Leaderboard

Popular Content

Showing content with the highest reputation on 03/26/2024 in all areas

-

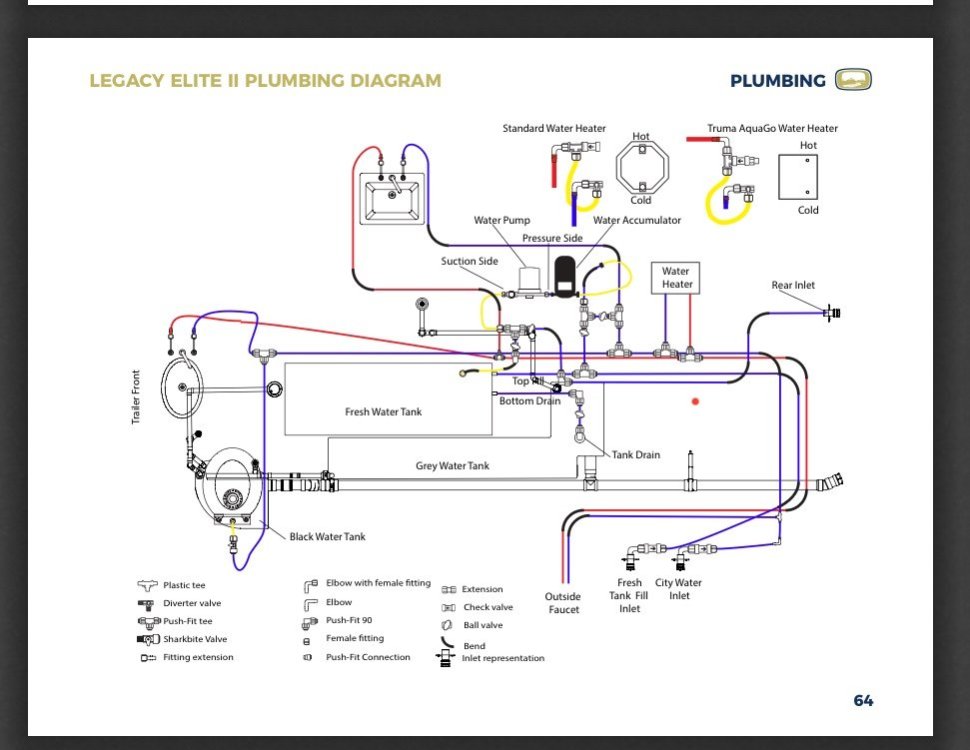

@Lisa Rae @jd1923 I have hull 313. I have 2 check valves under the basement floor just under the door. This is a picture that I made in September 2019 of mine when a few Olivers were having problems with split check valves. I’ve not found any of the brass Camco “pressure regulators” down there. The plumbing diagram shows the check valves but doesn’t show any “pressure regulators”. Oliver provided a brass Camco “pressure regulator” (or flow restrictor) for use externally to limit the incoming water pressure and I used it when our trailer was new. We noticed that when we turned on any water that the flow would be strong and then it would quickly slow. I did some reading on the internet that lead me to replace the “pressure regulator” with a diaphragm type pressure regulator. Video from July 2019, flow with Camco pressure regulator in place at the city water faucet (hose bib). IMG_4032.mov Video from July 2019, Watts diaphragm type pressure regulator in place at the city water faucet (hose bib). IMG_4034.mov I am the kind of person that likes to know how things work and I have thought about cutting the flow restrictor (Camco “pressure regulator”) open to see how it works but, it is my backup in case my Watts regulator fails. (Boy Scout motto: Be Prepared). All of my information and suggestions come with the added warning that what worked in my case may not work for you.5 points

-

Go to Walmart and get a thermometer. Our first one sat on the counter or dinette and told us the inside temperature and had a sensor that would tell us the outside temperature. You can also get ones that have multiple sensors that can be placed in between the hulls, for instance in the water pump area. We also have one that is on the wall. Tells us the inside temperature, the date and day of the week (we’re old and forget which day of the week it is when we’re out camping 😂). Mike4 points

-

Jack up the side of the trailer that the fittings are on that you are trying to grease. This will relieve any pressure being placed onto the wet bolts by the weight of the trailer. That usually makes it much easier to get them to take grease. You may never get it to squirt out both ends of the bushing equally.3 points

-

3 points

-

Tell us what your tow vehicle is. If it’s half ton or smaller, I would keep the Andersen. If bigger, you could go without the Andersen. Mike3 points

