-

Posts

2,305 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

Bathroom Vanity Cubby Modification

Geronimo John replied to Frank C's topic in Mechanical & Technical Tips

-

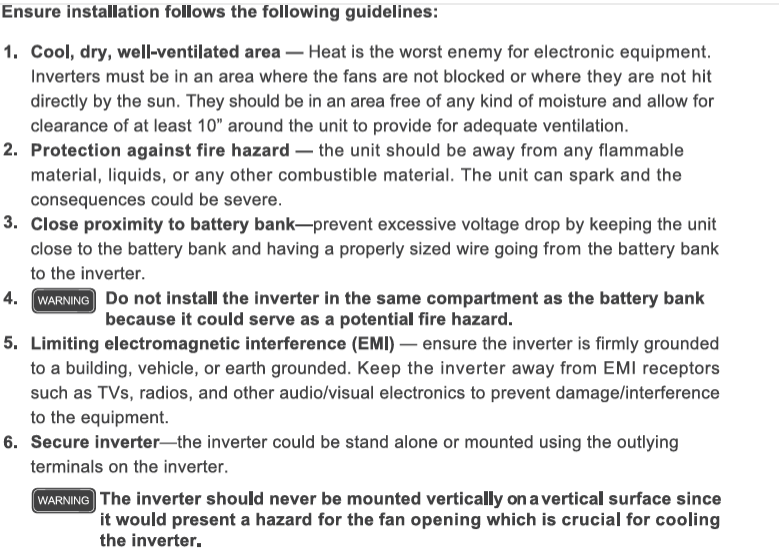

Tilt. Below is the Renogy installation instructions.. Kindly scroll down to item 6, and the warning below it. What I think they are saying is do not mount the unit up and down with the fans below the unit. Doing so will burn up the unit cause you cut off the air flow. That said, I mounted mine on the inside wall of the street side bed, using all the space of my former Xantrex... that died.... and then some forward. You'll need to add some shims to mount additional phenolic cutting board mounting. I highly, as n VERY STRONGLY, recommend using SS thru bolts (six I believe) from the unit thru the cutting board, thru shim stock and thru the fiberglass wall below the bed. Additionally add material below the Renogy to help support it's very heavy heft while installing. And nimble fingers to get the nylocks on the bolts between the cutting board and the Renogy mounts. Finally, the heads of the bolts are on the hallway side and have SS fender washers to spread the load. This mounting approach survived 45 days in Alaska, but the kitchen drawers did not..... GJ

-

8 amps 60 hertz 125 volts and CODE 7. Below may be useful GJ OM - Progressive Industries HW30-50C (4 MAR 2023).pdf

-

Replacing city water inlet valve

Geronimo John replied to The Loonies's topic in Mechanical & Technical Tips

I carry one of my throwable boat cushions with me at all times. Generally is sits between our Honda 2200 and the curb side rear of the F-150 bed. Great to kneel on when doing low work, or place on a 5 gallon bucket when doing mid height work. Much better than a towel. An because it serves as a pad between the generator and the aluminum truck bed, it is almost always where I am. -

12v only vs 12/120 compressor fridge

Geronimo John replied to C&MCurrie's topic in Mechanical & Technical Tips

For a critical element of your camping support gear, having a refrigerator that can run from 12 or 120 volts gives you twice the onions when electrical weirdness happens. I like having a back-up plan so, any refrigerator I get to replace our Dometic "Fire Starter" boiling ammonia HazMat unit will need to have two power options. I like options. GJ -

A good example of the DYI Pros that trailer batteries are considered as a matched set. One fails, best to either run one less battery, or replace them all. Lesson reminded. GJ

-

I am putting together some questions for these Yuma CIGS panels. But have a question for our owners: Not having access to my Ollie, what is the length and width of the above OTT Solar Package panels? Thanks GJ

-

First, I would buy spare fuses for all the sizes and types your trailer has. The trouble shooting process that likely will follow WILL likely result in your needing them. 😞 GJ

-

No. Emergency situations while in the bush are addressed under Forum Rule 12.34B and you are allowed to communicated in any way such events. Also, they are not considered as hijackering. Something that this owner never does and can't even spell the work correctly. GJ

