Leaderboard

Popular Content

Showing content with the highest reputation since 02/20/2026 in all areas

-

Barb and I have had our LE I for about 18 months now. We fancy ourselves minimalists, but truth be told, we viewed the LE I as a bit of an experiment knowing that it would be a challenge getting all of our gear in the trailer and the Pathfinder. What helps is that we are both perpetual organizers and efficiency nuts so we welcomed the challenge. The game changer for us has been connecting with the folks at Sea Biscuit. Knowing we needed a little more storage one of the first accessories we added was the rear basket from Sea Biscuit. We weren't quite sure what types of containers we could put in the basket, but we knew it gave us lots of options for adding storage. After looking at the myriad options of storage containers, boxes, etc. that could go in that rear basket, we settled on the rear storage box from Sea Biscuit. The locking rear box is home for our hookups, a large tool bag, our outdoor carpet for under the awning, and several other items that immediately come out when we land at a destination. Our sewer hose for draining the gray tank (we have a composting toilet, so no black tank hose) is still in the bumper and it is surprisingly easy to store and deploy when needed even with the box over top. The expanded storage we gained from the rear basket and box combo was our first game changing moment. It allowed us to move several items out of the Pathfinder permanently. Shortly thereafter we noticed the front box that many of the LE II owners had added. To our disappointment, the box was not compatible with the LE I, but we started a conversation with Dave and Kristine at Sea Biscuit about our options. Fast forward several more months and we are one of the first to acquire a front box unit designed specifically for the LE I. The front box is deeper than the rear box and fits neatly between the front jack post and the bull dog coupler. It sits on a steel platform making it super stable, and when opened leaves plenty of clearance for the jack post. The front box now holds our DC to DC charging cables, wheel chocks, and several other necessities that also formerly rode in the back of the Pathfinder. This was game changing moment number 2. One of the final accessories we added to compliment our storage accessories from Sea Biscuit was the rooftop basket from Rhino Rack. The rack holds our chairs and camp table that were also - yes, you guessed it - in the back of the Pathfinder. (Low and behold, I can now see out of the back window.) Barb and I are huge fans of the little Ollie having put over 15,000 miles on it, visiting 21 states in 2025. Our travel style is such that we rarely spend more than a couple of days in one spot so the flexibility of the smaller LE I, and smaller tow vehicle (17 mpg with the Pathfinder) is the perfect combination for us. For anyone who is considering an LE I, or who has an LE I and is looking for quality accessories to expand your storage, we cannot recommend the folks at Sea Biscuit highly enough. The products are top notch and the Hess's are awesome folks. See you on the road!9 points

-

After I had heard about the issues that Battle Born was having, I initially tested my three batteries. I installed my batteries about six years ago and at least initially didn’t have any issues with them. We were in the midst of a two month trip so my testing was very rudimentary. I just ran a 1500 watt electric heater on my inverter for about a half hour. That loaded the batteries to 122 amps which only put about 41 amps on each battery. With this test I was only checking for hot positive terminals. No issues there. After we got back home I decided to replace all of the Battle Born batteries with two Epoch 300 ah batteries at the wise counsel of another Oliver owner. Anyway, I decided to perform a more detailed test on the three old batteries. I had an old 400 watt inverter that I connected with a 100 watt incandescent light bulb (remember those) and connected the input to each battery one at a time. This would put approximately 8 amps load on the battery. I first charged each battery to make sure they were fully charged. I finished my initial battery test today. First and third batteries lasted about 12 hours each. The inverter will turn itself off at 10 volts which is the voltage that a lithium battery is considered dead. The 12 hour time frame seems about right, 100 amp/hr (battery) divided by 8 amps (load) is about 12.5 hours so I think my actual test is fairly accurate. The second battery only lasted a few hours and died to the point that the charger would not recognize any voltage so wouldn’t start charging. I had to jumper a good battery in parallel with the dead one so that the charger would start then after just a couple of minutes I removed the good battery and charging continued. Anyway, I’m going to re test the bad one tomorrow. My original 300 ah had turned into 200 ah! Over the past couple of years I had noticed that the battery pack seemed to draw down quicker than before and that I had to recharge them more frequently. We do all sorts of camping typically, a mixture of boondocking and various stages of campgrounds. We typically camp not just a few days boondocking which is easy for any trailer but we’ll boondock for maybe two weeks at a time. This past year we were in our camper for a total of six months. Four months in the west and two months in the south east. During that time we spent a week here and there boondocking and sometimes in campgrounds with no hook ups. Anyway, it had become more difficult to boondock in the last couple of years. We have a compressor fridge that of course runs 24/7 and then other typical loads. I didn’t know it but we had one third of our battery capacity gone! I’m glad I changed these out for the Epoch batteries! My takeaway and suggestion for others (not just Battle Born owners) is to periodically fully test your lithium batteries. There are load testers sold on Amazon specifically designed to test them and they are a little more elegant than the inverter/light bulb arrangement that I used. The Epoch Essentials 300ah batteries have Bluetooth and can be electronically controlled. The output or charge input can be turned off and on through the app so in a multi battery setup each battery can be isolated. I have not experimented with this feature yet but could potentially make it easier to test one battery at a time in place without having to remove them. Anyway, fellow Battle Born owners test your batteries!8 points

