All Activity

- Today

-

Model Year Changes - 2020 to 2023/2024

HDRider replied to Ralph Mawyer's topic in Ollie Modifications

This forum, and you sir, rock. I had called Oliver service after hearing such a noise. I never heard back from them and forgot about it until I read this. I was hearing the "creaks and pops". I just lubed the 12 zerks. Thanks so much -

Boudicca908 started following Yet another option for your Starlink Cable and Exterior 12v access!

-

@MAX Burner Wish I could have helped you find something but I don't get out to that side of town very often. Hope you have a great time at the Rally. Cheers mate! Oh, if you want a decent meal while in Guntersville check out The Rock House it is my favorite, Buck Pocket Steak house is good or check out City Harbor lots of good choices there.

-

Referring back to your previous comment shown above, the (Dexter) “4-leaf spring packs” have the known failure rate.

-

Welcome, welcome, welcome! You won't find a nicer and more supportive group of folks. Enjoy your new Ollie!

-

Welcome - Travel far, travel wide, and travel safe.

-

Made in USA leaf springs

STEVEnBETTY replied to Mountainman198's topic in Mechanical & Technical Tips

To the people freaking out over the Dexter spring. If your spring is indeed defective it will fail very quickly, I have 3 of the original springs with over 80,000 miles on them, 1 failed, it took approximately 2 hrs for me to change it, when they do fail it’s generally not a catastrophic event, the remaining spring eye and shock will hold the axle in place. You will need to replace it asap however since the remaining spring is carrying more weight. Personally I’m sticking with the original design, e trl can overnight replacement parts anywhere in the USA. I to would prefer to buy USA made parts and will go with Stl spring next time, I forgot about them when my original spring failed. -

Hi Craig and MaryLou, welcome to the group. Congratulations on getting your new to you Ollie. We did the same, and couldn’t be happier.

-

Made in USA leaf springs

STEVEnBETTY replied to Mountainman198's topic in Mechanical & Technical Tips

Around the year 2000 in took a broken 50 year old boat trl spring to St. Louis spring, with the request of 1 inch additional arch in the design, they made 4 of them to my exact specs, very happy with the results. -

Welcome Craig and MaryLou! MAX Burner is so right about all the info found in this wonderful forum. Happy Trails, Wendy & John

-

I too was concerned, so before proceeding I crawled into the basement and there is just under a 1'x 3'x 1/4" backer plate that the approximately 1' spare tire mounting plate is through bolted to with 4 - 1/2" bolts. Since the spare tire does not rest on the bumper box when hung on mounting plate (there is a couple inch gap between the tire and the box), the addition of the bike rack actually adds back the support of the Oliver cover by resting on the bumper box. In addition, I added the two ratchet tie down straps to absorb any stress of the assembly pulling away from the camper even though I didn't detect any movement when pulling on the rack. The weight is now being carried by three points (the massive mounting plate, the rack resting on the bumper box, and the angled ratchet straps). We stay on good roads when we travel, but I will still be checking everything regularly. I will update my post after a few trips to report what I experience. Thanks, Joe/769

-

Made in USA leaf springs

Mountainman198 replied to Mountainman198's topic in Mechanical & Technical Tips

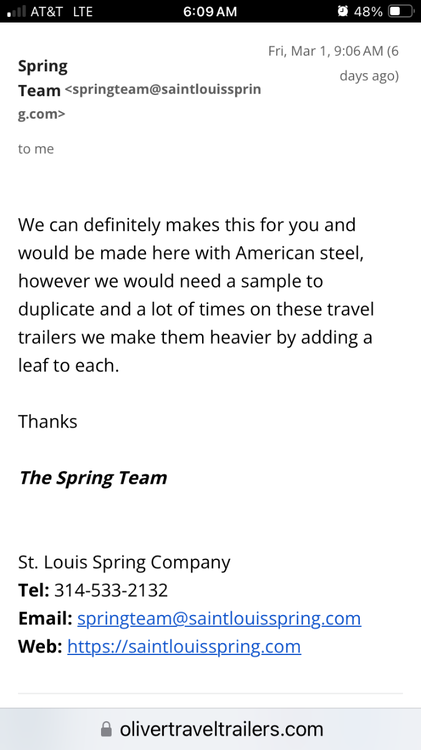

For those looking for alternatives made with US steel, here is the response I received from St. Louis Spring when posing the question to them about whether they could fabricate a set of 4-leaf, 1,750 lb leaf springs for me. To this date, I am not aware of a Oliver owner who has gone this route. Very interested to hear if anyone has purchased springs from them for their Ollie and how they have worked. One other source to check may be Deaver Springs in CA -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

