-

Posts

1,145 -

Joined

-

Last visited

-

Days Won

35

Everything posted by Ronbrink

-

New Hughes "Watchdog Power Center" coming soon.

Ronbrink replied to CRM's topic in General Discussion

Unlike the former version, this newer version is “engineered to be completely weatherproof”, which was a concern in using the original Hughes Autoformers voltage booster outside at the power pedestal. To eliminate said concern, I choose to mount mine under the rearmost dinette seat for ease of continuous use and protection. With the larger footprint of the Watchdog Power Center, I doubt it could be mounted in similar fashion and thus, no plan to upgrade. Both 30A versions have replaceable surge modules, the former with 2400 joules and equivalent newer at 3000 joules of protection. I also use a 30A 12,000 joules circuit analyzer at the power pedestal. Here’s a couple of pics of my install: -

Bathroom floor drain gray water valve problem

Ronbrink replied to Citrus breeze's topic in Mechanical & Technical Tips

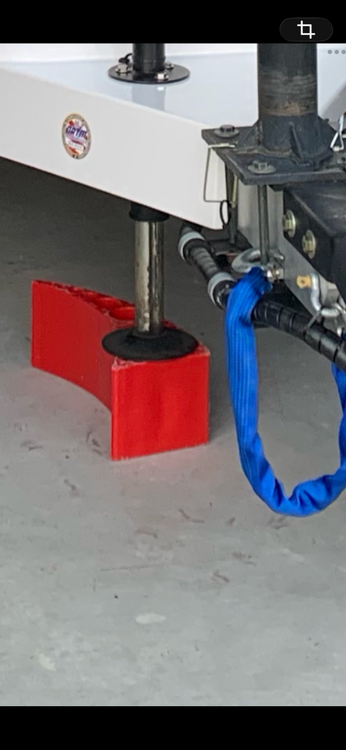

I too went with the Flap Jacks after five years using the taller Andersen Blocks at the rear stabilizers, primarily for the space and weight savings you mentioned. I bought two in individual carry bags rather than a single larger bag, easier to arrange and stow in the rear basement. The only thing I miss are the magnets on the Andersons for ease of positioning on the stabilizer feet. Even though both brands have the same 6,000 lb. weight capacity and equally sturdy, there is a distinct advantage with the Flap Jack design. To @Geronimo John’s point, both the top and bottom plates are solidly flat and thus, effective “slip planes”! -

I will preface the following by stating I have no real experience operating the Norcold in the conditions you question: It really depends on how extreme the cold is. In freezing temps the Norcold may lack efficiency or fail to operate. I would think running on gas would help provide some heat to the cooling unit, but may not be enough. Many do not like to operate the fridge on gas when underway. Hopefully someone will chime in with more definitive and pertinent information. Stay warm!

-

The key is to have enough slack in the hoses to enable lifting the regulator off the threaded stock when removing the propane tanks. This is my preferred setup, as the tank valves and changeover switch are all easily reachable via the housing screw port; and the regulator can be moved out of the way for more clearance when handling the tanks. Note the cable routed through the cross bar, around each tank handle the loop ends on the threaded stock seen behind the regulator, as well as the padlock for securement.

-

My Norcold is true to the trailer’s side-to-side level. I find the entry floor centered below the wet bath doorway the best location for a level reading. I should mention that when the top of the fridge door is perfectly level, the front of the Oliver is slightly raised, which is undetectable when moving around inside. Actually, this slight downward slope also facilitates condensate runoff from the Atmos 4.4 to the rear of the hull.

-

I often tell myself “life is too short to always stay confused”. Thanks for helping clean up one mess in my mind!

-

Like many I use an electronic device staged in the Oliver, which can be monitored from the driver’s seat whether searching for a desirable (somewhat level) spot when boondocking or parking at a designated site pad. Even with these devices, one must initially use a bubble level in the calibration process and routine checks for device accuracy. Once set, these devices are fairly reliable … until they’re not! The LevelMatePRO served us well for several years, but was not without issues; primarily battery life and connectivity regarding its sleep habits! I recently changed to the Beech Lane Wireless RV Leveling System in hope it will outperform the former. One thing that became very apparent in achieving my ‘optimum level’, was in respect to that of the Norcold 3-Way fridge. I found that having the Norcold absolutely level overrides that of the trailer proper. That said, I use the top of the fridge door as the benchmark when calibrating both past and current leveling devices. Keeping the Norcold ‘happy’ is paramount and a very close second to that of the wife! All of my past woes regarding the Norcold can be contributed to the aforementioned and easily mitigated with proper levelness. For convenience, I carry a folding level in a galley drawer. ‘Nuff said!