-

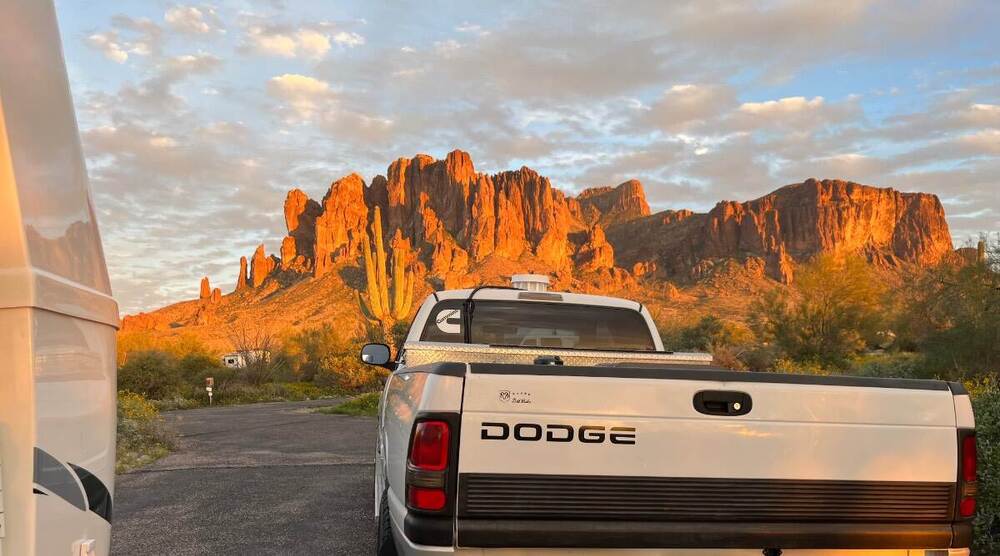

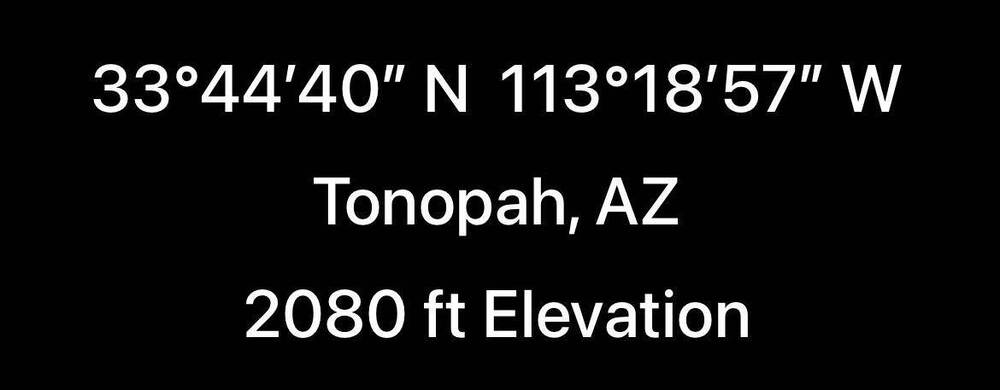

We'll have 4 peaceful overnights in this beautiful and mostly quiet BLM lands. Quiet except for occasional UTVs passing by to run the shelf road to the top of Harquahala Mountain! (3 groups so far on this Sunday.) We got 100 yards off the main road and all I hear are the insects of the Sonoran Desert (perhaps too dry here for many birds). Not one sound overnight! Up close and personal with the Cholla and Saguaro cactus! 75F this afternoon and should reach 85 in a couple days! Drinking coffee this morning, in shorts, shirt off, basking in the Arizona sun. From I-10, halfway between Phoenix and Quartzsite, take Salome Rd to Eagle Eye Rd north. Or take Eagle Eye Rd south off US Hwy 60 at Aguila AZ. The roads are all paved until you get to the staging area and the road to the top is of course dirt, where decades ago there was a Smithsonian observatory. Our tow vehicle is only 2WD and I'm not much for hairy shelf roads anyway! I'd like to drive up close enough to hike the rest of the climb. We'll check it out soon! We each have a good book to read and getting some sun and warmth (got cold and snowing in Prescott) and much needed rest, is all we need to finish up this trip! 😎8 points

-

7 points

-

7 points

-

4th visit to Lost Dutchman. I’ll make it up Flat Iron one day (got halfway up last time as it was getting dark)! Came this weekend since the PPA Pickleball pro tournament is in Mesa this week, only a half hour away! What a view! Hangar steaks, baked and sweet potato with asparagus, cooked over the fire ring! 😎7 points

-

If anyone needs new chocks for the upcoming season, Harbor Freight has them on sale with the coupon below: Bill6 points

-

6 points

-

