-

Posts

1,121 -

Joined

-

Last visited

-

Days Won

35

Everything posted by Ronbrink

-

I’ve heard tank sounds, as well, more of a ‘high-pitched whistling’ rather than ‘ringing’; probably a difference in interpretation. Mostly detected when a tank is low and drop in ambient temperature; thinking maybe coming from the tanks safety cutoff valve. Briefly switching the pressure regulator to the other tank and then back again after a short period usually resolves the issue. Not a concern unless there is a propane smell, that very distinctive mercaptan odorant that has a sulfur-like smell.

-

I recently installed GasStop devices on each of my propane tanks. It is designed to perform a ‘minor gas leak test’ by following a simple procedure; very useful feature when a gas smell is detected to determine if you have an actual leak in the lines or supplied systems (appliances). With this feature, one can troubleshoot and perhaps save time, money and more importantly their camping adventure, by not having to shut down and have the system otherwise checked out. However, if an appliance is suspect and a problem not obvious, precautions should be taken and any service performed by trained professionals. As some have stated, the gauge on the pressure regulator is not a gas level indicator, whereas the GasStop does indicate tank ‘pressure’ and useful in knowing when a tank is near empty. The GasStop also has a ‘purge’ feature to prime the system prior to use.

-

I too prefer grilling steaks, reverse sear to be exact. However, when traveling I can cook a greater variety of foods, many simultaneously, on the BS; again personal preference. Enjoying this ribeye cooked to perfection at our Oliver dinette, along with sautéed mushrooms, roasted jalapeños and baked potatoes, all on the BS! With steaks in particular, a griddle can produce a better sear with regards to Maillard reaction, which further enhances flavor. I agree with your take on breakfast, most anything ‘breakfast’ can be made on a griddle, except for maybe waffles; we’d have to meet up with Patriot at Waffle House for that!

-

XANTREX FREEDOM XC PRO 3000 INVERTER/CHARGER

Ronbrink replied to HDRider's topic in Mechanical & Technical Tips

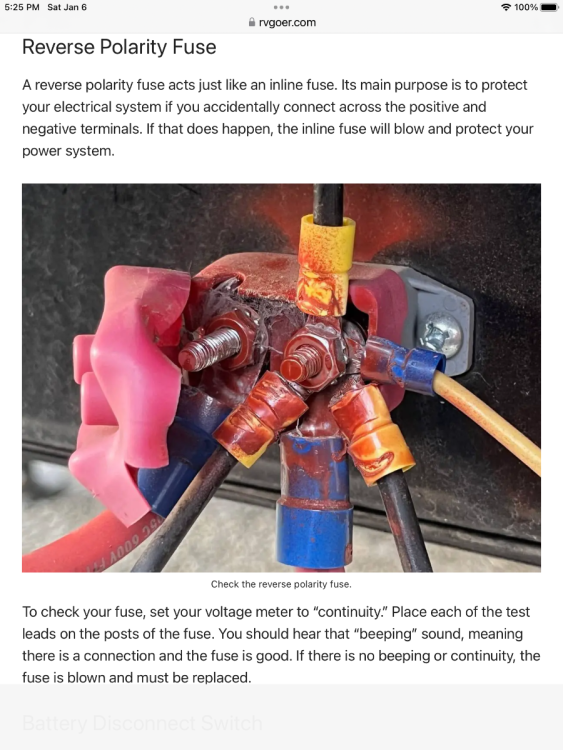

jd1923 cited some reading material in an earlier post: Should Inverter Be On When Plugged Into Shore Power? Ultimate Answer (rvgoer.com). In reading, I was directed to other articles by this author and came upon the following: -

