-

Posts

2,302 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

Alcan spring kit sprung stiffer or is it bad roads?

Geronimo John replied to taylor.coyote's topic in Ollie Modifications

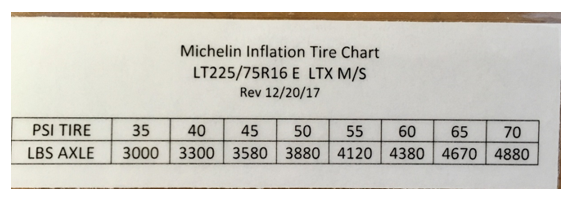

Dexter 5 leaf? Typo? Good that you are planning to change your springs before their roadside failure. The above generic chart provides general industry standard info. The Michelin provided chart for these tires also require at least 35 PSI. If an owner can not find a chart for their manufacturer, use of the above could be pretty good guidline. But with the internet the actual data for your tires is better. Here is the chart for mine OE2 tires: For talking purposes, a typical 6,000 pound OE2 will have a tongue weight of about 580 pounds. That calculates to about 2720 pounds for each axle. From the chart we are off the chart. One could mathamatically postulate that at the example axle weight we should use about 27/28 PSI. Not the case. The pressure shown on the left side is the minimum pressure to be used. But for the purpose of lowering running drag, and to give us more safe warning time when a tire is failing, most of us add some pressure. Likewise, I also run my OE2 with 40 to 45 PSI when on highway. If serious off roading I lower it further to 35 as per the charts. But if conditions dictate, for short duration I would not hesitate to go below the 35 PSI. And have twice with our Ollie. SUGGESTION: I like many other owners, believe that having a 20/18 volt air compressor (And a good plug kit) are musts when traveling far or traveling off road. GJ -

JD: Thank you for taking the time to summarize in detail what is needed for a Never-Lube axle bearing change. At my vintage, I would like the long time benefit of the Never-Lube bearings and the larger brakes too. Not to mention saving the time, grease and seals I use every year on my OEM's. I also feel the need to check in on the brake system. Doing annual service on the bearings allowed me to do that. If I went with the 5200's and Never-lube I would still want to look in on the Drum Brakes occasionally. If so, do we need all the above tools for just physically checking the drum brakes? thanks GJ

-

Alcan spring kit sprung stiffer or is it bad roads?

Geronimo John replied to taylor.coyote's topic in Ollie Modifications

Spring rating and spring capacity together determine how the road conditions impact the load. For a given load, a higher rated suspension will have less travel than a softer one. To put this at an extreme, if we go with an infinately strong suspension, say a block of wood, an input from the road will imediately be felt in the cab. This is not what we want. On the other end of the extreme, if we have a too soft suspension, the axle will bang the frame with every input. We don't want that either. And for this reason, all the springs and shocks being used by our owners fall between the two stupid extremes above. Hence they work. The root cause of these discussions as admitted by three Dexter Tech's to me that the original OEM springs being contineously loaded were under designed. That's why so many have prematurly failed. The good news is that many of us have upgraded our springs to higher rated ones. I personally recommend this to ALL OE2 owners who still have their OEM 1750 Dexters. So for those of us who have already done so, bascally all we are really fretting about is the personal selection of different options. It is Physics that if you have a stiffer suspension, you will get less spring travel. For some that is greatly needed. But if an owner of several years has zero witness marks on their frame and axle U-bolts, then likely they just need to address the under design issue and go with a compromise spring rate. As Ronbrink mentioned above, your shocks will wear in a bit and may help some. With the upgrades you have your rig is set up for great off road service. There is only one thing I can think of to amelerate your situtation. You may want to check YOUR tire MFG Pressure/Load chart for recommended tire pressure at your actual axle loading. If you don't know that number, please hit the scales. At 55 PSI, I would wager that you are well over your tire MFG recommended pressure. I recommend 40 to 45 tops for 95% of our OE2 owners weights. GJ -

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

For sure on getting the kits. Also having a smaller (2AH) and a larger (5AH) battery packs. I generally use the 5AH in the air compressor and the 2AH in everything else. I guess we should unhijack this thread. Sorry John and Jodi! John and Jodi: What tires were on your trailer? Having two tires to fail sounds like a thread we posted earlier this year. 🙂 GJ DIY - Two Flat Tires On An OE2.docx -

