-

Posts

2,305 -

Joined

-

Last visited

-

Days Won

64

Everything posted by Geronimo John

-

John: Your keeping the shades a bit above the track is a good idea for winter storage as well. The shades don't provide much insulation so why keep them in a potential wet zone? Good idea... Thanks GJ

-

Newbies taking the plunge - Are we missing anything

Geronimo John replied to Dennis and Melissa's topic in General Discussion

I recommend you check your vent stack in the closet and below the decks. You should not be selling smelling anything. GJ -

3Way Refrigerator Fan - Advice/Photos Please

Geronimo John replied to Wandering Sagebrush's topic in General Discussion

Hull #364 - The Roadrunner 2023 F350 CCLB SRW 6.7L Not knowing your year, but guessing your Hull 364 is a 2018 as is ours. If that's the case, your should look like mine and it is the same as Rideandfly's pictures. We had under cooling and over heating concerns and added the double fan posted above. it has helped quite a bit in very warm or HOT conditions. GJ -

3Way Refrigerator Fan - Advice/Photos Please

Geronimo John replied to Wandering Sagebrush's topic in General Discussion

Here's my DIY document for refer fan. GJ DYI - Titan Motorhome Fridg Fan.docx -

GJ NOTE: Below costs were created with total disregard for either the cost of money or inflation: +++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Several times I, and other owners have discussed running dehumidifiers as you successfully do. For a group of us though that can't monitor our trailers for months at a time, the issue becomes the condensate pan service. Your post rekindled this problem and sparked an idea that may work. I store Ollie covered in a dark barn. In the fall, as part of my winterization I run the A/C temp down to around 60 degrees F to dehumidify as best as possible. OPTION ONE - DAMP RID: To aid in humidity control, I use two of the large Damp Rid buckets and deploy them inside Ollie before I protect her further with a trailer cover. Each summer I uncover her and the Damp Rid buckets have fully exhausted their abilities. So, I know that at some point they have no longer been able to keep the humidity quite low. That said, I have not had any problems so far. The Damp Rid costs $28. Three year Damp Rid cost = $84 OPTION TWO - PRO BREEZE: To use the Pro Breeze for extended unattended use, I would place it on the counter by the sink. Then place a funnel and drain tube under the existing condensate drain port . As the Pro Breeze worked it's magic, the condensate would drop into the funnel and down the drain tube. I would run the tube down the kitchen sink drain and past its P-Trap. Once past the P-Trap, the condensate would drain downhill to the gray water tank. By running the hose past the kitchen sink P-trap it would not render the P-trap antifreeze in the trap ineffective. I would keep the trailer nose a bit high and crack the gray water tank drain valve a bit open to ameliorate the Pro Breeze condensate freezing concerns. The hardware to install likely would include a freeze stat to prevent running of the unit when temperatures are below freezing. The costs of this would option are about: $28/year in power (Assumes 4380 hours run time, at 16 cents/kwh.) Three year power cost: $84. Hardware, about $30. Assuming it lasts three years, $70. Three year Pro Breeze cost = $184 Your thoughts? Any better ideas?

-

Newbies taking the plunge - Are we missing anything

Geronimo John replied to Dennis and Melissa's topic in General Discussion

Smell just Much more likely is you are smelling one of the sources as mentioned above. But just to cover a very remote possible source not yet mentioned: Take a strong wiff of your over the door head bumper. Could have gotten wet and went south on you. Not likely, but worth a 4 second check. GJ -

Simple AGM to Lithium Conversion question(s)

Geronimo John replied to Danno and Donna's topic in Mechanical & Technical Tips

Ditto with our hull. I really prefer having the Inverter and Converter units physically isolated. Problem potential for a "double whammy" power outage is pretty much eliminated. Also, when our the combined 120V Load Center/Converter fails, I'll replace it with two separate components. This will reduce the potential of a Converter failure impacting the Load Center or the converse. Other energy redundancy options to consider: Dual fuel/power refrigerators (120V and 12V) unit with Danfos compressor. Heat Pump vs. AC for second heat source (Plus having a cheap ole 1500 watt plug in heater). Converter, Solar, Litho's, DC to DC , and Generator charging systems. A second 120V auto transfer switch for the A/C (Serves as an installed spare should the primary fail too). Twin Furion power ports. (A lower priority to the above.). Having an inexpensive 400 watt 12V to 120V converter with alligator clips on the 12V inputs. This one will ruffle some feathers: Not having totally necessary electronic systems for controlling of power/energy that may put you electrically wise out of business from all power sources with a single lightening strike on the RV park electric poles. Having at least 50 feet of 12 AWG ( plugged for 20 Amp draw) or 10 AWG power extension cords. With an assortment of electrical adaptors. A 15 amp multi plug strip. Saran wrap to weather proof the above two items should rain be expected. What other redundancy energy ideas can we think of? GJ -

Best Bumper Rack for Honda EU generator?