XANTREX FREEDOM XC PRO 3000 INVERTER/CHARGER

Ronbrink replied to HDRider's topic in Mechanical & Technical Tips

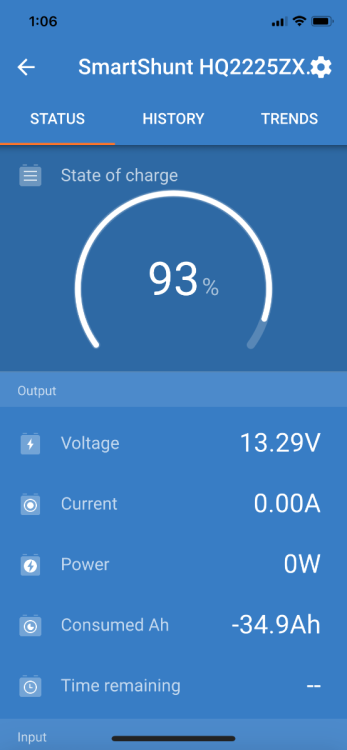

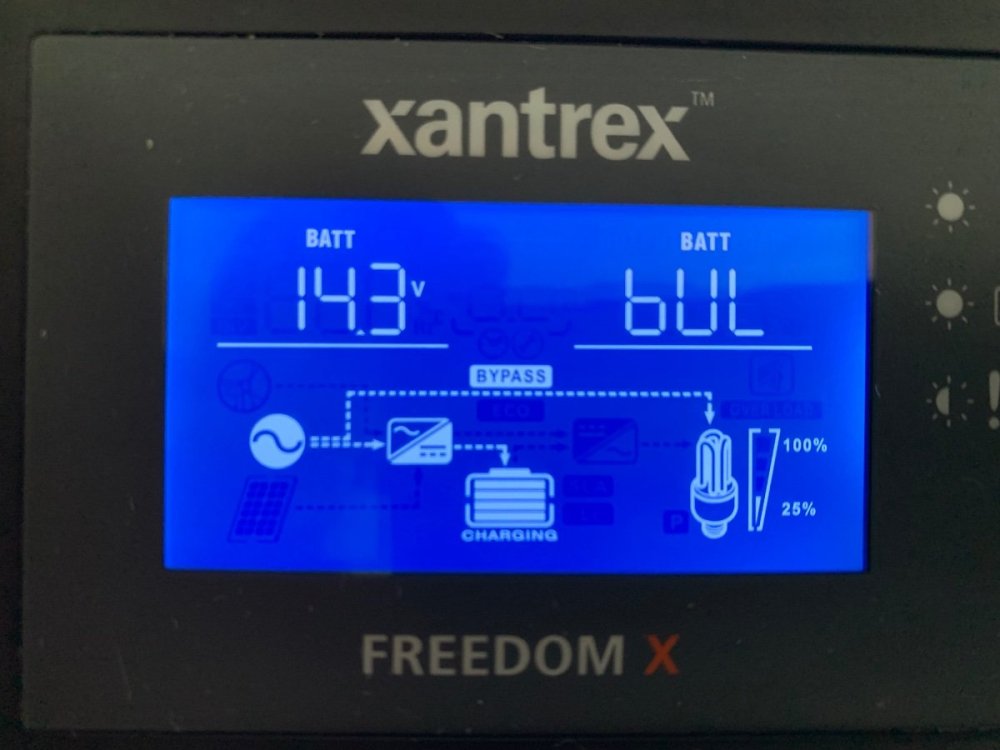

In theory, if you turn off the main manual reset breaker powering the inverter/charger and similar breaker powering the DC buss, you will be killing all battery power. Mystery solved! By manually tripping the 200A breaker shown in the upper right-hand corner and the 60A breaker in the lower left-hand corner of the below pic, the battery bank is totally isolated; thus no 12V power draw from the batteries by the Oliver, as evidenced by the above VictronConnect screenshot. -

XANTREX FREEDOM XC PRO 3000 INVERTER/CHARGER

Ronbrink replied to HDRider's topic in Mechanical & Technical Tips

I don’t know about that, but my Oliver has a ‘reverse polarity fuse’ under the street side bed next to the 60A breaker for the DC buss bar. I purposely have the breaker tripped in this pic, the red rubber boot next to the breaker is said fuse. -

