Leaderboard

Popular Content

Showing content with the highest reputation on 07/16/2024 in Posts

-

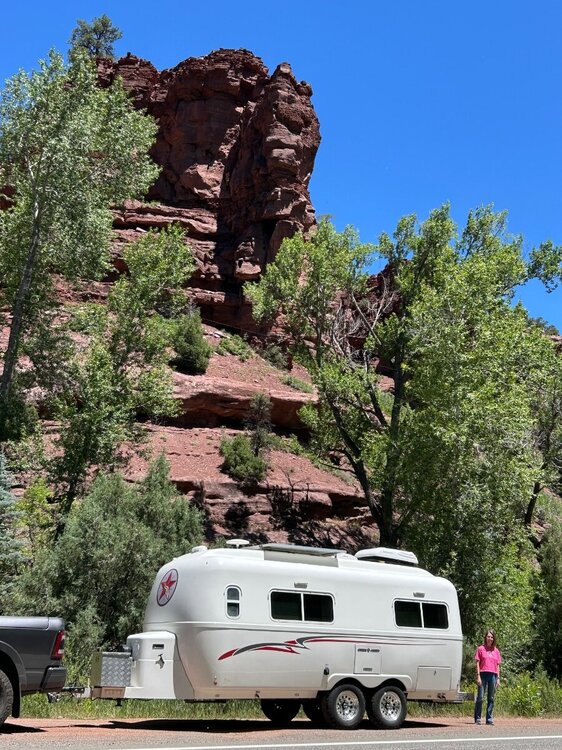

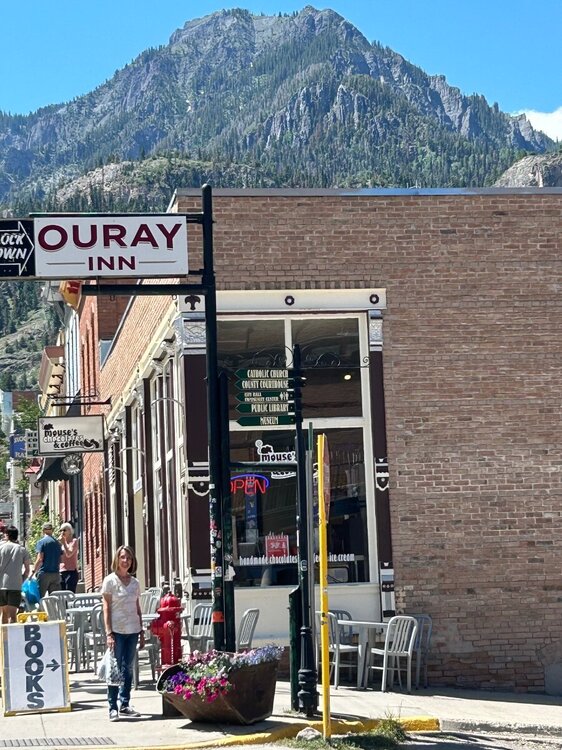

We spent last week at Ridgway State Park, just 20 minutes north of Ouray. We drove up from our son’s house in Durango but didn’t take 550 this time. We took the western route which is about 40 minutes longer but provides with some different scenery. It takes you by Telluride. It was a nice drive. This is just a few miles outside of Telluride on the way to Ridgway. Another stop on the way up to Ridgway. Our site at Ridgway State Park We did a walk around the town of Ridgway. This is the town park in the middle of town. Downtown Ouray. Downtown Ouray. Hiking around the Ridgway Reservoir. Nice hike, good views. More hiking.5 points

-

I would remove the air filter and check the condensation drains. They pass through the air conditioner to roof seal on each side. There should be some sticky caulk around each tube. Also I would check the four hold down bolts. There’s one in each corner. To access these you’ll need to remove the inside cover/trim. I think that there’s six screws holding the cover. Don’t over tighten the bolts, just make sure that they are snug.4 points

-

4 points

-

Thanks for posting such great pix, Mike! Ouray, "The Little Switzerland of the Rockies", that place never gets old! We've stayed in Ridgeway many times and love the scenery - be sure to drop into Telluride and have lunch at "Brown Dog Pizza", it shouldn't disappoint! Enjoy!4 points

-

4 points

-

My theory of what happened may or may not be correct. We will have to wait for Chris to let us know what Oliver Service says and/or what his axle sticker says (if it is still there)2 points