Geronimo John replied to Margaret's topic in Mechanical & Technical Tips

You and Joe did a nice job to create a secure yet light weight storage solution for your Honda. I really like the idea of open door, remove Honda gas cap, and fill through the top plate fueling port. Also the fan and electrical options that are included such as hard wiring a plug to the trailer panel for distribution, as well as having a single phase plug so that another trailer could plug into your single phase 30 amp plug and share some power. I am curious as to why it was mounted on 4X4"s/ It appears to encroach just a bit on the Bulldog, but not that much. The only option I can think of is to add a bolder catcher filter on the air intake side. With your set up, I bet you don't even know when the generator is running. Really nice set-up. -

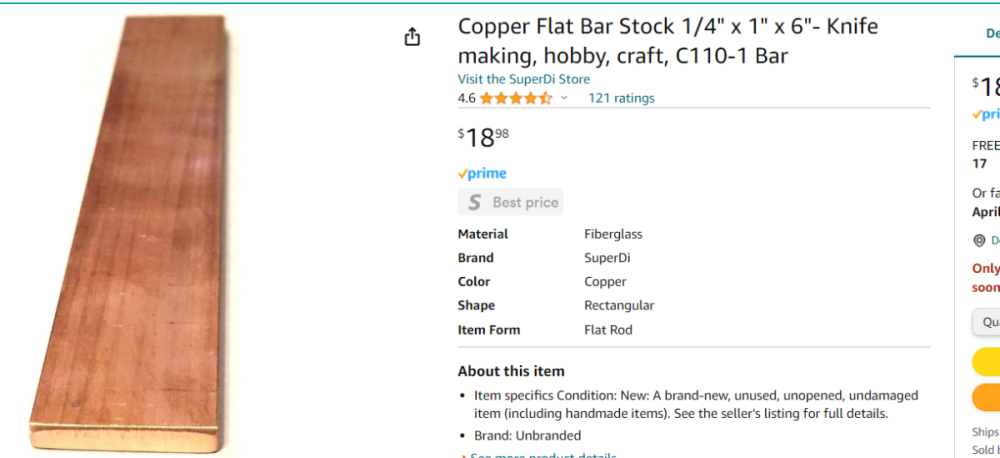

Both MaxBurner and I (And several others) use this bar from out negative Litho battery bank to a BlueSeas Master Switch, and then to the shunt. I copied the buss bar idea from another owner here on the forum. GJ

-

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Spring Replacement Build Sheet: Somewhere up above here in the scores of pages of this thread is a suggestion to get your Dexter axle build sheet(s). I did so today. You will need to record the serial numbers of your axle(s). I took photo's. Then call Dexter at (574) 295-7888, Option 1. Ask them for a copy of your axle build sheet(s) and give them your e-mail address. That's it. Be sure to keep a copy of your build sheet(s) in your trailer so that down the road you are not wishing you had it. Great Customer Services from all four of the Dexter areas I have spoken to today. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

SPRING REPLACEMENT OPTION: Here is another option for our spring replacements via Dexter. With the help of a Moderator, we know that the axle springs on most of our OE2's is their PR4B springs. They are made in China and we can purchase replacements for $38.95. I worked my way up three layers at Dexter and their very helpful Technical Services Rep identified another Dexter option that will fit. It is their PR4 2400 # double eye spring PR4. This is a four leaf axle spring made of thicker and wider steel. The cost is $61.99, and it is also made in China. DEXTER WARRANTIES: Dexter manufactured springs come with a 5 year warranty. Their Chinese made springs have a 1 year warranty. THE QUESTION: That said, we now know how Chinese springs got onto our trailers. They are Dexter sold. In at least one perspective, that's good news I think. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

We could continue to speculate on this a long time. For me, I'm now hibernating in my rabbit hole on this topic until OTT completes their process. Now for anything about how to DIY replace our springs or helpful hints from those that have done so.... that's good topic to continue. So, I am thinking it would be a good idea for a Moderator to split off the "DIY Replacement of Springs Lessons Learned" topic from this thread. -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Yep, made in China. There are hundreds of plants there that make springs. Some great some not. Who knows. Most of us surely don't. Maybe time to chill and give OTT the time they need to fully figure this out from the past and future perspectives. I feel certain that they are all over this. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Neither do I so believe. My question has no answer from my end. And now that I am a little bit informed by Mr. Google of the ownership and leadership of Dexter, nor do I feel it proper to speculate further from the rabbit hole. -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

