-

Posts

3,137 -

Joined

-

Last visited

-

Days Won

227

Everything posted by jd1923

-

Christian, it's thorough of you to replace new equalizers too. I observed the internal bushing wear that can only be recognized when disassembled, not sitting mounted. The dual-lever design of the EZ Flex equalizer causes the center sleeve to swivel back and forth with use, ovaling the bushings on each lever. My guess is that any trailer that has run several years, greater than 20K miles should replace this part. I'm happy that ALL hardware has been replaced in working my upgrade. I wasn't sure re the red ones The red ones states 8000 LB and eTrailer does not have a weight spec listed on the gold ones. Our EZ Flex was installed in 2018 and they were gold, so I order the gold ones which comes to a $45 + tax savings. I also purchased two new mounting bolts for the equalizers. Red or Gold are for 35" wheel centers and they both show the same measurements picture showing 7 3/4" center-to-center left-to-right. I ordered two of these and two mounting bolts as well. Congratulations on your new Oliver!!! 😂 https://www.etrailer.com/Trailer-Suspension-Parts/Dexter/013-144-03.html https://www.etrailer.com/Trailer-Suspension-Parts/TruRyde/TRFA73Z916DLNZ.html

-

Full Suspension Replacement - Alcan Spring and Dexter D52 Axles

jd1923 replied to jd1923's topic in Ollie Modifications

It was exactly 2 weeks as promised and the replacement axles were here. This time they were mounted on a custom pallet 100" long! Two steel straps holding one to the other and two nylon straps to the skid, and no furniture wrap! 🤣 It's time for the work to begin. I'll walk through the process but enough for today. It's been fun working on this, first axles install ever for me! There will be several points to consider in having this work done, that I will discuss later. Not too many of us would do this work ourselves. Going to Alcan Spring is a great excuse to visit SW Colorado! 😂 -

Full Suspension Replacement - Alcan Spring and Dexter D52 Axles

jd1923 replied to jd1923's topic in Ollie Modifications

So while I was waiting for the new shipment, I thought why not check out the inner workings of the Dexter Nev-R Lube bearing? In seemed a reasonable use while these damaged axles were hogging up space on my garage floor! -

Full Suspension Replacement - Alcan Spring and Dexter D52 Axles

jd1923 replied to jd1923's topic in Ollie Modifications

Dexter estimated 3-4 weeks to manufacture the new D52 axles, and it was just 4 weeks when they were delivered to our home. The bad news was that Dexter did such poor job packaging they came to me a basket case. What a waste! They used a single nylon strap (and a whole lot of stretch wrap) to secure the two heavy axles to a standard sized skid. But trailer axles are longer than a skid! They had slipped off to one side! FedEx Freight propped up their packaging on another skid but the damaged had been done. The one drum hanging lowest took a bad bang bending the brake backing plate, to the point that the drum could not turn at all. These could have been repaired, but soon enough I decided to refuse the shipment. Why should I pay over $2K for this mess?! On the weekend, I emailed Tim at Alcan Spring to report the damage, several pics included. When Tim called me first thing Monday morning, he already had contacted Dexter re the shipping damage and got them to place a rush replacement order, with promised delivery in 2 weeks. I accepted their offer. -

Full Suspension Replacement - Alcan Spring and Dexter D52 Axles

jd1923 replied to jd1923's topic in Ollie Modifications

Met up with Ken and Mary Kay in Montrose and we had a great time together! They had dinner ready for our for first night at Riverbend RV Park, considering our long day. Our second night we went to dinner at Ted Nelson’s Steakhouse! A couple days later we had another evening together at our next campsite, Basecamp550 between Ridgway and Ouray. We headed home slowly, other good camps along the way. They stayed another few days at Riverbend until their scheduled Alcan Service appointment. -

