-

Posts

2,302 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

The Houghton is a great unit that is rated for 122 degrees F. I recommend it based upon it's performance excellent design. However as of this date, the supplier's web site indicates that the manufacturer still has not addressed the need for a remote thermistor and relay to shut down the fan when the compressor shuts off. There are two published Mods that correct these topics and they work well. But are not recommended for most owners to attempt. Also doing so of course violates the 2-year warranty. As such, I recommend coordination with RecPro for them to accomplish Mods 1 and Mod 2 before delivery and to honor the 2-year warrant. You will need a thermistor with at least a 10-foot lead. See OTT Forum posts on this topic for more info. If they would do so, I believe their Houghton unit would be an outstanding unit for our OE2's. We have used ours for three seasons in temp's over 105 degrees in full sun. Zero problems. GJ

-

Chris: Yep for sure. Gotta get the refrigerant oil down to the compressor where it will....... lubricate the compressor. On it's side of upside down, the compressor oil mixed with the refergerant will not be doing it's job in the compressor. Same thing is true for our desktop ice maker. The Amazon spec's post the unit size as: Can you confirm these meassurements? Can the unit be stored in the Attic for storage standing up? If yes, would attic removal tilt to get it out of storage likely result in an oil entrapment issue? Your thoughts? thanks GJ

-

Dave: I agree that only having the scuppers would not do much as there would be no "draw". But as Bill stated, and I also nearly always do is to also open up the bath room vent. This and the air leaks from the Max Fan (When closed) do provide a draw for the scuppers below. Now is that adequate enough? I would respond with a "Maybe, it depends". LOL. The maybe part depends on factors such as: How old is your trailer? Has it off-gassed the offending VOC's to a great extent? What's being cooked or items brought into the trailer that could be adverse to the users? Wind direction and velocity. Construction or Fires in the region generating particulates. Other factors such as distance from an exhaust source, local pollution, etc. It is helpful that our OTT's with their solid surfaces, are easy to clean and those surfaces don't generate much off gassing once cured. But as you stated some individuals need to be more or even extremely cautious and I certainly recognize this as a valid concern. So your approach to the topic is spot on. Experiment if you can and act according to you and your family needs. For those where a HEPA filter would help, having a small HEPA filter such as the below Honeywell that we use during fire smoke events has been very helpful. Another planned benefit is that if we must excape a fire/smoke situtation, the 20 to 50 watt power draw can be plugged into our Ford F-150 400 watt inverter to run the unit in the truck as we get out of the hazard zone. This could be useful for other disaster situtations as well. PS: Be sure to close the outside air vents on the truck A/C should you find yourself in the "Fire Country" scenario.) For travel we wrap our HEPA in a towell and it fits easily into the OTT OE2 Attic area. GJ

-

It was at this cost that I reacted that a discount was in order to encourage owners to renew them when faded. From $345 to $73 now that's a discount. I want to hire you as my lead negotiator. There are several decals "on the side" and one on the front. I suspect the $345 quote was for a full set on three sides complete inclusive of the "Sort of Niki Swish" down the two long sides. And the $73 was just for the decal over the storage area hatch/water heater. Can you kindly clarify? If the $346 quote was for a flll set on all sides, that seems really reasonable. Or was there a scope change for the labor to be provided? Thanks GJ

-

JD: You sure don't fool around when doing a project. Congrats! Looking forward to the finished project this summer. GJ

-

I ASSUME that the cost would be for two. Regardless, a 50% discount would make the advertisement more likely to be replaced over time. Also improves the look of the fleet as it ages. GJ

-

For sure. That 711 miles from Houston is a bit far. Hopefully we'll hear of other firms that also do great PPF work. I cover many states west and can deviate routs easily with planning time to do so. GJ

-

Audi Q7 without air suspension as tow vehicle for Elite II?

Geronimo John replied to Emerson's topic in General Discussion

On all three of those mountain passes, with a F-150 I DO stop and scan my brake temp's. Not because they were starting into or were in fade mode, but out of an abundance of caution. The Big Horn to DT brake temps were high and a cool down was the smart stop to do. I transverse an 10% gravel road in OK twice a year. With our F-150 I use low range 4WD and lock up the rear axle as well. As you state a larger truck for these roads would be nice for sure. But overall for us the F-150 Super Crew FX4 is overall our best solution. Would love to have a 6.7 diesel with jake brake in the F-150. Just dreaming.... GJ -

City Water Port Winterization

Geronimo John replied to Dexter Adams's topic in Mechanical & Technical Tips

I have yet to use my city water hookup. Fresh water hookup and boondocking ports are my preference as I control peak pressure to the system with these. The city water hookup is a gamble as the city water pressure can be very high. Sometimes dangerously high to our plumbing. So that's why I don't feel the need to "Feel Lucky"! When winterizing, I also find it more difficult to get the RV antifreeze into the city water hookup unless I remember to "vent" the system: Opening the exterior shower valve and it's handle latch helps just a little. Removing the exterior shower head helps a bit better. Opening an interior cold water valve works even better. GJ -

Post deleted. See JD's post above for the real skinny!

