-

Posts

2,300 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

intermittent running light/tail light failure

Geronimo John replied to JRK's topic in Mechanical & Technical Tips

More than a few of us have completed the John Davies kitchen drawer strap mod for the very same reason. -

I like using a fine tooth circular hole saw. Cut softly into the fiberglass to slowly penetrate. GJ.

-

I am thinking that it is a wise idea to install a negative regardless of which Victron 12-12 30 you purchase. Why: One way or another the rated power of the DC - DC charger will be flowing from the TV battery to the Ollie batteries. With my clamp on amp meter, tests with a pair of 4 AWG wires for the pathway, I see 100% flowing via the Positive, and about 70% flowing via the Negative cable. So, the rest, 30%, is flowing via the frame/Andeson Chains, and Bulldog to the frame. Without the Negative cable "home run", all of it would be going thru the frame via the Bulldog, greased balls and Anderson chains ending up at the Battery Cable for the TV. The Battery Cable may or may not be sized for the additional load. But for sure, the series of resistance connections on that path would be a concern. With a clamp on amp meter and our 712 Smart, we can learn a lot. Kind of fun exercise as well. GJ

-

Thanks Patriot. Believe it or not, your update is appreciated. But since you chose to again mention your approach on springs: There is a hand full of owners that believe a heavier duty, more compliant 4-leaf spring is a more appropriate option for the 6,000 pound OE2 fleet use. Out of courtesy to this thread, I'll leave it at that. If you will. GJ

-

Steve: Great video. Thank you for taking the time and devoting your skills to produce it. Participants: Did you hear of any OTT reactions/comments relative to the failing Dexter Springs? Thank you, GJ

-

Crazy Horse says "Me thinks JD will receive burning arrows when he hijacks another's forum." But there is always hot coffee in my teepees. At home or on the trail

-

MS AI says the dimensions by model are as follows: (Suggest independent verification) GJ When I had to replace my OTT OEM toilet due to a 25 cent part breaking and no available parts, my research yielded the below info. I chose to go with the low profile elongated seat 321 Full Timer. Hope this is useful. GJ MODEL 311 Part Timer 320 Full Timer (Wrong P/N - My Error) 320 Full Timer 321 Full Timer E-Trailer # DOM67FR DOM87FR DOM87FR DOM99FR DESCRIPTION Low Profile Round Stand. Height Elongated Stand. Height Elongated Low Profile Elongated SOURCE: OEM PROVIDED May 2018 E-Trailer OR# 113709215 Shipped to Idaho, 83255 Dometic Warranty Replacement Need this model COLOR White White Same White STATUS Plastic Flush Rod Failed. Discarded in Idaho upon receipt of E-trailer replacement. Replacement toilet purchased. Flush ball seal not centered. Leaked water & sewer gas Still in original unopened box. DEPTH 19" 22" Same 22" HEIGHT 14.25" 19.25" TILT! Same 13.5 The 5" step between the toilet mounting surface and where you feet go is why just about all of us under seven feet tall need the low profile model. For more efficient printing, I have transformed the above into my DIY format. DIY - Dometic Toilet Replacement Specifications.docx

-

It's the screws that cause cracking, not the drilling of holes when properly done. In this case, the holes were in play and the fixture was set up with holes. So, Mike pretty much needed to use the holes. However, use of SS bolts, nylock nuts and washers on the inside would likely reduce further cracking.

