-

Posts

2,300 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

Bow Shackle on Anderson Hitch Goes Bye Bye

Geronimo John replied to Cort's topic in Mechanical & Technical Tips

Cort: Yes possibly. How many threads do you travel with on your chain end "studs" and nuts? Has the Anderson chain anchors been moved from that which was set up by OTT? For a less capable tow vehicle I used for a year (2005 Toyota Sequoia with truck frame), I need 7 threads of tightness from the OTT setup. When I went into rough conditions, I always loosened them up to 2-3 threads. Reason was that in a dip, the geometry of the Anderson will significantly tighten to an extreme level if I did not. You likely are experiencing the same situation, but well beyond my incident. GJ For GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

So you want to keep it up. Ok, I warned you. So now the nice studious GJ has left the ring. _______________________________________________________________________________________ Punching back is his evil twin. My handle has been Crazy Horse (CH) for 30 years. So, after 16 pages of "fun", why would any owner now order out a 4-leaf 1750 spring? Maybe order out a 2,000-pounder or more if their needs so dictate. Maybe even think about a US made 2000 to 2400 four or if they like stiff rides a 5 leaf as that really smart nice guy suggested. But not a 1750 of any leaves.... But to answer your bolded statement above: Because this group is smarter than that to do so. Now you have to agree with that one! 🙂 Crazy Horse (CH) -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

GJ Update: "Properly quoted the "Every spring that I have seen broken has been the fifth leaf..." to the proper source = ScubaRx. Sorry for my error. GJ ScubaRX: Interesting that you are just now reporting the failure of the 5 leaf springs. Here I thought you were the hatchet man for the 4-leaf springs! LOL. Me thinks you have typo's in your post. 🙂 CJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Steve: That's been my experience for defective springs as well. They go south quick. From materials sciences, most often for under rated springs that get over loaded, it takes more time for the overloaded alloy grain boundaries to propagate cracks sufficient for destructive deformation to occur. In such circumstances, the failure will generally occur at the highest point of stress concentrators, and that is usually at the end of the shorter section above the longest section. Just as we have seen in the pictures. Good thoughts. thanks GJ +++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ For some others: I have been stating that the 1750's are under rated for the load and for how we use our trailers. By this I mean that this spring does not have enough steel to earn a higher rating. It is not give license to believe that the Chinese were in bed with Dexter and they fraudulently conspired to spoof the rating data to increase sales. It only means that there is not enough steel at 11 or 12 pounds to do the job of a more stout spring that we seem to agree we need for our trailer weights and how we use them. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

JD: If any of the posters (Other than mysself) had found a 2000 to 2401 USA made 4 leaf spring I would have bought American. But after two and a half months, I have seen zero. Not one. Like the early adopters, I had to make a call for repacements. Mine are shot and I have 7,000 miles to roll this summer when I get there. I did my homework. My mistake was trying to convnce you and others that the SOB's were not what an OE2 needs. Add to that the dishonest representation, intentional or not, of springs to the early adopters by SOB of a spring set which was way over what had been sold is bad. But what followed is far worse. Having been strong armed by several owners that by my suggesting that a 2400 pound spring would be too hard a ride, only to find that they had purchased a 2750 pound springs.... and all fall in line with that's what they need. Pure confirmation bias. Then to say that they will be running their super springs at over 20 pounds over the Michelin E-rated tires pressure chart recommends. Hopeless. And now trumping the discussion with the idea that I am not patriotic by not buying an American made spring is beyond my limits of civility. As a retired USAF Colonel who served in several war zones for 30 years, and 40 year plus engineer, I will just say that... I hope your end up loving your springs. I suggest that this post be locked until OTT advises what they are suggesting for the fleet. Further discussion is no longer healthy for this forum. I'm done. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Paul: Thanks for your post. You basically shrunk down into a few sentences about 15 pages of posts. Really good to see your pictures showing how the 2400-pound springs have achieved their rating. Priceless. After all the negative vibes I have received from being "The Lone Dissenting Target" on this topic, it's nice to see some positive vibes for a change. In my research, and subsequent purchase, I learned that these springs do come with nylon bushing inserts as stated above. A few weeks ago when I ordered the 2400's, I also purchased brass bushing inserts. I'll switch them out in July when I install my springs. I apologize for not mentioning this earlier. But as you can sense, I was buried by "Confirmation Bias". Hopefully OTT will step in and give us their fleet recommendation on the 1750 topic. Way overdue. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Of course. Murphy's Law rules. Yes we can add him to the long list of us that have previously come to that conclusion. Including two Dexter Tech's. +++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ The distinction that many are making is thinking that 4 pack spring sets are by definition always bad, and the 5 packs are good. Also that everything made in China is bad and everything made in USA is always good. Hopefully we can also agree that these logic lines are full of holes. What we do KNOW is that the spring sets rated at 1,750 pound rating of the OTT OEM OE2 fleet for many years are failing as a result of the spring not being sufficiently rated to the use. Not that it is always crap because it was made in China or that it is a 4-leaf spring. Now some of them may well have been. But Dexter has used those springs in thousands of applications just fine. But for our OE2's, they are failing because they are under rated 1,750 pound springs. Not because they are Chinese or 4 leaf. I think that the vast majority of respondents to this topic agree that a stronger spring is needed for the OE2 fleet. And that the path to take for their OE2's can be very owner specific. I believe that a higher rated more compliant 4 pack may work just fine for our and likely for the fleet use. As such, I chose to purchase the Dexter 2400 pound rated 4-leaf. But what I think, and what other specific owners think is best for their specific use is only relevant to the specific use. But that does not necessarily make it suitable for general fleet use in my opinion. But OTT as the OEM of future OE2's will be looking at the issue from a fleet perspective. It will be interesting to see what they feel is best for overall fleet operations. I think we can agree that it likely will not be the 1,750 pound rated 4 leaf spring set. But will it be a 2750 pound 5 leaf? I do not think it will be. So, I will wager a beer to any of the above owners that have gone with the ALCON spring set that that choice will not be what OTT goes with for the future fleet as the standard spring set. Want to take my wager, list you names below in the next 48 hours. GJ -

