Leaderboard

Popular Content

Showing content with the highest reputation on 10/03/2021 in Posts

-

5 points

-

Honestly, people get phobic about "wood." As mounting, wood/marine plywood is an excellent material. Holds fasteners well, everyone (mostly) has tools to work with it, and water resistance is built in. Lasts a really long time. What's not to love?4 points

-

We have a 105# male black lab. He stays outside as much as he can tethered on a long lead to the sturdy stairs. Sleeps on the floor between the twin beds on a washable dog rug, he’s snoring there now. We reach down and pet him before we get out of bed to let him know we are not going to step on him. I blocked off the aft furnace outlet vent so it wouldn’t scorch him when it’s running. We have to sweep or vacuum daily with a mini Shark vac. Water bowl is in the shower much of the time so the slop over is manageable. We spend a lot of time looking for swimming holes.3 points

-

The E. Coli is stored in the black tank. Definitely avoid drinking from that.3 points

-

This is the bottom of the battery box without the aluminum support bracket connected. The box is firm, with no movement apparent or possible, nor with any apparent cracking of fiberglass in the battery box or in the interior, that I can tell. It looks like it was glassed in place and is resting on the wheel well, with some compression of the insulation after bolts fell out Can someone with a 2020 or 2021 take a look at there’s and see whether there is normally space between there? Opening ticket with Oliver, but given the lack of flex in the box, I’m thinking best recourse may be to just drill new holes through the ones I can see and secure as-is. Assuming I can get drill in there. Haven’t gotten a photo, but I can feel a lower hole and upper oblong hole on the floor bracket, but no play to get a pin or punch through both2 points

-

My trailer had only one bolt installed, I added a second one in the empty holes. Yes, it supports the battery floor, they definitely need to be in there, and tight…. .Look around with a mirror and flashlight or stick your phone in there and take some pics, make sure the floor is not settled or cracked around its perimeter. The floor is a piece of 1/8” diamond plate aluminum, with 1/8” fiberglass at the top and bottom. Open a support ticket, Oliver Service needs to be notified. Yours is probably not the only one with improper assembly 😳 John Davies Spokane WA2 points

-

Yep, there should bolts in those holes, the vertical angle supports the battery box. And your right about nuts and washers being MIA. If you can see through any of the holes, you might try a drift pin to line up one set of holes and get a bolt into the other set. Mossey2 points

-

One of the issues with shedding is getting fur (or hair) on the "sail switch" in the furnace. Besides using JD's advice above regarding filters, a small can of compressed air could come in handy for blowing off the switch. Bill2 points

-

Weird - A couple of years ago I was having "issues" with the remote display. Like you, Progressive sent me a new remote display. Before receiving it (shipment only took a few days) I found that the negative cable wasn't tight on the protector. I tightened that but didn't test it before installing the new display. In any case - I've not had a problem since. Good luck. Bill2 points

-

If you live near even a small town (8,000 people) there is probably a sheet metal shop near you. Simply take measurements, make a rough drawing of what you want and take it to them. You don't need "handy", you don't need talent and you don't need equipment - all you need is money. 😃 Bill2 points

-

Hello Everyone, We only started looking at Oliver Travel Trailers a couple months ago due to a need we had in the family. After reading everything we could find and watching lots of videos we decided it was the one for us. On our way home from a 36 day driving vacation out west, we decided to get an appointment to tour the factory and talk to someone in person. We met with Anita on 9/23 for the tour and discussion. As someone mentioned earlier there were several Ollie's sitting in the parking lot awaiting pickup. However, there was also one whose owner had a major health issue and was not able to pick up his 2021 Elite II. Anita told us to take a look at it. We fell in love. It had more options than we were planning to purchase, but since it was a 2021 the cost was within our budget. We bought it! And we pick it up next Wednesday, Oct. 6. We are so excited and can't wait to take our first trip. We have learned so much from these forums and are looking forward to learning a lot more from you pros. We are totally new to camping. We both recently retired and looking forward to many years in our Oliver. Thank you all for the wonderful information you have shared. Kathy1 point

-

I think the street side is always an option and it only comes powered Ralph. Steve1 point

-

Agree, really meant gelcoat. My guess is there is enough flex across the wall where the battery box is fitted to mitigate it or I would have seen damage from the unbolted condition. Looks good now...1 point

