voluntary recall in the cards. Not likely, as it could bankrupt their company. As such it will likely be necessary for a federal recall to be demanded for the installed fleet. On the other hand, is it possible for Dragon Fly to redesign the B+ termina? Sure. They may even come up with a voluntary recall process to update those terminals for free, but likely we will be eating the shipping costs. But in the meantime to stick us with fees and charges, not to mention shipping costs to verify they have a known problem is a bad business decision. Think Ford: Cam Phaser Mess approach: Deny, Stall, Think Toyota: Cam shaft approach: Admit, Apologize and Fix IT, GJ

-

I Chris: Thanks for testing the power consumption by setting. As most of our time is boondocking, power consumption, even at these low levels, is always a consideration. With a ducted setup, just running at 60% or 70% for most situtations sure looks like great sweet spots. GJ

-

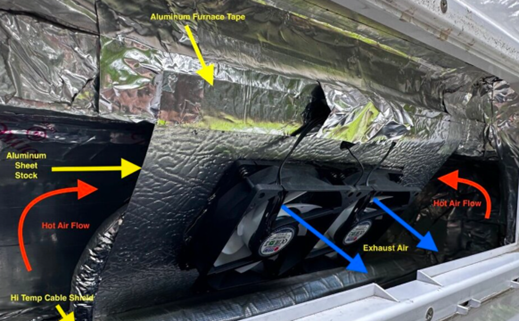

I have the titan fan system, but the controller was defective. Just been running it in manual until the fans die. When in use, my fans run 24/7 at a moderate speed. Will be replacing it with the already purchased Beech larger fans. My plan was to mount them in some sort of manner to create a ducted fan approach. Thus eliminating teh flow of outside air into the top vent area. This would allow a lower fan speed to get the same amount of cooler air flow from the below vent. Your picture closely approaches this concept. Best I have seen so far. I also like your use of the thin sheet alumnum. Easy to work with and inexpensive to boot. It appears from the picture that you have covered about 3/4 of trhe width. So I would call it a mostly ducted approach. I am wondering why you didn't just cover the full width to move all their discharge to be hot air from the frig, not a mixture of hot air and cooler air from the sides being sucked in the top vent? Concerning the control module placement, I'll likely be using JD's approach and mount it inside the upper cabinet. Concerning the power source, WAGO is the "way to go" since I have already done this for the Titans. But for a first time install another owner may want to check into the existing fan power source ...if it is active when the frig is on. Creative ideas you have emplyed and thanks for the post. GJ

-

I am impressed that Pat Radack took the time to search the archives and then posted. Well done Sir! And welcome to the family. Maybe not Craig's list, but I am aware of two OTT's that were destroyed and totaled. They went somewhere and likely were parted out. But your point is well taken. When I'm worried about where I've parked our Ollie, I remove the fuse to the front jack after I have lowered the tongue all the way down. Then I put a locking collar on the hitch, and pull the safety chaines up to the front box and padlock them there. Possible Future Enhancements: But I'm thinking of a couple of hidden game cameras and several of the anti-theft tracker disks. Maybe post a sign that there are 8 of them in/on the trailer even if there is only two. But I would like to learn about the trackers with battery back-up. Maybe a motion sensor that would put 50,000 volts to the hitch to take out the theft tow vehicle electrical system. Oh, June says that would also take out our Ollie electrical. Ok maybe a mortar from the propane tank to disable their TV? Ok maybe this is overkill. Besides the above suggested Claymore mine would be more effective. I guess the WiFi trackers is the way to go. But that's another thread already! I bet Pat could track it down and revive it. Surely there have been technical updates over the years.

