-

Posts

2,305 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

For many apps (Such as connection for a telephone call), the iPhone uses Bluetooth. However, for navigation mine has to be plugged in to the truck USB port.

-

Four thoughts: A. Topgun2's statement is spot on. There is not much we can do about the heat in our tires except changing our driving habits as the road surface varies. That said, there are a substantial number of blowouts due to heat related to under-inflation causing sidewall flex and that causing blowouts. So, general consensus is that within the tire pressure range, it is better to be a bit high than lower. B. Knowing the impact of your trailer and all loads in and on the TV is important. Get this by weighing your TV and trailer, each fully loaded. Also weigh your TV with just normal day to day loads. With these numbers, check the tire pressure guide from your tire MFG. Adjust accordingly. And keep Thought "A" in mind. C. It took me a long time to understand how much tire pressure changes between "Cold" and hot conditions. I often thought I had a slow leak or a bad air pressure gauge during morning checks. So I recommend checking tire pressure early in the morning while the sun has not yet had much of a chance to mess with the tires. Once you have set them, don't worry about them during the heat of the day. As a young man while towing across Texas, I checked them at the gas station in El Paseo in 105 degrees. I made that mistake of lowering the TP to "Cold" pressure. The result was two blown trailer tires about 90 miles from nowhere. Sidewall flex heat generated from under inflation.... Once again, see Thought "A" above. D. Get a TPMS for your trailer and TV. They can give you advance warning that can easily warn of a slow leak or underinflation before it becomes a mess. I highly recommend the below air compressor and tire pressure gauge. I also use the below TPMS and have had good service. It however is a bear to program and reprogram. I bought my TPMS in 2018. Hopefully by now there are more user friendly ones. So, I recommend looking to the OTT Forum for more current TPMS recommendations. Bottom line is for this topic, for sure buy quality. ESSENTIAL TIRE MAINTENANCE TOOLS Dewalt 20V Air Compressor TPMS JACO Air Pressure Gauge NOTE: Every Jaco product is designed, manufactured, and supported in the U.S.A. Jaco has been manufacturing in Franklin Massachusetts for more than 45 years. Their tire pressure gauge is calibrated accurate to ANSI B40.1 standards.

-

2 5/16" Bulldog Hitch Available for Oliver Elite II

Geronimo John replied to Dale C's topic in Towing an Oliver

Comment A: We could debate what "Not Matches" means, but for the sake of a brief response, the more you need weight distribution on your TV, the more one has to crank-up the Andersen Chain Nuts. More chain tension for such proper set-ups results in greater 2" ball wear. If you are towing with a 250 Super Duty, you certainly would not have much squat and a lot more load headroom on your rear axle. For that set-up, not much chain tension is required (if any). As such you would not have much ball wear. If you have a Land Cruiser or a Sequoia as John D has and GJ had, then seven threads would likely be all you could get and ball wear was in fact excessive on the smaller ball. Comment B: Your comment has some merit for some owners. But as written, it could be considered by most OTT owners to be a bit less than appropriate. Just saying.... Please take this constructively. After all you home run average is off the chart. -

Ford Ranger XLT - any owner use this vehicle?

Geronimo John replied to VFI Vacations's topic in Towing an Oliver

For towing an LE2 with an F-150 3.5 EB, I and others here get the 36 gallon tank, and FX4. For mine, the Heavy Duty Payload was not offered. In our case we absolutely use the first options every trip. For our use, the HDP package would have been nice. But not REQUIRED (for us) as the first two. -

In the down position, It would put the mounting screws in more sheer. With it up, the TV is resting on the mount. That should take off most of the stress of travels. So my pea-brain says it should be up on rough travels. That said Thanks Seph and Dud B for the oops. If my mount looked like the below, I would consider adding an aluminum plate between the TV and the rack to stiffen up the TV side of things.

-

Great info Bill. Question about your cell phone connection. In my 2019 F-150 I'll be following the plan of this thread. I use an I-Phone that "talks" via an apple cord through the Ford USP port to the Sync 3. This allows the onboard Ford navigation systems and other programs to operate and also keeps the I-phone charged. Assuming I tap the cigarette lighter (vs. plugging the I-phone cord into the F-150 USB slot), would that negate use of the Sync 3 Nav and other programs that rely on the iphone data?

-

I don't recall reading anything about "Up" or "Down". Did I speed read over this chapter when I read the O&M Binder?

