-

Posts

3,136 -

Joined

-

Last visited

-

Days Won

227

Everything posted by jd1923

-

2026 YM Oliver awning style windows and other changes

jd1923 replied to Patriot's topic in Ollie Modifications

What the heck is that wood-looking thing? A valence, and for what? I installed shelves up there! Please don't take everything I write to heart. 😎 We love OTT and 2x that sentiment in owning Hull #113! But do take me seriously when working M&R on a trailer, our tow vehicles, or anything I tear apart! This mod was pretty cool, however I later mounted the cupholder (on my side only) to be rear of trailer. It was in my line-of sight when propped in bed looking out the window. Chris loves hers as-is. I just love waking up in the Oliver, crack the window shade open a few inches. Looking to see, what kind of day will it be? 😂 Give me a replacement window? My user-story is one about it functioning fully while lying in bed as it does today. Otherwise who cares? Sure is pretty! 🤣 -

2026 YM Oliver awning style windows and other changes

jd1923 replied to Patriot's topic in Ollie Modifications

For sure, we're all different! 🤣 At home 6 years ago, I removed our electric induction cooktop (it was an older cooktop, perhaps not the latest technology), ran natural gas pipe to a new cooktop. Then I used the 8 AWG wire that was for the cooktop and added a sub-panel so that our fridge and Emeril Oven would have their own 20A circuits! It's been a great kitchen mod and we would never go back. So, quite the opposite from Rob's comment. We like the simplicity of gas, what you see is the heat applied. And when camping, we must have LP for outdoor cooking, and our fire ring for sure. The LP Atwood furnace is another must have, don't want heat pump running above our heads! We're going to keep those two 30# LP tanks in addition to more/better batteries! We prefer the stainless sinks too, but can see how this would make installation easier and costs lower for OTT. This thread seems like fantasy-land to me. Out of all of us reading and writing, who is in the market for a new Oliver anyway? Not us! There is only room in life for one Oliver, for sure. I'm truly glad we prefer what we already have with mods already made. It's like when OTT went to touch lights, nothing but problems. Our old switched lights, working now 10 years, and would not change a thing. Don't want those new windows either! 🤣 -

I thought about the mod many of you have gone with and decided to go with the standard configuration. The end bolts are easier forward facing and the shackle bolts are easy enough with an elbow fitting and power grease gun. Takes a bit of extra reach or climbing under when the Zerks are facing inwards. Half the time when lubing, I’ll likely have the wheels off anyway to check brakes, adjust the “self-adjusters”, check the tires thoroughly, pressure wash the backsides, and remove all the annoying gravel (when doing so, I’ve found countless nails and other metal objects in tire treads. BTW, pulling and replacing wet bolts is NOT easy, as the bolt alignment is not always there. 🤣

-

I generally prefer working on my own vehicles (and home) vs. contracting trades. However, the reasonable amount Alcan charges for labor is well worth it! This is not as easy as it looks! 🤣 Both axles are in today. Torque the wet bolts and brake wiring yet to do. Friday I have new E-Z Flex equalizers coming.

-

Starlink Mini Installation- 2022 LEII- Alternate Approach

jd1923 replied to dhaig's topic in Ollie Modifications

Thanks for the idea! I should do a magnet mount version, since I have power and Ethernet wired to the top of our tow vehicle. Our router is inside the TV too. @SeaDawg raised one issue and the back of the Oliver is not level, so you have the get the mount angle to the north of course, and at the same time the angle off the horizon must be the same as the Mini kick-stand. Your mount has great flexibility but likely would take climbing up there a few times to get the proper angle. Thanks again and best wishes. -

-

Thanks. I came up with this idea a couple days ago and purchased these. It allowed me to disassemble all without a helper and should work the same for the installation of the new axles and leaf springs after building the assemblies on our garage floor. https://www.amazon.com/dp/B0CWTW7TQY/