-

I bet we are getting pretty close to your thresholdl. Could not resist asking: Are we there yet? LOL GJ

-

In my eyes, John Davies was a pioneer in DIY efforts. I have often referred back to his wisdom and approach when doing my own. Sadly I have neither the tools, equipment or skills as this great craftsman. But I sure can gain insights on how to do things in our trailers from his efforts. Attached is a list I "Borrowed" from his posts. Saving a copy as a MS Word document lets me easily search his DIY Library. I hope it is useful to you. When you do, say a thanks to John D. It would be good Kama! Geronimo John John Davies Posts Index (April 2023 Version).docx

- 7 replies

-

- 10

-

-

-

Ok us BB owners are not real happy just now. But let's stop for a moment and ponder a bit. So far none of us OTT's owners to my knowledge have experienced a heat related failure as denomstrated by Will. Why is that? Likely because we tend to have several BB's all tied to a 300 amp fuse and virtually no possible way we could stress them further. We have been told that each of our 100 AH BB's can produce up to 300 amps of current. But with three of them we are likely never to be drawing 100 amps from each of our three batteries that would be necessary to fry our fuse. I have yet to hear that due to overloading our 300 amp fuses have blown. Even if there is a unicorn out there, it is a rare one. But for most of us that went to BB's the reason was to have a system that could run our A/C while off shore power with a 3,000 watt inverter. That's how we got to buying three BB's. The OTT OEM ifusing supports this max loading: (3,000 watts / 75%) /12.5 Volts = 300 amps Ok it is resonable that we'll not intnetionally be overloading our fuse. If we did, it the inverter will support momentary overloads, and we could blow the 300amp fuse. But how may blown 300 amp fuses have we heard about here in the last 8 seasons? Ok, point is we don't blow the fuses. And if we did, it is a mistake we don't repeat. Hence, enerally speaking in our OTT's we are operating at a current density way under what others likely could be. So until we know more about what the circumstances are to cause failures such as Will has presented, maybe it would not be prudent to take a fire axe and chop out our BB's .... just yet. But the issue is certainly serious enough to have our attention, and to monitor the temps and keep a close eye on our system demands. MOST IMPORTANTLY: What if you see high temp's on any of your B+ posts, or see discoraraton, or lateral weakness? I suggest following Will's recommendation. Just don't use a fire axe though. GJ

-

I have often said: "I like having options". Welcome to the keep it simple, field maintainable, and having options group! GJ

-

In my eyes, John Davies was a pioneer in DIY efforts. I have often referred back to his wisdome and approach when doing my own. Sadly I have neither the tools, equipment or skills as this great craftsman. But I sure can gain insights on how to do things in our trailers from his efforts. Geronimo John John Davies Posts Index (April 2023 Version).docx

-

- 2

-

-

Part of what concerns me is that earlier they indicated that they have 400,000 of the same design. I have insider knowledge that the NTSB has been made aware of our concerns. John Russell, PE Russell Engineering

-

Propane/CO alarm quick-disconnect?

Geronimo John replied to GlacierGirl's topic in Mechanical & Technical Tips

See John Davies switch DIY to accomplish this goal. GJ -

For those of us with the Victron 712, we have a spare unused port. One of the uses is for temp monitoring. I never hooked it up as it was "Not" needed. I am rethinking that one for sure! GJ

-

When I saw Will's "Sparking" demo, in my mind's eye it turned from a safety one time feature into a serious "Oh Ship" issue. If an owner has BB's, I highly recommend getting a thermal temperature gun for checking the 4/0 system. It is also very useful for checking Ollie's brakes... especially if in the mountains. GJ

-

I think BB has a problem. They should initiate a recall. In the mean time, I highly recommend inspection of the terminals and thermal temperture testing of all 12V 4/O connections. GJ

-

DIY Solar Power by Will Prowse has been around for many years. His take it apart and inspect approach is well received. Basically a common sense approach to looking at problems. He in my opinion is not the definative expert in the detailed design elements. But he is able to communicate well and calls issues as he sees them. I know of no other technician with his experience in taking apart and then making common sense reviews of hundreds of different batteries. So, is he raising the red flat on Battleborns before at least calling Dragon Fly for comment? Yea sort of I think. Was his post raising a flag that all BB owners need and should be aware of? Yep. GJ

-

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

Sadly I do not trust most of the items made in China that are sold on E-bay. Especially for life safety items such as lug nuts. GJ -