CO/propane gas detector replacement

Geronimo John replied to rideadeuce's topic in Mechanical & Technical Tips

That is exactly what John Davies proposed in his "DIY" for the switch. A flag you hang out of the dinette hatch as a constant reminder to imediately buy a new detector. Here is his full post. GJ -

Run 12v System w/out Batteries in Oliver 1

Geronimo John replied to GeoffChapman's topic in Mechanical & Technical Tips

Just be mindful of the polarity. GJ -

Carefree Awning not opening. HELP

Geronimo John replied to Teaney Hull 292's topic in Mechanical & Technical Tips

Another possible cause: If an awning is repeatedly subjected to water weight more on one side than the other, it will streach a little each time. Basically the rectangular shape of the awning is asmetrically streached into a trapazoid. The trapazoid will walk towards the streched side. Ours was 1/4" per revolution. At some point the awning will be against the edge guide and jamb. Assisted pull-out as you suggested is necessary. A bigger guy/lady on the crank without the pullout assist is a bad idea. In our case, I had a habit of having the awning support pole near the entry door about a foot higher than the back support pole. My rationale was I wanted the rain to drain towards the back of the trailer vs. up by the entry door end. Great Idea. But.... I got to buy a new rectangular shaped awning. Only good news is that the awning fabric makes a good entry mat. -

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

Very EXCELLENT! Please add: ON LEVEL GROUND and tie a ribbon on the steering wheel to indicate "No Move". I also use the OEM jacks for all my maintenance efforts. When on level ground. Why? The jack forces are compressive down the jack leg. On a slope the forces are compressive and sheer. These jacks are not designed for sheer forces. For that you would need a "floor jack". Not something to carry cross country. Safety John -