-

Geoff, I thought some regulars here may notice! I did use jack stands at the fronts of the steel frame members, took them away for the picture! 🤣 I have the jack stands back under the Oliver overnight in the same front positions so the weight of the Oliver is spread over 5 points, sitting nice! With the Alcan leaf springs, I purchased everything new from them, HD shackles and new wet bolts. You may have to remove your wet bolts, the ones not accepting grease, and clean the dirt out of them. After removing ours today, they do get dirty inside! After 25K miles? It certainly could be time for new wet bolts and bushings. After 2 hours cleaning up our Dexter E-Z Flex equalizers, I found the main center bushings cock-eyed and heavily worn, the end bushings for the shackles also a bit worn. After cleaning, the center bolt sleeves just wobbled inside of the bronze bushings. I would not have known this without removing them and fully cleaning, disassembling and inspecting them. I need to replace them, but cannot wait for parts now with work in process. I have no idea total miles on our hull. Good to get a fresh start after 10 years. I've got a whole lot more to write about soon!

- 800 replies

-

- 11

-

-

-

-

3500 pound versus 5200 pound axles on a LE2

jd1923 replied to John and Debbie's topic in General Discussion

I'm installing ours this weekend (more info soon)... Out with the old and soon in with the new D52 axles and Alcan leaf springs! 😂 -

3500 pound versus 5200 pound axles on a LE2

jd1923 replied to John and Debbie's topic in General Discussion

I just ran across this older post... You'll be happy to know they are NTN brand made in Japan! More info here: https://olivertraveltrailers.com/forums/topic/11020-dexter-nev-r-lubetm-bearings-–-will-bearing-replacement-be-necessary-on-the-road/#comment-119901 -

Water Pump Switch in Bathroom

jd1923 replied to David and Gail's topic in Mechanical & Technical Tips

Thank you Geoff. This is so nicely and concisely stated, now easy to understand! So if I truly do understand, when ON one of the 3-way switches is supplying power to the pump, by connecting 'hot' to the 'traveler' and the pump is grounded independent of the 3-way switches. -

Water Pump Switch in Bathroom

jd1923 replied to David and Gail's topic in Mechanical & Technical Tips

It's odd but true that the simple OEM ShurFlo water pump has two RED wires (see pic1, look very closely) which means it would run in either polarity. When I upgraded our water pump it certainly had explicit RED/BLACK wiring designating DC polarity (see pic2). The water pump switches are 3-way. You need to get the RED positive connected to the correct lead and the two other brown wires are grounds and perhaps the order of these two wires do not matter, but of course they must stay connected. Perhaps on our hull we were lucky to have a past owner to correct these many issues, but in two years, we have not had a wire disconnect while traveling, never a window shade fall off, a kitchen drawer open, or anything else. Thank goodness our black and grey tanks drain without incidents... The Oliver is a robust campin' machine! 🤣 -

Weatherstripping/molding for doghouse cover

jd1923 replied to Fritz's topic in Mechanical & Technical Tips

This is what I used: https://a.co/d/cytULgu- 1 reply

-

- 4

-

-

Likely not, when first hitched. However after towing, the engine, trans, everything connected and under the hood gets very hot! The hot starter armature and battery cables will create resistance requiring more current to turn and start than when cold. Also as the starter armature gets fried, carbon buildup will also create mechanical resistance requiring more current to turn. Given the new starter resolves this issue, it shows the starter was on its way out and soon or later would not start the engine even when cold.