That is an excellent price! I only had to carry a Weber Q a few trips to learn how hard they were to clean and stow. I have the 17” BS and it has served us well; the 22”, especially with the cover and carry bag, is also travel worthy, just a bit heavier and bulkier than mine. That said, I have a 36” commercial grade SOB for home use, and the 17” is just as capable in preparing a ‘table for two’ (or three) meal when traveling. I usually stow mine either flat or upright on the backseat within easy reach, thus allowing room in the truck bed for our folding ebikes. Mine did not come with a metal lid, rather a slip cover made with to same material as the travel case. Next is a bonus tip: the base can be used to stow most, if not all, of your cooking utensils, seasonings, oils, drip pan, paper towels, foil, etc., even the hose, regulator and 1lb propane tank, if wanted. A real space saver and convenience. Breakfast is my favorite meal to prepare, with smash burgers, steaks, fajitas a close second, followed by chili dogs and grilled sandwiches. I’ll admit, camp food is the best regardless of how it’s cooked!

-

XANTREX FREEDOM XC PRO 3000 INVERTER/CHARGER

Ronbrink replied to HDRider's topic in Mechanical & Technical Tips

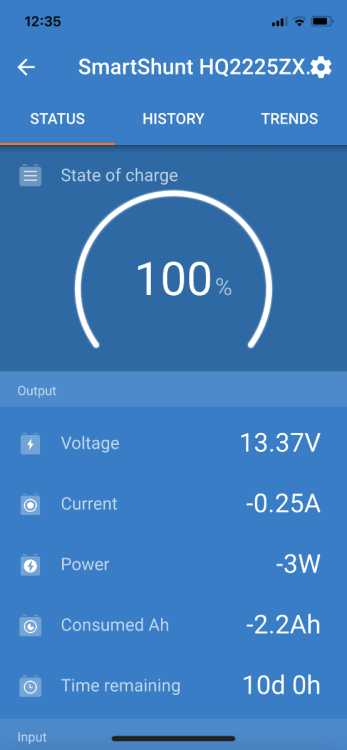

In response to HDRider’s offer to ask questions, I have a ‘mystery’ that may be somewhat tasking! It is my understanding that there are many components in a TT that only operate on DC, specifically 12V power from the house battery(ies). These components include, but not limited to, the water pump, exterior and interior lights, radio, vents and blade fuse panel, to mention a few. It is also my understanding that if the 12V power is disconnected by some means, then said components will no longer operate. Are my understandings correct? Yesterday, while plugged into shore power, I manually tripped the factory installed 200A blade circuit breaker on the positive cable leading from the battery bank, thus turning off power feed to the Xantrex/OTT. Here is a screenshot afterwards showing a -0.25A draw from the battery bank via the VictronConnect app; likely a minimal draw by the Victron SmartShunt, since it alone remains connected directly to that power source. I then made certain that the button on the Xantrex remote panel was in the Off position, as well as the button on the unit itself. Here is a pic of the Xantrex remote panel showing that unit in ‘BYPASS’ mode. I observed what sounded like the fan on the Xantrex, continually cycling on and off at varying intervals of a few seconds to minutes in duration. Also when tested, the lights, MaxxFan and radio were operable, and the blade fuse panel was powered. How can that be if the battery bank is presumed to be isolated? Furthermore, the VictronConnect app was showing the added draw by said components. What is wrong with this picture? My only assumption is that the Xantrex (even though totally off, bypassed and disconnected from battery) in someway is the 12V power source, OR the battery bank is not fully isolated by way of simply manually tripping said circuit breaker. Any thoughts (good, bad, comedic) are respectfully, appreciated. -

Likely not, unless it has been replaced and you have the optional BT remote panel. My 2020 OLEll is equipped with a Xantrex XC 2000, which is not BT.

-

Thanks, used a 10% off discount code, no tax, free shipping on my purchase of two E50s from the referenced website!

-

Truma Varioheat furnance not working with error code

Ronbrink replied to Mike and Jill's topic in General Discussion

These are great heaters, but come with many precautions; so anyone using them should be well versed. Proper ventilation is key, but even with that I experienced humidity issues when using; condensation on the interior windows would form and run down the wall onto the bedding. Breathing alone can create this condition, but the Mr. Heater seemed to worsen the problem and thus, no longer carry with. However, Mr. Heater is a great alternative to a gas fire pit! -

With my Oliver at the side drive, I can always get an app reading in the adjacent living room within a 15’ range (thru a single wall, expansive entertainment center cabinet, exterior brick veneer), and sometimes up to 25’, but not often. That said, I generally cannot sit behind the TV steering wheel and expect to monitor via the app, go figure! However, I can make use of the LevelMatePRO while driving in search of a level spot and backing onto the Anderson leveling ramps, no problem!