-

2 points

-

Wayfinder, Appears hangars on 2015 #75 LE2 are positioned inward similar to your hangars, if I understand you correctly. We have original 5200 pound axles with original Dexter 5 leaf springs, no issues on 5200 axle springs yet, that I'm aware of: Purchased a spare # PR5 five leaf 3000lb spring, 25 1/4" eye to eye & 1 3/4" wide," from Dexter off the shelf that matches the original if I need to replace one along with # SP01-060 U-Bolt kit for 3" axle. Installed bronze bushings after picking up at Dexter:2 points

-

I'll have to admit that I have never wished that the "Head Bumper" was not there.2 points

-

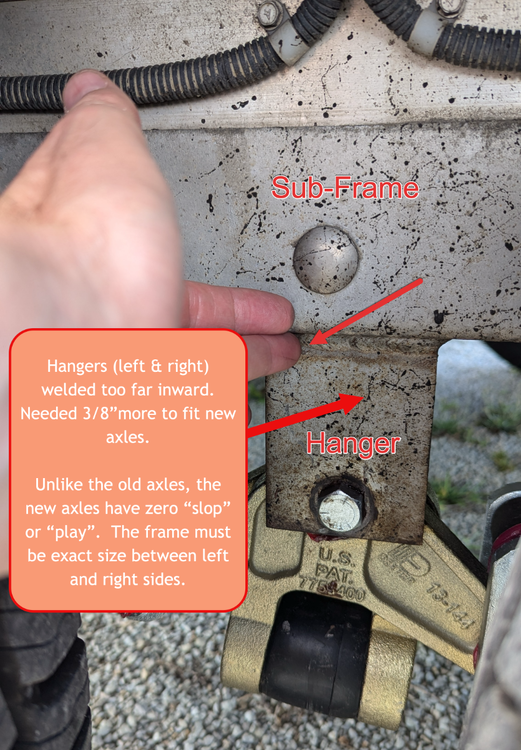

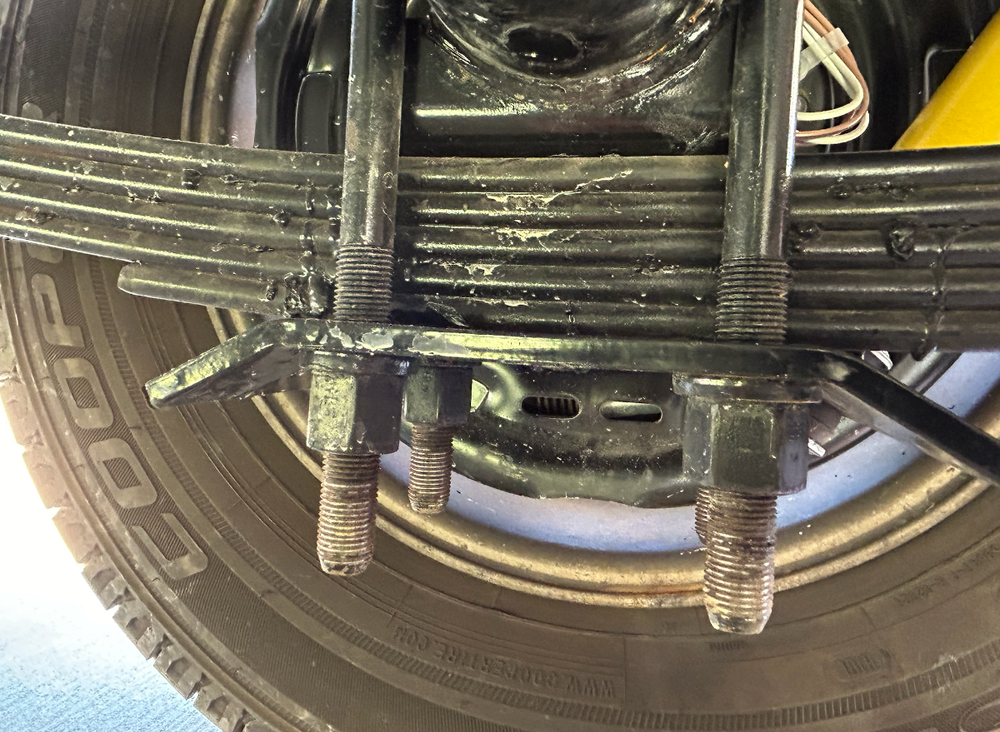

Okay, here are more details on the new axles not able to be fit onto #110. In the attached picture, my trailer's hangers are welded a bit too far inward on the sub-frame. The new axles do not have ANY "play" or "slop" in them for a fudge-factor. This is unlike the original axles. The frame hangers MUST be spot-on in regards to measurements. So, between the left and right hangers, there is not enough room. They needed 3/8" more to make them fit correctly. Oh well, it saved me a bit of $$. They said my shocks are still good and they installed my self-provided EZ-Flex suspension parts for me. The new windows and shades look awesome and the new batteries are working with more Amp Hours than I had with the crappy Interstate batteries. Jason seemed to give me a "facial & verbal compliment" and said the trailer is still looking great. I think he was a bit surprised due to the age of the camper. Wait until CGI gets their hands on it