Full Suspension Replacement - Alcan Spring and Dexter D52 Axles

jd1923 replied to jd1923's topic in Ollie Modifications

Seeing is believing! I’ve worked manufacturing a few times in my career, like the ol’-school RAM Golf Club manufacturing back in the early 70s in Melrose Park IL. Later I spent a decade, the 90s in Motorola manufacturing! My immediate first impression, observing a relatively small manufacturing facility which I truly appreciated! I realized a team of good people, working hard with little to no BS, and as busy as they were they took time with me, helped me answering all of my questions. If they could have serviced me that day, or that week, I would have stayed and had the work done. I knew from the start that I would not upgrade springs without upgrading to D52 axles. I’m one of the unlucky few who not only got the inferior D35 axles, but also in a half dozen hulls where OTT installed the 1/2" shorter 50” axles (what the, why?)! Alcan had a skid full of the 50.5” axles from all their Oliver business of late, but replacement of the rare 50” axles must be special ordered! So I’m talking/texting with Ken, when he said, “Don’t let them sell you my springs! 🤣 Ken had a service appointment scheduled for the very next week. I purchased Alcan Springs on this day. When Tim said, they could special order for me the correct 50” axles for our hull and charge me the same going price Oliver owners were paying for the 50.5” axles which they had purchased in bulk. This read like a very good one-time good offer, from a helpful, fully knowledgeable company rep! This is TRUE Customer Service! 😂 All I could say is “let’s do it!” Renee wrote up the order. Tanner assembled the leaf spring parts they manufacture in house, and then he went through their installation instructions and torque specs and later loaded the spring parts in my truck. I wrote Renee a check for half+ down and an hour later we were back on our trip! What was accomplished in an hour was spectacular! Lunch and a fuel stop in Grand Junction and we’re headed out of town… -

Our OEM suspension was still in good shape. I had worked a full brake service, including the Timken bearing upgrade, two years ago just after we purchased our Oliver June of 2023. Our OEM leaf springs were still properly arced and no rust given life in the SW, never an issue. Until the “Made in USA leaf springs” forum post came up, I had not worried about it, nor ever concerned that the Oliver suspension might be undersized in some way. I headed the warning, but not at first wanting to pay for this extensive upgrade, so I purchased a spare pair of 1750 LB leaf springs and U-bolts to have on hand in case of possible failure on the road. We were on our 5-week June trip to Minnesota, and on the way back we took the northern route. I wasn’t at all thinking about a suspension upgrade! I’m in regular communication with our friend Ken @mountainoliver and realized they were camping in Colorado and perhaps we could meet up. They were there waiting for their scheduled appointment at Alcan Spring in Grand Junction CO. At the time, we were camped in North Dakota on the great Missouri River! But were soon cross Colorado from the NE to the SW on the way back home. Given we could see our friends and the many mentions of Alcan on the Forum, I thought we should visit Alcan Spring to at observe their operation. I called and talked to Tim and made an appointment to visit, not a service appointment. "Every picture tells the story" don't it! The first pic is much later in the process as a preview and the second one was only two years ago after working a complete brake/bearing maintenance. I believed we were good! 🤣

-

Our Oliver came with the Lippert chrome manual lock. We also read here regarding many failures to the touch pad and batteries loosing charge at just the wrong time. $220+ for keyless entry, sorry no thank you. Our hull being 10 years old, the door lock is still working as designed but gear mechanisms and striker parts do wear out over time. I found this on Amazon and at the time it was only $50, same lock in a nice white powder coat. It's for when we need it or when we may upgrade our entrance door. And yes, extra keys are easy to have on hand too! Just match the code on your key to your order. https://www.amazon.com/dp/B00S2IELG6?ref=fed_asin_title https://www.amazon.com/Pair-Keys-Global-Link-Precut/dp/B0BQWVR6YP/?th=1

-

Incredible noisy AC, any solutions in sight.

jd1923 replied to Nick and Linda Stratigakis's topic in General Discussion

Yeah, the OEM Dometic A/C is a horrible POS and to not bother your next neighbor, and to get some sleep yourself, you will eventually replace it (sooner rather than later). Search on this Forum for keywords like Atmos, Tosot, Turbro, Greenland and Pioneer, maybe even Houghton is still viable (nice if Houghton brings an inverter A/C to the states). -

Doesn't she look pretty?! 🤣 We ran two 30 mile test runs, U-bolts torqued now 3 times. Before the test drive today, I manually pushed the little self-adjuster gears on all 4 wheels. She was braking quite well today, so very nice after so little mileage. New D52 axles, new HD leaf springs, new EZ Flex equalizers, new wet bolts and HD shackles, totally new suspension! 😂