-

Replacing city water inlet valve

Ronbrink replied to The Loonies's topic in Mechanical & Technical Tips

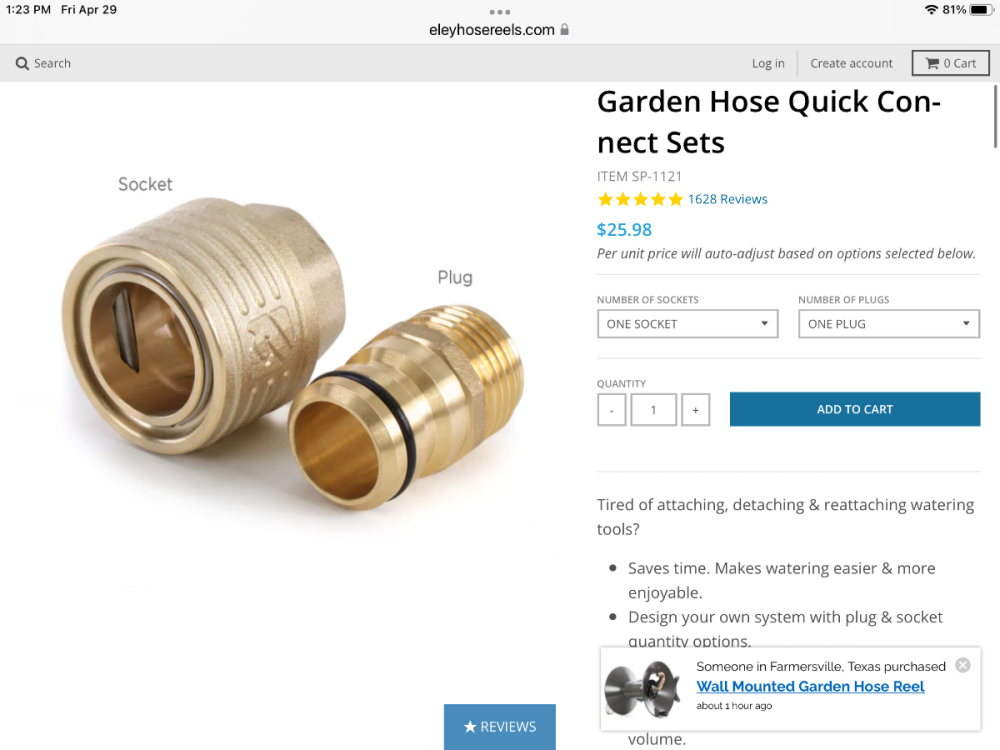

No doubt, as well as Amazon. However these Eley connectors are commercial grade, made with quality materials to ensure longevity and safe drinking water, of bigger overall size for a full 3/4” unobstructed flow, have serviceable o-rings and a 10-year warranty! You definitely get what you pay for IMO. That said, I also have been very pleased with several of the Gorilla Easy Connect hose terminal ball valves/couplers/nozzles, which I will share with if anyone is interested. -