Hi. Go to Google and search for "Oliver trailers lithium upgrade." Several relevant threads pop up, including this one: Lead Acid to Lithium - Ollie Modifications - Oliver Owner Forums https://share.google/oayGb76nRTfLxwQnx Lots of good information in those threads that can help you.6 points

-

If for any reason you are not satisfied with the color match, I'd guess that you could lightly sand out some of the Marine-Tek and coat over it with the appropriate color gelcoat. Note - Oliver can tell you what type and color gelcoat is on your Ollie.6 points

-

@HDRider Jeff: I do not think the bumper needs to be removed. On my OTT, Elite II, the trailer hitch receiver needs to be removed.5 points

-

Well we had a “warm” day today so I decided to do one final upgrade that several others have previously done to their propane systems. I got the right angle fittings for the regulator connections a few weeks ago and finally decided to install them. It only takes a few minutes to do in place. The adapter fittings that come on the regulator have check valves built in, so I purchased standard 1/4” street elbows and reused the original adapters to make the connection. One little trick to make the installation easier, with the cold temps, the hose is stiff and feels like it will split if you try to reshape it into the new configuration. If you take the hoses into the kitchen and immerse the rubber part in a pan of boiling water for a minute, the hose will naturally straighten out, and while warm can easily be installed on the tanks and regulators with little tension in the process. There’s a much gentler bend in the hose when completed that should make the hoses last much longer. Before: After: Thanks to everyone who previously made this upgrade and for sharing on the forum.5 points

-

“Curiosity” is currently parked next to “Dickens” at CGI Detailing’s shop in Murfreesboro, Tennessee. Getting the shine even shinier!5 points