-

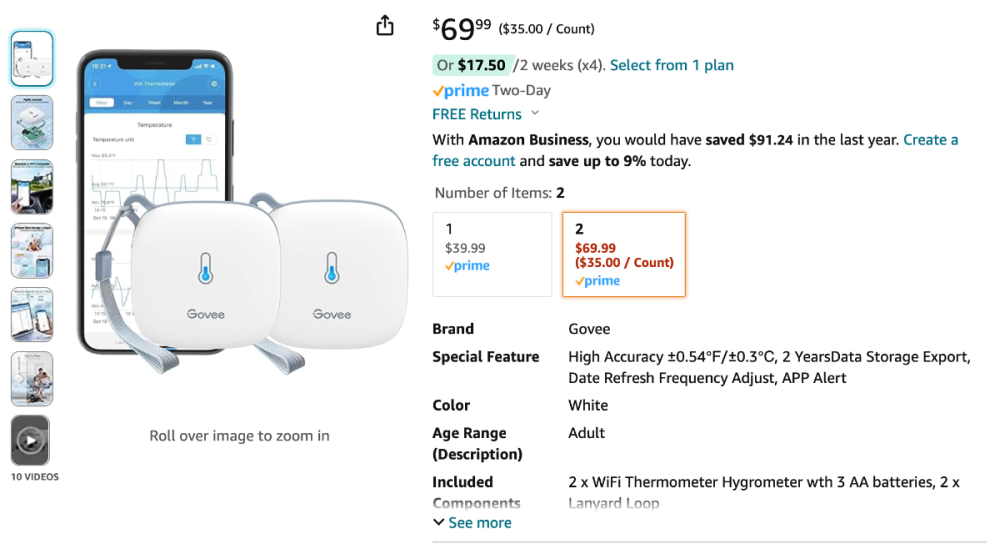

Upgrade to the MicroAir T-stat - gives a nice BIG readout of set temp and current inside temp. If other upgrades are on your radar screen, such as a Victron SmartShunt, it's app will give a reading of the compartment it is mounted in, which is convenient to know in 18F climes. Concur 100% w/ @topgun2 & @Mike and Carol's solution sets... In addition, you might consider a Bluetooth unit like this: ...that can be mounted, say in the "dog house" near the LPG bottles for OAT, and another in an identified "coldest" compartment (ie: basement/garage, under vanity sink, near water pump, etc.). The BT app is easy to use capturing historical data for future planning.... Tons of options - just have fun making you own mods and upgrades. It might become somewhat addicting. Cheers!3 points

-

My habit last year was to read the thermometer that is mounted on the wall -- but maybe it isn't accurate enough. Also, @topgun2 makes excellent points about the location of thermometers outside for accurate reading.3 points

-

I'd recommend the multiple sensors - or at least one that has the ability to add multiple sensors to it. And having humidity levels is important too. The first reason for this (for me at least) is that you want to know the temp and humidity level inside the main cabin. The second is that I want to know the temp and humidity outside so I know how to dress. I place two sensors outside for this purpose. If you are camped such that the front of the Ollie is facing the sun and place the sensor under the "dog house" then that sensor will tend to read too high due to the sun warming the front of the Ollie first. Therefore, I place the second sensor under the spare tire cover in the back which in this circumstance will tend to give me a more accurate reading. Next, if you are camping in cold conditions, it is helpful to know the temps in the basement area such that you can direct more heat down there to avoid frozen plumbing if necessary (as Mike points out above). An expandable system gives you the option of experimenting to see just how many sensors works for the camping that you normally do. Bill3 points

-

Spot on. It took me five season to get up to speed with enough confidence to convert a couple of marine lead acid to Litho's. But the time was well spent in learning from many of the same folks here on our forum today. Now there are many proven ways to get there. And as you pointed out, each technology matures and better ones arrive over time. When I purchases our OE2 in 2018, Litho's were relatively new and very expensive. In time their priced dropped and my time came to use the most proven and best reviewed technology. Good new is you have a good system now. Why spend today's dollars to change it if it works for now. Garner all you can from our friends here at the OTT forum and when your system is ripe for upgrade, you will know that is then far better than we did last year. But always be aware that words here, especially from engineers, make a difference. Your reputation is very good and is growing. GJ3 points

-

Me too, isn't that why we login each day? Thank you GJ, this made my day! @Mike and Carol reinforced my thought that my 450AH of LA might be good enough for many camping styles. And we have a near new battery bank the prior owner purchased in 2021. @MAX Burner also reinforced the idea, stating 300 AH works for them (although Art has a KILLER DC-to-DC installation). I'm going to keep reading, learning and likely will put off an LI upgrade for a couple of years. Just ask @SeaDawg, as she has been babying her AGMs for years. At the same time, would love to have 600AH of Epoch LI batteries ready for your next trip. All in time...3 points

-

Four 100 amp Battle Born batteries will in fact fit into the 2017 version battery tray. I say 2017 version because Oliver has used a couple of different makes that I am aware of. Oliver history buffs maybe can clarify this. Since the Battle Born brand batteries can be mounted in any orientation, four of the standard form factor batteries can be mounted on end. Battle Born also has a vertical form factor battery. Four of these vertical batteries also will fit in the tray. For both types of batteries mounted vertically, the cable connections get a little challenging. There is a forum post that covers a lithium battery installation and I think that it covers the four battery choices. Of course in recent history, there are several manufacturers who have large amp batteries that don’t require trying to shoehorn multiple batteries into the tray.3 points

-

I started in photography back in the mid 60's when everything was manual. No auto exposure or focus. My first camera did not even have a light meter. Had to use a hand held one and set the camera's aperture and shutter speed from that. Manipulating either or both to create different effects. Bought 35mm film in 100 foot rolls and wound my own cartridges in total darkness. It was all black and white. I thought I was Ansel Adams. I even lugged a big 2-1/4 square camera and tripod to the top of Sentinel Dome in Yosemite to duplicate AA's picture of the old Jeffrey Pine growing there. Here's Ansel Adams original: Unfortunately, unbeknownst to me, the tree had died during an extreme drought three summers before despite the rangers best efforts of hauling water to the top every day to try to save it. So all I have to show for my trek up the dome is a picture of a dead tree. Oh well, it was a famous tree.2 points

