-

Posts

923 -

Joined

-

Last visited

-

Days Won

18

Everything posted by Rivernerd

-

In our experience, twice, it allowed water to enter the cabin. I believe this is because the air conditioning unit is mounted over a large hole in the roof, and is not internally sealed. Truma relies on external, not internal, sealing.

-

After I recently submitted another service ticket noting leakage under the Truma Aventa air conditioner, I was referred by Jason Essary to Truma. Truma recommended sealing those countersunk holes with silicone sealant. Once on the roof, the sealing process took about 15 minutes.

-

Agreed. It makes no sense, particularly since green glue costs more than either PVC or ABS glue. But, our Hull #1291 has that same strange mixture of PVC fittings and ABS pipe. No plumbing inspector of my acquaintance would pass it. In Idaho, for example, only one transition from PVC to ABS is permitted per drain line. PVC is commonly used for Drain Waste Vent (DWV) pipe assemblies in the Eastern USA. ABS is commonly used for DWV pipe assemblies in the Western USA. I don't know why, but that is what I see. But no state I am aware of allows the two types to be mixed throughout a drain line. I wonder if the rules don't apply to RV manufacturing? That said, as long as the correct green transition glue was used, a drain line with PVC fittings and ABS pipe should hold up fine. That is why I did not raise it as an issue when we took delivery of Hull #1291. I did note one place where insufficient glue was used on the top of a DWV joint, but I chose to address it myself when I got home. Properly adding glue to a partially-filled DWV joint requires preheating the joint with a heat gun. Much like "sweating" or soldering copper pipe, if the joint is preheated, then the glue is applied, the glue gets sucked into the void to create a proper seal. Unsure if Oliver would use this method, and since the void was on top of the pipe, I just chose to do it when I got home.

-

They are colloquially called "Ferncos". They should be available at any hardware store that carries plumbing parts. They are code approved for Drain Waste Vent (DWV) connections, like the one in your photo. IF you can move the pipe enough to achieve full insertion into the female flange part of the fitting shown in your photo, you can glue it with ABS glue. ABS glue is available at any hardware store. Buy the smallest can you can find, because it has a short shelf life once opened. Place a shop towel or 2 layers of paper towels under the joint to catch any drips, then daub glue on both the inside of the female flange and the closest 1" of the pipe, then immediately insert the pipe into the female flange and hold it in place for 30 seconds. The glue will take hold by then, and you can let go. IF the pipe won't move enough to allow full insertion into the female flange part of the fitting, using a Fernco is better than trying to glue the joint. Just be sure to measure the outside diameter of the pipe, and buy the right size to fit that. It looks like you can pull the pipe far enough away from the fitting to enable you to slip the Fernco coupler completely onto the pipe. Once the Fernco is on the pipe, then slip the end of the pipe as far into the female flange part as you can. Then slide the Fernco coupler back toward and over the flange so the coupler is centered over the joint (as best you can). Then tighten the hose clamps until they are snug. If you tighten with a slothead screwdriver about as tight as you can, that should be about right. If you use a nut driver, be careful not to over tighten, or you can strip out the screw in the hose clamp. Good luck!

-

How do you import images from the FXC Control app on your smart phone so you can post them on the forum? I have not been able to figure out how to do it.

-

Thanks for taking the time to test, and report your results. It is very helpful to me! I recommend you submit a service ticket to Oliver. Your results suggest that using your microwave even at 99% state of charge is resulting in inverter shutdown. The more service tickets submitted for such issues the better educated the Oliver service department, particularly Jason Essary, will be about the issue. They may, indeed, have gotten a bad batch of circuit breakers. Jason has been very responsive, and really cares about getting to the right result for the customer. I have requested a replacement inverter breaker. I hope it is not another bad one!