JD: If any of the posters (Other than mysself) had found a 2000 to 2401 USA made 4 leaf spring I would have bought American. But after two and a half months, I have seen zero. Not one. Like the early adopters, I had to make a call for repacements. Mine are shot and I have 7,000 miles to roll this summer when I get there. I did my homework. My mistake was trying to convnce you and others that the SOB's were not what an OE2 needs. Add to that the dishonest representation, intentional or not, of springs to the early adopters by SOB of a spring set which was way over what had been sold is bad. But what followed is far worse. Having been strong armed by several owners that by my suggesting that a 2400 pound spring would be too hard a ride, only to find that they had purchased a 2750 pound springs.... and all fall in line with that's what they need. Pure confirmation bias. Then to say that they will be running their super springs at over 20 pounds over the Michelin E-rated tires pressure chart recommends. Hopeless. And now trumping the discussion with the idea that I am not patriotic by buying an American made spring is beyond my limits of civility. As a retired USAF Colonel who served in several war zones for 30 years, and 40 year plus engineer, I will just say that... I hope your end up loving your springs. I suggest that this post be locked until OTT advises what they are suggesting for the fleet. Futher discussion is no longer healthy for this forum. I'm done. GJ -

I will add that if the total assembly is 60-70 LBS, and you ride nicer suburban roads/eastern Interstates, you should be OK. Keep in mind that in the Jeep picture shown above, the single mounting bolt is mounted to a steel frame, not fiberglass. We just got back from 2 1/2 weeks, from here and throughout SW Utah. We would hit a cattle grate on a side road and even a simple bridge seam on a major US Hwy, and the TV and TT would bounce heavily! You try to see them coming but it will look fine and then bounce hard.

-

Hey Golfnut, It has cleared out quite a bit from the busy weekend crowds. We look forward to meeting you. Safe Travels!

-

@CW. Welcome to the forum, and wishing you many happy miles and smile traveling with your Oliver! Cheers! Patriot🇺🇸

-

Whoa, Pilgram! 🤣 Did you look at what/where the spare tire bolt is connected? This design has the weight of 1-2 bikes on one (1) threaded bolt! What is it, just a 1/2" bolt? Came back from our last trip and the spare fiberglass housing was loose, the large, winged nut to hold the spare was also loose many turns. This bolt is designed to hold up the spare upright while its weight is held by the frame below. I'm not crawling into the Oliver basement/trunk to see what is supporting the main bolt for the spare, but you certainly should do so before you go on a Rocky Mountain excursion, or anywhere else. It may look good in the driveway but as a seasoned engineer, and 45 years a car mechanic, I'm not seeing it! Do you due diligence. The downside would be your precious bikes and spare tire bouncing down the highway, leaving a hole in the Oliver fiberglass hull the size of the bolt head and washer, or whatever support bracket may be there. To boot, ask anybody here, I'm more the risk-taking person, but I would not risk this! When you lose your bikes, you will not know it until your next stop. Keep on checking, keep that one wing-nut tight. Actually, the tighter you make that bolt, the more likely it will bust the fiberglass. This would drive me crazy! Certainly, I can be wrong, we all are at times. Please let us know what you experience. BTW, welcome to our Forum! God Speed and best wishes. JD

-

So, two members have purchased the Dexter brand 2400 LB springs and more than 10 of us have purchase the Alcan product, rated at 2750 LBS. When I upgrade, it's Alcan for sure! It's not that everything made in China is bad, just literally millions of MADE IN CHINA products are of extremely poor quality (go ahead and take your chance on your $100K investment). The marketing slogan is Better-Faster-Cheaper though they often forget the first word is BETTER! When give choice, I will NEVER purchase from the CCP and will pay hundreds more for first choice MADE IN USA and second choice ANYTHING BUT CHINA. I need a bumper sticker that SCREAMS this sediment. I believe I also wrote this on page 6, or maybe it was page 9, no 12! I'll bet this thread hits 20 pages... The design of the Alcan has the second leaf fully extended to the full length of the main leaf. @ScubaRx just wrote it clearly in B&W, @MAX Burner mentioned it at least twice and I wrote of it before. No brainer, this is the cause of failure. Good ol' Dexter can make a heavier spring, but not a better one. EOF

-

Model Year Changes - 2020 to 2023/2024

rich.dev replied to Ralph Mawyer's topic in Ollie Modifications

Correct, the plates are now spaced to fit the 2 x 200w Newpowa solar panels. -

Model Year Changes - 2020 to 2023/2024

ScubaRx replied to Ralph Mawyer's topic in Ollie Modifications

The in-hull anchor plates were still there, but since they're now using a completely different panel, the plates are in the wrong spots. The old panels are too short to easily use them where the old mounts were installed. -

Bill, I found this picture and post from John E Davies, the picture shows the position of the rubber strips. Not sure if jd's is the same, but looking at this picture from John, there's a rubber strip lenghtwise on the front of the box between the 2 gussets/L brackets (probably the 3/8" thick), and the 1/4" thick one diagonal in the back. Below is the picture and HERE'S the link to that post.

- Yesterday