-

@Geronimo JohnThat water is not pumped water. Those videos are with trailer hooked to city water through a hose bib on the house. One video with water flowing through a brass Camco “pressure regulator”, which I call a flow restrictior, and the other video with water flowing through a Watts pressure regulator.2 points

-

Just keep in mind that Art has exquisite tastes when it comes to beer! GJ2 points

-

When I was 11, Mickey Mouse was in second place, right behind Bonanza! And Captain Kangaroo was in last place.😎 My dad and his poker buddy’s guarded those cards and chips better than the whiskey and the clothes pins where in use on my rubber band gun! Mossey2 points

-

By the way, after eight nights in subfreezing temperatures, we finally depleted the first propane tank. Very impressed. And I now know how the regulator works. I also know that you can Google the Truma error codes and get a wonderful description of what’s going on. I could not have asked for better automation.2 points

-

If you need it - see Mike's post above this one - then watch several of the YouTube video's out there referencing the Andersen. Also, know that it does get MUCH easier the more you work with it and understand what you should do in the varying situations. There are also a bunch of posts here on the Forum about working with the Andersen. Even though our Ollies do not sway and even if you don't think that you need the Andersen, please be aware that if you are towing with a 1/2 ton (or similar) vehicle the manufacturers of those vehicles call for a weight distribution hitch. Given that, if you decide to not use this Andersen then you will subject yourself to liability in the event of an accident where you are not using it. Once you know how to use the Andersen, it really isn't a big deal to hookup and detach (99% of the time). Invariably, that 1% happens when you are in a rush, its raining, its cold, you're not happy (for various reasons) and/or you are (or have to) hookup at an angle much different from the angle at which you unhooked. Take your time - it will get better. Bill p.s. put the info below as your signature and you will not have to do it again. Also, it will tend to get you better and quicker info if you need help in the future.2 points

-

2 points

-

We have a thermometer with 2 extra sensors. One goes in the fridge, the other either outside or in between the hulls. For remote monitoring we also have a Govee WiFi sensor that we can check from anywhere through our hotspot.2 points

-

Well written, GJ! Great advice... And OBTW, @jd1923 - John gets FULL credit for the cool DC-to-DC set-up in Casablanca. We communicated directly last year for several months (takes that long to get my "pea-brain" around the concept!) before coordinating the install - of which, about 60 - 70% of the effort is on the TV! The effort on the "OTT side" is straight forward if one chooses to mount the charger in the trailer - (otherwise, mounting the unit in the TV would be 80% effort on TV/20% on the Oliver, IMO). There advantages either way depending on a given camper's needs... PS: As GJ and I've mentioned in earlier threads - all of the necessary "cable-making" tools are available here for owners that want specific custom cable diameters, lengths, and lug configurations... Bottom line, the cardboard sign at the I-25 intersection could read, "Will Make Cable for Beer."2 points

-

Appears that some folks think that Litho's are maintenance free. They sort of may be, but all the other stuff we put in there are not. In the ole days we would use high mounted light tension springs to encourage the cables to stay out harms way. GJ2 points

-

That mirrors what we’ve experienced with our three BB’s.2 points

-

Certainly there at least two other brands that have similar safety characteristics as the BB's and can also fit into an OE2 battery tray and provide more than 300 AH. But the brand that MountainOlivers is stating is specifically the Battleborn's. At some point, my experience with them will be out of date. But as of today, I have not yet heard of anybody getting more than 300 AH's from Battleborns in an OE2 battery box. Hence my reaction to the statement of "three or four Battle Born batteries". Have they come out with a new product that will let us get four of their batteries into an OE2 and get more than 300 AH? If so, I'm all ears! GJ2 points

-

Same here for us, Mike. AGMs served us just fine with our previous TT - however, for us at least, the Lithiums have been a game changer. For example, we just returned from a short 3-nighter to Columbus, NM. We started each afternoon with 100% SOC on the BBs (200w portable solar module tucked away in the TV). Standard boon-docking afternoon/evening drill for us is fridge operating in gas mode, inverter OFF, dinner off the gas grill, cocktail lamp - "LIT", furnace OFF, Starlink up and an after-dinner "Shoot 'em Up" movie (neither one of us makes it to the end before crashing-out)... The three nights averaged an 11% drop in SOC by morning. The OTT 340watt solar module roof mount (during MAR sun angles near the US/Mexico border) brought the SOC back up to 100% by 3pm-ish. FYI: DAY-2 was overcast, but we still had 100%SOC before we lit the cocktail lamp - we're love'n this system! Cheers, ALL!2 points

-

2 points

-

Amazing when anyone doesn’t want to produce something or for anything for that mater throw in the liability card seems to be the best answer these days. My question would be what is the liability? If that’s the case you could also claim the whole trailer a liability then you shouldn’t sell it. A wiring diagram is a very helpful tool if your out in the middle of nowhere and a electrical problem occurs. Even new vehicles you can obtain a wiring diagram. Wouldn’t help much because they are so complex it would be like reading ancient romans symbols who knows what they are, 🕉⛎♈️😳 very disappointed in Oliver you make a manual make it a complete manual.2 points

-

Labeling would be the gift of a lifetime for DYI owners. Liability? No it would be a liability defense for OTT. After all if I had known what that big red 1" diameter wire was, I would not have licked it to see if it was energized.......1 point