-

Two get backs: A. If I recall that was a DIY of the past. Your pictures certainly demonstrate its usefullness for all owners to seriously consider. Thanks for posting the pic. I do hope that OTT has picked upon the idea as it is a no brainer for them to just do. B. Your picture is also "Gollden" in another way! Love the tank gauges! GJ

-

JD: I also do not use the auto change over valve. For those of us who want to know when a tank has run dry, why not replace the change over valve with a "T". Then replace the getting gray hair OEM hoses with less "tight turns" ones that the change over OEM setup has. All: Any unintended consequences that come to mind would be appreciated. PS: I do think it wise to carry a spare regulator. Would be interested in a good brand. Below is what over the years I harvested from several owners: GAS REGULATOR: · The OEM Hull 505: GR-9984XF with 345,000 BTU from the Main Service Cylinder. · Possible Smaller Replacement Part if above is not available: GR-9994XF has 262,500 BTU PROPANE REPLACEMENT HOSES: 12” with 90⁰ Street Elbow Preferred Topgun2 Cautions: A couple of notes: Check the size of the connections on the hoses. Be careful that you do not over-tighten the fittings. I believe that the torque setting is 25 foot pounds (confirm this). Use yellow "gas" tape or gas pipe dope. May need a ¼” male NPT X ¼” Female inverted flare fitting.

-

JD: I do wish I had your "Super Power" system. Our three Battleborn's pale in comparison. Regardless, Battleborn advise for 8 months of storage where a deep freeze is possible mirrors your concept. They stated to Equalize, and then draw down SOC to 60% SOC. Kill alll power flow via a master switch and let it go for the winter. So far it works well. I typically find 8 months later that the SOC has only dropped a couple of percent at most. Their logic is that in our case the Battleborns may freeze, but with ZERO power draw until the next summer they thaw and all is good to go. Up on arrival I record the SOC and equialize within a few days. GJ

-

Humidity Spikes - Cielo Testament

Geronimo John replied to Ronbrink's topic in Mechanical & Technical Tips

Not me. The two mods FIXED the Houghton Set 2 humidity issues and short cycling. But as previously stated, the mods are not something many owners would want to risk. GJ -

Just about every owner's location can impact the winterized trailer. In addition to studying your battery Owner's Manual, I suggest that you contact your battery MFG and state the conditions you will be storing your Ollie, for how long, and if power is always available there during the winter. GJ

-

How to Insert Rear Window Screen

Geronimo John replied to Alberta and Randy's topic in Mechanical & Technical Tips

Is this correct, or is it mounted from inside of the trailer, just inside the window track? Asking as I have the same problem you solved. Thanks GJ -

Winterization Issue (As Storm Approaches)

Geronimo John replied to Cort's topic in Mechanical & Technical Tips

Was in travel status CONUS. Now back in HI. I'm a little late in this conversation. You have a relatively new Chevrolet Express 4x4. Likely with their max tow capacity of up to 10,000 pounds. Why worry with the tank valve issue and just get down to a lower campground? GJ -

I agree with both of the above. We are incontact with the bumpers and frame typically at the dump station and when hitching up. Maybe a few times during our stop. BUT the steps are the one that could get most of us.... many times a day. Not just casually, but when one foot is on the step and the other contacts the earth. GJ That said, I'll not be changing our PI Power Mgt System any time soon. Two other things that I do keep top of mind when working electricl are: Situations where "The Step Potential" could be in play Forgetting to keep one hand in my pocket when working a open hot panel or device.

-

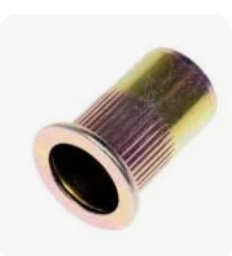

These fasteners rely on the strength and having thicknes of the mounting board. I prefer to use Rivet Nuts (AKA RivNuts/Blind Flange Nuts). They have the advantage of expanding on the far side of the connection as well as board strength for pullout. I've found them to be quite strong when the surface being mount to is solid. Would not work on "foam board", but for PVC and metal they are super... at least from my experience.

-

Foggy Memory Reason: Because so many of our owners have great names, but I had never seen it named "Ollie", short for Oliver. Hence a unique name that I can actually remember. And my trailer's name gets mentionedd every time someone says Oliver! Hence it wins the most popular name award. Real Reason: I didn't have a creative name that I liked. LOL GJ

-

Totally agree with Mossey. As to a product to use with your next size screws I would consider is a small tube of silicon sealent/adheasive. It will allow removal of your new Stainless Steel screws, yet help keep them in place. Thanks for your post. Frankly I have never really LOOKED at mine. Will do shortly! Geronimo John

-

Ollie of course! 🙂

-

Why?