Replacing city water inlet valve

Ronbrink replied to The Loonies's topic in Mechanical & Technical Tips

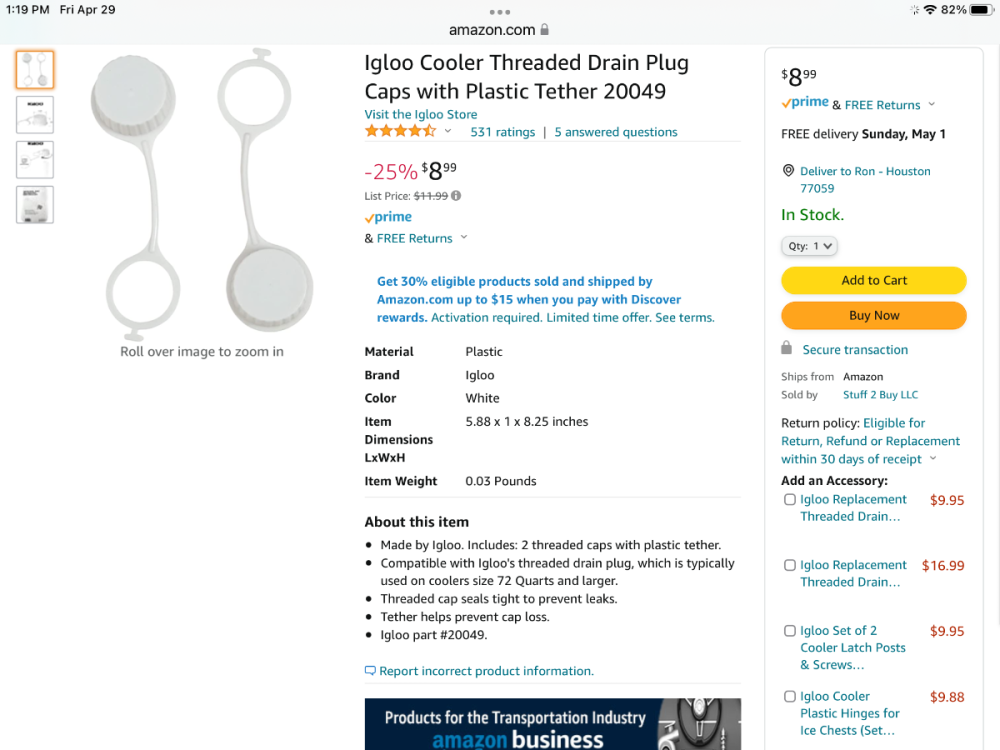

I bought this Eley Quick Connect System product for all hose connections in my setups. Think one-handed operation! The components. Water pressure regulator and filter configuration. Eley installed at Oliver water inlets. Protective caps in place, utilized chain hardware from original stock caps Caps purchased. -

I added an ‘Edit’ to my last, which may be of interest!