BLUF: When we get into a hurry, sometimes we miss the elephant in the room. I was trying to find an on-line way to get my axles SN/LN Configuration Build Sheet. Was not successful, so I'll take two aspirins and call Dexter in the morning. In the mean time, for reasons unknown, my pea brain wanted to know where our axles are made in China. So Mr. Google stepped in and told me: From Dexter Web Site: Founded in 1960 by Leonard Dexter, Dexter is recognized as a progressive industry leader providing quality products manufactured in the U.S. and Canada, employing state-of-the-art robotics, precision welding equipment, and automated machining processes. Well that can't be true because we have Chinese springs???? So asked specifically a different way: Are Dexter axles made in the USA? A second reference said the same thing. YEP! All right now I know that can't be right. I've seen those Chinese springs. So I asked WHERE ARE THE DEXTER SPRING PLANTS? Dexter Plants: Answer is here, and not over >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>HERE So at this point I am beginning to believe Mr. Google. But wait... WHO OWNS DEXTER? Dexter Parent Company: Dexter is owned by DexKo Global, which was formed in 2015 by combining Dexter and AL-KO VT. This combination created a global leader in highly engineered trailer running gear components and systems, with over 130 years of trailer and caravan componentry experience. DexKo Global is managed out of Novi, Michigan, by a strategic staff focused on leveraging the resources of the combined companies. Well Ok. But maybe it's a shell company being run by those guys overseas! Right? So I asked WHO IS THE LEADERSHIP TEAM FOR DEXKO? DexKo Global Leadership Team: So now, my brain has to ask if Dexter makes their axles in the USA, supervised by an American leadership who work for a parent company who is also all American........ How is it that we have Chinese springs in our Dexter axles? Friends, my brain jumped me into the rabbit hole and we are buried there. If you want to find us, bring a backhoe because the answer is way beyond me. GJ -

From your comment, and this picture: It appears that the Truma is mounted on about a 3" high platform to allow the A/C vertical height for the condensate to drain over to the OTT internal drain lines. Creative solution. The stock OE2 on level ground with the full diameter (16") rims/tires and the Dometic Penguin AC is 9' 8". Any idea how tall it is with the pictured A/C and drain kit installed? GJ

-

Looking for the best way to change out the bathroom faucet

Geronimo John replied to Markmck's topic in General Discussion

Perfect! 15 years ago I needed one of those wrenches so bought the set. They have been hanging on the wall since then untouched. So, YEA I can use one of them again. thanks for the model number and cartridge info. Very good info to have in my KEEPER file. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Thank you for the get back. I may have gained a bit of clearance with the Houghton low profile install. Not sure how much though. I for sure will be going real slow and checking many times our first reinsertion into the barn post ALCON's. Will -

I'm not sure where I would want to use an automatically resetting breaker in an RV. If there is a short, I would far prefer that it NOT auto reset reset. If it is "automatic", it will continue to cycle between on and blown until something ends in smoke. Am I missing the boat on this? GJ

-

Looking for the best way to change out the bathroom faucet

Geronimo John replied to Markmck's topic in General Discussion

I momentarily thought I saw a model number for this faucet. Have reread the thread, but apparently my eyes are fooling me again. I would appreciate knowing the faucet model number. And golden bonus info would be the repair cartridge you used. thank you GJ -

What exterior caulk is the factory using now?

Geronimo John replied to Townesw's topic in Mechanical & Technical Tips

Dave: Your quote is amazing. It certainly can apply to many other situations as well. Even our forum. GJ -

Made in USA leaf springs

Geronimo John replied to Mountainman198's topic in Mechanical & Technical Tips

Only concern I have is trailer height changes. Reason is that I have only about an inch clearance on the barn door frame. If it is possible and not already too late to do so, can you get an accurate trailer height difference that the new springs result in? Many thanks. -

That's a keeper. Thank you! GJ

-

What exterior caulk is the factory using now?

Geronimo John replied to Townesw's topic in Mechanical & Technical Tips

This topic having a very high probability of my needing to find the answer resulted in my saving the post in my Ollie KEEPER document. Cut and pasted below: OLLIE CAULKS AND SEALANTS: JEssary Oliver Staff 4 MARCH 2022 (EDTS BY GJ) The Oliver service department utilizes ASI 335 white & clear silicone, Red Devil butyl sealant, butyl tape, and Dicor self-leveling sealant to re-caulk/reseal the exterior of your camper. . Due to Oliver’s double fiberglass hull construction, any leaking water is trapped between the hulls until the water can find an escape point. Those points are typically a window cutout or one of the weep holes in the lower outer shell. Windows being a primary entry point often leads to an initial diagnosis that the window is leaking which is not necessarily the case. During the yearly maintenance, use Acetone for cleanup, and seal the exterior with ASI 335 silicone. Once the silicone is cured, bolts and screws located on the roof then have an additional application of self-leveling sealant to provide an additional layer of protection, again, these areas aren’t typically “seen” surfaces. The additional layer also helps protect the silicone from sun exposure as well as sealing the head of screws and/or bolts. Re-caulk any gaps found. Carefully check roof penetrations and the marker lights. +++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Sadly my skills with a caulk gun are legendary..... BAD. I to love gaskets as a result. Wow you hit the nail on the head with that one. I have been told that the 2018 marker lights don't streak because the black supplier gasket was eliminated and they were caulked. My 2018 trailer has the supplier gaskets and the black streaks continue to this day. About a month after pick up of our hull 342, I reported the black streaks and suggested OTT get a better gasket. The response was caulking. Hopefully one day we'll have a gasket for these exterior lights because if I caulk it, it would be a visual disaster.