Leaderboard

Popular Content

Showing content with the highest reputation on 09/12/2025 in all areas

-

I use this and it works flawlessly. Super simple set up and dials XPLOR in dead level. Strong reviews and the price is reasonable. I would buy again without hesitation. I mounted it on the inside of the closet wall out of sight. Tested, Manufactured and made in the USA! 🇺🇸 https://www.amazon.com/gp/aw/d/B0C28VJLG5/?_encoding=UTF8&pd_rd_plhdr=t&aaxitk=d3c72cff5eef1b3a98013caddad9f9dc&hsa_cr_id=0&qid=1757682231&sr=1-12 points

-

Make a checklist, like a pilot, and stick to it. Failure to follow my own list has led to a could of expensive mistakes over the years.2 points

-

@Pat Radack We all started somewhere with regard to learning and towing our Ollies around the country. You can ask away and we will glad help you out. Not sure if you use social media such as F/B? Oliver has a great Oliver Owners FB page as which also a wealth of information. We still use our checklist when we set up and break camp and my bride and copilot truly is my second set of eyes!👀 Pro tip - Never be in a hurry when settling up or breaking camp and packing up. Take your time and it will become second nature. We are on the road right now headed to the Great North Woods! Enjoy that Oliver and go camping! 🍁 Patriot🇺🇸2 points

-

We moved back to our AZ home seven years ago after living for 12 years back and forth between two homes, where my tools were spread between the two and my truck. On Craig's I found large stand-up Snap-on toolbox and was lucky to find a huge, well made workbench setup that Adam and I disassembled to move and rebuilt it to fit a custom L-shaped layout around 2 stalls of our 3-car garage, the center stall being my workspace. I also found a used Tuff Shed for storage, so my garage would be solely an auto workshop, not junked up with storage items. I installed other standing toolboxes and cabinets, enough room for a major 45-year collection of hand tools and spare parts. Then I emptied every hand-carry toolbox into the larger stationery toolboxes. During a winter cold-spell I spent days sorting our every box and package I hade with nuts & bolts, auto parts, electrical and plumbing parts. , etc. I bought a case of blue plastic single-gang electrical boxes (cheap effective storage bins) to hold all the small screws, nuts & bolts, nails, crimp parts..., drawers full of them in mounted file cabinets. For years now to the present, I know where every tool and most spare parts are located. I return all tools to where they belong daily, unless I'm in the middle of a job I will continue the very next day. Spending considerable time in organizing your tools is well worth it. I get repairs done now in half the time, not having to hunt for parts and tools! In getting ready to work, climbing under truck or trailer, I think a hard 5-10 minutes and collect part & tools needed in flat plastic trays that I lay on the ground where I'm working. The other thing I bring, since I/we will always forget something is my phone. With Chris' office just inside our home from the garage entrance, she's nearby and often happy to help. 😂 She'll come out to hand me a tool or two, knowing its easier for her to do so vs. what it takes me to get off a hard garage floor, and then climb down again. I do mean the word 'climb' as the downs and ups are not as easy as they used to be! 🤣 We all prefer to work preventive maintenance at home vs. getting stuck on the road. I have enough extras that I've assembled a small dedicated toolbox and a plastic parts box for the Oliver. They sit in the bottom of my large truck toolbox along with a 3/4" breaker bar, cheater bar and other long items. Proud to be keeping our truck and trailer in good maintenance so that these tools just sit ready, and have not been yet needed, 124 overnights in two years with our Oliver! Hope to never need them, but I have what we need to change tires, bearings, leaf springs or do a truck repair, like replacing an alternator or water pump on the road. Now that we've upgraded to Alcan Leaf Springs, I just removed the spare set of 1750 LB springs from the TV. The Alcans are not going to fail in my lifetime, though I do have tools with to replace wet bolts/bushings or most anything else!1 point

-

For what it's worth, we "bit" last year on an "upgrade" offer from a Levelmate Pro to a Levelmate Max, because of battery issues with the Levelmate Pro. But the Levelmate Max has unreliable connectivity and the software is "buggy". It became so frustrating we reverted to 2-person campsite setup, with a torpedo level. Having now used both the Levelmate Pro and the Levelmate Max, we wish we had instead purchased the Beech Lane (as suggested by Patriot, above).1 point

-

Agree. Levelmate works well and another benefit over using bubble levels is that you can monitor the trailer degree of level while moving into the campsite. I camp in boondocks sites where the gravel/dirt is uneven and I can monitor from the drivers seat while moving back or forward to find best level spot.1 point

