Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/2024 in all areas

-

When we were in the early build stage of our Hull #050 back in late 2013, I asked Jim Oliver what he suggested for axles for our new Elite II. We were coming from a 2008 Elite that had a 5200 pound axle with five leaf spring packs under it. He quickly said that he would want the same ones we had on our first trailer. So that's what we went with. The plan at that time was to use 2 x 3500 pound axles with four leaf spring packs on the regular production Elite II's. With the exception of a few trailers built in 2015 with the 5200 pound setup for the reason stated previously by @rideandfly this has been the standard on all production units since the first 2014 models rolled off the line and continued that way through model year 2021. The 2022 to current Elite II models saw a change in their axles. The Elite's axle remained the same as they had always been but, In an effort to streamline production and simplify their inventory, the decision was made to use the same size axles on both the Elite and Elite II trailers. All trailers delivered since 2022 have been supplied with two 5200 pound axles with the Dexter Nev-R- Lube hubs on them. However, they stuck with the 3500 pound 4-Leaf spring packs that have always accompanied the 3500 pound axles rather than the 5-Leaf spring packs that are standard on the 5200 pound axles. Their reasoning is that the stiffer springs would cause a rougher ride and could lead to drawers coming open or cabinet doors opening up while under tow. This why the GVWR remains at 7000 pounds. In addition, Oliver has also changed from 16" wheels with LT tires to 15" wheels with ST tires. There has been some recent owner interest in obtaining the Dexter Nev-R- Lube hubs. This requires a complete axle swap as they are not compatible with the axles all the older trailers (pre-2022) are equipped with. If you are contemplating ditching the OEM 3500 pound axles for the new setups with the higher rated axles, be aware of this spring issue. I can personally attest to knowing of at least 10 spring failures on the 4-Leaf spring packs on both the older trailers and a few that have recently been delivered over the past year or so. All of these springs have broken in exactly the same place. Also, I have never heard of a single failure in any of the trailers that are equipped with the 5200 pound axle with the 5-Leaf spring pack. This includes all the Elites ever built and, to my knowledge, none of the Elites II’s that were originally built with the 5200 pound axles and the 5-Leaf spring packs. My predication is that the 4-Leaf spring packs will continue to fail no matter which axle they are installed with. My advice is if you are changing out your four leaf springs for any reason, consider a stiffer spring that the originals and to purchase and carry with you at least one extra spring pack. If you’re going to Alaska carry two sets. One owner was up around the Arctic Circle when he discovered his were broken. Not the ideal locale for a FUBAR.8 points

-

A couple of months ago I posted about wanting to flip the cabinet door above where the coffee pot is. It's finally done (almost). Every step was a two person job. Three wonderful people helped me. I dragged my feet a bit because, honestly, I loved having it open. But it was a pain when moving. Scrapped the old calking and glue off with plastic blades. Cleaned off lingering stuff with acetone. Removed the door from the frame. Flipped the frame upside down and glued it back on using 3M 4000 adhesive. Note, the frame is flexible and wanted to sag, getting it right was tough. The door fits tighter than I'd like but it closes. Screwed the door back on. What a pain. Tiny little screws that aren't magnetic and there is nothing to brace the door on while trying to get the screws started. Because of the curve of the ceiling, the hook had to be placed out aways. Right now it's just being kept open with a couple of bent paperclips until I figure out what's best to use. Here's the finished product:4 points

-

A different suspension design would be great going forward but I doubt that it actually could be retrofitted at a reasonable cost. Right now I’d be happy with USA made springs. That small change could make a huge difference. Maybe Oliver could start buying just the axle assemblies from Dexter and springs from a different manufacturer. I know that none of the other mainstream trailer manufacturers would ever do anything so bold or even consider out of the box thinking but Oliver often thinks out of the box, that’s the very reason we have such a great trailer and they’re in such high demand!4 points