-

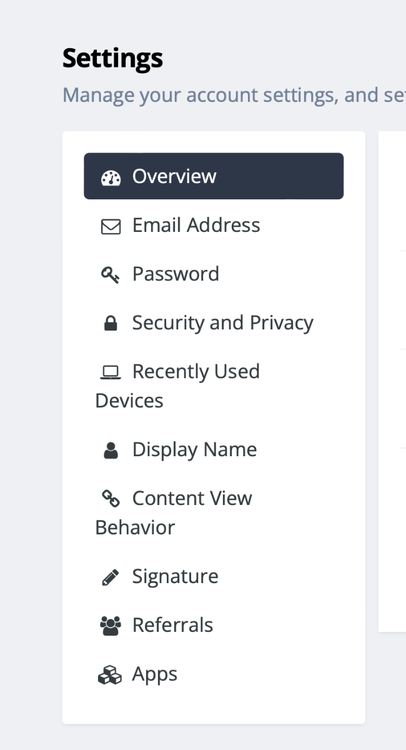

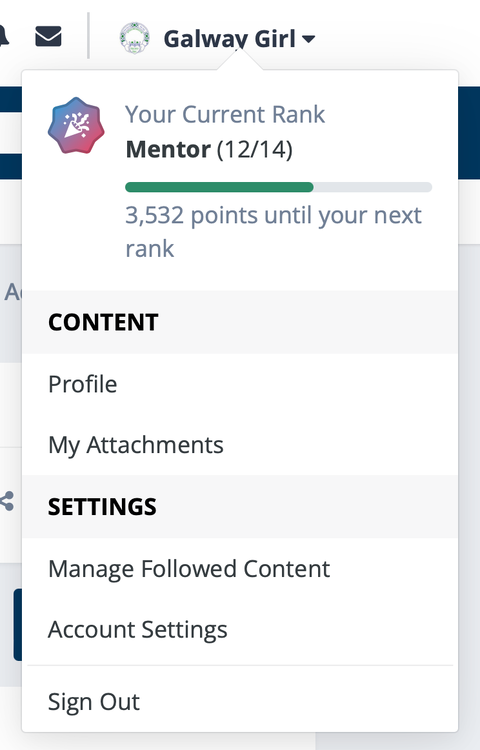

To make changes in your signature: Click on your name in the upper right corner of the page. It will pop open this window: Look under SETTINGS and click on account settings. In the settings tab that opens up...near bottom you'll see signature with the pencil icon. Click on that signature line and it will pop open...you can add what you want including maps of your travels, hull # etc. Craig That brass port is the anti-siphon air gap from your black tank flush. The inlet to your external black flush hose bib on the side of the trailer (down low just below the dinette window) runs up to that antiphon then back down to the side of your black tank which is where it connects to the wash head. Once done flushing, that air breaker enables water to drain back out of the inlet port line out the street connection to your flush port. The air gap is an anti suction device that keeps black tank water from coming back out the exterior flush lines. It also makes that line self draining to prevent freeze ups in the flush line. (After you take your hose off after flushing...you'll see about a quart of water drain back out the connection.) Hope that helps.5 points

-

My post was not meant in any way to be a complaint about my Oliver or the company. I believe Olivers are the best built trailer in the market. We have had nothing but wonderful interactions with the employees also. They have always treated us just like family. The quality shows after about 110 days camping in it in 2025 (90% boondocking). The post was only to help others with the issue if they experience it. Other owners post have helped me so much in the past. I will fill out a service ticket on Monday so Oliver can be aware of this. We LOVE our Oliver Elite ll.5 points