-

Darn it Sherry, I had not ever noticed the off center. Now that's all I see! DRATS! 🙂 GJ1 point

-

The flow reduction may be caused by the pressure in the accumulator depleting down to the pressure of the activated pump. Worth a consideration. GJ1 point

-

Wouldn't be surprised if that changes as more and more Truma appliances migrate to the RV market... right?1 point

-

I have a 2 inch thermometer clipped to my backpack. For years, I have checked it before getting out of my sleeping bag. Apparently, I’m not as sophisticated as y’all. LOL. TYVM1 point

-

Sure - but - I still don't know what a "parralax" is! And that door is still shaped oddly! 😁 Bill1 point

-

1 point

-

@johnwen, you are correct- yellow is ground and red is 12VDC. I believe you were referring to the image below: Please note, I later relocated the fan control to the upper storage cabinet above the refrigerator and microwave oven. The power connections for the fans remained unchanged from what is shown above. Regards, Don1 point

-

We used an equalizer hitch with our Tacoma and airstream. Basecamp 16 x. It was a great hitch and we had a lot of squat in the Tacoma wo the equalizer. We now have a F250 Tremor, factory 3” lift and reportedly the 250 and 350 both have 350 rear springs. We tow our LE2 on the ball and generally have had a great experience. The only issue was on a trip to Fruita, CO with a particularly strong gusty crosswind and had to slow down some. Otherwise the setup is stable as can be. One of the primary reasons for the upgrade to a F250 was the ability to tow wo a weight distribution hitch. In the greater scheme of things hitching a WDH is a minor issue but certainly something to avoid if possible. The other primary reason was payload.1 point

-

OK, First day on the road with the new ALCAN springs and can say there was no appreciable difference in ride. That said, I did note there was slightly less side-to-side rocking of the trailer as we traveled down low speed side roads which is where I would normally detect that in the past. ALCAN warns that the 7/8 U Bolt nuts need to be checked and re-torqued at 50/100/600 miles. I can attest that the nuts certainly needed tightening. I have one more tightening to do. Easy to do BTW. U bolts are easily accessible just laying down next to the trailer. Use 7/8" deep set socket and set torque setting to 90 ft lbs. Ten minute job. Nothing inside the trailer appears to have been negatively affected by the upgraded springs thus far. I'll continue to report as we move along.1 point

-

The 6-bolt wheel pattern on the Oliver is more readily available on the 5200 LB axles. Most 3500 LB axles generally come with a 5-bolt pattern.1 point

-

Yup that’s the factory heat duct, comes std with the truma varioheat furnace/heater.1 point