tomorrow. Oh, also, they are out of trailer covers and likely will not order them again, since not too many folks get them and .... some other reason, can't remember. He suggested I call Calmark Covers to see if they can still get me one. It will make the ceramic coating last longer. Mostly only cover it in winter and early spring.1 point

-

Yes, for example the Battle Born folks provided the charge parameters for their batteries. Blue Sky Battle Born setup.pages I sent the BB folks a copy of the Blue Sky setup pages and they supplied the parameters that they wanted to see for the 3 BB batteries that I have. You will have to do the programming procedure as per the Blue Sky instruction manual. Very easy process.1 point

-

Is your 2023 trailer still under warranty? If so, a call to Oliver would be an obvious first step.1 point

-

I just opened a ticket for Jason. Maybe he'll have those exact hanger measurements needs for the axles. I sent them a pic of one of my hangers, if they need to mark it up on the pic. If nothing else, maybe we can save his team's time by not entertaining the idea if the hangers don't meet what the new axles expect. New tech, old tech - they don't usually play nice together. Like mentioned above, it's not a defect. It's just the way things were done "back in the day" and now we all expect to have the shiny new "gear" on our old rigs. It's just not usually practical in the real world. LOL. This is why we constantly need to upgrade our computers. Dang it. Difficult to plan for the future widgets not yet on the market. Here's is pic of my driver's side hanger. We specifically talked about the position of this one.1 point