-

Ford 3.5 EcoBoost Phaser Rattle Update

Geronimo John replied to Geronimo John's topic in Towing an Oliver

I also have a bit over 40K miles on our 2019. Guessing that 75% of those miles have been pulling hard with our OE2 in tow. Vast majority at interstate speed (plus) from TX to mountain sites out west. Because of the phaser rattle history on these engines, I purchased the FORD extended warranty. Like you, we have had no issues at all and also are consistently amazed with this engine. 🙂 For every dry start (Not having been run for a few days or longer), I use what I call the F-150 EcoBoost Forum "Full Throttle No Start" procedure to pressurize the oil system without the engine getting fuel. I believe that using this process has and will greatly extend the life of the old style phasers: Hold the gas pedal to the floor. This action tells the computer to not allow the fuel injectors to send fuel into the combustion chambers. No fuel and your motor will not start. Crank your engine for 10 to 15 secs at a time. Wait a bit in-between spins so the starter can cool a bit. While spinning the engine, watch your oil pressure gauge. It will climb as the oil pump pressurizes the oil galleries, turbos, timing chains and most importantly your phasers. When the oil pressure reaches "normal", take your foot off the gas peddle and your engine will fire off and run. I won a beer off my brother who said the above would not work. It does on all the Ford EcoBoost engines we have tried it on. GJ -

How to Repair Outside Courtesy Light

Geronimo John replied to MandD's topic in Mechanical & Technical Tips

Matte: I often think that our Owner's Forum IS the heart and soul of the OTT Research and Development Department. Seems that they do implement our ideas and solutions on a regular basis. Sometimes takes a while... but they do pay attention to our musings. This is yet another GREAT part about owning an Oliver. SO... if we are their advanced R&D team, then I would say yes, it likely having a "Bug Light Option" will be something from Oliver. 🙂 LOL! PS: Love your traveled map. Impressive! -

How to Repair Outside Courtesy Light

Geronimo John replied to MandD's topic in Mechanical & Technical Tips

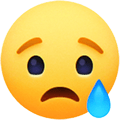

Thanks MobileJoy, Mossey and WandR! Some terminology confusion between Courtesy (Puddle) lights and Porch Lights. Regardless, the idea on the table is to locate both Courtesy (Puddle) AND Porch "Bug" lights. From Mossey we have the below recommendation. At .5 watts, that would seem to be a great solution to 50% of the effort. thanks Walter for sharing Mossey's find. In my case, I would like to replace the Courtesy (Puddle) light at the door entrance with one of these. The other Courtesy (Puddle) lights don't give me much concern from a bug intrusion. If you see any down side to this logic line I would appreciate your thoughts. Moving up about 6 feet, I suspect that the porch lights are a higher wattage than the Courtesy (Puddle) lights. Any suggestions for a suitable wattage LED Bug Light for this application? Many thanks, GJ -

FREE Install on Truma Aventa ECO Air Conditioners

Geronimo John replied to BBL's topic in Ollie Modifications

Not sure where to post this, so picked this one. The Houghton unit uses a remote for control. As such, several have mentioned the desire for a spare one. To those owners this may be of interest from the RecPro web site: GJ -

Check your hose attachment fittings

Geronimo John replied to Townesw's topic in Mechanical & Technical Tips

thanks guys. I edited my post. Speed reading... BAD 🙂 -

Granted this post is not about our "Wonder Egg's". However more than a few of us are towing our OTT's with late model Fords with the very capable 3.5L EcoBoost engines. This post BRIEFLY addresses those engines and their faults. ENGINE GENERATIONS: · Gen 1: 2011 – 2016: (Have problems with: Phaser Rattle, Turbo’s, Timing Set, Others) · Gen 2: 2016 – 2017: (Fixed about all the Gen 1 issues except the Phaser Rattle issue) · Gen 2: 2021+ (No new problems Identified that I am aware of, but they now have an again redesigned phasers. UPDATED PHASERS: Old part numbers start with a HC3S. The new phaser stock numbers start with ML3Z. New ones have a semi-enclosed face (Can’t see sprocket). This semi-enclosed face I suspect captures oil to lube the cam sprocket while system oil pressure builds and stabilizes. With oil, the phaser rattle is reported to be solved. Stock numbers for the new design are: · ML3Z – 6256A Cam Intake Phaser · ML3Z – 6C525A Cam Exhaust Phaser Any owner of Ecoboost engines model year 2020 and older: Make sure you get the new Phasers for your engine, not old stock as Ford is currently (as of this date) still selling and using. For more info about this topic, kindly review this video:

-

Check your hose attachment fittings

Geronimo John replied to Townesw's topic in Mechanical & Technical Tips

Wow. I just completed a 15K miles trip through Canada and did not garner any citations. Are we sure they are mandatory in Canada? Kindly disregard. Operator error. 🙂 -

-

How to Repair Outside Courtesy Light

Geronimo John replied to MandD's topic in Mechanical & Technical Tips

Mobilejoy: It was your post about not finding an actual amber LED replacement light and having to do a covering film that prompted me to ask if anyone has found an amber light we could use instead. My experience with films has been good, but over time, especially in a stone hazard zone (like under Ollie), they eventually start "leaking" white light rays. i would rather replace the white light source with an amber one and not have to mess with it again. Hence my question. I'm not an outdoor low wattage LED expert for sure. However, surely someone knows of a small LED low wattage 12V amber light that would fit into these fixtures or better a fixture such as Mossey's for this application. If not, then MobileJoy's amber Lamin-X film solution would be acceptable I think for the Porch light as it is not in a flying rock zone. GJ -

