Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/2024 in all areas

-

Congratulations and welcome! From the looks of your first picture, it looks like you may already be in Mayport! The cabbage palms, sunshine, blue skies and the Atlantic Ocean in the background lead me to think you made the trip south successfully, congratulations. Mossey2 points

-

We are the new owners of Piccolino (original name as we have not yet had a decommissioning/recommissioning ceremony with appropriate amounts of rum to change the name) hull # 1346 and are on our inaugural trip from MA to Mayport FL. We had a fabulous experience with the previous owners and are thrilled with our new rolling nest and our new tow vehicle aka The Beast, 2024 GMC 2500HD Denali using the Gen-y Boss hitch. Jason and Kelly were so helpful as we marched up our learning curve in towing and Oliver's. This forum has also been a great source of information, thanks to you all. So far, our tow experience has been great, feeling very stable and at ease underway. Our first two nights saw temperatures down to 14F and we remained warm and dry. Unit is winterized with composting head so no worries for frozen lines. We have previously owned a 2016 J Navion and a 2019 Tiffen 34PA and are finding our Oliver to be so well designed, engineered and manufactured. But I have to admit, I still need to understand how the toilet paper holder is designed! See you on the road!1 point

-

Congratulations! Always happy to welcome another Ollie to the Sunshine State! Welcome home!1 point

-

1 point

-

@grweber1 Gary and I have a bit of history. His 2KW Inverter is the one removed from our hull when I upgraded to our Victron 3W MP2 inverter/charger. This 2KW Xantrex model is inverter only, no integrated charger. To upgrade to LiFePO4 he had to upgrade to the newer PD model or add the suggested pendant. This is added to the PD charger, independent of the optional inverter as wired. This was a very good reasonable upgrade for Gary, who does not have solar and just wanted an inverter for coffee makers, occasional MW use, etc. Since I upgraded to an integrated inverter/charger I disconnected the OEM PD charger vs. upgrading it for LiFePO4 (reconnect the black/hot wire to the 120V breaker panel and it can be used as backup if ever needed).1 point

-

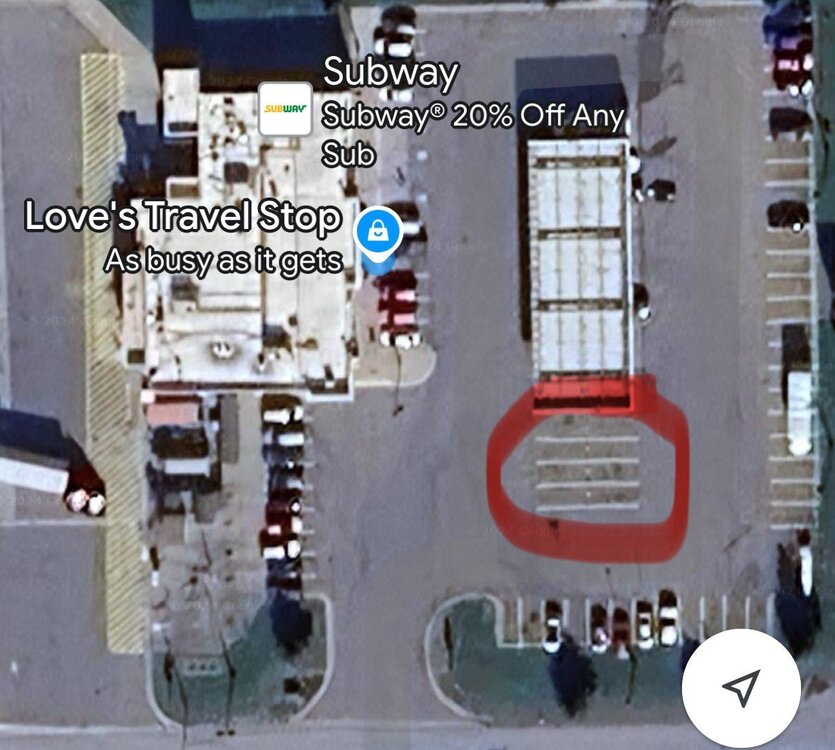

Treveling to Albuquerque, NM from New England in the middle May 2025. I am considering staying at Love's Travel Stops. One night at Love's Travel Stop in Hubbard, OH. A second night at Love's Travel Stop in St. Louis, MO. A Third night at Love's Travel Stop in Oklahoma City, OK We would like to get gas there and use the showers and bathrooms at those locations. Has anyone stayed at these location and is this a ok plan or are there other suggestions? Thanks1 point