-

On the way home from the SW this year, I had the pleasure of experiencing a broken LR leaf spring while underway. It broke in the usual place (see pic). Fortunately the broken spring was noticed quickly and I found a safe place to overnight and perform the repair the next day. Unfortunately, I was not carrying a spare spring. After finding a pair of springs locally and installing them I made it home the next day. What I found when inspecting my broken spring was what appeared to be a defect in the steel (see pic). In no way do I blame Oliver for this failure as the trailer spring market is monopolized by Springs made of Chinese steel and Oliver, like all other manufacturers source from the same pool of components. In fact, after opening a service ticket, Mike was extremely helpful in getting me the specs and info I needed. I decided that once I got the trailer home I would replace all four springs with the best springs I could find. Preferably from a US company, made in the US and with US made 5160 spring steel. What I did not appreciate was that there did not appear to be any trailer parts sources which met this criteria. This was not proving to be a simple task. Everything I could find in the RV aftermarket was sourced from China. No exceptions. The only good news I found was that Chinese springs are cheap ($35-55ea). I remembered a Spring Company from my offroading days and gave them a call. They had a set of four springs which fit the measurements provided by Oliver Service and were made in the US with US 5160 spring steel. Cost is $150/ea spring but since I had already spent a fair amount of $ upgrading to stainless lugnuts and US made Timken bearings this did not prevent me from placing the order for a set of four springs and new ubolts. New springs should be here later this week. I will update with pics once I get the springs and also once I install and of course again after towing a few thousand miles.3 points

-

Larry: This really is significant. It appears that the heat treatment was not consistant across the cross section of the spring. This would set up the spring to have force concetrations and/or embrittlement fractures. I have been contemplating various ideas to stiffen up our OE2 suspension, and the higher rating for the spring rate with a small air bag may be a step in that right direction I think. Once you have a chance to install, if they work out as hoped, I am thinking that there will be a significant number of us that will want to replace ours. With commitment for a lot of sets, it becomes possible to negotiate a group purchase at discount. Paid in advance of the production run with an option to pick up at the factory or shipped to owners desires address with additional cost. I know more than a few of us could be in their fine city later this summer. Do they have a facility suitable for installation on our trailers? The would be helpful for those of us on the road. Your thoughts? GJ PS: I OFTEN take posts of significance and turn them into a condensed word document. Hope you don't mind, but my version is attached. I find it handy having an electronic copy for down the road, and having the info you posted is GOLDEN! Made in USA leaf springs (6 FEB 2024).docx3 points

-

3 points

-

My new springs arrived today. I confirmed measurements are correct and that they are the same size as what my E2 had when it shopped from the factory. Should be a direct bolt-in. Here are the specs on the new springs: -Made in USA with USA sourced 5160 spring steel -Bronze eye bushings vs. plastic -2,000lb rating/ea vs. 1,750 (will not change gvwr as axles/bearings remain determining factor) -5 leaves vs, 4 -second leaf extends underneath eye on each end (protecting common break area) -steel, bolted spring keepers (one each end) vs a single, sheet metal band -width = 1.75" -drop = 3” -length (eye-to-eye) = 25.25” The company I sourced them from is ALCAN. They are known for durable offroading springs and have been building custom springs for rock crawlers and overlanding vehicles for decades. Attached below is their contact info. Ask for Mike and tell him you are interested in the 1.75” wide trailer springs like he sold to Lance from Colorado. I will report back when I have them installed, but that may not be for a couple months until after the snow melts up here in the Rockies3 points

-

We were traveling on I-8 in Arizona heading eastbound to Organ Pipe Cactus NM and spotted 2 Oliver’s Westbound and 2 in the campground when we arrived. On road spotted: Westbound, before Yuma, Blue & Grey logo towed by grey F150 Near exit 67 I8 Az , Gold logo pulled by white Mercedes suv Two others in Twin peaks CG , Gary Foy Lin a 2022 pulled by F150 hybrid. tbd other unit. tgats more sittings in one day than the whole time from Sept 2023 to today Craig hull 505 - Galway Girl2 points

-

2 points

-

This was the case with ours, fiberglass dust had gotten into the panel switches; the blue indicator LED would flicker along with the cabin lights in our case.2 points

-

Always a treat to spot one or be spotted and see a post about being spotted. We were at Galveston Island State Park and an Owner with their Oliver drove by and posted seeing our Oliver. We saw the post and replied back😊 The best was having a phone conversation with Steve Landrum while we were both on I-20, Steve East bound and we were West bound. We all waved passing each other in a blur.2 points