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

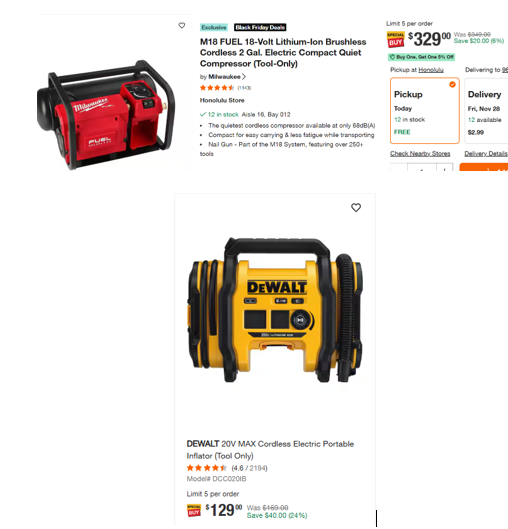

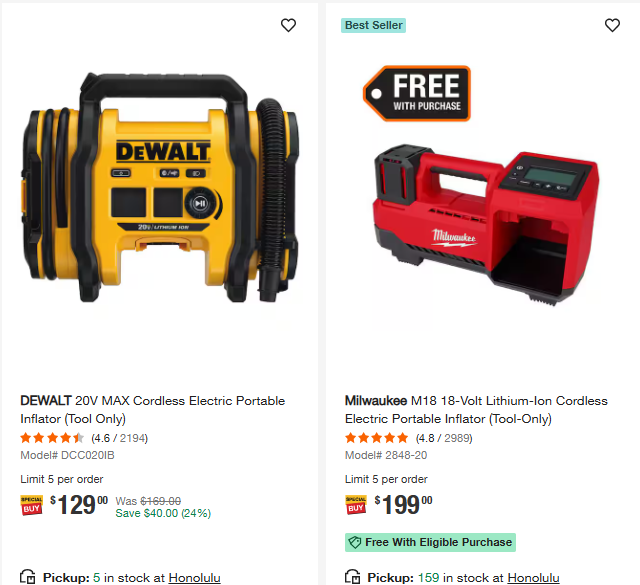

Chris: I have to agree that likely the Milwaukee line isbetter quality than the DeWalt line for just about everything. At a cost penalty of course. But the 20V vs. 18V difference compensates a bit though. In 2018 I wanted to "lighten up" my industrial tools for use in our travel gear. I was replacing my ancient (Seriously WW2 vintage) drill, impact and masonary drill. My oldest son inherited these monsters. At the time I went with the DeWalt line. One of the deciding factors was a common 20V battery, as that's the real cost factor in all of the 18/20V class lines. Since then I have acquired Dewalt multi-tool and a grinder. Have not needed to buy any additional batteries. Knock on wood.... I love my Dewalts. But, if one were to offer a 1 for 1 trade to the Milwaukee line.... I would join you. So long as I didn't have to pay for the swap. 🙂 The only Dewalt 20 V that I don't recommend is their "skill saw" my son-in-law purchased. It is a battery eater 2X/day. All the others can generally work all day on a charge while doing carpentry work. -

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

I carry pretty much the same roadside kit. I also carry a Dewalt 20V air compressor. GJ -

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

Steve: Thanks for the correction. I updated my post accordingly to "Chrome Plated" steel. Our 2018 OTT rims came with the “bulge acorn” style. Replaced them with the same style as recommended by Frank and by MaxBurner sold by Summit. They have worked very well and my standard sockets work with them. I do use a Dewalt 20V impact to remove and snug up. But for the final three tightening stages by torque wrench. (Retorque in three stages (60, 80 and 95/100 ft-#). GJ -

Changing tires in the wild - lessons learned

Geronimo John replied to John and Jodi's topic in General Discussion

This issue has been a long running one. Some time ago I copie Frank's post: OE2 LUG NUTS: Frank 😄 For anyone getting replacement lug nuts, make sure you get the proper type for aluminum wheels. The correct ones are the “bulge acorn” type which have a larger conical seating surface for use on aluminum wheels. Aluminum wheels are softer than steel wheels and require the larger seating surface. The ones installed by Oliver are the correct bulge acorn type so get the same style. “Acorn” type have a smaller conical face and are for steel rims. JPR: COMPARE SPECIFICATIONS! 24 required. I believe it was MaxBurner that turned me on th these chrome plated lug nuts from Summit Racing. My regular sockets work well with them and no interference with the wheel rims on our 2019. -

That time limit is pretty consistant with what I learned at Guntersville this past spring. For some owners who still can wax their OTT's, spending a rather large amount of $$ and amortizing it in just three years is not a positive calculation from their perspective. Now if the life of the coating were ten years, for me anyway, that would be a game changer.

-

I hear you for sure. But as an ole brown shoe engineer I beleive that glittering glossy covers don't often meet well with realities of life. Said differently: There is now no doubt that the Ceibo will work with the remote control systems listed. It matches the IR techonology and that is a given. What it does not say is that the functioning of the system "Will Do No Harm". So the real question that it does not answer is: Was the start/stop impact of the Cielo system cause any harm to the A/C in the process? I would bet a $1 Cielo did not test 175 AC brands and at least 4X that all models of AC's to make the case. Hence my Wait and See approach. Yep, I'm ole school for sure. But I'm not from the "Show Me" state, but love their motto! GJ

-

IMHO: YES! A master switch and a fuse is recommended. That said, MANY of the OE2's were wired with 4/0 AWG with a 300 amp fuse from the factory. I am running three 100 Amp Battleborns using this set-up with zero issues. Your max load with the 3000W Xantres will likely be less than my 3000W Renogy. I believe the Xantres is more efficient than mine. GJ

-

Thanks for the post. Under Houghton it shows the below T-Remote. This is the same remote used by their 3400 Houghton (Low Profile Not Ducted: The one several of us are running) as well as their 13.5 KBTU ducted unit (Not low profile).

-

I share your frustration. The product very cleaverly SOLVES the humidity issues, and gives owners greater flexability in operation of their A/C as well. However, there likely are more than a few reasons for the majority of owners to "wait and see". A big one, as I posted in the previous thread, is not knowing how numerous hard shut down and restart cycles per hour will be tolerated by the existing control boards out there. Or probable warranty impacts on new units. Not being able and willing to mod their unit as some have done with the Houghtons for about $50 in parts. Not wanting to add another complicated device in their lives. Not being able to install the device, or trouble shoot it should it fail. My hope is that manufacturers get the message that they need to provide the remote T-stat and fan control features as standard features. Oh, and in my dream state, design the units to be able to use an internal condensate drain system! Please don't wake me up. GJ

-

Greenland Turbro 13.5k Inverter AC / Heatpump install.