-

I use the standard Andersen levelers, as necessary, to raise one side or the other when backing up the last few inches. These standard levelers provide 1/2 to 4” of lift; whereas the Andersen Rapid Jack you mention provides for 7” lift, designed mostly for use with tandem axles to facilitate tire change. I primarily use the Rapid Jack laid on side for the 6” of base it provides under the front stabilizer jack. On rare occasion a site is level enough and thus, the standard levelers are not needed; in this situation the wedge chocks, generally paired with said levelers, are used to simply stabilize one tire (front and back) to keep the trailer from rolling when unhitched. As shown in the first pic, the round Andersen Jack Blocks used under each rear stabilizer jack. I have since changed those for Weigh Safe Flap Jack Blocks, which are much more compact when stowed.

-

My OLEll has the new style, which solved much of the problem with trays coming loose in older models and causing damage to box doors. However, one should take care and ensure both catches are fully engaged when closing. Occasionally upon slamming the tray into the secured position, only one of the catches will fully latch correctly. It’s easy to overlook, so owners with this type tray need to visibility verify that each spring-loaded catch is properly seated. A second ‘slam’ usually gets it done! Because these catches are horizontally mounted at each side of the battery tray, it is more difficult to further lock them in place in such manner as @jd1923 and @mossemi have successfully achieved. Has anyone figured out a way to deter theft with these new style battery trays? Early in ownership I replaced the stock 12V Bright Way SLA/AGM batteries with 6V Trojan T-105 flooded lead acid batteries. In time the off-gasses from the Trojans deteriorated the battery securement straps, both the webbing and plastic buckles. This caused the tray hooks to loosen and require vigilant inspections. When upgrading to LFPs, I made a new set of straps which have held tight thus far!

-

Yes, that would be golden IMO; just be sure to confirm the heater is working in winter conditions (LFP truly above freezing temp). I like to discharge the battery bank to 50% SOC if time allows, otherwise at least slightly below 75% SOC. Reason being that I have two chargers, the Xantrex 2000W inverter/charger and a dedicated Victron Blue Smart charger; 80A and 30A charge rates, respectively; 110A combined charge output. The Victron charger is triggered by a Victron Cerbo set to activate it when 75% SOC occurs. Incidental discharges above the 75% SOC threshold are serviced solely by the Xantrex charging component to maintain 100% SOC.

-

Although there are varied recommendations among LFP makers, in general it is not good to maintain 100% SOC for extended periods of time in storage; extended meaning three months + with no demand. In this instance, isolating the batteries and storing at 50% SOC seems an acceptable practice. Personally, I continually maintain 100% SOC year-round given the fact that I routinely go to the Cow Barn to check on things and make it a practice to exercise the LFPs. During summer visits the air conditioner is ran off the batteries and likewise that unit’s heat pump during cooler weather; cycling the battery bank in this manner is good ‘care and feeding’! I’m fortunate to have enclosed storage with electricity, which is adventitious in this battery management scheme. That said, my COW is turned out often and thus, rarely sees ‘extended’ periods of nonuse; always ready to search greener pastures!

-

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

And his first post got hijacked with good intentions! We all learn from the wandering and rambling of forum member’s comments, at least I do! -

For the first time since incorporating the two cargo boxes in the Savana 15 months ago, I had reason to clear the cargo bay yesterday to haul a 75” QLED TV. I generally keep one box in the van as a trunk, while the other is stowed at the Cow Barn full of camping gear in readiness. For perspective, distances from the rear doors to the rear passenger seat is 6’ and to the back of the two front seats is 10’. I snapped a couple of pics this morning of the new rubber mat layout and to illustrate the unhindered spacious area of the cargo bay. The second and third 24”x36” floor mats from the rear are positioned in the footprint of each box when carried and fit perfectly atop the boxes for added protection. The aluminum plate is a runway for our folding e-bikes followed by a few extra cargo strap attachment points to secure the Dometic fridge/freezer when camping or other miscellaneous cargo, as needed. EDIT: Went back to the Cow Barn to reload the ‘trunk’ cargo box and snapped a pic of it positioned with the rubber mat on top. Ignore my foot reflection as I lounged in the rear passenger captain’s chair enjoying a beer!

-

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

Hope it works out well for you! My spare is part of the routine wheel rotation and thus, kept at the same pressure as the running tires. If fitment in the spare tire housing is an issue, deflating to a lower pressure may help. -

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

I went to the Cow Barn today to “verify size” and obtain photo documentation to add credence to my former statement: “My 2020 OLEll tires are all the same, Cooper Discoverer HT3 LT225/75R16.” Upon physical inspection my findings are conclusive, the four trailer tires and spare tire are the same size; something I already knew, but compelled to check as part of the verification process. However, I can’t explain away the spare tire housing discrepancy! -