-

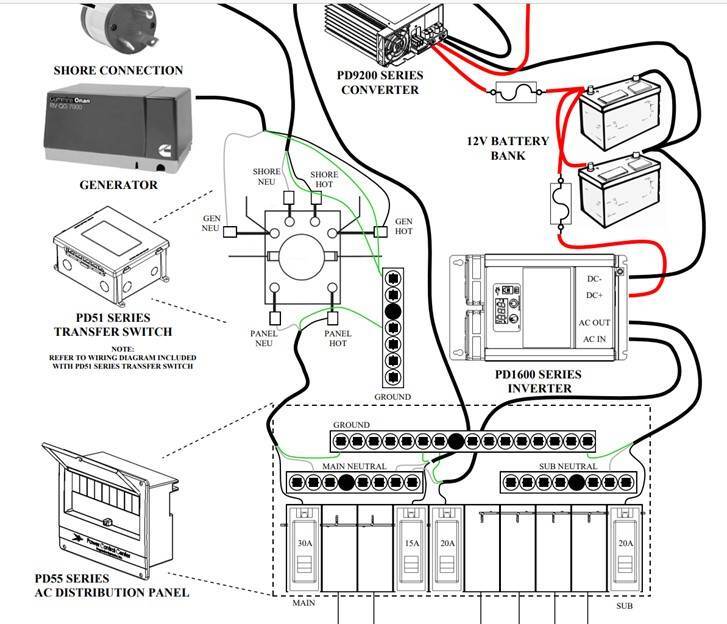

These are very good reasons. We're all different and we all have choices. I am the DIY guy in anything automotive, electrical and mechanical systems. For example, I only pay for an alignment after I've replaced every suspension part myself. I learned solar/inverter system installations on a Bigfoot Class that had none to start. Installed rooftop panels using only VHB tape, drilling only two 1/4" holes for the wires, a dab of Dicor on each. Installed a PD 1800 KW inverter/charger and customized the AC power panel to be a split bus panel (sawed the bus in two, one for A/C and one for inverted circuits)! The graphic below from PD gave me the insight I needed to do so. "Should we ever sell? No way, never! 🤣 I still have my 1984 Goldwing Standard restored to factory condition. Two Lexus, a 1992 SC400 and '08 GX470 both restored. Call our son Adam lucky, as none of these, especially our Oliver, will ever be sold. They will one day be his, always kept in the family. When you put 100s or in this case 1000s of hours in our now amazing hull #113, she's here to stay, and should in its present condition outlive me! That hull named XPLOR has had only the best of love and care! Likely the best looking, best outfitted hull out there! My bet is... David will never sell! 😎5 points

-

Ron, From what you describe, this is a power issue, not an audio source issue. So you can rule out the HDMI ARC feature of many modern components that sends a signal to automatically switch the stereo to the active sound source. However, there is another HDMI feature on some higher end TV/Stereos that allows the TV to also turn on another component such as a stereo. If this is the case with your TV, then you might have a HDMI cable issue causing spurious signals. Try unplugging the HDMI cable to see if that resolves the problem. If it does, then try a new high quality HDMI cable with a Ferrite choke (little barrel looking thing that goes over the cable). This is a quick and easy check to eliminate one potential cause. If that doesn't work, then it could be something to do with the yellow Accessory trigger wire common on 12 volt stereos. I'd have to think on that one a bit more, so let us know what you find. Cheers, Geoff5 points

-

4 points

-

Over the years I have found that more amp/hrs would be of benefit. I initially felt that the 300 amp/hrs of the BB batteries were enough but with the compressor fridge on 24/7 during winter traveling and a few cloudy days here and there, my batteries would draw down to less than I am comfortable with. Anyway, two of the 300 amp/hr batteries seem to be the wave of the future. Having two still gives me the redundancy that I like. As built, Oliver used 4/0 welding cable for the main battery connections to the inverter. These are large enough for the 2,000 watt inverter and are protected by a 250 amp fuse. The wire used for all other dc circuits is #6 welding cable and is adequate for the existing dc circuits in the trailer. I did not install a larger Progressive Dynamics charger or a larger inverter so I didn’t feel it necessary to upsize any wiring. I do have the air conditioner wired so that I can run it through the inverter but it only draws about 90 dc amps. The microwave by comparison draws about 120-130 dc amps. Really the only thing I did when I initially installed the lithium batteries six years ago was to clean up some of the wiring by moving all of the #6 wiring out of the battery box and I added a circuit breaker. Not too involved.4 points

-

Yes, I saw all of the glowing reviews six years ago when I did my upgrade to lithium batteries. Back then Oliver had just introduced their lithium trailer and there weren’t many choices for lithium batteries. Battle Born was the gold standard then. This goes to show that lab testing has little resemblance to real world life testing day in and day out over the years. Even now and with most things we buy, we do our homework and research the best we can and select the best option. I’m not too upset with the way this has turned out. These batteries have traveled many miles in six years and have been well used all without any maintenance. We on average spend four months out of the year in our trailer every year, in 2025 it was six months. We are ready for the next chapter!4 points

-

I had 3 BB 100’s in use for 5 years, worked great, no problems. I was getting increasingly paranoid about my family safety, so I sold them on Facebook Marketplace for $150 each. I tested each one and made sure the buyer was fully informed of the issues. He was aware, but was looking for a bargain and willing to take his chances. I could perhaps have gotten a higher price, but my conscience kept me from being greedy. The way I figure it, I had $2450 total invested, so the cost of 300AH of trouble-free use cost me $400/year. I saved way more than that by boondocking. There are several dozens of them for sale on FB Marketplace in my local rural area, so my guess is many others feel the same way. It might interest some that @Overland had 2 out of 4 go bad in 2021. This was before the present design problems were known, apparently BB told him the BMS went bad. I recall he did a lot of off-road, so maybe his terminals shook loose internally and got hot. @Overland was able to get BB to pay for shipping and replace. https://olivertraveltrailers.com/forums/topic/4956-lithium-battery-upgrade/page/2/ Those were the days when BB was widely regarded as the #1 brand, and there were no reliable Chinese competitors. See Will Prowse glowing endorsement on YouTube from 2020 if interested. Yep, same guy that blew this up on the web, may have been indirectly responsible for becoming one of BB best salespersons.4 points