-

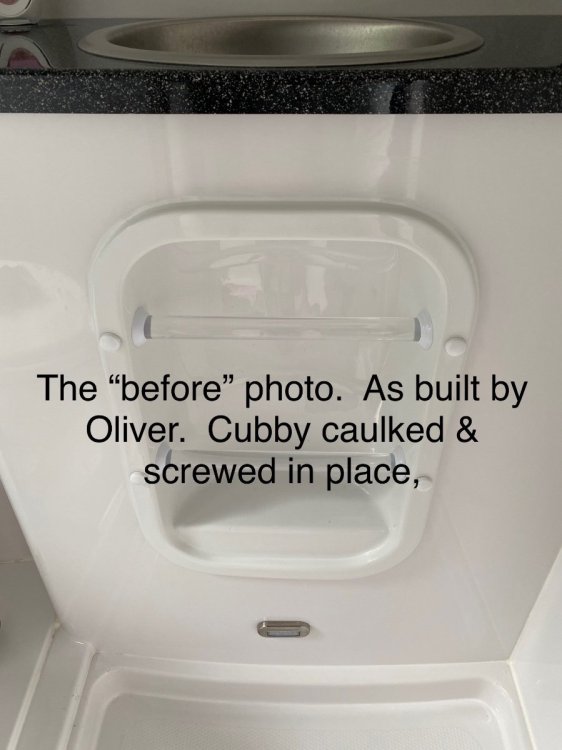

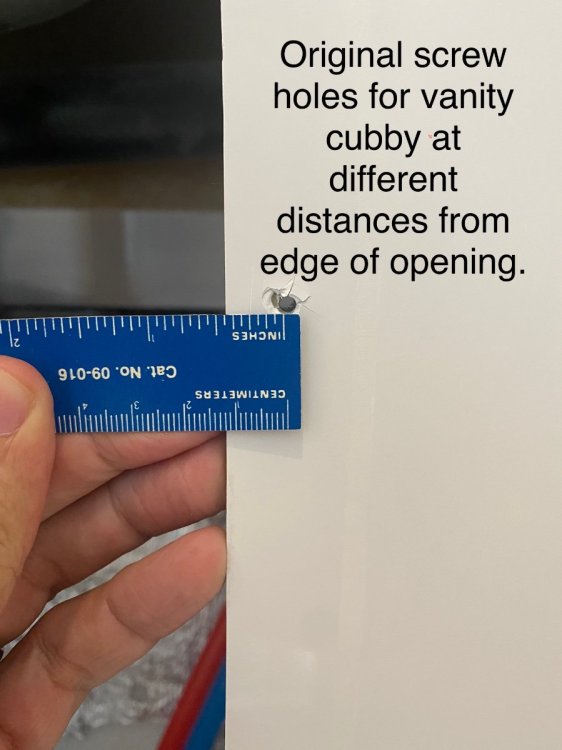

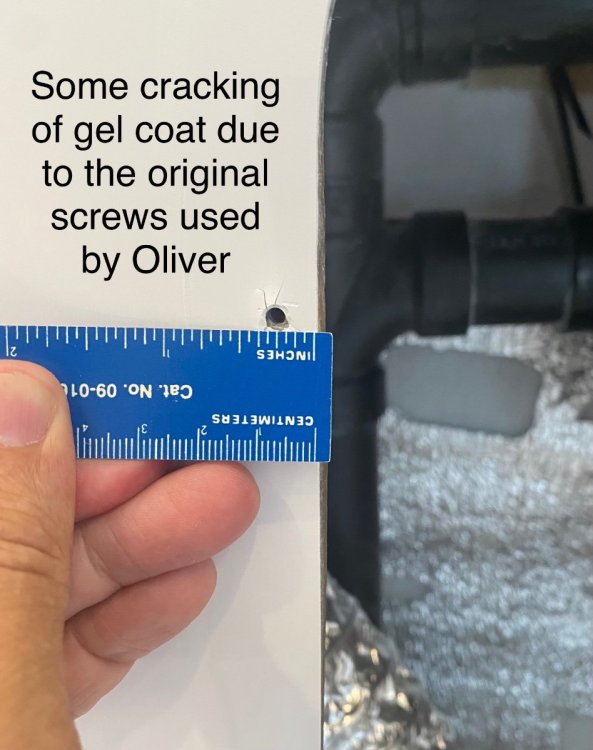

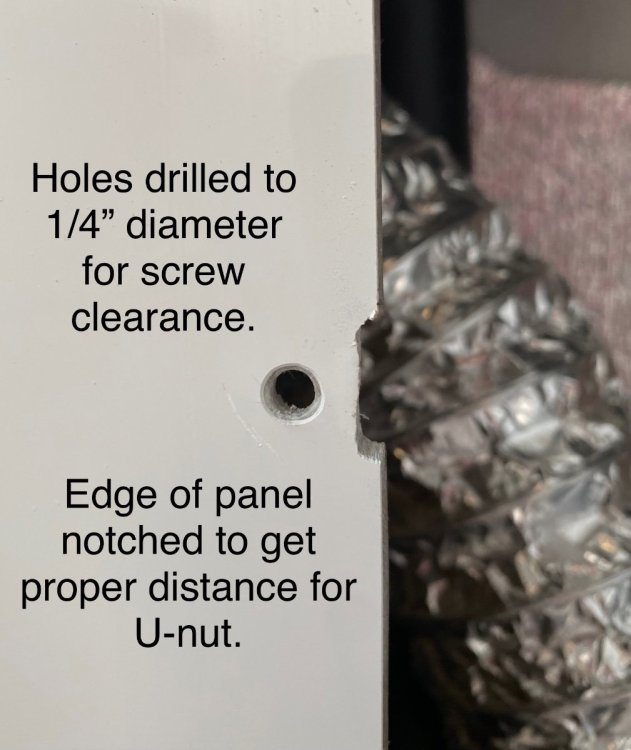

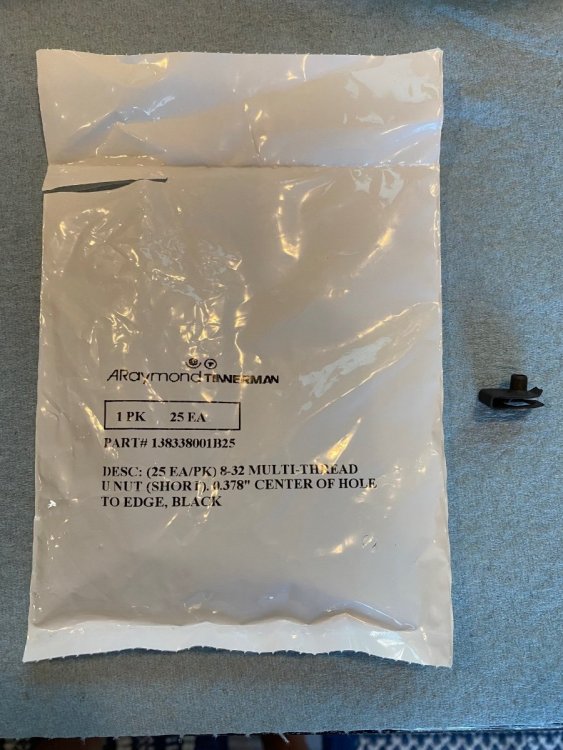

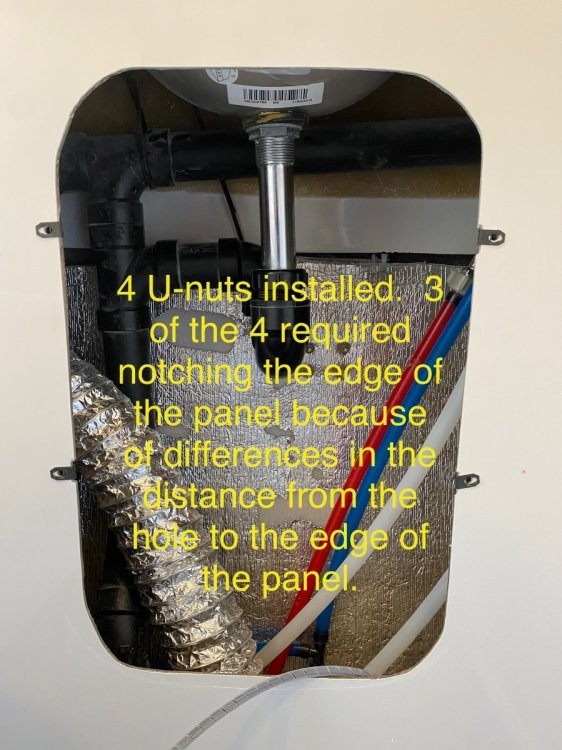

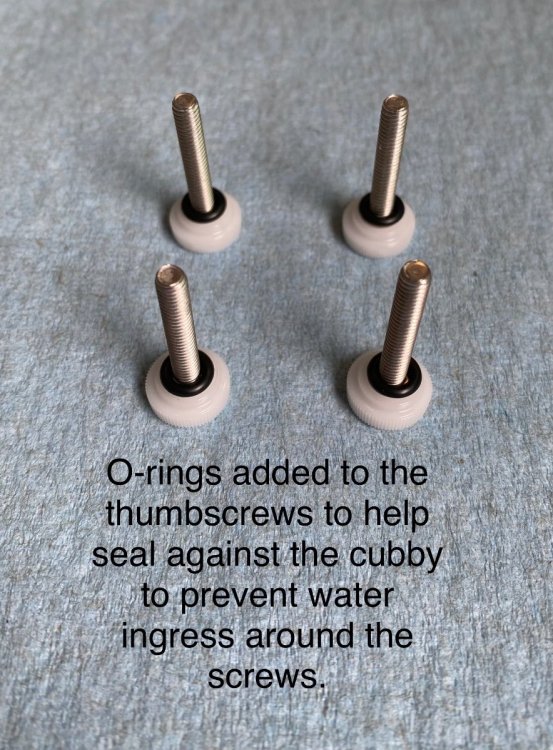

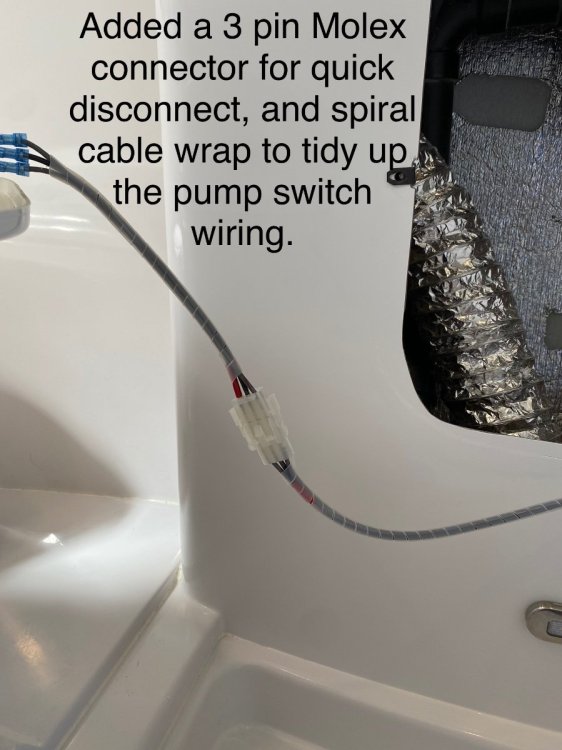

One of the great features of the Oliver trailer design is the fast and easy (no tools needed) access to ALMOST all of the plumbing, heating, and electrical systems through the hatches under the dinette seats and the beds, or by removing the kitchen cabinet drawers. One area that’s NOT readily accessible is the area under the bathroom vanity, even though there is plumbing, electrical, and furnace ductwork all tucked inside the vanity. The storage cubby in the front of the vanity is screwed AND CAULKED in place by Oliver at the factory, so access is a bit more complicated than the other areas. I recently needed to get into that vanity area for some inspection and maintenance, and after completing that I wanted to make future access easier (no tools needed and no caulking). I know some owners have replaced the storage cubby with a hinged marine access panel, but I didn’t want to lose the cubby storage. So here’s a detailed description of a simple modification I did, along with links to the parts used. Access is now fast and easy. No-Slip Clip-On Barrel Nut, for 0.025" to 0.15" Panel Thickness, 8-32 Thread Size https://www.mcmaster.com/94850A111 #8-32 x 1" Thumb Screw Stainless... https://www.amazon.com/dp/B09FZVLZKD?ref=ppx_pop_mob_ap_share uxcell Edge Trim U Seal Extrusion, Silicone White U Channel Edge Protector Sheet Fits 0.5-2.5mm Edge 3Meters/9.84Ft Length https://a.co/d/1uWUZB3 Molex -3 Match Set - (3-Pin) w/14-20 AWG, Wire Connector - 2.13mm D, Latch Lock, MLX https://a.co/d/gapvioi1 point

-

1 point

-

If you find it hard to thread the cover back on, use a little lube on the threads, Vaseline, WD-40, lite weight oil, doesn't take very much, less is probably better them too much. trainman1 point