-

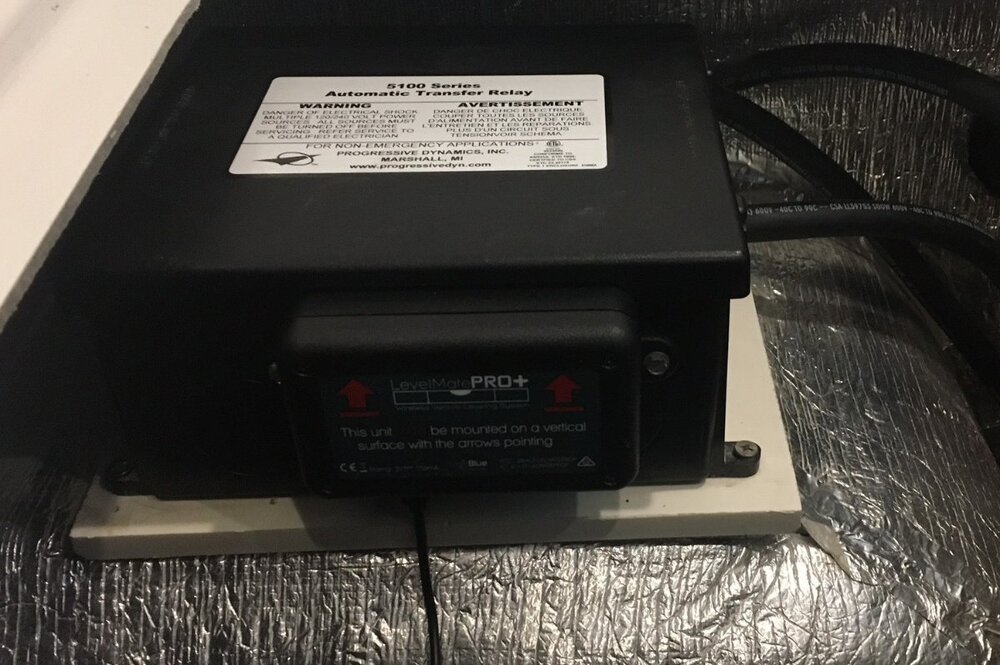

No complaints EVER on the LevelMatePRO+! Make sure you get the '+' model. Batteries, big batteries, we don't need no stinkin' batteries! You hardwire the + model to 12V in any easy location, like under dinette seat where 12V connections are right there. Know you'll never have to touch it again, leave it always ON, always working, always active when needed! 🤣

-

We moved back to our AZ home seven years ago after living for 12 years back and forth between two homes, where my tools were spread between the two and my truck. On Craig's I found large stand-up Snap-on toolbox and was lucky to find a huge, well made workbench setup that Adam and I disassembled to move and rebuilt it to fit a custom L-shaped layout around 2 stalls of our 3-car garage, the center stall being my workspace. I also found a used Tuff Shed for storage, so my garage would be solely an auto workshop, not junked up with storage items. I installed other standing toolboxes and cabinets, enough room for a major 45-year collection of hand tools and spare parts. Then I emptied every hand-carry toolbox into the larger stationery toolboxes. During a winter cold-spell I spent days sorting our every box and package I hade with nuts & bolts, auto parts, electrical and plumbing parts. , etc. I bought a case of blue plastic single-gang electrical boxes (cheap effective storage bins) to hold all the small screws, nuts & bolts, nails, crimp parts..., drawers full of them in mounted file cabinets. For years now to the present, I know where every tool and most spare parts are located. I return all tools to where they belong daily, unless I'm in the middle of a job I will continue the very next day. Spending considerable time in organizing your tools is well worth it. I get repairs done now in half the time, not having to hunt for parts and tools! In getting ready to work, climbing under truck or trailer, I think a hard 5-10 minutes and collect part & tools needed in flat plastic trays that I lay on the ground where I'm working. The other thing I bring, since I/we will always forget something is my phone. With Chris' office just inside our home from the garage entrance, she's nearby and often happy to help. 😂 She'll come out to hand me a tool or two, knowing its easier for her to do so vs. what it takes me to get off a hard garage floor, and then climb down again. I do mean the word 'climb' as the downs and ups are not as easy as they used to be! 🤣 We all prefer to work preventive maintenance at home vs. getting stuck on the road. I have enough extras that I've assembled a small dedicated toolbox and a plastic parts box for the Oliver. They sit in the bottom of my large truck toolbox along with a 3/4" breaker bar, cheater bar and other long items. Proud to be keeping our truck and trailer in good maintenance so that these tools just sit ready, and have not been yet needed, 124 overnights in two years with our Oliver! Hope to never need them, but I have what we need to change tires, bearings, leaf springs or do a truck repair, like replacing an alternator or water pump on the road. Now that we've upgraded to Alcan Leaf Springs, I just removed the spare set of 1750 LB springs from the TV. The Alcans are not going to fail in my lifetime, though I do have tools with to replace wet bolts/bushings or most anything else!