-

2 points

-

Most of the sleuthing will have to wait until we get home. Dust may be a culprit, we had gusts to 70mph, blowing talc fine dust at Mesquite Springs, DVNP. Getting rained on at the moment.🤷♂️2 points

-

I am sure there are other US Spring manufacturers that use US made 5160 spring steel. I encourage people to do their own research and let the group know if you find other sources. In my week-long search I found only two manufacturers that returned my inquiries. I knew previously of ALCAN and their offroad spring Creds and they had the springs in stock so I went with them. St. Louis Spring also replied to my inquiry but required that I purchase a new replacement spring of the specs I wanted and send it to them to replicate. I have included their response below in case there are owners local to St. Louis and for whom this requirement would not be such a obstacle. Note in their response they also recommend adding a fifth leaf. Best of luck in your own sourcing. Please post any concrete updates on places which meet the "made in USA with USA 51560 steel" criteria. It is always good to have multiiple sources from which to choose. Also, perhaps Oliver may wish to follow this path for suspension on future trailers. Our legwork may help facilitate this as a future upgrade, placing Oliver even farther up the quality metric amongst the pool of RV mediocrity. As far as running a set of 8,000 springs vs. 7,000 I am prepared to run even lower tire pressures to smooth out the ride in order to avoid the roadside PITA of a broken spring, instead having a potential trade-off of quicker tire wear and lower towing mpg. I was lucky that my issue was noticed at a Love's with a newly built, adjacent RV Stop RV park which featured large, newly poured cement pads, new luxury showers, power and quiet sleep. Also, a local, Good-Ole Boy RV shop/contractor who had the pair of springs to get me home and did not bend me over the cash register. Your mileage may vary should this happen to you. I am doing everything I can to make sure I do not end up in this predicament again. At minimum, I recommend buying a spare spring (or two) to carry with you on every trip. Ironically, ScubaRX and I had this exact discussion not more than two weeks earlier (after meeting another E2 owner in Quartzsite who had broken a spring) and I was planning to order a pair of springs to carry as spares once I got home...UGH. Best wishes, Lance Spring Team <springteam@saintlouisspring.com> Fri, Mar 1, 9:06 AM (6 days ago) to me We can definitely makes this for you and would be made here with American steel, however we would need a sample to duplicate and a lot of times on these travel trailers we make them heavier by adding a leaf to each. Thanks The Spring Team St. Louis Spring Company Tel: 314-533-2132 Email: springteam@saintlouisspring.com Web: https://saintlouisspring.com2 points

-

Our daily OTT spotting record is 2. One was @Mike and Carol on I-10 westbound near AZ/NM border in JAN. We also had a unique OTT spotting experience last MAY in CO - while northbound on I-25 in the right lane near Trinidad, we had silver 2022-ish Tundra (same as ours) pass us in the left lane towing an Oliver of unknown pedigree... I immediately woke up D and said, "Hey baby, that's what we look like when we're passing another Oliver!"....2 points

-

You are correct, Generation 3 uses RJ45 connectors and I have confirmed that everything must be shielded. While I am thinking about it, for others ....... I first tried a hole drill on the outside connection but had good success with a router blade for my Dremel, very easy. One other thing for those considering this. I want my Starlink to be powered by 12 V and there is now a relatively inexpensive device that means you don't have to cobble together different devices -- https://www.trioflatmount.com/shop/p/gen3-12vconversion, the company claims it used 4.5 amps. So, all my stuff is due today so I will see if I can get it to work, thanks for answering.2 points

-

2 points

-

This is the direction I would like to see as well. One of the US Spring manufacturers (St. Louis Spring) said they would replicate the springs on my E2 with USA sourced 5160 spring steel if I would send them a new one to copy. Knowing what I know now, I certainly would have paid a premium at time of purchase of my Oliver for USA made springs. I would like to see Oliver investigate this path. Now that they are at dealers, it would certainly further set them apart from the rest sitting on Chinese suspension. I cringe now knowing that my trailer went 25,000 miles supported by a $150 set of springs (again, not Oliver's fault. The entire RV components industry has gone to the cheapest possible cost model without regard to quality or safety).2 points