-

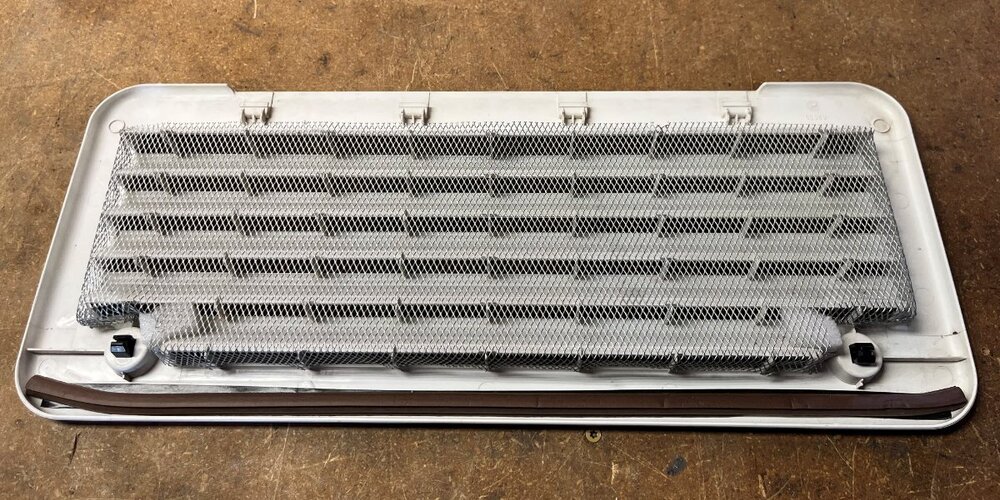

There was another thread re bug screens, so I added them after my fan install. I went with the idea Ron mentioned. It was very easy to make my own screens. I had a roll of 6" aluminum screening we had purchased for bug-proofing air vents in our home. I did the same for upper and lower screens, cutting and bending the screening to fit. You can't see it but I riveted the screens to the plastic vents, two rivets on each left and right sides. They made the vents fit nice and snugly, where before they rattled around a bit, even after adding new push-turn mounts. New fans, new screens, mod done! 😂

-

Dexter does not set the self-adjusters, as they come new very loose. I’ve heard this now from you and others with new axles. When I pulled a drum off a new axle it came off wobbling like the OD of the shoes was much smaller than ID of the drum. They must believe they will adjust soon enough. Not good when you drive off just installed and hit mountain roads! I’ll tighten mine up some, to the point I can just hear a light scraping sound, shoes on drum, before I mount the wheels. 😂 I just installed new rear shoes on our truck rear drum brakes. I overdid the adjustment! The brakes were so good, that the parking brake engaged with a 1” push on the pedal, and I found the rears were braking while coasting! 🤣 Understanding the issue, next day I lifted the rear of the truck and loosened the self-adjusters about 1 1/2 turns and my new brakes are now working perfectly, better than ever! 😂

-

Alcan negotiated with Dexter and they agreed to refund my shipping cost. Thanks to Lew at Alcan for working this out for such a positive outcome, to David for this good idea, and to Ron, Ken and @2008RN for your related comments. They promised a 2-week rush build, and today, exactly two weeks after I entered my complaint, I have new axles delivered! They sure are pretty this time, so the extra time was well worth it.😂 I'm working this week, followed by 10 days off. So likely this Friday or latest Monday, I'll hitch up the Oliver and park it on our driveway. Then all I have to do is figure out, how in the heck to install new Dexter D52 axles and Alcan Springs!!! Love the challenge of a new project, learning something new and the achievement! I'll take pics and start a new installation thread when I get into it. Can't wait to see a picture of our Oliver sitting up in the air without axles, leaf springs, wheels or tires! Or perhaps to be safe, I should remove and replace one axle at a time! 🤣

-

I have.no idea how this happpened

jd1923 replied to Dennis and Melissa's topic in General Discussion

I believe it is. The tire is still well planted on the bead of the wheel. That lip edge is superficial. You’re going to want to source a like wheel and center cap soon, but you should be safe finishing your trip. Try to keep that trailer on the road! 🤣 -

Congrats and good to know OTT is over the 1600 mark!