-

Ralph - Glad you found and fixed the problem but sad that it happened in the first place. Keep a close eye on that fiberglass (particularly the gelcoat in that it is more brittle than the glass itself) over the next 1,000 miles or so. Bill1 point

-

Hey Jeff, I think your Tundra will do fine. The Elite II is heavier and longer, but there are lots of folks towing with a half ton and 5.7L. We’ve been in a lot of tight FS, BLM and COE sites, I don’t think you’ll be too restricted with the larger Oliver. If you go to the Oliver main page there’s a “See an Oliver” button on the top right. That would get you set if there is someone in your area who can show. There are a lot of loyal Oliver owners, the likeable part….. 🤣. Welcome to the forum - Mike1 point

-

1 point

-

1 point

-

I suspect assembly problems at the factory, if the pilot holes are drilled too large, the screw threads will not hold. Mine are doing fine after five camping seasons. I used the same material in a 1” thickness to add additional mounting plates, I bonded the HDPE to the fiberglass with JB Weld, then screwed 6061 T6 aluminum to that with stainless sheet metal screws. As an ex A&P tech, structural aluminum is my material of choice, I won’t add any more wood to my Ollie, no way. John Davies Spokane WA1 point

-

Feeling sorta chastised now, since I commented on my water sterilization method. Sweetheart got involved and now after spending some more money, we have a Better Method to assure that I don’t comedown with ecoli.😂1 point

-

It seems like RV solutions always end up at marine-grade just as old motorcycle solutions always end up at aircraft-grade. 😉 Thanks for the suggestion.1 point