-

Nice, I spotted one on Sunday around 12:30ish EB on Hwy 401 in the Whitby area (Canada, Ontario). I was WB on Hwy 401 otherwise I would've made an attempt to stop it for a chat! Seeing another Oliver up here is vary rare, probably just a handfull up here in Canada. It was towed by a black PU Truck.2 points

-

How about an individually adjustable pneumatic airbag type suspension for Ollie? No axles - lighter, smoother ride - less damage to OTT and components, no more broken leaf springs, more ground clearance by adjusting air pressure, enhanced braking, and "drum roll" please.... no more zerks! ...screenshot taken from an earlier thread on "Aussie Quality RVs": ....just say'n2 points

-

If you're on shore power and your converter is working correctly (batteries stay charged, etc.) when this happens that lowers the odds it's a voltage problem, but it would still help to get a voltage reading when your furnace kicks in. You could use either a multimeter or a volts readout from a monitor in your cabin (not sure what monitors your year trailer had). Other options would include a bad connection, with the furnace observation being just a coincidence. First thing I would look at would be the switch. The contacts may be worn or oxidized, or you could have dust in there. Do the lights function correctly when switched on/off? No flickering or delay after you flip the switch?2 points

-

I most certainly will. Waiting to see and touch them first and confirm the measurements and specs are right (should be no issue). Once I have confirmed this I will share the info and contact details.2 points

-

No. We have the Oliver-installed shower curtain, which keeps the toilet area, including the return air vent location, fairly dry during showers. And, like you, we squeegee the shower walls to speed up drying of the wet bath. Given the amount of air flow whenever the furnace is running, we have experienced no moisture issues in the underbelly. I believe the more abundant source of any moisture in that area comes from condensation when outside ambient temps are low and humidity is high. The flow of return air through the underbelly, which is enabled by the return air vent in the shower, actually helps dry out this condensation.2 points