-

I serviced the front jack after we purchased our Oliver near 2 years ago. It sounded dry and the front lift jack is certainly used at least 2x more often than the rears. The rears are also protected from the elements. To date the motor/gear sounds on the rear jacks where good. I've been replacing the Dexter axles and leaf springs on our Oliver and using the rear jacks for the heavy lift, getting the wheels off the ground, a few times in the last couple weeks. Yesterday the curbside sounded like the motor was drawing too much current (slowing down) and then started clicking not lifting. The clicking sound was like the sound you get when releasing the jack, lifting the shaft too high hitting the stop, but it made this sound while pushing down to lift the trailer, only halfway up, nowhere near the 18" lift-height of the VIP3000. From rebuilding the front jack, I noted wear on the worm-drive gear that's attached to the motor (see picture of motor gear from my front jack service). If the rears show the same upon disassembly, I will need to replace the motor(s). I found this part with a quick search. I can buy 3 of these for the cost of one complete VIP3000 and we know the rear jacks have a custom weld that must be reused or replaced. https://highskyrvparts.com/barker-mfg-trailer-landing-gear-motor-16263 Have any of you have to service your rear jacks, including replacing any worn parts? I understand how to remove them and service them. I guess I'll only know after I remove the jack that is presently not functioning. See page 2 of this link to see the service I worked on the front jack. I will keep y'all posted on the repair... https://olivertraveltrailers.com/forums/topic/4094-how-to-vip-3000-electric-stabilizer-jack-service/page/2/#comment-94339

-

Yes, English Spring Spaniel, liver & white!

-

No easy path! 🤣 The outer and interior shells of the Oliver are tight and in-between, lot'sa luck in doing so. Many have asked, but nobody on this forum has demonstrated a viable build. Perhaps it's an idea that does not have a feasible solution. IMO, drop the idea. In the same vain, I wonder why some want an inferior 12V television, when with LiFePO4 batteries an inverter can simply run an 120VAC TV. 12V TVs have limited selection and truly lame resolution. Instead I prefer to run a 4K high-def Samsung monitor, 3/4" thin white and beautiful on 120VAC. IMHO...

-

Reason to ask more questions! There's no such thing as a dumb question (what I tell my students daily in project management training). Many members here want to help. All questions are good and you've already shown you search the forum first, ask good questions, and have quickly added a proper signature. To operate trucks, tow vehicles effectively, and towing trailers requires a wealth of knowledge! What can we help you with! 😂

-

Bring up your cute little kitten soon in the Oliver and s/he will love it. Spend time in the Oliver and driving in the tow vehicle regularly, no problems. Dogs are easy. Charley loves the Oliver, though he prefers the TV and the sound of the Cummins! We better have him in his personal back seat in the truck, before I start 'er up, or he thinks we could leave without him! He doesn't understand we would never leave without him! 🐶

-

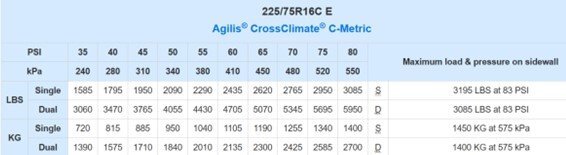

I run 45 PSI highway and when boondocking on local washboard roads I reduce to 38 PSI. I was just testing our new suspension over speed bumps at 45 PSI and I could see the tires nicely compress while taking in the speed bump. 40 PSI is enough however since we are certainly running less than 7K LBS GTW. Some have written they will lower the tire PSI because of the stiffer springs. PSI should be determined on trailer weight. This upgrade has likely added about 150 LBS in heavier parts. Running D52 axles and Alcan springs going a little over the 7K GTWR should not be a big deal. With axles, springs, wheels and tires that can handle over 10K LBS, only the Oliver frame is the limiting factor. We know a member with multiple upgrades, upgraded suspension with disc brakes, my guess is he is well over 8K LBS actual GTW. 45 PSI is a good MAX number for most. I do not believe in adding PSI as a buffer allowing notification time using a TPMS. The PSI should be adjusted for actual GTW only. On the Michelin Agilis 40 PSI gives you 7,180 LBS and 45 allows up to 7,800. 50 PSI allows for 8,360 LBS GTW. Do you need more pressure?

-

Yes 120VAC, and so are the inverter-compressor models like the Turbro Greenland and Pioneer. 12VDC requires running new heavy gauge wire from batteries to the A/C location on the roof since the amperage draw of 12VDC is 10x more than when running on 120VAC. Therefore, 12VDC models are generally light-duty with BTU ratings under 10K vs. 13.5 to 15K BTU that is required for living and camping in most of the USA!