-

Here's a couple more of the campsite and I have supplied GPS coordinates. We are a couple miles past the staging area. There are campsites at the staging area, one large flat one with picnic table and fire ring. Many RVs were also camping south of the entrance down Eagle Eye Rd. To get here, you'd have to tow down and up 4 narrow washes. Some may not want to pull their Olivers through these washes! I descend slowly, then when my truck is at the bottom I let off the brakes, the weight of the Oliver then pushes the truck through and then quickly hit the pedal to pull up, some were very steep! 😎 There were two other nice campsites on the way to ours and only one past this location. Yesterday we drove up some, to the turn-off to the Monterey Mine. The maps on On-X Offroad are good. With 2WD and not wanting to air down, this was enough. It gets very steep and sketchy the rest of the way to the top. Some of you, airing down with a capable 4x4 would have no problem getting to the top. I understand from the top you can see ALL of SW AZ, from Phoenix, all the way to California, south to Mexico and north to the heights of the Prescott NF! Harquahala Mountain at 5600 FT is the tallest peak in all of SW Arizona. I wish we could travel with the Oliver and somehow bring our 2018 Textron Havoc SxS with us! She would fly to the top with ease!!! 🤣4 points

-

Chris, I truly commend you for your recent upgrades and attention to detail… Promise me one thing, when you retire, don’t get lazy! 🤣4 points

-

I know that the general subject of quality control has been on the minds of a number of members of the Forum - particularly recently concerning the issues with the battery box support post. I can tell everyone that Oliver does have a fairly extensive quality control system and procedures. Unfortunately, these systems and procedures simply didn't exist back in the day when 2015, 2016 and probably 2017 units came off the production line. However, it does exist now. In the Forum guidelines the Moderators have requested: "Some have asked why our forum is linked to the Oliver website. Valid question. Since the beginning of our forum in 2008, Oliver Travel Trailers (OTT) has paid for our Oliver “sandbox”, including our web space and an administrator who knows way more than we do about maintaining the software, for which we are very grateful. OTT DOES NOT CENSOR OR INTERFERE with the moderators’ management of the forum content. Moderators are not employees of OTT. We are Ollie owners, and receive no remuneration. OTT does have a employee designated to read the forum for the purpose of improving the “Ollie Experience” for all, but that’s a few minutes a day in a busy job description. If you should ever have an issue or a warranty claim, call tech support. Your post might not be seen on the forum by an Oliver employee. With that in mind, we moderators ask you to communicate directly with the company and afford them an opportunity to satisfy any serious needs before flaming OTT on the forum. We are not asking that anything to be swept under the rug. Just, please, let Oliver Travel Trailers have the first shot to meet and exceed your expectations." Specifically in answer to the question, "Are they reading?" the answer is more than likely - NO. Therefore, the only way that we (the owners of an Oliver trailer) have to inform Oliver of a quality control issue is to fill out a Service Ticket. Bill p.s. for those that have not recently viewed the full set of Forum Guidelines, they can be see HERE4 points

-

I just received a call back from Oliver parts so I just ordered from them what they use. Someone on here asked what type of adhesive Oliver uses. I’ll know for sure after I receive the replacement part but looking at what I removed, it appears the adhesive was probably already on the gasket.4 points

-

This thread show an excellent inverter/battery upgrade installed by a local service company. If you are going to DIY, I've documented installation posts that show these installations step-by-step. You asked, "I assume the Xantax 2kw was the inverter or?" Yes, in my case you can see that on page 1. No more Xantrex 2KW inverter (only) with the small PD charger in the power panel (kept it there for back-up). No more lead acid... Now the Victron MP2 and 900 Ah (3x 300) Epoch LiFePO4. You will find mine is a simpler installation. Did not spend on Lynx products and I did not want a cabin screen (we seek battery info 98% of the time outdoors, while towing or from the living room of our home). IMO, Bluetooth apps are all you need, but many like having screens. When doing so, I also removed all fuses and breakers from under the streetside bed so they can be conveniently accessed under the rear dinette seal. The best addition that several Oliver owners have added is the DC-to-DC Charger! Every time we tow we add at least 40 Ah for every hour towing. This is about 4x what we get from 320W in rooftop solar. See this for the complete installation. => Hope this helps! 😎4 points