-

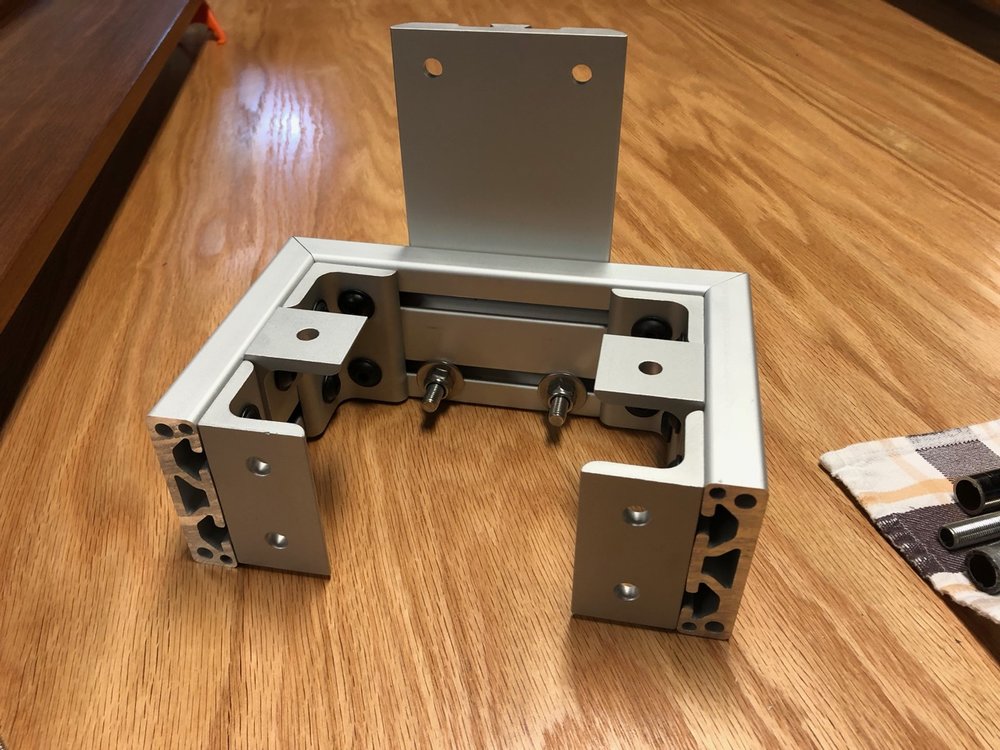

I think like a lot of Elite II buyers, we were torn between the twin beds vs the king. We chose the twin, but not so much for the size or comfort of the beds as it was the utility of nightstand and easy access to the overhead compartments. But we liked the idea of having a table and a large lounging area in the back, and so I set my mind on the idea of trying to have both. At first I designed a custom table for the back that would latch into the nightstand in the back with a pole in front, similar to how the dinette table works. I showed it to Oliver and they thought they'd give it a try, but as time went on and things got delayed or forgotten, I sort of gave up on that idea and asked if they would just sell me the standard table top and legs and I would figure it out. They did, and it was a big mistake since I could never figure it out. The table was just too heavy and bulky to put up and take down, and there was absolutely no place to store it. Plus the height with the standard legs was too short for the mattresses we had (another poor decision on my part). So on our first trip it was labeled the Albatross Table and it was just in the way the whole time. It didn't make another trip, just the two mounts screwed to the floor to remind me that not every problem has a solution. But the solution does exist in the Lagun table. I'd seen them before in the king bed model but I had sort of dismissed them as being too small to be of use. But that was before @rideadeuce started this topic about their upgraded table top. Their top was much larger, foldable, and just generally nicer looking than what I'd seen before; and so it clicked with me that with the Lagun mount, we could have a foldable table that could easily be stored or moved out of the way for access to the upper storage. Also the height could be whatever we wanted and unlike the table we had, could be quickly locked for travel. There were just two problems for us - the mount in it's normal location would block the nightstand drawer; and on top of that, we had opted for an access hatch to the basement right in that same spot where the Lagun is usually bolted to the hull. I needed a way to mount the table to the side somehow. So I made one of these - This contraption is made out of 15 Series extrusion from 80/20. I cut, mitered, and erector setted this little block and associated connectors to go beneath the bed overhang. The Lagun mounting plate (the vertical piece) bolts to the mount and then the whole thing gets bolted to the side wall under the bed in four places and to the bed overhang in four places. It looks complicated but if you have a miter saw and can play with Legos, you can build it. Here are some pics of the block in place so you can see how it mounts. The top two bolts on the Lagun plate bolt into the side of the bed extension, then there are two bolts on the block that secure vertically into the base of the extension, then another four bolts that go into the side wall of the base of the bed, opposite the basement. I marked and drilled for the two vertical holes first, then temporarily bolted it in place to mark all the other holes. You need to do this since not all of the surfaces are perpendicular to the trailer or one another. But the flat bottom of the bed extension runs parallel to the floor so if you use that as your starting point then the table top will end up parallel to the floor as well. The end result is extremely solid - The table top I chose is the 35" Nautic Sail top from Marine Teak. Look around on their site and you'll find a number of styles and sizes, any of which would be a great choice. (This is the same company as this one, btw, but they have more choices in table tops on their UK site.) I debated oiling it, but came to my senses and coated it in a couple layers of low gloss poly. Taking it apart to seal is no problem, but you do have to keep track of a number of shims that go under the hinges to make them flush to the wood. So here's the final result. I really like the versatility of the top. Use it folded, unfolded, bar height, table height, sideways, lengthways, stick it over the bed for travel or to get it out of the way, or...however. With the mounting plate where it is, we can raise the table hight enough to clear the nightstand and lower it enough that it sits on the bed locked in place for travel. As you can see, the drawer clears just fine. The table will work best once we have our cushions made to replace the mattresses, but we just did a quick weekend trip with it and it works well even as it is. And best of all, it fits in the closet -1 point

-

Rivernerd I only have a couple of suggestions about heavier springs besides the obvious considerations. One potential issue or set of issues have to do with frame integrity. The Oliver frame is extremely strong and in all likelihood would never be an issue but overloading is overloading. Rest assured that there is not another mainstream trailer in the USA that has a frame that even comes close to the strength of the Oliver frame design. The overland trailers with heavy galvanized structural steel frames are in another category altogether. The other issue with loading the trailer heavier than what it was originally certified to will definitely cause insurance issues and liability issues and legal issues in the event of an accident. I personally am leaning heavily towards replacing my springs with heavier ones just to have a larger factor of safety and less worry about spring failure. I carry two extra springs in my truck just in case but I don’t at all look forward to replacing them on the road. At least I have all of the parts even if for some reason I can’t do the work myself.1 point