torque values for lug nuts

Geronimo John replied to Geronimo John's topic in Mechanical & Technical Tips

Nov 10, 2022 Update: I had provided Jason E. the manufacturers info and also our concern about using their MAX number for lugs. He sent it up the chain at OTT. Below is Jason's response to the lug not torque question. Glad to hear that OTT has recognized the reality of torque tool accuracy and not having owners exceeding the MFG maximum recommended lug nut torque. Especially when the MFG's provide a torque range. So basically, a small victory for the owner peanut gallery I guess. Personally I am going to use 100 ft lbs on my aluminum rim lugs. Gives me ten pounds over or under for my torque wrench accuracy. GJ ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ From: Jason Essary <Oliver@olivertraveltrailersservice.zohodesk.com> Sent: Thursday, November 10, 2022 4:25 AM To: John P. Russell, Jr. <jprredhorse@gmail.com> Subject: Re:[## 12307 ##] Tire Pressure Overstatement for many OTT units using aluminum 16" Rims Hey John, I have been informed that after speaking with the wheel vendor that they have stated that the wheel torque should be between 90 - 120ft lbs. With this being said Oliver has decided to drop our torque from the 120ft lbs down to 110ft lbs. Regards, Jason D. Essary Customer Service Director ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ -

Ditto. Up. That's how it was when I picked up our OE2. It took me a month to figure out how to lower it. (Doing so was low on my learning curve. 🙂

-

Ditto with calling the LE a lightweight. It is a lot of great things, but light IMHO it is not.

-

I appreciate all the marketing info you have been generating recently. 95% of it most owners would agree with. However, saying the the OE2 is the best FAMILY trailer I suspect would be considered n the other 5% group.

- 1 reply

-

- 2

-

-

Dometic 310 crapped out....

Geronimo John replied to chuckstovall's topic in Mechanical & Technical Tips

deleted as posted to wrong thread. -

OLIVER OWNERS: If you own any vehicle recovery gear, or could find yourself stuck, PLEASE take a moment and read this post. Thank you, GJ In pursuit of mountain top hang glider and paragliding launches, I have spent much of my adult life enjoying fire and remote unpaved adventures. I pride myself in trying to be a helpful Good Samaritan. More than a few times I have stopped and helped a fellow off-roader who had become stuck. I carry a 15,000 # rated tow strap that I have attached to my trailer ball on many occasions. After watching the below referenced video, it is apparent that my confidence in my recovery gear exceeds by a wide margin the actual safety ratings of my gear. The below info came from a recently posted by Colorado 4X4 Rescue and Recovery, Inc. that Good Samaritans should review. It involves an incident not all that different from what many of us have done many times. Sadly for Mr. Ryan Woods, a 43 year old Arizona off-roader, was killed by a Good Sam’s confidence in his recovery gear and/or lack of understanding of its limitations and/or how to properly use it. I commend Ryan’s wife for allowing Colorado Rescue and Recovery to produce the video analysis of the incident that resulted in the death of her young husband. (Pictures from video) The Good Samaritan apparently had looped their tow strap over their truck’s trailer ball and ran the tow strap to the tow hooks (Apparently below the cow catcher in the mud) of this Super Duty Ford. According to the video, the Good Samaritan’s truck was using an “Anderson Style” drop hitch and 2” receiver such as this one. In this case, the hitch failed at the truck receiver. But, as the video advises, there are several other potential failure points that could have resulted in the fatality. In this incident, It appears that the entire hitch assembly aft of the truck became a missile that killed Mr. Woods. It could have been the ball itself, or the shank pin, or the tow strap, or the tow hook(s) on the stuck vehicle. I think that the central point of the video is that all elements of a vehicle recovery system need to have the necessary ratings for the task involved. One of the video reviewers (Mr. Jeffrey Coomb) stated: “I'm guilty of using my tow hitch to recover trucks and trailers. I think for me it's a case of you don't know what you don't know, and when you find out, it's too late. I'm glad I found this video and really appreciate Ryan's wife for allowing you to use their story to educate others on the dangers. I am very sorry for her loss, but incredible that she see's the possibility to help others despite her grief. Quite a woman! I'm ordering the right tools ASAP. Please be aware that your trailer hitch ball and receiver may be significant failure point. Personally, I will also be taking a re-look at my recovery gear and for certain stop using my hitch as the pull point when using it. https://www.youtube.com/watch?v=Mb3BkeeXlIo

-

I agree with your thoughts. I like the fact that our OE2 is narrow enough to ride nicely in the slip stream of our F-150.

-

$1K... Ouch. Sorry for your pain. My first though are: A. If the motor has tested as failed, can you pull it and have it rebuilt. B. Many of us have manual awnings. Another option may be to convert it to manual. Surely someone has spare parts for your model. Ours is a CareFree awning, and it is for sure not care free...... GJ

-

Bryan: I can't speak to the electrical issues, but tracking of the awning is adjustable... but only to a point. In my case, it was caused by the owner asymmetrically deploying the awning. Mine was 3" out of square as a result of my lowering one side to keep the rain runoff away from the entry. tilt..... Also see my caution about those arms having a mind of their own and a propensity for suicide. Post link below. GJ