-

@dewdev we stayed mostly at Love's during our trek down from Guelph (Canada) to Quartzsite recently, and we loved it! We did not stay at the Love's campgrounds, too $$ for our liking at $50ish when they also have free overnight designated RV stops. Obviously like Walmart and Cracker Barrel these parking spots are dry camping for overnight parking where you don't unhich, but they're open 24hrs, just off the main highway, facilities are clean, its safe, I get 10c off a gallon, and they have good coffee! Now that said, these RV parking spots are right beside the auto gas pumps (pic of Love's in Hubbard below), so it could be too noisy for some people, I sleep with earplugs and no issues with noise, and my wife sleeps like a baby even without earplugs.1 point

-

1 point

-

Geronimo, if the inverter is disconnected like that, then it wouldn't be drawing any "parasite" losses because that's how it gets its power. However, I can tell you that it’s a negligible value and a non-issue if it's turned off. It doesn't even register a value on the shunt because it's below the margin of error. My guess would be something less than 20 milliamps, which is a general stand-by current value for electronic devices. Although it’s true that old and new inverters are not efficient at inverting power, that efficiency should not be confused with stand by current when turned off, and they should always be turned off when not in use. Here are some calculated values for perspective: A 20 milliamp current would take over two years to completely drain the subject 390 amp battery. However, the afore mentioned 481 milliamp fuse panel current could drain it in 30 days. . . or less considering other battery losses and drawdown limits. That's a pretty powerful argument for doing nothing more than switching off the fuse panel breaker. For those still on the fence about installing a battery switch, I think it’s important to understand this perspective in order to make an informed decision of what option is best for them. Hey, thanks again for the kind words and Happy New Years! Geoff1 point

-

@ScubaRx gave you the basic math. So you currently have 50% of 368 for 184AH usable. The inexpensive LiTime 230 at 90% is 207AH. This would be a 12% increase in useful capacity. There should be room for two of these in the slide-out tray for future upgrade. Glad to help Gary. There are several members here who have installed LiTime batteries who could chime in on their performance. I went Epoch to achieve 2x 300AH for 600AH in the tray.1 point

-

I'm with Geoff on most of these points. The Blue Seas switch is the best available but does not come close to running 4/0 cables from the batteries straight to the inverter. Yes, you can connect it by copper bar but resistance internal to the switch is the issue, two more lugs, bolts, etc. By the time I unlock the battery bay and the padlock securing the battery tray, it only takes a wrench on one bolt at the battery ground to disconnect power when servicing. We do not store our Oliver. As Geoff wrote, "I’m in and out of the trailer enough..." Not a good idea adding another switch under the streetside bed either. I spent hours rerouting the rear bus, solar and DC breakers to the area under the rear dinette seat. I removed over 10' of #6 wire and a good 20' of #10 to the 3 stabilizer jack fuses, and much other wiring. It's crazy how OTT added length to the wiring just to put this stuff under the bed. Some wiring removed had two inline crimped butt-connectors. All the extra length and connectors adds to resistance/voltage drop. All cable runs are now shorter, just 5 ft or less. I upgraded the positive bus with one that is made of 5/16" solid copper bar (not hollow brass like the OEM bus). I replaced the neutral/ground bus with a longer heavy-duty bus and doubled the ground AWG. In doing this I also removed four #6 cables that were run directly to the +/- battery terminals. I have mod posts of all this work and less connections are better! On the last point made above. I would not be concerned if the CO monitor was not powered when truly in storage, with LP tanks off, nobody inside anyway. Turning the DC breaker off is a good idea to eliminate parasitic draw. It seems it's all that is needed. Thanks Geoff.1 point