has anyone tried the new Dometic fresh jet 2200?

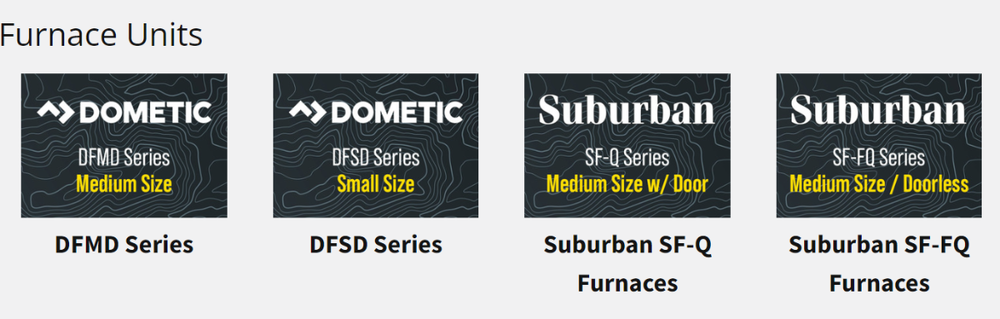

Geronimo John replied to Roadlotus's topic in Ollie Modifications

Me thinks your sales agent was not informed on the Houghton sound levels. We run ours on low fan speed the vast majority of the time. It is ULTRA quiet. I believe that the FreshJet is Competitor A. This is from their web site: That said, until Houghton series we purchased has some specific disadvantages to some others: No internal drainage system. Fan runs continuously with adverse humidity control. The thermostat is not remotely located so it also contributes to cycling/humidity issues. Granted, a handy DIY owner can: Add a relay to fix the fan issue fairly easily if electrically inclined Reroute the thermostat function by getting a longer thermistor. Installation is tedious for an Oliver. After a couple of years effort, I and others have not posted a fix for the drain issue. So the condensate drains overboard the roof. There is some indication that this may be resolved by a remote electric condensate pump, but I have not found any info on it yet. So, from a sound perspective the Houghton appears to be a quieter unit. But without having to rework the Houghton, I would not recommend it to owners that are not DIY inclined. On the other hand, the above problems are well known to Houghton and when they have provided the American market with an internal condensate capability, remote T-stat and fan off when compressor is off program it will be a blockbuster unit. As a DIYer, yes I would purchase a Houghton in a heart beat. But may owners would not want the hassle of having to update/mod a brand new unit. Hopefully another reader will have updates to my dated info. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