-

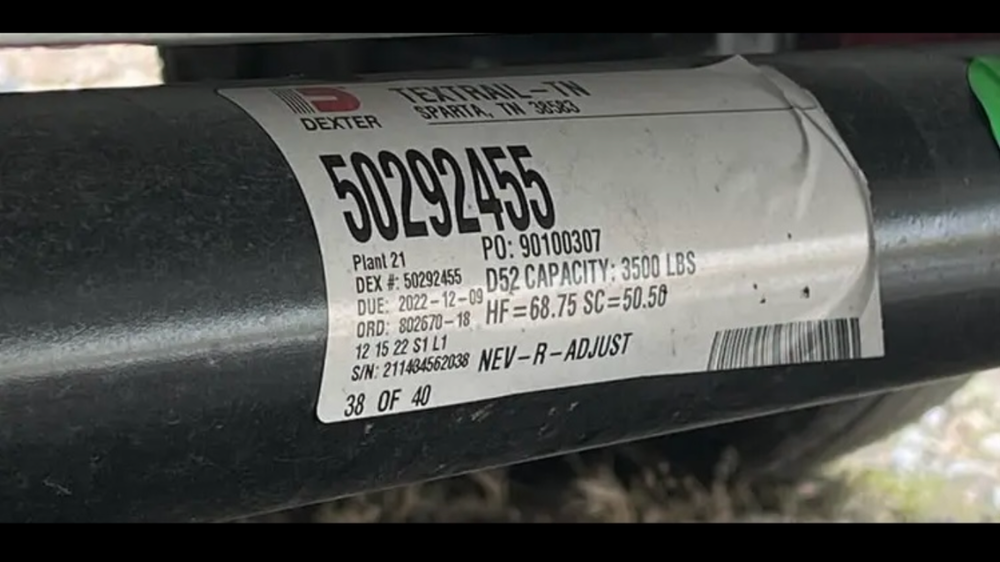

Without more specifics it is hard to prove for sure, but from what Chris has provided so far, I believe you are correct. From what I can tell, the current standard for E2 axles is a Spring Center(SC) measurement of 50.50”. This is the measurement from the center of each of the centering holes located on the axle spring perches, across each axle (see my axle sticker below). I do not know of Oliver manufactures the steel suspension frame to which the spring/axle assemblies are then bolted to the aluminum frame or if this component is provided as part of a complete suspension package provided by Dexter which is bolted to the aluminum frame. Regardless, it appears that there was a period of manufacturing where the axle SC measurement was less than 50.50”, necessitating that the spring hangers on the steel frame were moved inboard. Not a defect IMHO, rather a manufacturing change to meet the narrowed spring perches being provided on the axles at that time Couple of questions I have: 1) how many trailers were manufactured with these narrower spring perch mounts? 2) since the steel suspension frames are bolted to the aluminum frames, is it possible for those impacted hull#s to have the narrower steel suspension frame replaced with one with a SC of 50.50”, thereby allowing newer axles to be fitted? For those interested, HF (hub face) measurement of 68.75” (as shown on the sticker) is the outside to outside width of the axle, as measured by the outside of one hub, across the axle, to the outside of the hub on the other side. I believe that this should remain unchanged for all E2 trailers built.1 point

-

Tested my head bumper out the first trip out - Oliver campground 1st night... lol I have to say I remember it every time now when exiting.1 point

-

I’m not quite sure that OTT created any defect. It seems to me that Chris's 2016 LE2 was built to the axle specifications used on his trailer and have been in service for about 8 years without any problems. Mossey1 point

-

In the past week there have been four (4) reported spring failures. The trailer years might not be exact, but if I remember correctly 2015, 2019(2), and a 2021. That's a lot in a short period of time.1 point

-

I never realized how many torque wrenches we actually owned. Two shallow drawers full.. Is what it is. 🙂1 point

-

Back in the day , 2008, we had a number of liberties. Not sustainable, in a production line. Let me know if you need fabric choices for new cushions.1 point

-

If you look at mine there is quite a dent in it, like a prior owner kept hitting their head in the same spot! Cool you were able to chose fabric!1 point

-

I live in Duluth if you need a hand with anything! Happy to run up with some tools, beer, and/or moral support!1 point

-

There is no part number. When you call, ask for Lew or Mike and tell them you have a Oliver Elite II(this way they can make sure the centering pin is set up for our spring under axle configuration). According to Alcan, their springs are rated at 2,750 lb/ea. While most of us who have installed them notice very little incremental stiffness, you should be aware of this going into the purchase. If you order your new ubolts and nuts from them, make sure you know your axle diameter when you call so they send the correct ubolt size.1 point

-

I took both my torque wrenches to my auto mechanic. I've been a loyal customer and he was happy to take them. When the Snap-on truck stopped by, as they do fairly regularly, he had the calibration tools on hand in his truck as they regularly test/calibrate torque tools for all the shops they visit. One of my wrenches was a Snap-on, the other was a Precision Instrument. Fortunately, they both tested in spec. Good to know! Dave1 point

-

If you never hit your head, let it go. I do occasionally hit it, and I'm only 5'4". Cover it with the new fabric you choose, and put it back? You could use velcro, instead of screws, if you just want to put it up "sometimes." Our beloved head bump was installed that way, originally.1 point

-

John there are many videos on YouTube on how to calibrate it yourself, here’s one.1 point

-

The MultiPlus-II combines the functions of the MultiPlus and the MultiGrid. It has all the features of the MultiPlus, plus an external current transformer option to implement PowerControl and PowerAssist and to optimize self-consumption with external current sensing (max. 32A). - Victron The MultiPlus-II is a newer model; it is also a single inverter/charger unit, but it has some improvements over the original MultiPlus. It has a more powerful microprocessor, which allows it to provide more accurate and precise control over the charging process. - Victron MP-II form factor is longer and slimmer. So, depending on install may be easier to mount. Idle power draw is less for the MP2 11w vs 25w for the original. Having installed it, in retrospect, I might look at using Victron Lynx power distribution instead of DIY bus bars. A lot to think about. Best, Mike1 point

-

1 point

-

It amazes me that since OTT created this defect, back when hull #110 was built, that they did not correct it now when you were in the shop. They should have cut out the old hangers, and welded new ones at their expense and then you could have paid for your desired axle upgrade.1 point

-

Thanks for the details. I just looked at mine and the outside of the hangers are flush with the subframe so I assume I'll be OK if I ever need to change my axles. There I go "assuming" things again.. 🤣1 point