-

Indeed. I was thinking about trying to handle that ss deck plate, mounted vertically , in the rain, and all I could think about was how much it would hurt if it slipped and fell on my foot, at over two pounds. Ouch. I think I'd stay with plastic or composite. Plenty of available choices. White blends better with the doghouse, especially since the off center installation would bother me, visually, in stainless.1 point

-

I just took the cover off and unscrewed the screw ring, sanded them with 180 grit sand paper, painted then with an outdoor white spray paint for plastics, cost $4.78 for the paint and still have 4/5 of the can left for future use. So I have about a dollar in the restoration and it turned out perfect, it's been one year since it was redone. trainman1 point

-

Many of you know that this has been a long, drawn out project. I think I started talking about it to a few people at the 2019 rally - so it's been well over a year in the making, almost two. Not that it was particularly difficult (though certainly a more major mod), but because of laziness and indecision on all the components it ended up being a start and stop project, with months sometimes between fits of activity. And then it snowballed into a complete plumbing overhaul, which was unnecessary - but then that's how the trailer got its name, after all. I'll post about all the plumbing stuff later, but since there have been a few recent posts about shower and bath mods, I figured I'd go ahead and toss this one into the mix. This project started for a few reasons. One, I've always found the bath sink to be mostly useless. It's fine for washing hands, but for most anything else, you've got to crane your neck around with the front wall curving in to hit your head. And trying to use a tiny little sink for washing your face just leaves water everywhere. So we found that were using the kitchen sink almost exclusively. That was fine - no big deal - but with the bigger sink, I was getting tired of wasting water cleaning toothpaste residue out of the sink, and it seemed silly to have a bath sink that got little to no use. The second reason for the upgrade is that after we redid the kitchen sink, the bath sink just looked sad. In addition to functionality, the bath needed some sexy. So the obvious solution was a vessel sink of some sort. Since a vessel sink sits on top of the counter, I'd have much more leeway in size and placement. I could pull it forward as much as I wanted, plus it had the added benefit of raising the sink to a more comfortable height for us. Some experimentation with kitchen bowls of different sized showed that I could get a fairly generous sink that didn't take up too much shower space. I settled on something in the 11" to 12" range; which proved to be a little difficult to source, especially after deciding on the material. I had bookmarks for dozens of sinks of different materials, but I couldn't find one that I really liked. I almost picked a glass one off Amazon, but in the end I thought that was going to be too heavy. What I really wanted - since I had already swapped out almost all of the brushed chrome fixtures in the bath for polished - was a simple polished stainless sink. There were a few out there, but nothing in the right size, nor at a reasonable price. So the project bogged down a bit at that point; but I was confident that I'd find something eventually, and so I went ahead and ordered a new vanity top from Oliver, without any cutouts for the sink or faucet. I’m glad I did, since Oliver has apparently now stopped offering our countertop color And sure enough, a few months later I came across a discontinued sink on Overstock.com that was exactly right. 11.25", polished inside and out. It's the Acquaio sink from WS Bath, if you can find one. I know that other sizes are still available. It was still pricy even on discount, but by that point I didn't care. To make up for the splurge, I got a faucet from Ikea, which is actually pretty nice. The colors from chrome to stainless don't exactly match, but they're close enough and it doesn't bother me. Since I was swapping out the faucet, I needed to find a separate shower valve, which was another lengthy quest. I thought at first that I'd put one to the right of the bath caddy, like @mountainoliver has in his trailer. But most everything I found was just a bit too big to fit (I didn't know about mountainoliver's mod and the mixer valve he used until later). Then I found the Grohe Grohtherm valve, which was interesting in a couple of respects - it didn't recess into the vanity at all (which eliminated a potential issue with the plumbing), it matched the Grohe faucet that I had already installed in the kitchen, and since it was linear, I thought that it might actually fit in the space above the caddy, between it and the vanity top. And it did fit, but looked squished in place, plus I didn't think until trying to place both it and the sink that the the sink drain and trap was going to be difficult to work the plumbing around. Plus putting it there meant that the shower hose was going to be strung across the vanity and generally look bad and be in the way. The problem with this realization was that I'd ordered the valve and the sink before one of my 3-month breaks in the project and now neither was returnable - so I had to make it work. This meant that the shower valve was going on the closet wall. I also realized during the test fitting that when I pulled the sink forward, the drain trap was going to hit the top of the bath caddy, meaning that I couldn't get it far enough forward to work. Small disaster. But I realized though that the bath caddy wasn't symmetrical, and if I turned it upside down, everything fit. I'd lose the flat shelf on the bottom, but we only use the caddy to hold the bath mat, so not a problem. Small problem with the water pump switch placement, though, since it would be on the bottom - but a quick email to Oliver had a new caddy that hadn’t been drilled for the switch on the way. At that point, all the pieces were here, all the logistics worked out, and I was ready to go. Time for another couple months off while I built up the courage to drill through the closet wall. Then finally... First step was to remove the existing vanity top, which is possibly one of the most firmly attached things in the trailer. It's glued in place, so the only way I could find to get it off without completely destroying the vanity was to cut through the joint with an oscillating saw. That's a slow, tiring, dusty endeavor; and it generates a great deal of heat, so you've got to work in spurts to keep the fiberglass resin from burning - which is fine really, since working through the caddy access, your shoulders will welcome the rest. I had to do a tiny bit of trimming on the new top to get it to fit as snuggly as the old one; and once in place, I sealed it with silicone like the original. Top off, new drain lines in place, and I decided to attach the new top with industrial velcro to make it easier to remove in the future (works well). Next, shower lines teed off the existing plumbing, line to the nonexistent toilet removed, and some insulation added to both the plumbing lines and the outside wall behind the vanity. (I have a circulating pump on the hot water, hence the extra line.) I also glued a small PVC block to the back side of the vanity wall to tie down the water lines and prevent them from vibrating too much. And as always, cleaned out as much fiberglass dust as possible, cleaned up and wrapped wiring, etc. The access port on the closet side is something that Oliver gave me in the original build. The sink valves and drain trap are accessible from that port, and since I used velcro for the top, I have the option now of cutting the silicone on the top and pulling that off for access, in addition to taking out the caddy. New plumbing in the closet for the shower. I drilled out a short piece of aluminum as a backing plate for the shower valve. The plumbing is protected somewhat in the closet by the ABS vent, and we really don't keep much in there that could bump around and damage the plumbing. But a few layers of aluminum tape should help protect the insulation from getting beat up and gives a bit of a spaceship vibe. The valve is supposed to stand out from the wall about an inch or so, but I decided to recess it so that it attaches flush and as out of the way as possible. I caulked around the valve and it ended up making a nice little shelf for a razor, and I placed it low enough that my wife can use it to prop a foot while shaving her legs. You can also hang a bar of soap on one of the handles to drip dry. The faucet has a neat feature with stops on both valves, which can be custom set to whatever temperature and flow you prefer. The little buttons on the handles allow you to go past the stops when you want. And that's really it. Installing the sink and faucet is just drilling two holes and following the directions. The only change I made is that the sink came with a short stainless ring to mount between the sink and counter, but I didn't like the look and so just used one of the black rubber gaskets that was inside the ring. That way the sink looks like it’s sitting right on the counter instead of a pedestal. We tested everything out on our last trip and functionally, it all works as expected. The sink isn't in the way at all while showering, and really is so much more usable. Plus I think it looks great. The shower functions just as nicely, with the valve not being obtrusive. I added a second holder for the shower head up high, which works better for me, though my wife prefers the original one. I still need to swap that one out, since I think it's the only bit of brushed chrome left in the trailer. I added the same backsplash material that a few other owners have recommended. I wanted to order a new, wider mirror; but the original one is glued on and so I didn’t want to go through the trouble of trying to get it off. I suppose I could just place one on top of the other, so maybe that’ll be a future project. Glamor shots -1 point