-

I recall from a relatively recent post that the spring length's are not one of the common standardly stocked kind. Something about Mr. Oliver wanted to shrink the distance between axles to reduce tire scrubbing during maneuvers or something like that..... GJ1 point

-

It would need the hex tightened when leaking upon hookup. Since the City Water is leaking when running the pump from the Fresh Tank, it must be the backflow preventer (check valve). You have no sig, so can't tell hull number, but for ours in 2016 these are in the back of the basement/trunk (see pic).1 point

-

I was surfing YouTube last night and came across a video called "Shopping for the best quality travel trailer under 30 feet." The video started with a couple standing in an Airstream on a dealer lot and I thought, "they won't even mention Oliver," but as they were showing the AS interior I could see a couple of Olivers in the distance through the AS window. The plot thickened. They moved on to a couple of stickies, talking about the advantages of having 2 air conditioners and a dry bath (the AS shower was too small for him), before walking toward an Oliver. I thought, "they're going to hate it, because it's so small." However, they redeemed my opinion of YouTubers by immediately commenting on the look and quality of the Oliver. It wasn't for them (he's 6'3"), but they really were impressed with the quality and spoke very well of the Oliver product before they moved on to an InTech, which seemed to be their favorite. I was really impressed by the dealership, which seemed to have a great assortment of RV brands to look over. How often can you find Olivers and Airstreams on the same lot? It was great to see the couple compare Olivers side by side with other brands and come away with a favorable impression. They even said, "if only it was a little bit bigger..." which is the topic of another ongoing thread... 🙂 Here's the video: https://youtu.be/LRFQ8GAqvs4?si=GPqYM6PYyyyLleH01 point

-

…or this, see around time stamp 15:20. The Aussies know how to make a quality trailer!1 point

-

1 point

-

For the negative terminal to the Shunt, many of use 1" copper bus bar. Cheap at Amazon.1 point

-

Suggest starting a list of hull numbers, Month & Year MFG, trailer miles, and predominant use type (RV Parks, Boondocking, Off Road). GJ1 point

-

1 point

-

If you don’t mind, please share the information on where you purchased your new USA made springs. Last year I purchased two replacement springs from Dexter along with new U bolts and nuts, wrapped the springs and carry them in the truck just in case.1 point

-

Below is a photo the return air vent in the bath installed by Oliver in our 2022 Elite II Hull #1291. The photo is taken looking down; our standard Dometic toilet is visible in the upper right corner of the frame. This 3" vent allows hot air pushed into the bath by the Truma Varioheat furnace to return through the underbelly to the furnace. It does not create a draft. Below is a photo of the other side of the bath return air vent, taken from underneath the front dinette seat. In addition to this factory 3" return air vent, I added a 4" vent on the aisle side of the front dinette seat. A photo of that "owner-installed" vent appears above in this thread. The additional 4" vent further improved the flow of return air through the underbelly of the trailer. That allows us to camp in colder ambient temps without putting the plumbing in the underbelly at risk.1 point

-

See photo below, showing both the bottom and top vents I installed. As you can see, they are cut into the wall above and below the closet door, allowing air from the main cabin to flow into and then out of the closet. I am advised that Oliver is now installing such vents in new trailers being manufactured.1 point

-

Our Hull #1291 did not come with return air vents in the closet. I installed them, one top and one bottom. Our experience has been that before the addition of those vents, the closet stayed about 20 degrees colder than the main cabin when camping in cold weather and running the furnace with the closet door closed. After the vents were added, the closet temps stay just a degree or two below those in the main cabin. Convection of heated cabin air, between the bottom and top closet vents, explains the difference.1 point

-

Haha 6’2” and 220lbs, I was all scratched up from going in like a contortionist! Next project will be to relocate the one furnace duct from under the curb side bed to under the street side bed, and the return vent to the front dinette.1 point

-

1 point

-

Just finished my install today of the side mount. Plan to use the table now. Now I have a hatch into the basement, which I wanted for during cold weather to get some heat to basement, while using a small fan. Will insulate the outside hatches at some point. Thanks Overland for your post and Mattnan for your helpful hints.1 point