-

I agree with both of you, in a way. As per CRM, yea for sure. Heavy too!. As per Steve, yea great idea especially if your TV is a 3/4 ton or higher because such a design to be wind resistant/proof it would sure add PSI to your Ollie Tires. ++++++++++++++++++++++++ But, our OTT's are designed to be aerodynamically minimalists. Hence why I don't like and will not install ridged flat solar panels poking up into the airstream and obvious visual distractions from the elegance of Mr. Scott's design. Especially so to our audience with a minimalist's perspectives of architectural beauty. On the other hand, when we have proven, flat laid, Lightweight, efficient, flexible solar panels, that can last a long time directly adhered to the roof surface; that becomes a game changer for some of us. GJ Note: Can you believe that this pea brained Mechanical Engineer can use so many big architectural concepts and words in a row? OMG I may be turning into an Architect in my ole age. OK REDEMPTION is now necessary::::: It will be interesting to see how the CIGS panels actually pan out in direct sun, as well as the possible impact on the heat transferal through the skin of an OTT roof system. GJ Note: Whoo, that was close. Looks like I'm back to being a M.E. again. That rabbit hole could have been my demise. 😞

-

May be a good idea as we have basically hijacked the solar awning one. The Lightweight Solar Farm concept is valid now that the panels can be stored in a compact way, and cost wise appear less than ridged, not to mention being more eco friendly from a materials perspective. However, with the type of chemistry the CIGS are using, they operate so well in shade, and can be mounted on our entire available roof with NO AERO DRAG (My objection to the OTT and RV industry design so far anyway), the solar farm looses out to the LSF concept in a lot of ways. That's why I suggested adding this to the flexible solar panel thread. Either that or we patent the idea! Sorry Awning Solar Guys for this invasion...... 🙂 JPR

-

that's what I saw earlier. 🙂 I just posted their web. What I don't know yet is if the panels can accommodate flex in both directions. All the photo's only show it in the long dimension. If both diretions, then they could be mounted sidewise or long wise. Likely sideways would work best as Ollie is 7' wide. Start just at the curb side awning and run across the low roof, up to the high roof, down to the low roof. That dimension is 7 feet plus the two 5"? roof "poof ups" certainly is longer than their panels are long. Basically filling the roof three sections front 2/3 of Ollie with solar panel. I think it would give us at least 600 watts, maybe close to 800 watts if four will fit. I like this idea even better than the Ollie "Ground Solar Wind Farm" concept floated earlier. GJ

-

Still have not found the flexible solar panel, but I did find my post it note about it. Our forum member (???) was calling our attention to a new Copper Indium Gallium Diselenide Solar Cells (CIGS) that can be walked upon, shot repeatedly and run over by trucks and still keep on ticking. and the model is YUMA., sold by Bouge RV . They have several configurations and sizes on their web site. https://www.bougerv.com/products/yuma-400w-cigs-flexible-solar-panel-with-holes The video shows the flexibility and durability. I'm thinking this would work well directly adhered to the roof of ollie, or better as a ground based solar farm as i mentioned on the solar awing post. Video: https://www.bougerv.com/products/yuma-800w-cigs-flexible-solar-panel-with-holes If it is as good as they are stating, this is a game changer for flexible solar panels and the RV market. GJ Moderator: If you can find the original owner's post from the bread crumbs above, would you mind moving it and this post to the flexible solar panel thread? Thanks GJ

-

I read a post last week about a new highly flexible and walkable solar panel. It was a small hijack to another topic, but related. Anybody know where it is on the forum? Would like to get it moved over toe the Flexible Solar Panel topic.

-

For sure. Or worse a trailer fire of high order fueled by bad Hazmat. It would not have been a fun restoration effort, and then the long trip during your vacation trying to get Ollie back to the Mother Ship would be painful. Would not wish that on anybody. All in all, I think it was good news that nobody got hurt and the trailer is still fully intact. Cord has purchased his first mod, the 350 Blue Seas Master Kill Switch. I hope that other OTT owners that don't have a way to physically isolate their trailer from the batteries do so as well. GJ

-

My 2018 drawer bottom thickness is pretty thin. Longer screws would not work. Fatter ones maybe. But I chose small SS bolts with small washers and nylocks. Art (Max Burner) and I replaced them and with the bolt heads/washers on top, they pilled down enough into the drawer base that they are not a problem. Certainly we'll not find any drawers up by the bathroom again. GJ

-

What a terrible cluster..... A lesson I had never even contemplated before is to check with a volt meter that the + and - voltage markings are correct on a replacement battery! Likewise that the battery puts out at the proper 6, 12 or 24 volts desired. I previously got bit by buying a battery with the proper voltage and proper markings, but the posts were on the opposite side of my truck's. Hence the battery cables did not reach. Carried the battery back to auto zone and got the proper one. Was a long walk to the truck... So I have never forgotten that mistake on my learning curve. GJ