-

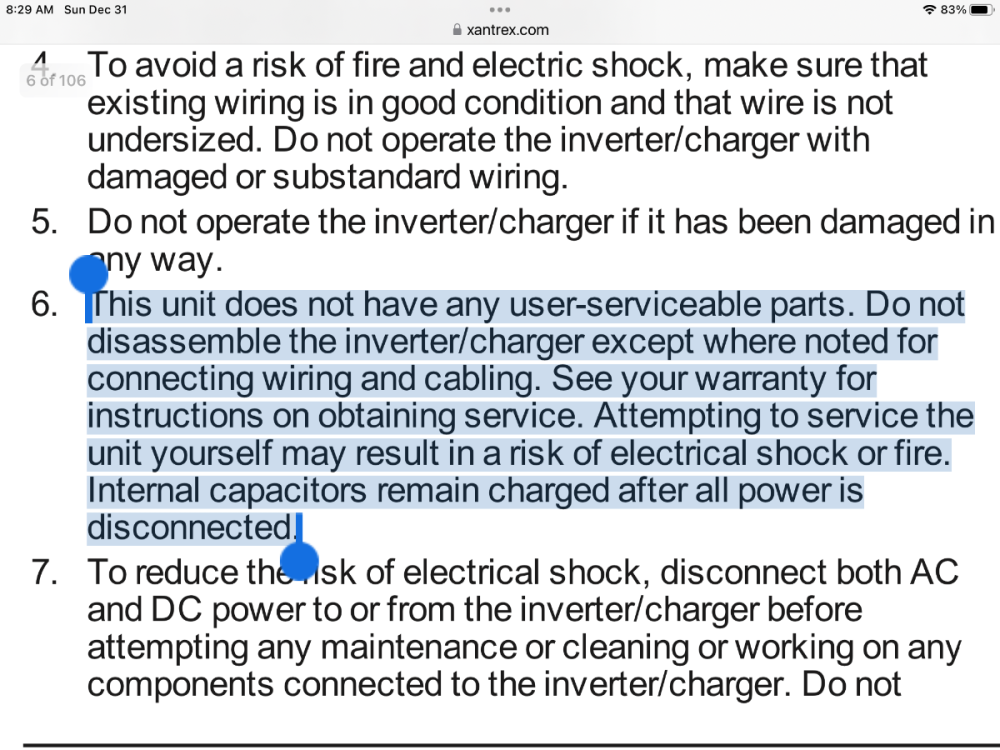

Thank you for your continued attention to this matter, much appreciated! In response to your questions: 1. Was the house battery negative disconnected or just the positive? You didn’t mention the B- cable. - - The negative cable was not disconnected, only the positive at the battery terminal. 2. I hate to do this, but I assume the tow vehicle was not connected, correct? - - That is correct, the Oliver was stowed at the storage facility and not connected to the TV. 3. Your forum signature states that you have a Renogy DC-DC installed, which I have no working knowledge of. Is it installed in the Oliver? Does it only work with the ignition on? Does it have the ability to store energy, maybe an internal capacitor? - - The DC-DC is installed within the rear dinette seat hatch. - - When the unit is plugged into the TV via a dedicated cable, it only receives power when the engine is running/alternator turning. - - Regarding an internal capacitor, a brief search indicates there is a very small electronic capacitor on the motherboard, this based on a teardown wherein a “JP” capacitor, 105C was referenced. The following statement by Renogy may or may not be useful information: The DC-DC battery charger isolates the input and output to prevent voltage transmission errors and interfere with house battery charging. 4. You might try turning off all 12v breakers and removing fuses. Verify the power is off with the Victron Smart Shunt app or a DC clamp on Amp meter. Then remove the main battery fuse as a different method of disconnecting the 12v supply from the battery. At least you would be inside if the fireworks started again. - - Good suggestions, my retired Navy-trained electronic specialist Son will be visiting New Year’s Day; I will certainly commandeer him to help troubleshoot! I will say that he has either assisted and/or advised me on all of my electrical upgrades to the Oliver, so I have a high level of confidence my current inherent issue(s) to be minor and easily remedied. Another bit of info; although the lead positive cable was disconnected to isolate the battery bank, a small positive jumper wire feeding the SmartShunt remained connected. However, my Son assured me that was not a potential power source contributing to the anomalies observed. Edit: Following the event, I gave thought that perhaps a capacitor in the Xantrex XC2000 inverter/charger could be the culprit, but holiday celebrations put the thought on hold until you jarred my memory. A quick search in the Xantrex Owner’s Guide and voila; under Product Safety Information, line 6: What think you?

-

In watching a video wherein two CIGS panels (each 14”x85”x100W) were applied to a sailboat deck, care was taken to avoid adherence of these panels directly in contact with the fiberglas gelcoat; reason being difficulty of removal and potential damage to the gelcoat in doing so. Rather, the panels were positioned in select areas where a non-skid surface treatment was already applied, the thought being that removal of that surface treatment along with the affixed panels would be easier and lessen any chance of gelcoat damage. That said, a similar practice may be of benefit with an Oliver rooftop install. I too like the advantage of said panels, as they can be laid to conform with design curvatures while maintaining a low profile appearance, aerodynamics and “architectural beauty”!

-

That was my first thought, but on the second trial there was no 120v input and the result was the same. I am still hopeful for a switch install, but need to first understand a ‘fix’ or ‘workaround’ for the anomalies experienced. I see where others have installed such switches, even directly atop the batteries, but do not recall any talk of resulting adverse conditions. Thanks for your valued input.

-

GJ, I will premise the following based on the many discussions in this forum regarding the use and/or installation of a master battery cutoff switch, specific to OTTs. I was surprised to learn that my Oliver wasn’t equipped with said switch, perhaps because I didn’t opt for solar? I have one of the Blue Seas switches, but when trying to figure out where and how to install I first disconnected the positive battery cable to supposedly isolate the battery bank, as would such switch. The trailer was hooked up to shore power at the time, so after the makeshift battery disconnect I ventured inside to see the effect on the inner workings. In short, it was not a happy place! There were several anomalies observed: a few of the under-cabinet lights were fading on and off, the Furion radio was making strange noises and panel flickering, popping and crackling noises were heard coming from the under belly, the GFCI on the Xantrex tripped; I swear, I thought the trailer was ‘possessed’! In fear (not from the devil on my heels) of causing irreparable damage, I rushed back out to reconnect the battery cable. Thankfully all was found back to norm, thus deeming the ‘exorcism’ a success. But wait, there’s more! My inquisitive mind wanted to know if having the shore power connected in correlation to the battery disconnect had anything to do with the observed anomalies. So upon removing from shore power, the battery disconnect process was repeated; as was the ‘possession’, yikes! Given the scenario, if anyone has any insight as to what could possibly be happening, your thoughts and/or advice would be greatly appreciated. GJ, does this qualify as a bonafide thread hijack?