-

Well, I ran the test yesterday. At 99% State of Charge on our 390 Ah battery bank (per the Lithionics app), the FXC Control app (the one from which SteveCr's screen shots were taken) showed about the same DC amperage being drawn, but 12.1V (as opposed to his 12.5V) under load. Although the inverter was seeing 12.1V, it did not shut down during a 4-minute microwave test. I expect that is because State of Charge was at 99%, which yielded a voltage before application of load at 13.2V. So, I then put a multi-meter on the DC inverter inputs to measure actual input voltage under the 1500 watt load. It read 12.24V under load vs. 13.1V with no load. To determine what impact, if any, the Optifuse 300A inverter breaker had on the impedance, I tested voltage at the breaker input stud under 1500-watt load: 12.53V. I concluded that the Optifuse 300A inverter breaker causes a voltage drop of 0.29V (12.53V-12.24V) between the battery bank and the inverter inputs. This seems high to me. It makes me wonder if the Optifuse 300A breaker is defective. Has anyone else checked this out? And, do any of you engineering types see a flaw in my methodology?

-

Yes, copper. No, the lugs are aluminum. That is the way Oliver built it. And, significantly, many other Elite II owners with the same package report no issues. You cannot plug directly into the inverter. The inverter output runs through 12 AWG solid copper Romex to the 120V main panel, which has multiple circuit breakers. There are two 120V circuits with receptacles that the microwave 15A cord can plug into, both wired with 12 AWG solid copper Romex: (1) the dedicated microwave circuit and (2) the GFCI protected general receptacle circuit. Whether I plug the microwave into either circuit, the results are the same.

-

Makes sense to me. There are millions of vehicles on the road much smaller than both our tow vehicles and our Olivers. 18-inch tires don't work well on small vehicles, like our Subaru Outback. I, for one, am not worried that I won't be able to find good 16" tires for my Elite II in 8-10 years.

-

Thanks for the reference. I just found a reference to type JLE-1-41340-250 breakers in a Lithionics manual. The photo of that breaker suggests it is designed to be installed in a panel, like circuit breakers in a household electrical system. The Optifuse 300A circuit breaker is mounted on a PVC board near the inverter, not in a panel. When I jumped the Optifuse breaker, the voltage drop was reduced from 1.2V to 0.8V under a 1500 watt load (the microwave). 0.8V is still too much, according to Jason Essary, who reported a 0.4V to 0.5V voltage drop when testing another Elite II with the same inverter. But, the reduced voltage drop, with the breaker jumpered, enabled me to run the microwave for 5 minutes without inverter shutdown, as the DC voltage displayed on the Xantrex remote never dropped below 12.2V. I stopped the test at 5 minutes, because I was not comfortable running a DC circuit with a 1500 watt load for very long with no breaker protection. Didn't want to start a fire! I am not an electrical engineer. Do any of you engineering types out there have any suggestions for possible solutions?

-

This new thread is a spinoff from the Door Lock Problems thread. I mentioned the issue with the Xantrex inverter to commiserate with the poster who had the door lock issue. So, here's the issue with the Xantrex Freedom XC Pro 3000 watt inverter: it inverts as expected with loads up to 1100 watts (like the Truma air conditioner), but loads like the 1500 watt microwave cause a low-voltage shutdown after a few seconds (sometimes) or a few minutes (at other times). This seems to be affected by battery state of charge. Voltage drop when under load is normal; I am advised that a 0.4V to 0.5V drop under large inverter loads is normal. But our 3000 watt inverter shows voltage drops from 0.9V to 1.1V when a 1500 watt load is engaged. If, for example, the voltage reported on the Seelevel monitor is 13.1V, engaging a 1500 watt load will cause an immediate drop down to 12.4V on the Xantrex display, then less than a minute later, down to 12.2, then 12.1 and finally 12.0 in less than 3 minutes. The inverter then does a low-voltage shutdown. This limitation makes the microwave unusable on inverted power at State of Charge levels below 75%. With lots of responsive help from Jason Essary, I have been troubleshooting first the DC side, then the 120V AC side of the trailer wiring. I have found no loose connections which may cause the unexplained DC voltage drop. This included removing the 300A Optifuse breaker from the DC side (by placing both the lug from the battery and the lug to the inverter on the input side of the Optifuse breaker. That produced only a 0.1V improvement in DC voltage drop with a 1500 watt load. A post by Tom and Doreen on the Door Lock Problems thread suggested the source of the voltage drop could be the Optifuse breaker, and that Lithionics specifies a different breaker, which may have a much lower resistance specification. Is anyone else with the 3000 watt inverter having this issue when using the microwave on inverted power? What 300A breaker does Lithionics specify? Could that be the answer?