-

Make sure the red lever on the Optifuse resettable breaker is pushed inwards (see arrow on picture). The Optifuse breaker on the left shown in the photo is in the open state when the lever is popped out like that. The Optifuse on the right is closed. The red rubber covers on the outer two items are just contact covers on the other self resetting breakers. The Optifuse breakers can manually opened by pressing the little red button on them (which will make the red lever pop out), and then pushing the red lever back in to reset. And this is my first post in a long while since we sold our Ollie. A sad day when it was towed away, but it went to a good new owner. We’ve moved on to other travel plans now. But I still lurk here on the forums occasionally 🙂1 point

-

1 point

-

1 point

-

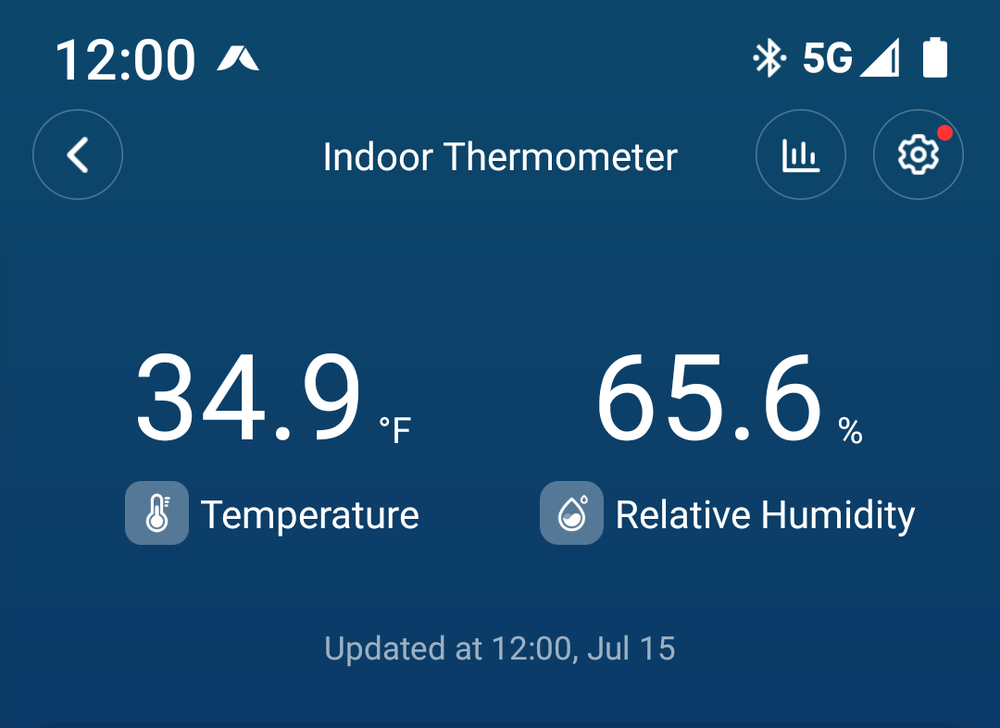

We’re on our way to Colorado to escape the south Texas heat. Overnighting in Roswell, NM which does not get us out of the heat! It was 106 when we pulled in to our campground. No sitting outside, we’re enjoying 70s inside with our loud Dometic AC. We’re at the Red Barn RV Park, very small but clean and convenient. We’ve stayed here at least a dozen times on our way to/from Colorado. Yes, that’s a Red Barn. It’s the office, rec room, rest rooms. She keeps a cooler there with bagged ice, food, ice cream and drinks. Farm field behind us, there’s only about 12 sites total and several are long term folks.1 point

-

Ran a valid test today. Had to wait 24 hours for the glue to set on the vents. Cooked hash brown patties for our breakfast today. The Emeril was set on air fryer, 380 degrees for 21 minutes. The vents were just warm to the touch, not hot. The RUUVi sensor mounted above the Dometic thermostat on the right upper outer wall of the oven went up just one degree, kicked the A/C on. The cabinet facing, in front just above the oven, was a little warmer than the vents, yet I could still rest the back of my hand on it NP. The kitchen cabinet above was not hot at all due to the heat insulation wrap installed. I'd say this mod passed the test! 😂 We can now have crispy air-fried foods on the road, no setup time dragging a heavy oven out of storage, no extra time cleaning up. This way, we will likely use it daily when camping, like the larger Emeril we have in our home kitchen. Anybody else interested in this oven? Check out the Amazon used price at $80! They also list a "very good" one for $85, that is new but not in original packaging: Amazon.com: Emeril Lagasse Everyday 360 Air Fryer, 360° Quick Cook Technology, XL capacity,12 Pre-Set Cooking Functions including Bake, Rotisserie. Broil, Pizza, Slow Cook, Toaster and Much More, Stainless Steel : Home & Kitchen1 point