-

-

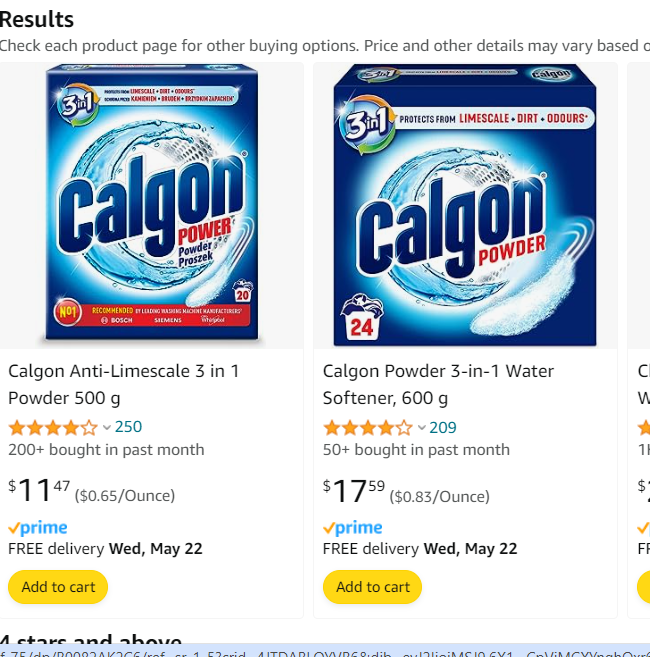

Really? That's strange because Amazon sold 250 of these this past month. Here is their hyper link: https://www.amazon.com/s?k=calgon+powder+for+laundry&crid=4JTDABLQYVB6&sprefix=Calgon+Powder%2Caps%2C213&ref=nb_sb_ss_ts-doa-p_1_13

-

Mike and JD: Combining your two responses with one of mine was a bit transformational. They have caused me to rethink my previous thoughts on this subject over the past 30 years. . I have always suggested and used "CHEAP" dishwasher pods. But to get the water softening needed for many of the sites we use, those water softening agents certainly would be good So, I'm going to shift over to using a small container of the more premium dishwasher pods for tank cleaning such as this one. For this product, I like that it has both Dawn for grease cutting and anti-sudsing agents that keep the suds to a minimum. Amazing technology for sure. However, the shelf life of such dishwasher pods varies by brand, but generally, they last for about 12-15 months. The cheap dishwasher pods typically las two years in my Ollie. To mitigate the shelf life, each season I'll either bring back to the house the left over pods. Or justbring 6 pods for the summer tour. Maybe I have come to a good solution considering shelf life, cost, weight, and performance. Surprisingly, this old dog can still learn new tricks. Thanks for the idea! GJ

-

The Calgon water softener is basically a water softener in a box or bottle. Way back I used the liquid and don't recommend that due to the propensity for spills and the weight. But their powder is good stuff for carrying in our RV's Softer water in the tanks makes the detergent more effective. Better Dishwasher pods have water softening chemicals therein. So it becomes a trade off between using less dishwasher pods with Calgon or just using more dishwasher pods. Either way, it gets the job done. if you have real hard water, then I would lean towards Mike and Carol's approach. GJ

-

My Ollie gets used 3 - 4 months, and then cold storage. Somewhere along the tour, when I am leaving a FAMCamp and going to a place with an easy dump station, I'll do the tank clean with two pods. At the end of the season, my last clean is with three pods. Why 2 or 3 dishwasher pods? No justifiable reason what so ever. Guess it just felt right. Let's try it with one and then 2 for the end of season and save another 1/3 of the cost. Easy to check the black tank with a strong light and a mirror on a stick. Have not thought of a way to check the Gray tank other than to just see clean water during flush. Good question for sure. GJ

-

HDR: Yep, was a great long standing approach for Black/Gray tank cleaning. Used it in my previous camper. But, "In 2011 it was discovered Pine Sol, Glade, Tide, Febreze, Clorox, and Simple Green, contain chemicals that are known to cause hormone disruption, pregnancy complications, birth defects, and cancer, and can aggravate allergies.". So it was reformulated. The new version does not have the punch of the ole one. Combined with the bath beads, it still is pretty good for our purposes. But it is an expensive blend compared to the cost of two or three dishwasher machine pods. Comparing the effectiveness of the two approaches, they seem be about the same. So either one will work. But comparatively, why not save about 2 1/2 pounds and some $$ too? Certainly worth giving the dishwasher pods a shot. GJ