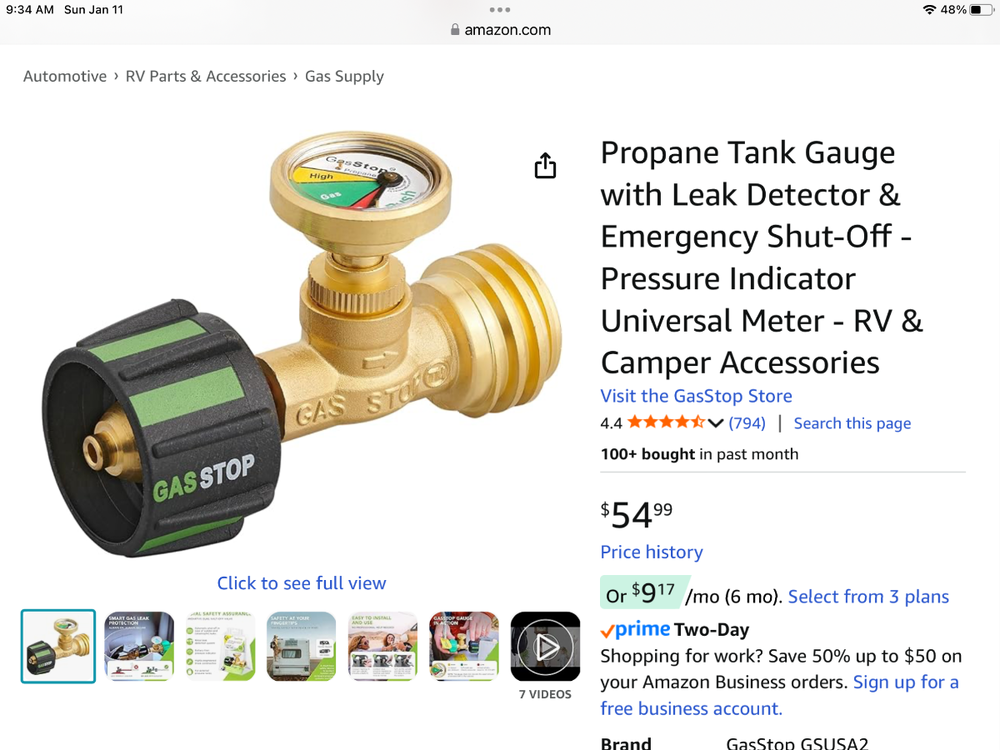

A more expensive, but much better option. I have these on the two mounted 30# tanks and a spare 30# tank carried with; the gauge accurate, purge feature very useful and emergency shutoff essential!

-

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

Understood, I was actually making reference to your previous statement: “we have found that a pair of Bilstein 5100's shocks and air bags on the rear axle have made a wonderful improvement in our driving experiences.” My air bag pressures are the 25 and 35 psi preferences for non- and towing instances. Since we don’t off-road, the trailer tires are currently maintained at 55 psi, but giving thought to lowering them to 50 psi; still hesitant to go any lower even though you and others do 40-45 psi on paved roads. -

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

Good point about the different tire diameters. I’ve always viewed the 23.5” as a ‘ballpark’ height to shoot for when fitting a ball hitch to a TV. I prefer hitches with one-inch increment for adjustment to better reach a targeted height and then the rear air bags to dial in the best towing level. I find 25 psi and 35 psi with my Air Lift LoadLifter setup for a good ride and tow, respectively. I also installed Bilsteins on the Savana after reading your praise on them, huge improvement! -

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

My 2020 OLEll tires are all the same, Cooper Discoverer HT3 LT225/75R16. -

I suggest you replace the breaker with a quality Blue Sea Systems 285-Series Surface Mount component.

-

What is Towing "Level" and Does It Matter?

Ronbrink replied to Sam Heumann's topic in Towing an Oliver

I think Oliver recommends the distance from ground to top of ball at the Bulldog coupler to be 23.5”. -

Shock absorbing material on steps bracket coming out

Ronbrink replied to Randy's topic in Mechanical & Technical Tips

I’ve had rubber migration at the steps, A-frame and undercarriage cross beams; inspection of these areas is part of my routine maintenance. I have used slight pressure on the underbelly to provide necessary clearances by way of a jack and a 2x6 to distribute force on the fiberglass, then clamps used to further restoration. The strips of rubber at the cross beams have a screw at each end and thus, will not fall out completely. I was able to use zip ties at the A-frames where the rubber protrudes beyond the chassis to keep it in place. Unlike the aforementioned cross beam rubber strips, the step strips have no screw securement and can come out. The ones shown in the beginning photos at each side of the steps are the most difficult to reposition and secure. -

Water pump not working -- problem solved -- FYI

Ronbrink replied to ZLarryb's topic in Mechanical & Technical Tips

You are correct, I have used that technique upon occasion when a more critical application of pressure is required for a fix. Thanks for your insight! -

I have TST cap sensors on the four trailer tires and four TV tires, as well. Up to a couple months ago, only trailer-related tire issues have occurred requiring attention to flats or valve stem leaks in the past five years. However on a recent trip a slow leak was detected at a rear tire on the TV, a screw puncture was found. My TV has tire pressure readout, but no alert system and thus, so thankful I had sensors installed. I was able to repair the tire before further damage incurred due to under-inflation in tow.

-

Greenland Turbro 13.5k Inverter AC / Heatpump install.

Ronbrink replied to CRM's topic in Ollie Modifications

I assure you this was as painful to read as it likely was for you to post! Sorry you weren’t able to enjoy the upgrade experience and now an Amazon return missed opportunity!