-

What circuit breaker does Lithionics specify for use with a 3000 watt inverter? I have searched, but not yet found a reference. I may replace the Optifuse and see if that resolves the issue. And, I will start a new post on the Xantrex inverter issue, as this is a thread drift, yet others may benefit from the information posted.

-

Have you tried adjusting the directional vanes, and the "front vs. rear" slide switch in the bottom middle of the unit? That slide switch can divert air flow either all forward, all aft, or a combination of the two. And, the rotating directional vanes can move air flow side to side.

-

Do you turn off the Master Light switch when you leave the trailer? When that switch is off, our touch lights all go off too.

-

Before we took delivery of Hull #1291 last November, I compiled a list of nearly 100 potential manufacturing defects reported by previous Oliver owners. Strike plate misalignment was not one of them. Fortunately for us, our door and latches were installed correctly. Sorry you are the victim of poor door and strike plate installation. Even though your DIY remedy was effective, I recommend you submit a service ticket, so the Oliver Service Department is advised of yet another sorry failure by the folks in the manufacturing department. Kinda sucks when you pay so much for an Oliver, doesn't it? Lest you feel unlucky, I have spent most of the last several days troubleshooting inverter issues, and sealing the external screw heads on the Truma air conditioner (after leakage) in our 6-month-old Elite II (at Truma's recommendation). Jason Essary has provided indispensable help with the electrical troubleshooting, and even initiated the Xantrex warranty case for me. Our 3000 watt Xantrex inverter won't invert more than 1100 watts for more than a few minutes without shutting down, even when the batteries are at 100% State of Charge. Although it is frustrating to experience such issues with a nearly new, and very expensive, trailer, Oliver's Service Department has provided invaluable service helping me isolate the source of the problem, and pursue warranty relief. It appears to me that quality control in Oliver's production facility remains unacceptable for such a premium product. But, Oliver's Service Department, and particularly Jason Essary, continue to effectively counterbalance those oversights with exemplary customer service after you take delivery.

-

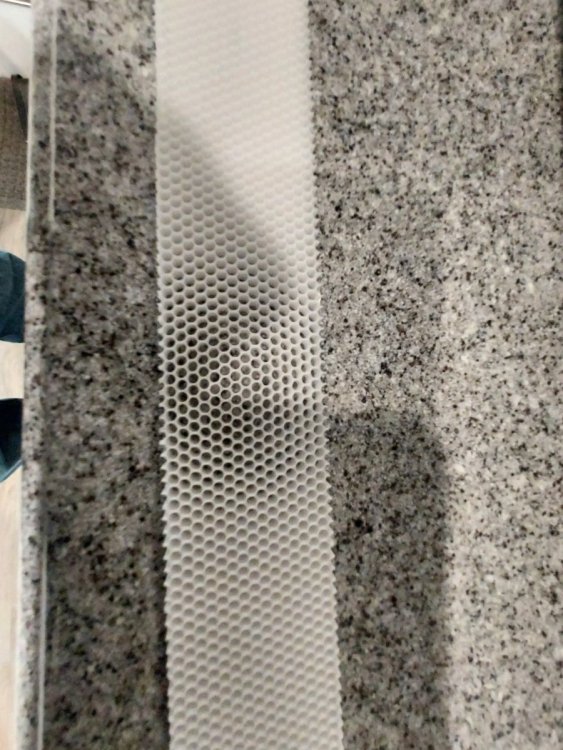

Who am I to dispute what Truma says about its products? That said, attached are three photos showing: (1) one of the two filters removed from our Truma Aventa air conditioner on the countertop above the fridge; (2) a close-up of the filter, so you can see the plastic honeycomb and (3) me washing a filter in our home kitchen sink. Silly me for thinking they could be washed instead of replaced for $$$$$$$$$$$$$$$!