In the case of the Cielo's, they are killing power with every cycle. I would have concern for both the mother board and start capacitor at a minimum. Both of which don't like to be prematerly knocked off power and the "Cold Started".... especially with every cycle. Point is we don't know what is going to happen until it is tested in the real world by owners that don't cook the data. As usual I agree with your statement and I appreciate your doing so. I too believe that any A/C that is short cycled will exoerience additional wear and will have a shorter life. Now the real question is it 2%? 50%? We don't know. If it's 2% sweet. If it's 50% not so sweet. We'll see in about two years or less I suspect. BTW the Soft Start Systems went thru the same learning curve. That example worked out really well for all. gj

-

WELL STATED WAYFINDER! Preceeding your post are several disconnects and confusing statements. Part of the confusion is that there are two different designs of our electrical systems. I am not so sure it can be differentiated for label purposes by "Old" or "New". I suspect that the selection of your OEM inverter size determines which system was used. I mention this as looking at the pictures of the 2016 vs our 2018 and the more advanced layout appears with the 3,000 watt inverter, and the more simple approach was used for the 2,000-watt inverter such as our 2018. As such, I believe the OEM inverter size is the deciding factor in which set-up an owner has. Digesting all of the above, my pea brain has summarized the two designs as: 2000-Watt Inverter Systems: May/may not have dual shore power feeds. Will have a PI Eenergy Management System (EMS) located under the rear dinette seat. The PI EMS display has a 15' cord, and as such the display can be found in several locations. In our early 2018 OE2, it is located under the street side bed. Power (City or Generator) flows into the trailer directly to the EMS. The EMS provides power noise filtering, voltage regulation, spike and surge protection. The output of the EMS goes to the Auto Transfer Switch(s) (ATS). This ATS acts as an A or B switch between two power sources. The input is either the 2,000-watt inverter or the EMS. It's output is to the PI Combo AC/DC Power Panel located under the rear dinette seat. At the time, we were stuck with Lead Acid/ATM batteries & power hungry hammer mill Air Conditioner. With the goal in mind of being able to run our air conditioner off newly installed Lithium batteries, an inverter upgrade would be desired. My intent was to do this upgrade with our 2,000-Watt inverter died. In my case the next season, our 2,000-watt Inverter failed. Perfect excuse to upgrade to a 3,000-Watt inverter. But my single 20-A ATS needed to also be upgraded to handle the additional current. A inexpensive and simple solution was to buy another 20-Amp ATS and install it with the output only going to the A/C. A simple mod. The old style EMS has a lifetime warranty. This in my opinion is a good reason not to change the 3,000Watt design below. Keeping the lifetime EMS makes sthe dual ATS approach financially advantageous. A second advantage is that the twin ATS approach greatly reduces the load and in theory increases the life of the twin ATS units. It also is not an "all your eggs in one basket as we have "Hanging Spare" gives you options should an infield failure occur. I like options. 3000-Watt Inverter Systems: May or may not have dual shore power feeds. These newer design systems bring in power from the outside port(s) direclty to the 5100 ATR. This single unit appears to have power condition and protection simular to the EMS above. It also has the power interuption and switching capability as the EMS above. It combines in one box the EMS and the ATR roles mentioned above. Thereby saving in cable, connections and weight. All good. As such the power switching must handle the extra 1,000-watts from the inverter, the switching was upgraded to the 30-A level. This new style design is more compact and from all indications is very reliable. If I had this system, there would be no consideration to going back to the older design. I would however consider carrying a spare 5100 ATR. A good $128 investment. I like options. Hope this clears up some of the fog. GJ

-

Makes sense now. Thanks. So basically it goes back to the OEM size of the Inverter. In a way, my employment of twin 20-Amp ATS units gives me a "Hanging Spare Part" if one fails. If away from a parts source and lose an ATS, I can decide if I want AC for the A/C or want AC for the Converter (For Microwave, Coffee Pot etc.) When one of my 20-Amp ATC's fails I'll replace it with a 30-Amp to match better my 3,000 watt Renogy Inverter. Thanks for "The Paul Harvey"! GJ