-

Welcome Pat to our wonderful Oliver TT Forum and Community!

-

First @Mountainman198, Lance get the cat OFF the dinner table! 🤣 We have dogs now, but Mom was a cat lover, we were brought up with cats. They prefer their own space! Bill & Nancy, love your idea to mod the front dinette area! Give it some real thought while taking some time developing your best plan. Being an Oliver Mod guy… you have a very good idea.

-

Wow, never seen a post after the phrase, “9 years later!” That’s almost as old as our old hull. 🤣 You can put all the hardware you want on your Oliver and if I wanted to, I’d just wrap a chain to the front of your trailer, winch it up on the back of any truck and drag it down the street, gone! Some believe planting the stabilizer jacks down and switching off the jack power helps. No, no way, do that and as I’m dragging your Oliver down the street, you’ve just caused damage to your 3 jacks and likely body damage to your hull. Yep, good news is there’s not a black market for Oliver parts, given we are a small tight-knit community. I promise you thieves would target Winnebago and the other big names. I’ve never seen “Parting an Oliver” on Craig’s! 🤣 Get insurance, do the security basics, and enjoy life in your Oliver! This is coming from a man, brought up in Chicago, the crime capital of the most of the US, where back in the day, I would bar the windows in my garages on the West Side! We try to leave these negative feelings in the past. Try to enjoy more than you worry. Now at home on purpose, I leave our cars unlocked overnight! It’s therapy. There is enough to worry about trailering an Oliver through the mountains and to remote corners of America. Have FUN! 😂

-

Good to know and we're looking forward to your build thread! 😎

-

Hardwire your LevelMate Pro for under a buck!

jd1923 replied to Snackchaser's topic in Ollie Modifications

It sure is! And as usual Geoff... You can wire anything that comes to mind (we are not worthy) 🤣! This is a GREAT upgrade for anybody who already has the PRO vs. the preferred PRO+. When we were shopping for ours two years ago, I came close, but soon realized the PRO+ included a wiring harness. Anybody reading not have one, OMG get one and pay $120 for the PRO+ vs. $100 for the PRO. I paid $102 Nov 2023 for the PRO+! I stay in the driver's seat of the truck to level. I open the app and move back and forth to get as close as possible. Then Chris gets out after I tell here where to place the Andersen levelers. When she gets them in place, I pull up or back depending and we can be at near perfect level, set the parking brake and we're done! Running this device on battery - OMG NEVER! I would be truly upset if the app could not find the device (for a dead battery). I wired ours under the rear dinette seat, where our B+ and B- buses are located in reach of the PRO+ included wiring harness (no splices or butt connectors required). The side of the PD ATS provided a good horizontal surface, installed in a just few minutes (see pic). We would not leave home without these accessories: https://www.amazon.com/LogicBlue-Technology-LevelMatePRO-Wireless-Leveling/dp/B083ZMZPR8/?th=1 https://www.amazon.com/ANDERSEN-HITCHES-Accessories-Leveler-Leveling/dp/B01MQNGOWD/?th=1 https://www.amazon.com/ANDERSEN-Accessories-Stabilizers-Jackstands-Quickjack/dp/B0888SDR63/?th=1 If you have the PRO, certainly work Geoff's mod ASAP! If not, buy the PRO+ and if you do not have either... Get out of the dark ages! 🤣 (life is short) -

Finally done! Worked on this every-other-day this week. Looks great, doesn't she?! Alternate days are for Pickleball. My body can only take one kind of daily trauma! 🤣 Days on the court cannot be combined with hours climbing under truck or trailer! How many times did I get down on the driveway, sitting on a milk crate, craning my neck to fit under the Oliver fenders. or lying down on the ground, and then climbing back up? Way too many times, no matter how well I plan having parts and tools required! UPS came early yesterday allowing me to finish with new E-Z Flex equalizers from eTrailer (2-day ship only $6.50 extra, adding another $316 to the grand total)! You should check your equalizers. Some may have upgraded leaf springs without the equalizers being removed and cleaned up for inspection (it's the right time to do it). Details on this and other concerns soon. Look for a new thread on this subject. All that's left now is to torque and grease the wet bolts (our son Adam will power the torque wrench under the trailer and the DeWalt power grease gun makes this easy). Mount wheels & tires and test drive. I'll tow some miles on local highways and hilly/winding roads, then retorque the U-bolts upon return. Park the Oliver to free up my driveway again. Another trip to Southwestern Colorado is just 3 weeks away!

- 800 replies

-

- 10

-

-