-

I am not sure what the height above the floor you need, it is indeed possible to access the space between the battery box wall and the inner hull wall. Possible, not at all easy! In your shoes I would make a substantial aluminum backing plate and install threaded inserts (nutserts), so you will not need to fuss with nuts and washers, and you won’t need to get a wrench in that tight place. I guarantee that if you don’t go this route, you will say a whole lot of bad words..... Here is the technique, I used it to fish a couple of backing plates deep into a 2”x4” aluminum beam, for my rear rack tiedowns. In your case, you would pre-drill all the holes in the fiberglass, run the wire down toward the inverter, and drag the plate back up into position. VERY carefully... You could tie a string onto it too, from the bottom, so if it falls and disappears you can easily pull it back and try again. It will be trickier with the large size plate needed for your table mount, but if you have one hole centered at the top, it should balance/ align itself pretty well when drawn into position. For more accurate advice, take a picture of the area and annotate it to place an arrow or circle where you want to mount the bracket. I have looked up in that gap several times, each time I wonder why did they built such a promising place to mount things, but made it so hard to get to...? Good luck, post pics of your cool project. John Davies Spokane WA1 point

-

I think I understand your question, but maybe not. The battery box and the pantry base has an air space around it that is about 1" to 2" in various locations. I don’t think a backing plate it the battery box would work because of that space, it would compress too much. The backing plate would need to be between the inner and outer hulls. I have gotten my hand up in the area between the bed and pantry to replace a cable gland. It was a struggle, but persistence paid off. So if you are trying to place the Lagun mount in the aisle, you would need to work from the access cover under the bed and see if you can get you hand and arm up in that area to hold the backing plate, washers and nuts in place while inserting a bolt through the table mount. My inverter would be in the way of accessing that area so I would remove it to increase the work area. It’s doable, just not as easy as the nightstand or under the bed overhang areas. Although I haven’t worked with the 8020 equipment, it seems that you are only limited by your imagination. Mossey1 point

-

In the above thread, the source is linked to: https://8020.net/3075.html The table mount is not something I can use but, I remember the 8020 site because I never knew that place existed! D1 point

-

I'm saving this post . . . . you'll retire some day 😀1 point

-

My bracket is 5 3/16" deep by 8 ¼" wide. About the other table styles, yes, I looked at the marine pedestal tables, but I thought that the Lagun was more versatile and easier to remove. And as it turns out, we don't ever take it down - we have good access to the beds with the table folded, and since my wife sleeps facing the wrong direction she uses it as her nightstand.1 point

-

Oh you’re not talking me into that! But I promise if I were retired I’d make them for everyone.1 point

-

1 point

-

1 point

-

Can do - hopefully later today. If all you want is to center the table then the location of the mount isn't all that important, since you don't need to mount the table top in the exact center of the pivot. You'll actually get the most versatility out of the table the farther off axis you place the top. That way you can spin the top around for different positions. I'd concentrate more on keeping the leg as far out of the way as possible. Of course the closer to centered you mount the top, the more stable it will be. You'll have to experiment. How I set mine was to clamp the mount in place in different positions while experimenting with the placement of the top. I was hoping to get a position that would allow me to turn the table sideways so that it could be used as a desk over the bed for someone leaning against the pantry. I couldn't get it that far forward without the leg getting in the way (maybe it will work with some extra pillows as support), so I settled on a position that allows it to center in front of the nightstand lengthways when open, and crossways when closed, so that it could be used at 'bar height' with plenty of room in front by the beds. Here's an action shot of the table in full cocktail bar mode - And, uh, we don't really drink that much. I just like to be prepared, you know.1 point

-

If anyone wants to make the block I made, here's the list of pieces you'd need to order: #3075 Extrusion, 24" #4303 Bracket, 4 pieces #4302 Bracket, 2 pieces #3320 Bolt Assembly, 14 pieces You'll also need some stainless ¼" or 5/16" bolts to fix the block to the hull. I think most can be 1" or 1.25" long but you'll need two 3" bolts for the two vertical ones that go through the bed extension. I used lock nuts and large fender washers to spread the load against the fiberglass. I also cut off all the bolt ends around the bed side with a dremel and cutoff disk and filed them smooth so not to damage the mattress or cushions.1 point

-

Recent Achievements