-

Beech Lane attaches labels to both sides! Look at the two photos I attached, and Ron's, and note the side where the wires are showing which is the exhaust side. When you look at the my first picture and Ron's you see the wires and the fan bracketing (the exhaust side). My second picture show just the fan blades, with wiring and frame on the back side. I did not realize these were "designed to be in the lower cabinet." I must have missed that as I'm not one to carefully read instructions vs. just start installing parts! 🤣 My thought when installing was exactly what Ron stated here. I also tried the additional interior fridge fan that Ron suggested, but returned that one as I could not measure fridge interior temperature improvement, it took valuable fridge space and you could hear the fan when sitting at the dinette. Geoff ended up with a superior installation with his great knowledge of wiring sensors and switches. The Beech Lane control box, although I installed it in the interior cabinet above the microwave where the LEDs are not visible, you still have to reach in there every time you turn the fan switch giving it power. Correct it will not remember a previous setting when last powered on. I do not use its temp sensing function, even though it's wired for that. When camped on a hot afternoon, I will turn the panel switch on and then the fan to 50% speed on the control box (the lowest speed setting) and generally I hear the fan running after dinner or before bed and with the panel switch turning it off is easy! It appears in Geoff's installation the fan is powered by temp sensor where ON/OFF is automated! 😂 I was able to feed wires without removing the microwave which is a bit of a trick! DC power is located through the bottom vent and it's easy to feed new wires to the upper vent. Then I poked through the upper insulation with an electrician's steel fish-tape to push new wires to the panel switch. With a curved section of fish-tape I was able to follow the curve of the hull up into the cabinet above the microwave for the fan control.

-

Nice work Geoff, as always. Your aluminum frame is a very well crafted! I did mine last summer. I have the control panel in the cabinet above the microwave and we switch it on most hot afternoons. Beech Lane makes a good fan and it moves a lot of heat out from behind the fridge. I purchased a second fan that cools the basement area where I installed our Victron MP2 inverter-charger. Not near as much heat down there, but use it on occasion.

-

Do you drink the water from your fresh tank?

jd1923 replied to Dennis and Melissa's topic in General Discussion

I felt the same way until recently. There could never be enough cold water, with room in the fridge for at most 6 water bottles. We make ice too, but for drinks other than water. I long pooh-poohed the idea of an extra fridge, but it makes all the difference in the world to ALWAYS have fresh cold water! We keep 1-2 of these pitchers full in the outside fridge and one inside. When the inside one empties, I bring in one from outside and refill one so we always have one cold in and another cold one outside. Another 6-8 store-bought water bottles outside too for anybody who needs one. Now I'm getting thirsty! It's how we roll. 🤣 https://www.amazon.com/dp/B08VFK4WS6/?th=1 https://olivertraveltrailers.com/forums/topic/11018-dometic-cfx5-refrigerator-tow-vehicle-installation-with-solar-power/ -

Do you drink the water from your fresh tank?

jd1923 replied to Dennis and Melissa's topic in General Discussion

No, not drinking from RV water tanks! And as @routlaw wrote, we do not use it for cooking either. We too had been doing your #1 until more recently we started with your #2 idea. I didn't want 5-gal containers, too heavy, and we have ample room with a long-bed truck so don't need collapsible. I purchased some 2.5-gal and 1-gal food-safe PBA-free plastic containers from Hudson Exchange: https://www.amazon.com/dp/B07G9MT3MB?th=1 https://www.amazon.com/dp/B06XVZ3X49 I fill two or more 2.5-gal containers, stored in the truck bed with an insulated cover (to keep out of sun since we have an open bed). And fill four 1-gal bottles kept on the closet floor, with one handy on the floor under the dinette. On average, we use at least 1-gal a day for coffee, cooking and Charley's drinking water. 🐶 Last time out was a 6-day trip and we had all the filtered drinking water we needed filled from home. When three 1-gal bottles empty, I refill 3 about 85% full using one 2.5-gal jug. We also bring the Clearsource 2-filter system so water from a campground is filtered. And we purchased these to keep cold drinking water ready in our new Dometic CFX5 45L cooler! Drinking from good quality cups or Thermos bottles instead of endless plastic water bottles of which I could easily consume 6 water bottles a day! https://www.amazon.com/dp/B08VFK4WS6?ref=fed_asin_title&th=1 We really like how this is working and should have done it sooner. A lot less trips to grocery stores or Walmart merely to buy water! -

NO BRAKES ; 2019 Oliver Elite II-Hull #448

jd1923 replied to BoondockingAirstream's topic in Mechanical & Technical Tips

You need to get some elevation! Was in the mid 90s today. We had our 3rd brief Monsoon rain for the season after 10 months of drought. Sitting pretty at 5440 ft, and now at 7:30PM it’s 67F now, windy with a drizzle, turned off the A/C, opened the windows. Life is Good! 🤣