-

This is what keeps me interested in the Oliver forum. I was tipped off to a problem in the making which had the potential of turning into a uncomfortable situation where I would not have had the control over time or place of the inevitable outcome. Then I am able to access multiple perspectives from fellow Oliver owners on research and solutions to the problem. This greatly speeds up the processes and helps illuminates the possibility of over looking a flaw in ones thinking. One thing we have to keep in mind is that there are always multiple ways to resolve a problem and we may not always agree with each others solution. Thanks to all who contribute to this forum.1 point

-

Absolutely correct, Steve. We did the same procedure by drilling-out our spring plates for the 9/16" U-bolts. Not only are the U-bolts beefier, but the Alcan-provided nuts are 50% longer than those on the standard Dexter axle made with sub-standard Chinese spring steel leafs. More thread contact between bolt and nut = mo betta. This was one of the main decision points in going with Alcan versus Dexter spring packs for our application. Dexter's 5-pack springs are designed in the same fashion as the 1750# 4-packs - with the 4th longest leaf extending to only about 3.5" from either eyelet. This is the traditional break failure point that Steve's referring to in his description above. With the Alcan design, that 4th spring fills the gap by extending to the point where the 5th leaf starts curving for the eyelet. Another feature of the Alcans, previously discussed but adding here for clarity, is the larger walled bronze bushing - 3/16" versus 1/16" for the Dexters that had bronze bushings. This thicker walled bushing creates an even larger diameter eyelet = mo betta. Please note that the current Dexter 1750# 4-spring packs w/D52 axles are fixed with plastic bushings. I observed this first-hand last week when replacing our D35s for the D52s. Serious NOTE: Owners with the newer Dexters should determine if their axles are equipped with either bronze or plastic/nylon bushings. Why, you ask? If a rig's running gear is fixed with an axle kit using spring packs with plastic bushings and using Dexter EZ-flex wet bolts, the bushings will likely not last a season. The petroleum-based grease used for the wet bolts can decompose plastic bushings. Not good, IMO. The pic below shows Alcan's extended 4th leaf right to the curvature point of the 5th spring's eyelet - a robust design feature not found in either the 4- or 5-pack Dexter Chinese-made spring kits (FYI, the traditional breaking point with the Dexter 4-packs is about where the end of the 3rd spring is located, see below pic): Comment on Shocks: If one assumes that OTTs are "under sprung" - i.e., not heavy enough leaf springs, then the constant expansion/contraction rate that the Monroe's experience is very high. IMO, this wears out the shocks much sooner - and which were never designed for an "under sprung" suspension to begin with. Using heavier-duty shocks on the same running gear may last a bit longer but shock failure will occur sooner than if they were mounted on running gear of heavier design. The Alcan option may just allow our shocks to last their designed lifespan... who knows? Let's get some miles on these babies and find out! 'nuf said.1 point

-

Larry: This really is significant. It appears that the heat treatment was not consistant across the cross section of the spring. This would set up the spring to have force concetrations and/or embrittlement fractures. I have been contemplating various ideas to stiffen up our OE2 suspension, and the higher rating for the spring rate with a small air bag may be a step in that right direction I think. Once you have a chance to install, if they work out as hoped, I am thinking that there will be a significant number of us that will want to replace ours. With commitment for a lot of sets, it becomes possible to negotiate a group purchase at discount. Paid in advance of the production run with an option to pick up at the factory or shipped to owners desires address with additional cost. I know more than a few of us could be in their fine city later this summer. Do they have a facility suitable for installation on our trailers? The would be helpful for those of us on the road. Your thoughts? GJ PS: I OFTEN take posts of significance and turn them into a condensed word document. Hope you don't mind, but my version is attached. I find it handy having an electronic copy for down the road, and having the info you posted is GOLDEN! Made in USA leaf springs (6 FEB 2024).docx1 point

-

0 points

-

Recent Achievements

.thumb.jpg.e34bf01ef7f7d5e99ad31856d45afbeb.jpg)

.thumb.png.fbbde3486e933f990ff511bff8d6bda0.png)