-

The Collar, ABUS lock with 2” de-shanked hitch ball locked in the jaw. If leaving for extended period, will remove safety chains. If they want it, they will find a way to take it, merely deterring honest and lazy thieves is the goal. Buddy had SOB trailer stolen from his drive by thief merely wrapping safety chains around hitch and dragging it off, sparks flying down the road.1 point

-

Many use the LevelMate products for front/back and side/side adjustments with use of a phone app. Leveling blocks/ramps can also be used to lift one side and rear stabilizer jacks then to fine tune. Front jack used for front/back leveling often with a block to reduce jack extension. Perfect leveling made simple!1 point

-

1 point

-

No easy path! 🤣 The outer and interior shells of the Oliver are tight and in-between, lot'sa luck in doing so. Many have asked, but nobody on this forum has demonstrated a viable build. Perhaps it's an idea that does not have a feasible solution. IMO, drop the idea. In the same vain, I wonder why some want an inferior 12V television, when with LiFePO4 batteries an inverter can simply run an 120VAC TV. 12V TVs have limited selection and truly lame resolution. Instead I prefer to run a 4K high-def Samsung monitor, 3/4" thin white and beautiful on 120VAC. IMHO...1 point

-

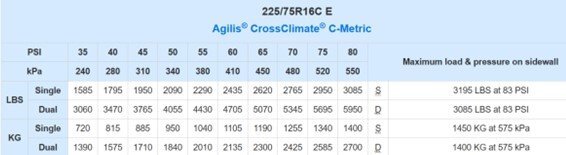

I run 45 PSI highway and when boondocking on local washboard roads I reduce to 38 PSI. I was just testing our new suspension over speed bumps at 45 PSI and I could see the tires nicely compress while taking in the speed bump. 40 PSI is enough however since we are certainly running less than 7K LBS GTW. Some have written they will lower the tire PSI because of the stiffer springs. PSI should be determined on trailer weight. This upgrade has likely added about 150 LBS in heavier parts. Running D52 axles and Alcan springs going a little over the 7K GTWR should not be a big deal. With axles, springs, wheels and tires that can handle over 10K LBS, only the Oliver frame is the limiting factor. We know a member with multiple upgrades, upgraded suspension with disc brakes, my guess is he is well over 8K LBS actual GTW. 45 PSI is a good MAX number for most. I do not believe in adding PSI as a buffer allowing notification time using a TPMS. The PSI should be adjusted for actual GTW only. On the Michelin Agilis 40 PSI gives you 7,180 LBS and 45 allows up to 7,800. 50 PSI allows for 8,360 LBS GTW. Do you need more pressure?1 point

-

No recent mention of the many tracking devices used and recommended by Oliver owners in this forum. Not to highlight the referenced tracker in the above 2016 post, but rather bring attention to the fact that GPS trackers are readily available and a useful tool in the event of theft.1 point

-

1 point

-

1 point

-

Not the Euro-style I was expecting. We had these on a previous trailer. Not much airflow. I wouldn't replace all my windows with these but might do just the one over the dinette for airflow on rainy days. Are they double pane?1 point

-

max of 3 inches? Ouch, that does not seem like a lot of airflow.1 point

-

I serviced the front jack after we purchased our Oliver near 2 years ago. It sounded dry and the front lift jack is certainly used at least 2x more often than the rears. The rears are also protected from the elements. To date the motor/gear sounds on the rear jacks where good. I've been replacing the Dexter axles and leaf springs on our Oliver and using the rear jacks for the heavy lift, getting the wheels off the ground, a few times in the last couple weeks. Yesterday the curbside sounded like the motor was drawing too much current (slowing down) and then started clicking not lifting. The clicking sound was like the sound you get when releasing the jack, lifting the shaft too high hitting the stop, but it made this sound while pushing down to lift the trailer, only halfway up, nowhere near the 18" lift-height of the VIP3000. From rebuilding the front jack, I noted wear on the worm-drive gear that's attached to the motor (see picture of motor gear from my front jack service). If the rears show the same upon disassembly, I will need to replace the motor(s). I found this part with a quick search. I can buy 3 of these for the cost of one complete VIP3000 and we know the rear jacks have a custom weld that must be reused or replaced. https://highskyrvparts.com/barker-mfg-trailer-landing-gear-motor-16263 Have any of you have to service your rear jacks, including replacing any worn parts? I understand how to remove them and service them. I guess I'll only know after I remove the jack that is presently not functioning. See page 2 of this link to see the service I worked on the front jack. I will keep y'all posted on the repair... https://olivertraveltrailers.com/forums/topic/4094-how-to-vip-3000-electric-stabilizer-jack-service/page/2/#comment-943390 points

-

Recent Achievements