-

Pics 4 and 5 were taken at my storage facility and prior to bringing the Oliver to the house to complete the install. When checking for leaks, I put the soapy water to good use! I looked at these, but really didn’t like the way the hoses came straight out of the regulator and bent abruptly, so changing the hose angle at that point made more sense in my installation.

-

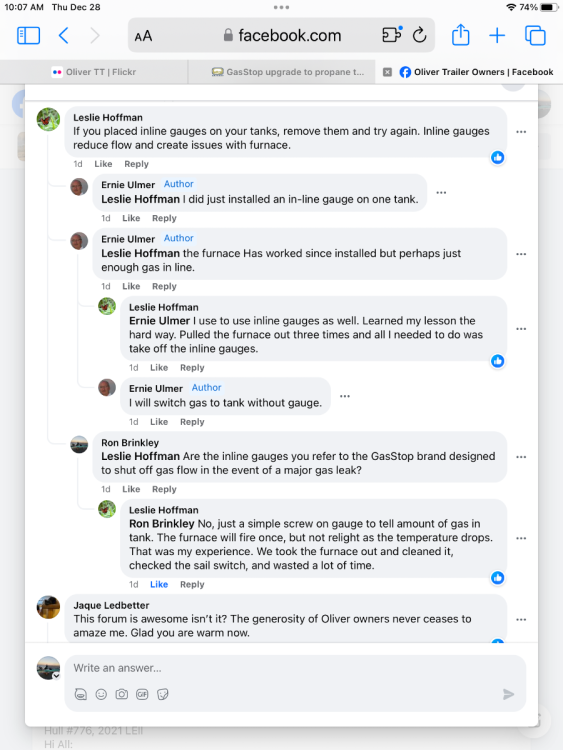

The issue was recently addressed on the Oliver FB as follow: Based on this discussion, I do not anticipate any such issue with use of the GasStop. I do have Truma AquaGo, but a Dometic furnance; test pending!

-

Yesterday I installed GasStop emergency shutoff devices to the Oliver’s onboard propane tanks. The process was very straightforward and relatively easy. However, did require a couple of longer pigtail propane tank connectors and additional fittings; the stock 12” pigtails were too short, given the added length to the tank valve assembly, and the ‘elbow’ fittings to lessen hose bend for improved fitment. Yellow thread sealing PTFE tape (gas-rated Teflon tape) was used, as necessary, in the installation; however, the pigtail connection is beveled and self-sealing, thus no tape necessary. The device: The pigtail: The fitting: Fittings to regulator: GasStop devices mounted: Pigtails mounted (Note the angle of the ‘elbow’ fittings were adjusted downward for best fitment): Gas level indicator/system prime: Another view (Note the cable and lock for theft deterrence): Once the installation was completed, a soapy water test was performed to check for minor leaks. With this device, the gauge also serves as a ‘primer’ by pumping it several times, as well as occasional pressure checks for leak detection. The system prime feature should benefit times when a tank is isolated for use with a generator, fire pit or grill/griddle to purge supply lines of air prior to initial use. Nuff said!

-

My 579 came equipped with a Xantrex Freedom XC 2000; I recently added a transfer switch to operate the Dometic Penguin 11,000 BTU A/C with Micro-Air EasyStart via the house batteries. Of course, be mindful there are limitations on run time and load restrictions in doing so. I use the A/C in this manner primarily during rest stops and lunch breaks when traveling, and the DC-DC serves its’ purpose when back underway.