-

I too had a battery box separation and repaired it 3 days ago. Unfortunately I badly damaged the door gasket. So far I haven’t been able to get a call back from anyone in Oliver parts. Does anyone have a source or make & model for the battery door gasket material?4 points

-

Hello @Mroth, this is not truly my area of expertise, but given how many holes are drilled in OTT installation processes, and that I have removed many of the old-tech products on our Oliver, I've filled way too many holes! I've used this epoxy based product and the color match is good. It's just a touch whiter than our older hull and I've read somewhere that the newer hulls are a tone brighter. I would say this product may work well for your purpose in the shower. It's simple and inexpensive. https://www.amazon.com/Marine-Tex-RM305K-White-oz/dp/B0014419V0/ I have also plugged the holes made for the TV mount, the drain pull handle in the bathroom, the door hook outside, both cameras and everything in these pics (see before and after).4 points

-

The first time I replaced brakes was just a couple of years ago, I’ve got 110Ksih miles on the trailer now. 24K is way too soon for normal braking. I also agree with the comments on bearings, they should not need replacing, just repacking. Mike3 points

-

3 points

-

I think closer to 6.0 is typical. The shop must think the bearings were subjected to excessive heat and thus, likely damaged as the brakes wore out prematurely.3 points

-

3 points

-

My first thought is thanks for sharing! Even though we have ample carrying capacity, it's still of interest as what you have done here is truly excellent work! I've also heard very good reports re Sea Biscuit. Your white boxes, especially the rear box with the white railing surround, even white supports, look to be a perfect match like it was done at the factory, just gorgeous! 😂 18 months now? We remember meeting a friendly couple with a brand new E1 at the fall 2024 Texas Rally! Would that be you? Please, keep having fun in your cute little Oliver!3 points

-

Saw this post from another user...quite detailed. I mounted the sending unit for our system (not Tire Minder brand) on the outside of our front jack power head. You can easily pull 12V from the inside of the power head and decide if you want/need an on/off switch for the circuit. * I just leave mine on all the time...as the draw is minimal.*3 points

-

If you’re referring to the little device that relays the sensor signals I installed mine in the front jack housing, there is power in there and room for the module. I repurposed the switch that controls the jack light so that I can turn the module power on and off.3 points

-

I don't mean to overwhelm you. While you are under the Oliver looking at the shocks, Pay close attention the leaf springs. Look to make sure the leafs are not sitting flat on one end or the other and/or over-sprung. If they are it could cause the shocks to wear out prematurely. If they are there is a huge topic on leaf springs ( more like a book). Remember to just take one thing at a time, you have an older trailer, but is built to last. There is a ton of information on this website, and people that care about there Olivers. Happy Travels.3 points

-

I suggest Nylok nuts and washers, no loctite needed. First do the lift as @David and Gail has showed above. Drill a second hole, top of slot, hand tight both bolts. Also, the angle of your two support beams seems greater than in other pics. The base looks off angle (notice angle of base not square with floor in your first picture). Check below where it should be welded to the frame.3 points

-

Similar outcome shown by the “Grand Adventurer” RV guy, the YouTube video I posted above. You have 1 of 3 bad and he had 2 of 6 bad. Both of you noticed your SOC was not what it used to be! Good test Ken! I still have a drawer full of incandescent GE Reveal bulbs at home, for the health of our eyes and heart!3 points

-

The second test of the “bad” battery just finished. That battery started out fully charged this morning and only lasted for 6 1/2 hours. It again shut down with so little voltage that the charger will not recognize a voltage and start charging. The other two batteries took the load for over 12 hours, the inverter shut down at 10 volts as it should. The charger was able to begin charging immediately. This second test confirms that this one battery is defective in some way and can only handle a load for a short period of time. No telling how quickly it discharges under a much heavier load. My Battle Born testing is done! Two good batteries and one bad battery. Now I’ve got to find something to do with these two batteries.3 points

-

Jolli Olli is camped in San Antonio for 4 nights visiting college friends and reliving the early 70's. Highs in the 60's and lows in the high 30's. Thursday headed to 3 stops along the Gulf Coast for 13 days.3 points