-

If ABS was not available at Ferguson Supply, you must be in the East somewhere. I cannot explain the reasons, but it is my observation that PVC is used for drain/waste/vent plumbing in the East, while ABS is universally used for drain/waste/vent plumbing in the West. I prefer ABS, not only because I am in the Western US, but because no primer is required. I have heard that some plumbing inspectors will fail a PVC installation if purple primer is not visible at each joint.1 point

-

Thanks, and I agree on the PVC. It was a debate when I was doing it (can't remember if it was here or with the guy at the Fergusons counter - possibly both), but ABS wasn't available and the advice I got was to not worry about it. And of course I had it inspected. Electrical, too. Promise.1 point

-

I took delivery of #797 on May 7th. The delivery was a very pleasant experience. Having owned an Elite 1 previously, I knew how most of the stuff worked and had already done the research on the stuff I didn’t know about. As I advised this forum, I discussed electrical diagrams with Jason. He has been asked about this by old and new customers many times recently, so I got a smooth and polite response. I’m guessing my experience was similar to Donna and Scott. The short of it is electrical diagrams are not available to us at this time. Liabilities, many variations in design due to options, etc. He suggested I use the 2019 version in the Oliver University, and call and ask questions about anything I can’t figure out. I’m In the process of inspecting and mapping out the key systems, and labeling the wires, fuses and breakers myself that are not already identified. Yes, it’s a hassle, but I try to pick my battles. I had several questions my delivery person could not answer, but she went and found Jason, who expertly answered them all, I was very pleased I did not find any significant problems with my Oliver (still looking). I had come prepared with a checklist of every problem I had read about on the forum, and I went looking. Many of the minor problems have been corrected, it seems Oliver has been listening to feedback. The trailer was not perfect, but much better than my expectations, and nothing I can’t fix myself easily. My wife and I are just grateful to have it, been waiting since September! Life is good.1 point

-

We talked with head of service department today. Basically Oliver has decided that they will not be providing wiring diagrams for our 2021 at this time. Oliver feels it would be a liability issue to do so. Lets hope in the future that Oliver will reconsider. Maybe if those purchasing 2022 and future models pursue requesting the wiring diagrams, Oliver will review this subject again.1 point

-

Given the quality of Oliver wiring at times, I think they'd be more worried about lawyers than competitors.1 point

-

I've asked Service (Jason) and Sales (Phil) for them by email and phone. No luck. I know of several owners that are asking. It's crazy. I've opened a handful of tickets just because I don't have the electrical diagrams - simple questions that could have been answered. For someone who loves to work on their Ollie, I have it listed as my number one quality issue / gripe by far. Now I know Patriot is after them too. I'm going to open a service ticket and see where that gets me.1 point

-

Recent Achievements