Geronimo John replied to CRM's topic in Ollie Modifications

I agree that the small plenum area is a root cause of noise from most RV a/c units. Why? It precludes space for proper turning vanes and insulation as you stated. I also agree that the outside portion of the noise is not a prime concern for newer designed units as we are seeing now on the market. But for the 95%+ of the units that are still out there hammer milling away... their uninsulated and non-vibration isolated designs certainly do make inside livability an issue. While on our month long Florida tour this past October, in Key West we were parked for a week next to an older Casita. Their ancient A/C noise inside our OTT was distracting. I could only imagine what it was like inside their trailer. But then I suspect due to their hearing aids it likely did not impact them at all..... -

Moving Stabilizer Jack Switches

Geronimo John replied to Tony and Rhonda's topic in Ollie Modifications

Amen to that! Not doing the check and moving Ollie ultimately will make you cry.... -

I felt the same way with the Houghton. But learned that it appears that over time the remoted thermistor and unit would track actual cabin temperature much closer than I thought. Try selecting a temp and let it run for an hour and then check the accuracy with a reliable thermometer. What I had been doing was making changes to the setting and expecting to see a result soon. Would love to know how they do that.

-

I found a thermisor with a 10' lead. I used all of it for the route that I ended up using. It got me well away from the unit and out of the airstream of the plenum. Your test is limited by the length of the existing thermisor. None the less if you shield it from the airflow it will increase validity of the effort.

-

Short version: WOW good news. Why: The Houghton's sense the delta T between the set point and the thermistor reading. For not modified units, the thermistor is in the return air path of the inside the cabin plenum. If in auto mode the fan will run high when there is a large delta T. As the cabin cools it will switch to medium, and then low fan speed. That said, many of us just run the unit on low speed. Either way, the unit would be running on low fan speed when the set point is reached. The Ciello shutting the unit down would do so when the unit is expecting to be shut down. This would be good. The consecuences of such though would be: Loss of the periodic "Stirring" of the cabin air. (A good thing in my opinion as it can be annoying especially when sleeping) No change in the short cycling of the unit due to the thermistor location in the air plenum. This would still require the Mod to relo the thermistor to a location actually in the cabin area several feet from the unit. (In my case I used a 10' long thermistor to place the thermistor at the fore end of the streetside bed. This is a relatively easy mod as compared to the relay mod for fan control. However it does require an unusual way to get there. Not being assured that the control board does not have a problem with repeated full power shut down when cycling. My two cents assuming the Cielo power cycling "does no harm" to the control board: The Houghton would only need the thermistor relo mod. It becomes "Doable" for "handy owners". With the mod, the Houghton and Cielo would provide an ultra quiet reliable unit that also can run in extremely hot conditions (122 degrees F per RecPro web site). It appears to be a game changer for Houghton and RecPro. GJ

-

Greenland Turbro 13.5k Inverter AC / Heatpump install.

Geronimo John replied to CRM's topic in Ollie Modifications

My take away from the above is that the current distribution box (Plenum) does not effectively allow good control of airflow in different directions, and that the air flow velocity is excessive out the 1/3 section that does work. I've seen several different inside plenum's and they are pretty all passively turn the air flow and discharge it into the cabin. Noise is directly attributed to that from the over roof section and the noise generated by turbulance in the plenum itself. It would be worth a try to place about 3/8" of washers between the ceiling and the plenum at each securing screw locaton. (You may need longer screws to do this.) Doing so would effectively provide a 3/8" gap all the way around the unit. Some portion of the supply air will exit via that gap. This extra air supply path will (hopefully) slow down the air velocity as the air transits into the cabin. That in theory reduce the noise associated with the current design. GJ -

I heard from an inside source a couple of years ago that their Tech guy was doing relay mod. I have not checked back with them since. As far as adapting one to the Cielo, or just doing the two mods at RECPRO or having the factory do so WOULD for sure sell a LOT of units. GJ