One lesson to be learned is the impact of a strong 5 stack spring vs. the far more compliant 4 leaf. Certainly the strong stack will transmit forces to the trailer frame much more than a wimpy 4 stack. With stronger axles the same effect will take place. So, with super spring and super axles, super shocks will likely be needed to contain those forces. To visualize, consider the ride of a F-150 vs. a F-350 dual axle, both unloaded. Put a dozen eggs in the bed of a F-150 and a F-350. Likely the eggs in the F-350 will be scrambled for you. Ditto with Ollie and stiff suspensions. This is likely why Mr. Oliver went with the 4 leaf. Suspension compliancy when hitting obstructions is a way for the energy to be ameliorated. The parts that do this are the tires, springs. EZ Flex, and shock "Team". Reduce the compliance by having 50 PSI tires, strong springs and axles.... and the extra energy is transmitted to the load. Remember you WANT to have the axle moving up and down within the range of our suspension system clearance ... and for our OTT's that is not a lot of headroom..... Knowing the amount of impact our rigs can handle and not imprint witness marks on the frame for both the cases is really important. Also to understand that the damping(I.E. energy to be absorbed) that is necessary to slow down and stop the rebounding of a heavier suspension is substantially greater than to do so with a lighter one. It will be interesting to see how all this plays out with this grand experiment in suspension design. I recommend that you start out using the Michelin Tire Pressure Table (Sub 30 PSI if I recall for our weights) and then move up to higher tire pressures as you gain experience with how the new design will perform. Go slow and safe and observe performance before trying it out at hammer down. I know I will be in July when I get my rig upgraded. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Very fortunate catch! I hope that you are correct in that the Monroe's were defective. I highly recommend checking the new ones in 10,000 miles to see if they are OK. If yes, SUPER. -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Steve: You are set to fall from a 3th floor to the concrete ground. You can choose between wearing multiple layers Bubble Wrap or Alloy Steel? or this: Conclusion: In many instances, more steel is the wrong answer. So far, it appears that we, Dexter Techs, and ALCAN Techs all seem to agree on is that the OEM 1750-pound 4 leaf springs were not strong enough to haul the OE2’s at the weights and uses we today are requiring. I continue to believe that increasing the load capacity to 2400-pound rated 4 leaf is the better solution for the OE2 fleet. Why? Because I feel that a 37% increase in a 4-leaf spring capacity (as compared to OEM 1750) is sufficient capacity and the ride of a 4-leaf spring is less harsh than the 5-leaf option. On the other hand, the 2750-pound rated 5 leaf springs would be a 1,000-pound increase per spring, a 57% increase in rating. That much spring and being a 5-leaf will result in too harsh a ride for the OE2. It likely will exasperate frame weld failures, as well as other ride related issues. So, we agree to disagree. When OTT decides to wade in on this discussion remains to be seen. But likely it will be evident in follow on year’s products. GJ -

Good news: No screen to clog. Bad news: With no screen sediment and "Stuff" will be sucked up into your system. Resulting in low water pressure and at times no flow due to sediment, plastic from MFG, and some plastic from OTT as they install plumbing. GJ

-

Motorola had it's reasons for the design of their land mobile hand held radios. We need to keep in mind who at the time their PRIMARY customer was.... The Military. Troops in the field have used their heavy, ugly, bulky, near water and mud proof and almost indestructable hand held radios successfully for many years. They have even been used as a weapon of last resourt to throw at combatant. We called them a "Brick" for that reason. Did I mention heavy? Any troop could pick up one and use it. Push and talk it communicated. But for the civilian perspectice you are spot on...... GJ

-

Emptying the Holding Tanks in an Oliver

Geronimo John replied to jd1923's topic in General Discussion

-

Exactly! We also always park Ollie a bit nose high to: Keep the Refer door closing vs. free swinging to a hinge lock out. Allow the Houghton over roof drainage to mostly miss the street side rear window. I need shoulder room so sleep head forward. I also like to sleep up hill. Even if you are hyper vigilant with water sources, stuff will accumulate in any fresh water tank. Especially if boondocking, or using well, or rain water. I have alwlays considered the last 4 or 5 gallons of fresh water in the tank as the "Sludge Zone". It was designed with an elevated pump draw tube. This is a standard "Good Engineering Practice" for all freshwater tanks. So for some of us getting those last 4 or 5 gallons would result in getting "Stuff" into our fresh water distribution systems. But for ALL of us, regardless if you do or do not do the mod, it is extremely important that you filter every drop of water you onboard. Even if you only fill out of your special home tap. Not doing so will result in silt and other "Stuff" accumulating in your tank. Now here is where I'll stir the pot: We all are aware that the drain port on these tanks is way too small for effective flushing. So if I were to choose a FWT mod, for a new trailer, it would have OTT put a 1" drain line in, and not mess with the draw tube design. GJ UPDATED: Spoke with experienced OTT Tech's and Art: The Fresh Water Tank is a PITA to get out. So the recommendation should say that for new trailers, a larger drain port and valve would make a lot of good sense.