-

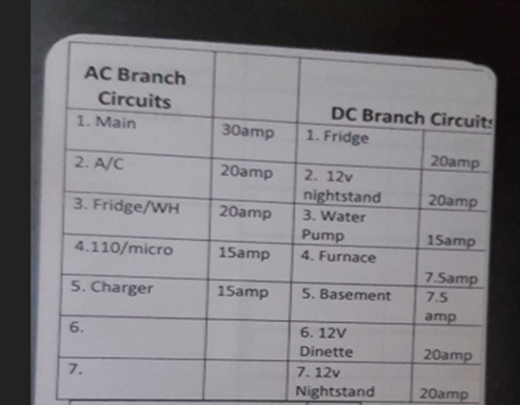

WOW. Nice to know that for 2020 OTT upgraded the panels. Not only more breaker space, but extra breakers too, and 20 amp to boot! But for our 2018 and But for Going Costal (2019 OE2 ) and our (2018 OE2) we are stuck with no spares and some 15 amp breakers with 14 AWG. Wonder if our PD's can be upgraded to your version? Thanks for sharing. Good info to know. GJ

-

Closet shelving and drinking glass holder

Geronimo John replied to chiwald's topic in Ollie Modifications

We use the washable, reusable, and recyclable version of those very cups! My dad would give each of us kiddo's one washable, reusable and recyclable red solo cup with our initials Magic Markered for us to keep track. I actually got four camping trips out of my cup. 🙂 GJ -

Anything of significant size hanging off Ollie will be subjected to wind loads. We know where that goes. I am thinking that wherever we camp there most of the time is lots of ground space. I saw, and lost on this forum a new walkable flexible solar panel. Searched and can't find it now.... Regardless I would think a few rolled sections of it placed on the ground with a few stakes would make a great solar farm. Being flat on the ground and staked the wind damage concern would be minimal, and it certainly would be a LOT less ugly and heavy than most other systems I have contemplated. "Ground Solar Wind Farm". You heard of it right here. Geronimo John

-

Disadvantage are that it becomes a unique connection on my extension cord. Or finding a replacement while on the road would be more difficult as well compared to our OEM. So long as our OEM is working, I'll pocket the $140. GJ

-

I can think of only one way to do so that does not badly mess with or put the existing panel and electrical system in jeopardy. The below only works well if you have a 30 amp shore power source. Just be aware that doing so will greatly reduce your power flexibility inside Ollie as a result. Purchase a small panel with a 30-amp main breaker and add two 20-amp breakers for distribution. Locate it adjacent to the Furion Power Port on the side of your Ollie. From one of the new 20-amp breakers, connect the output to the existing 30 amp wire going to the existing 30 amp breaker in the OEM panel. NOTE: Doing so has power flexibility disadvantages as stated above. The existing Ollie outside power outlets are pretty much daisy chained. To figure out which one is at the end of the line is pretty easy from the circuit diagram that came with your year of Ollie. Now run a new 12 AWG Copper Line (White, Black and Ground) to the end of line outside outlet (See Below). Connect to the end of line outlet. Make safe the original feed for later reuse should you determine down the road that the cooker was not THAT important, or simply want to restore the Ollie to Factory Condition. The specific electrical cord I would use is called SOOW. The SOOW cord is a heavy-duty portable cord used in many rough duty applications. Since running it across Ollie at this point likely will result in the cable not being properly supported along it’s way. Using SOOW with a rubber casing will go a long way in ensuring that it remains serviceable for many years. It is also water and weather proof, just in case you flood your basement. GJ

-

Tire pressure confusion - Legacy Elite 2 POLL

Geronimo John replied to John E Davies's topic in Towing an Oliver

Where ever I park Ollie, I use my 2" X 6" X 11?" blocks, and I never just use one. My purposes are to shorten the amount of jack travel, and to act as a slip point should the trailer be moved in error. Having a shorter jack sticking down increases the odds that at least two of my blocks will slip against each other and save my jack and rear jacks as it falls. Point is if I were to take two of them and router out a pattern of the frame and spring plate, they likely would stay in place for our scenario. So, please measure them up for us when you get around to thee retest. Sure wish I had a wood router!!!! Nope I had not thought of that one. Moving the support point back increases tongue loads and decreases load on the axles. Good idea. Rates right up there on "Using your very best tire out of the five (or possibly 9 for some TV's) on the lame side. So, adding another item for the list: Will you TV spare tire fit your Ollie? Good to know in advance. If so, what rating and CONDITION is it? Better than Ollie's? At some point I'll take all the above suggestions and make a check list out of them and repost the group in a condense version. By laminating them and placing the half sheet of paper on top of the spare (Sorry John D.) the check list would be where you discover it (again) in your moment of most need. Ok after that brief diversion: What else should we be thinking we should have in mid for the scenario? GJ