-

In a different lifetime, I used food grade dyes of various colors to trace water sources. Start with Gray water lines with a lighter color dye, then try the black water system with a darker color. Then a very diluted light blue color for the fresh water. If none of the colors show up, it's condensation. Just a matter of elimination of possibilities to get you to the solution. Lessons learned the hard way: Suggest being careful to maintain control of all the effluent as it will stain concrete. It does not take much dye to be effective. More than just a tad and you can create problems for yourself. Wear gloves. My left hand was blue for quite a while! Used to hold it up and say... "I've got the blues". 😞 GJ

-

I'll say this, you "Starlink Fellows" are a smart group of owners. My slide rule based pea brain is amazed and impressed with your installations and the capability that it brings for boondockers to also be remoted gig workers. Been working with several owners, especially AndrewK, on how to route a long wire thermistor from the Houghton A/C control board to the former location of the Dometic thermostat. Andrew has shared detailed instructions on a possible way to "poke" a wire between the hulls. If I am unsuccessful in that process, use of your flat, low observable clam will certainly open up opportunities that I had not even considered. So, MANY thanks to you from all the OTT Houghton Owners that have been pondering our thermistor relocation goal! GJ

-

Both Dishwater Soap and Laundry Soap can get sudsy. However, Dishwasher Soap does not. If it does not suds, you can use more of it. Just suggesting less suds, the less potential for a Bubble Bath In Ollie!

-

Model Year Changes - 2020 to 2023/2024

Geronimo John replied to Ralph Mawyer's topic in Ollie Modifications

Really cool idea of replacing your zerks with ones that all point towards you in the middle. Will make greasing easier and faster too. Are those 45 degree zerks? GJ -

Bow Shackle on Anderson Hitch Goes Bye Bye

Geronimo John replied to Cort's topic in Mechanical & Technical Tips

For newer Anderson users: Let's assume you know what your target threads are to get the load transfer you need. The number is your number, what ever it is. I'll call it Z threads on each side. By now you probably know that If you back Ollie in at an angle to your site, getting the Anderson hooked back up can be a PITA. But some times you have no choice. Un hook with no worries. You will notice that your whale plate will be at an angle to the TV. When leaving, raise you Bulldog by raising it using your front jack which you have put some blocks under the jack foot. Then hook up one or both of your chains if you can. Do not worry about thread counts. But if you can get one side tightened to Z threads that would be grand. If only one, secure the loose chain. Depart the camp site for a larger stress free area. Then turn your TV so as to have the tight chain pull the whale plate around far enough that you can get the other chain hooked up. Then adjust the big nuts to Z on both sides. Ideally you do want both chains to be Z. This lets you do very hard right and left turns. If not reasonably close to Z, you will put the system into a bind and hopefully you only break the Shackle. Also, if going into difficult terrain be sure to loosen both nuts to allow the trailer and TV to ride over big humps/dips without causing damage. Hope this is helpful GJ -

Bow Shackle on Anderson Hitch Goes Bye Bye

Geronimo John replied to Cort's topic in Mechanical & Technical Tips

CH says maybe not. CH says that the whale plate is part of the ball shaft that is part of the ball. The assembly is not fixed to the Anderson receiver as it turn in a white material that is a friction cone. This friction cone is what some people need for sway. As such, Nope. You can tighten one side 7 threads and the other 1 thread and the friction cone will average the forces on the two chains. CH -

Bow Shackle on Anderson Hitch Goes Bye Bye

Geronimo John replied to Cort's topic in Mechanical & Technical Tips

For sure. Also tie a strong string thru the pin , shackle body and chain. If it falls out, you'll at least have the pin and shackle tied to your moving rig. -

Model Year Changes - 2020 to 2023/2024

Geronimo John replied to Ralph Mawyer's topic in Ollie Modifications

Also not the use of zerk caps. Very good way to keep junk out of the grease fittings. 🙂 -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Yea, don't mess with that Crazy Horse guy.... I've heard he will ride a pony 20 miles just to get one of Art's Beers! He just doesn't run out of feistiness! Geronimo John peeking back out from under the covers.