-

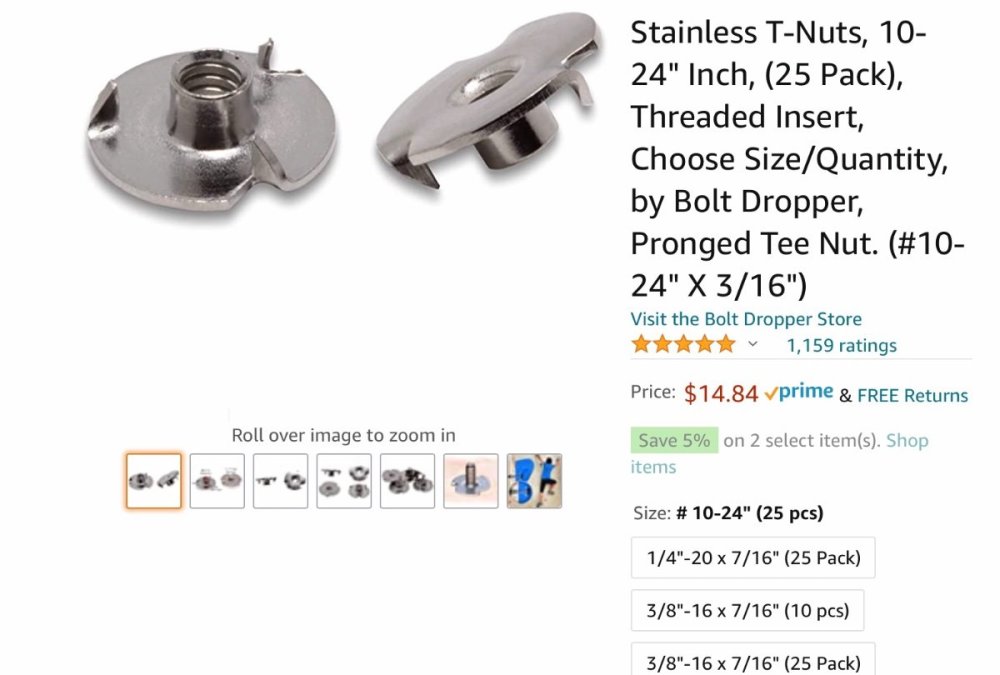

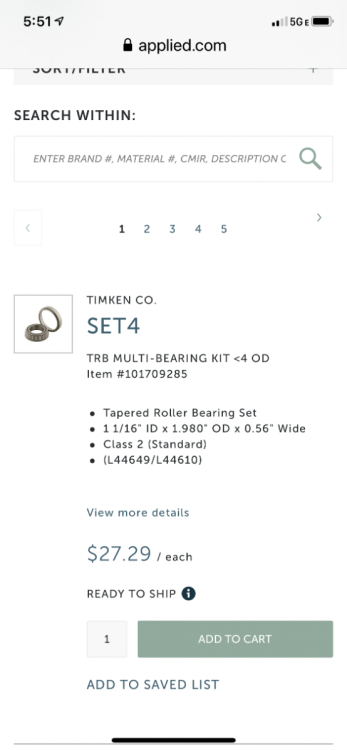

I’m planning to purchase extra bearing sets and seals to have for when the time comes to replace them. I’m skeptical of the “genuine Timken” bearings on Amazon based on previous discussions about counterfeit bearings. The low price always seems suspect, below Timken’s pricing. Set4 example shown. $12.45 on Amazon. $27.29 from the authorized distributor. Fortunately I have an authorized Timken distributor not far away.1 point

-

VBristo & Cameron: Most any heating company could make you one. Just have to fit-check it once made to see if it will hit wires or valves & the fiberglass cover will not rock around. Because i worked for a HVACR company and had installed LOTS of furnaces and AC units, I had experience in fabricating sheet metal fittings. Because of the small size 26ga or 24ga metal is fine.1 point

-

1 point

-

In regards to fur clogging vents, you could buy some inexpensive furnace filters or bulk filter material in rolls, cut out pieces and tape them over any openings at floor level, such as the furnace inlet grill and its outlets. Use a high quality blue masking tape like 3M, or even no residue gaffers tape, it won’t be hard to remove later and won’t leave residue. The masking tape should be fine for a season, since it will be out of direct sunlight, which tends to cook the glue…. Don’t forget to cover the propane CO detector too, it needs free airflow to its sensors. We used to travel with our two 40 pound Australian Labradoodles (99% non shedding) and it was fine except in wet weather, or when one found a mud puddle. But the older dog has gotten neurotic about traveling long distances, which freaks out the younger one, so we have stopped bringing them at all. My daughter house sits them for $25 per day, cheap compared to a kennel, which the dogs and their owners would hate. We and the dogs are happier with this arrangement. If we had to start over we would have only one animal, a mini Australian doodle of 20 pounds less. Non shedding, hypoalergenic, super easy to take care of, very people oriented. Great dogs! John Davies Spokane WA1 point

-

Mingy, Now let's not get too snarky here. Those of us with Ollies are fortunate not to have a unit with all the problems inherent in many stick-built units. (or hail magnets) "Stickies" do come in at a price point some can just afford to help them get their family out making smores around a campfire, or dipping a fishing pole into the water. It's about getting out there, after all. While they will not have the stamina of an Ollie. They do serve a purpose during their comparatively brief lives. Pete1 point

-

With some cross-bracing on the 'floor' of the interior wall where the mount is and judicious use of a small hydraulic jack against the aluminum mounting plate upper base(with wood between), I was able to inch the mount up so the holes matched, maybe 1/2". Not real thrilled thinking about fiberglass moving, but figured I got it back where it was from the factory. It was obvious the screws had loosened over time and bounced around in the holes before falling out. Guess I've got two nuts and four washers floating around in hull somewhere. The bolts were nice enough to drop right in a crevice by the support. I ended up installing zinc-coated bolts, with smooth portion going through the braces, in there for now, since I had them. That and double washers. John, worth getting stainless bolts with nylon locknuts? I have a hard time believing they were tight from the factory given the minimal highway miles on the trailer. 5000 miles on the trailer, but no idea when they fell out. I have no idea why they don't use nylon locknuts in places like that. Critical bolt and hard to get too.... Will see what Jason says this week, before I close it all up. This is the second time troubleshooting one small problem and discovering serious structural QC issues under the fiberglass. All fixed reasonably easily, but would have been serious if left undiscovered.0 points

-

Yes. I had repacked the bearings on the RV below just prior to this trip of 5,000 miles. I was headed east on I-70 just outside of Hays, KS and two young guys drove by telling me to pull over - the passenger side bearings had totally come apart and the whole thing was just about to catch fire. The up side of this was that I got to spend the weekend in Hays and when I got home I immediately purchased a TPMS. Between the tow and the replacing of the bearings it "only" cost me $650 and that was after AAA gave me $75 towards the tow. (Note where the spindle is relative to the hub)0 points

-

Recent Achievements

.thumb.png.fbbde3486e933f990ff511bff8d6bda0.png)