-

Best wishes for a happy holiday season to the entire Oliver community… Best group ever!1 point

-

Geoff: Thank you. From your perspective, use, & trailer options; I can understand and respect your justification for not seeing the need for a master battery switch for your trailer. Concerning some of your responses: Increased Resistance: Yes resistance is bad and should be minimized especially with the high amperages ... as you stated. The suggested switch install in the battery box, as several of us have done, uses a short copper flat bar, and no additional lugs or extra wire. The increased resistance induced is inconsequential compared to the terrible efficiency of many of our Inverters. Especially the older ones! No Place to Install: The suggested Blue Seas Series 9000 E switch has nicely been installed in the battery bays, under the dinette seats, and under the street side bed of our trailers. Depends on your priorities. If you wanted access inside, it can be mounted inside. If you want it outside we have space the battery box for many Litho Battery installs. (But not all). Either way, locations are not an issue. Huge Size of Switch: Tilt, see above. No Compelling Reason: How about the Fire/Rescue having the ability to stop the flow of power to an inside fire? This is especially the case for Lithium installations. One of the reasons to put the switch where they will first look for it. Un-necessary Burden of turning the battery off when In and Out of the Trailer: For most of us, that is not the purpose of this switch. Many of us only use it for storage and emergency use. It takes me less than 15 seconds to turn on/off, and that happens on our first season’s voyage and off 3 - 4 months later in the fall when we winterize. But some owners likely do so more often. For Standby Power Losses During Storage: Some lucky owners such as yourself have solar and/or shore power in their storage site 365 days a year. Some owners don’t need to worry about their batteries freezing. On the other hand, some owners do not see their trailer for months at a time over winter. Collectively this means that more than a few owners do need to isolate their batteries. Additionally some battery manufactures do not recommending keeping their Litho's at full charge when not being used, especially where deep freezes occur occasionally. Simply shut off the DC breaker that supplies the DC fuse panels: The purpose of the Master Switch is to shut off ALL DC power to the trailer from their batteries. The 60-amp DC breaker does not do this. I believe that it does not terminate the power to the Inverter which is wired into the 300-amp fused via 4/0 wiring. For our trailers, if we want to kill all DC current flow, without a 300 amp breaker, which I am not aware of any OTT trailer having, we would have to remove the 300-Amp fuse or disconnect a terminal in the battery compartment. But either are a PITA. So, we do so in 15 seconds or less by turning off the Master Switch. To summarize, many of our OTT owners don’t have such a great storage solution as apparently you are blessed with. Likewise, they and others have chosen the peace of mind that the DIY installation of a Master Switch provides. I hope you and the family are enjoying a great Christmas! GJ1 point

-

I recently experienced this at my storage facility, thanks for your explanation of the probable cause!1 point