-

Well crud... and I got lucky. I just checked my camper for the battery box separation and support issue. The box seems fine, and the single bolt that I do see, upon a quick inspection at night, revealed there is no nut on the bolt. So I will do a detailed inspection in the daytime and find a nut for that bolt. Thanks for posting this information! Great job guys!!!3 points

-

3 points

-

You have 12v only powered items, propane only items, 120v items and some that work on multiple inputs. 12v only: Furnace motor, water pump, lights, front and rear jacks, ceiling fans (Maxxfan and bath fan), TV and Furrion stereo. These items only work off of your batteries. 120v only: AC, microwave. Propane only: cook top Combination: Water heater (heats on propane or 120v or both at the same time), Fridge (on shore power it defaults to 120v, no shore power it goes to propane, if you want to run on 12v you have to select, at least on my 3 way Dometic. It’s most efficient on propane). Your furnace generates heat from propane only but the fan is 12v only, no shore power needed. Also, if you have the 2K watt inverter it works on 12v to generate 120v, if your batteries don’t have sufficient charge your inverter will not function properly. Hope this helps. Mike3 points

-

David & Gail - Hopefully you either have or will have time to submit your repair to the Oliver Service Department. There is obviously a problem in this area. Thanks! Bill3 points

-

After seeing this thread I decided to check my battery support this morning. I really didn't expect to see any problem, but I received a surprise. My battery box support had two holes with no bolts. After some searching I found the bolt heads peeking out from around the wiring harness and after getting those I lifted the wiring harness and found the nuts. The idea of using a small bottle jack in this thread worked for me. I was able to place a 4 ton jack in there and raised the bracket until the holes were aligned enough to start the bolts, but I could not get them to go all the way. The angle of the bracket was off. I chose to use a small c-clamp on the bracket going from curb side to street side, that allowed the bolts to go through enough to get the nuts started. Finished it up with some blue Loctite on the threads. I have enclosed some photos of the repair. Finding this on my one year old Oliver was not expected. I would encourage everyone to check this support bracket on your Oliver to prevent future problems.3 points

-

I just got off the phone with Mike (Oliver Parts/Service). The part number is: 3075 The part description is: 3/4 inch bulb The cost is $15.00 plus shipping The amount in stock is: 3 - more are on order Carnivore - during the call with Mike he remembered that you had called requesting this information. Mike called you back and left a voice message on your phone on the 18th. He also said that he was going to try calling you again right after he could get me off the phone. Bill3 points

-

@Trailerjohngo Shoot me a private message and I will be more than happy to discuss with you details of my install via phone call or PM. As you will see from my first post, I opted to have a complete Victron system installed professionally by an excellent company in White House, Tenn. My main reasons for a professional install is all components and install are warrantied by the company doing the work as long as I own my Oliver. The warranty also conveys to the next owner should we ever sell. My system allows for the company to remote in should I have any issues as long as we have a WiFi signal. We have a SL mini so that’s not an concern. I am not nor claim to be a DYI guy when it comes to this level of electrical work. I also wanted to be able show that Victron system was installed by experts should we ever sell. I opted to have the Victron DC to DC charger installed as well which eliminates having to carry a generator. Shoot me a PM if you I can help with additional questions! And welcome to the fourm!!3 points

-

Hi Trailerjohngo, welcome to the forum. Once you have a chance to look at this trailer let us know the model year and/or Hull number. There have been manufacturing differences over the years and it always is helpful to know the age of the trailer we’re talking about. Good luck! Mike3 points

-

I've just sent Mike Sharpe an email asking for this information. Hopefully he will have a chance to reply soon. Bill3 points

-

Trailerjohngo - Welcome to the Forum! There is simply a ton of "stuff" here on the Forum to include the Oliver University with videos concerning many of the aspects of the Oliver trailers (as Steph and Dud B point out above). With regards to your Elite II visit - be sure to take a camera and a notebook. If the current owner doesn't know an answer to any of your questions, either an Oliver Salesperson can answer it or come on back to the Forum and give us a shot at answering it. Many of the questions you might have are already answered here but you never know until you ask. Enjoy your visit and we all hope that you too will soon become "family". Bill3 points

-

Recent Achievements