-

I agree in principal recognize your TAKE OUR CHANCES perspective. Packing light and as a result often rolling the dice works well for a lot of RV owners. Others pack heavy and could never go where you and I like to go. Then there are others of us that are actually somewhere in the middle. It is all good. It is also good that our "spares/emergency/DIY gear) is different. No point in running across a situation and having the exact same gear. Better for our response if our Kits are different. MORE OPTIONS. I would wager that we both, and many others, carry gear that gives us more options so that we don't have to roll the dice very often. Also that neither of us go overboard on the weight or space side. GJ UPDATE: Talked to knowledgable OTT techs and pulling the FWT is a PITA. Not something they or I would recommend for any mod. So I did suggest that they increase the plug prone tank drain to 3/4" or 1" to facilitate tank flushing.

-

Aesthetically pleasing, low aerodynamic impact, and high power output, and not damaging to our Gel Coat! Been waiting 6 years for the technology to mature. Now we need to add at a "reasonable cost". GJ

-

Single point of failure means you have no options. I like having options. Such is especially important for running our Refrigerator and Furnace is important. For the Refer, our OEM was gas, 12V, and 120V. For replacements I'll not go with the gas (High risk of fire) and get one that can run on either 12V or 120V. Add to that a good quality "5-Day" ice chest. For Heat: I suggest getting a quiet heat pump when you replace your Hammer Mill OEM one. Next a 120V 1500 watt electric resistance heater. IF you are doing a lot of cold weather camping to also get one of the safer propane fired portable heaters and a couple of small disposable propane gas cylinders like these as well. GJ

-

Searching for info to reseal large windows

Geronimo John replied to Wayfinder's topic in Mechanical & Technical Tips

Chris: If you have water coming inside and onto your bunk, and it is not coming from above the window (As you determined), then I would clean the window tracks. It is a common source of water intrusion that many of us have experienced. Here is my cobbled together DIY for the task. GJHow To Clean OE2 Window Tracks.docx -

Our Annual St George trip and PPA Pickleball Tournament

Geronimo John replied to jd1923's topic in Campgrounds & Parks

Lived in Sandy, UT for 8 years and loved all the wide open spaces. Their National and State Parks are amazing! Super glad you are having a great trip. With a 23 year old diesel, I suspect you are seeing some age related issues. When newer those diesel 2500 trucks would pull loads a lot heavier up just about anything and not overheat. Suggestions: A transmission cooler upgrade. I would replace the thermostat if it is also OEM or even just 10 years old. They can corrode/wear out and then not open fully when needed with older age. If still a problem, consider having your radiator "boiled out with chemical" professionally done. Question: What is this on the roof of your truck? John -

Dometic AC Shroud Trashed

Geronimo John replied to Galway Girl's topic in Mechanical & Technical Tips

A few years back, another owner was concerned as well. I suggested using Rivet Nuts and SS bolts with fender washers to increase the contact area. Would work better than STS's. Sorry for the pain this service tech caused you. GJ -

Bathroom Faucet slow water flow

Geronimo John replied to Trainman's topic in Mechanical & Technical Tips

For owners with hard water sources, some of the defensive measure are: Filtration of incoming water. Frequent vinegar de-calcification. Lowering the hot water temperature set point. Using a city water pressure "L" shaped flushing wand to flush solids from your hot water tank. Use it more than just at end of season! Keeping a good quality anode in the hot water heater. If you see wire, you waited too long. Remove faucet aerators and wands for vinegar cleaning at least annually. While you have them removed, full flow flushing your lines one at a time. Do hot and cold flushing separately, not at the same time. Avoid very hard water sources when you can. Or at least don't fill your fresh water tank full if you can get by with less. Fully drain and flush your water systems at the end of the season even if you do not winterize! Consider wands that have bigger holes. All of the above will help reduce problems. But if you find that they don't, you'll need to consider using a water softener to lower the hardness of water from all your water supply sources. Here is one of the reviews for the ten best water softeners for RV's. https://buyersguide.org/water-softener-for-RV/t/best?Country=US&m=e&d=c&c=659084136666&p=&oid=kwd-2066914159841&lp=9032812&li=&nw=g&nts=1&gclid=CjwKCAjw88yxBhBWEiwA7cm6pTq4CWP-deBiQy2P_b4K_q0yn0LBGjkFPVOQI0RMo0TMsFYO411bcxoC-wUQAvD_BwE&tdid=10957326&gad_source=1 GJ PS: For an OE2 you do not need a 16,000 grain water softener. Take a look at what other owners are using via our forum.