-

Hey, Chris - we met at the owner's rally last month. Wish we could've talked more about this then and exchange a ton of info... Anyhow, I'm thinking you're right on track with your approach. Breaking this down a bit, IMO - the battery upgrade (whatever AH storage you choose) and the Victron SmartShunt is what I would call Phase-1. Your 4/0 connections between the batteries and inverter are spot on. Depending on the distance to your negative and positive bus bars - you may consider at least 4 AWG, but that's just me. We upgraded with 2 BB's for a 300AH storage and its suited us very well for our style of camping and boondocking. We'd love to have 640AH or more so we could run the AC for extended periods - that's on our radar, for sure. Don't worry about the "custom" battery connections because you'll be making them yourself with the proper tools - several posts regarding this are found in these forums. The new 45W PD converter board with the Lithium switch is another spot on move on your part. We did the exact same thing last year with the BB upgrade. We've had ZERO issues (knocking on my head) with the PD converter/charger. Regarding the Blue Sky charge controller - this is a great piece of kit. We ran an MPPT BS CC on our AS with 4 AGMs with no issues. The key is if yours is a PWM or MPPT controller. You'll get way better efficiency with the MPPT version - just something to consider. We chose to go with Victron's MPPT 30A CC - very happy with its performance with the 340W worth of modules on the roof. OK, Victron. Great devices, IMO. Except for our Renogy 200W portable modules - everything so far has been a Victron upgrade for our style of boondocking. Game-changer? Maybe. But your Phase-2 might be to get your Victron DC/DC charger. There's a new 50A model available - ours is the 30A unit, but it's plenty of current to get the SOC to max-out by the end of a tow-day. These chargers are real happy running off new smart alternators in TVs manufactured since roughly 2015. @Geronimo John has a wonderful LOI (list of instructions) for this modification, TV and OTT. Phase-3: Victron's GSX monitoring system with either the 5" or 7" touch screen. The screen graphically indicates the status of your charging/load conditions with just a touch. It's a sweet addition to any Oliver owner intend on extended boondocking operations - again, this upgrade is based on your particular style of camping/boondocking. Phase-4/5: Timing of this could easily be based on when your Xantrex 2kW inverter goes Tango Uniform. When ours goes down we'll go for the Victron 3k inverter/charger. Then crank in Phase-5 - this consists of upgrading to an "efficient and quiet" 13.5kBTU HVAC unit with appropriate auto transfer switches that can operate from the battery bank for extended periods. As you've probably already experienced, this path is a very deep and broad RABBIT HOLE! What you're contemplating is not a trivial endeavor - it's like trying to eat an elephant. It's doable, but you have to take it one bite at a time... PM anytime specific challenges arise - we'd be happy to help out, brother! My $0.021 point

-

Romex is household electrical cable, usually white or whitish gray, that contains 3 wires: black, white, bare. Yes, 3 connectors: hot (black wires), neutral (white), ground (bare). They splice the feed line, water heater, and fridge lines together. I put a bend in both Romex just before the connectors and tied the Romex together before the bend with zip ties. This was to prevent cable movement from pulling directly on the connectors. Everything in the junction box. The box is what prevented a possible fire. Electrical tape.1 point

-

JD: Most of that was a joke. 🙂 Some engineers are fortunate to have the time and resources for long term project improvement efforts. Sadly, the vast majority of the engineers do not. Hopefully as we return the US economy back to that of actually making what we use, the time and resources will be available for them to do so. I believe that OTT has invested in this forum in a way as part of their quality improvement efforts. This forum and our Service Tickets are many thousands of opportunities for them to do so. And every one of the items sent their way is in fact looked at and the vast majority are resolved. I also am aware that their Quality Team is active on several of the issues we have seen in this forum discussed. So when we have a problem, those service tickets, and this forum are gold mines for their Quality efforts. That said, I could not resist the opportunity for levity with the pets, toilets and filtered drinking water crack. PS: I love dogs. Cats and Alligators not so much.1 point

-

Some of us here are adding true mods, yet many of us are making corrections for cheap parts and inadequate design, and asking why in an expensive TT. And I understand being proud of Oliver! Yes, it's a good overall design in travel trailers. Continuous improvement must be a component of company culture, and OTT has improved through the years. It starts by admitting past mistakes. @Geronimo John, you must admit, user feedback was not asking for 1.25 GPM flow at the bathroom. "Please keep the pressure low, so my wife cannot rinse her hair!" Or the seasoned engineer determining, "a 45 PSI regulator is required for the 55 PSI RV water pump system." There is a disconnect here. No physical reason can be cited. We could also reference the half-a-dozen recent threads on the furnace duct system. Reason the return is arm's length form the strongest duct. Reason the bath duct has very little air flow with no return (again with improvements through the years). Reason why the main water lines are running along and touching the back wall, the coldest area of the trailer? Reason for Dexter China bearings vs. Timken. Reason for multiple leaf spring failures? ... I need a reason, and it's not just that I'm an engineer, or that I should take your word for it because you are. You wrote, "We may not know the reason (for) it, but they know it from experience." Sorry, I can't swallow that one. Never have, and never will. Not accepting the status quo, asking "How can we do better" is the basics of good design engineering.1 point

-

Recent Achievements

.thumb.png.fbbde3486e933f990ff511bff8d6bda0.png)