-

getting ready to camp after 2 yrs in storage

Rivernerd replied to LindaShields's topic in Introduce Yourself

The Additional 30A Convenience Connection is not just for generators. It is truly for the "convenience" of being able to plug a 30A power source, whether regular shore power or a generator, into the curb side of the trailer. That said, the fact that plugging shore power into that 30A curb side inlet did not charge your batteries suggests that your transfer switch is not working. If you had only the primary 30A inlet on the street side, you would not have a transfer switch. But when the additional 30A inlet is added, a transfer switch must also be added. The transfer switch is designed to direct power from whichever inlet is used to the trailer's electrical system. Many Oliver owners have had issues with their transfer switches. That is one reason we don't have an Additional 30A Convenience Connection on Hull #1291. But since you have it, it should be functioning properly for safety. I recommend you ask your "RV doctor" to take a look at your transfer switch, and probably replace it, so your electrical system will work as designed. -

LPG Tank Level Monitor Installation...

Rivernerd replied to MAX Burner's topic in Ollie Modifications

I bought the Truma Level Check before we took delivery on Hull #1291 last November. I found it cumbersome to have to remove the "doghouse" every time I needed to check propane level. After we returned home to Idaho, I purchased the Mopeka system, along with two of the Mopeka tank halos. The halos create sufficient clearance for the tank sensors, so I did not need the included metal shims. The sensors are somewhat sensitive to positioning, so they must be carefully centered on the bottom of the tank. And, when tanks are refilled, I double-check sensor location before hefting the full tanks back into the tank enclosure. The sensors coordinate seamlessly with the Mopeka app, so I do not need the monitor. The wireless range is good--about 75 feet, so I have had no issues with checking tank levels using the app inside the tow vehicle or the Ollie. https://technorv.com/products/mopeka-sensor-2-pack?variant=43661556875484¤cy=USD&utm_medium=product_sync&utm_source=google&utm_content=sag_organic&utm_campaign=sag_organic&gclid=EAIaIQobChMI8fDYiPLW_gIV5CutBh3DXAlWEAQYBSABEgKq3PD_BwE I am pleased so far with the performance of the system. Much better than having to go outside and remove the "doghouse" to check tank levels! -

The Truma Aventa filters are washable plastic grids. I have removed them, but have not needed to use the air conditioner enough yet to need to clean them. They are reusable.

-

I find removing the propane tank cover to be cumbersome, and hard on my aged back. I can do it, but don't like to do it very often. Removing the porthole cover is easy, and enables me to reach in and turn the propane tank valves on and off.

-

The nubs on ours broke off on the way home from Tennessee to Idaho. I opened a service ticket with Oliver, but was advised that the manufacturer does not warrant them. I could not find an exact replacement for the one Oliver installed in the propane tank cover. So, I ordered this screw-in 6" porthole assembly from Amazon. https://www.amazon.com/gp/product/B06ZZWYNVL/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 Because the one Oliver uses has nubs that fit into the outside ring, to install the screw-in kind, I had to remove the original ring from the porthole cover and replace it with the ring that comes with the screw-in replacement. Not very hard, just remove 6 screws, pull the ring out, and use the same screws to install the ring that comes with the replacement. You should only have to do this once. The screw-in replacement is much more secure than the one Oliver uses, and has no nubs to break off.

-

Trying to understand recharging the batteries

Rivernerd replied to HDRider's topic in Ollie Boondocking

Spot on. In my "real world" experience, a generator recharges our 390 Ah batteries much faster than the solar panels, even when parked in direct sunlight at mid-day. -

It looks in this photo like the top of the flex housing is threaded. Have you tried twisting it into a vertical position, then screwing it back in to the flange above it? If this method works, it would be easier than drilling out and replacing the pop rivets, after securing the flex housing to the flange in some way.